Production system for processing a wire material wound to form a wire reel, comprising a conveying means with permanent magnets

A technology for manufacturing equipment and conveying mechanisms, applied in the direction of metal processing equipment, conveyors, equipment for accumulating materials, etc., can solve the problems of relative movement between the driving roller and the wire, the tension limit of the unwinding device, the rough surface structure of the steel bar, etc., to achieve High flexibility, easy unwinding, improved friction locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should first be ascertained that, in the differently described embodiments, the same parts have the same reference signs or the same component designations, and that the disclosure content contained in the entire description can be transferred reasonably to the components with the same reference signs or the same component names. same parts. Positional specifications selected in the description, such as eg top, bottom, side, etc., also refer to the currently described and illustrated figures and can be appropriately transferred to the new position in the event of a position change.

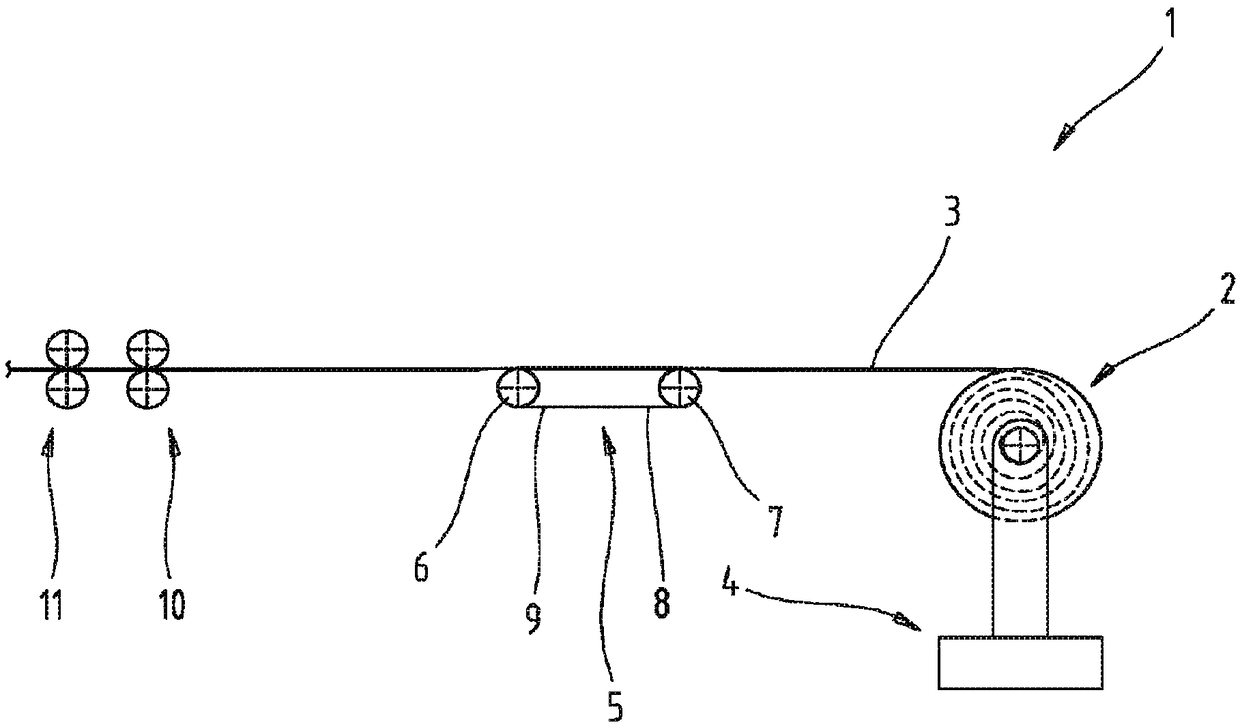

[0031] figure 1 A schematic diagram of a first embodiment of the manufacturing device 1 is shown. The manufacturing device 1 is configured for processing a wire 3 wound into a coil 2 .

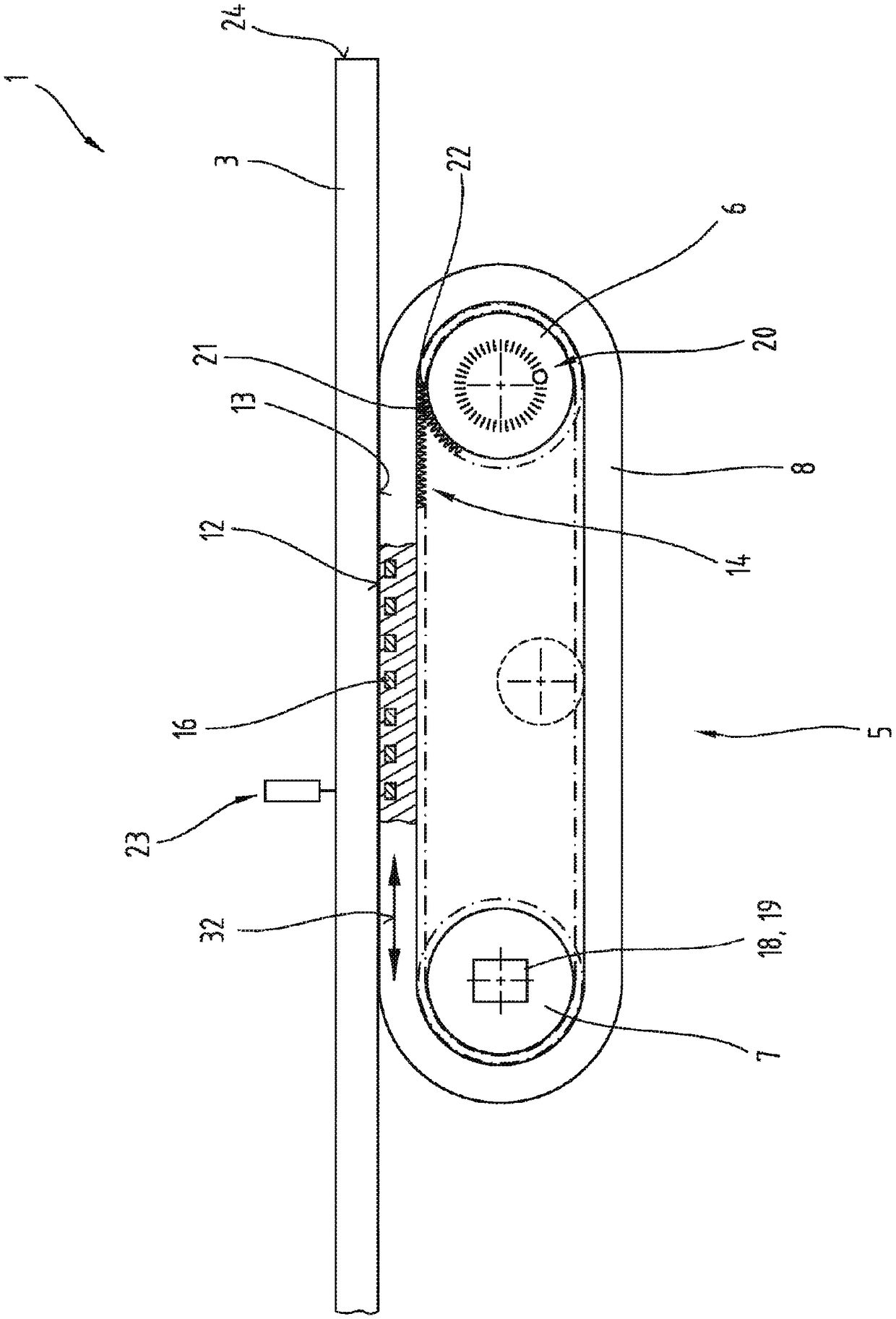

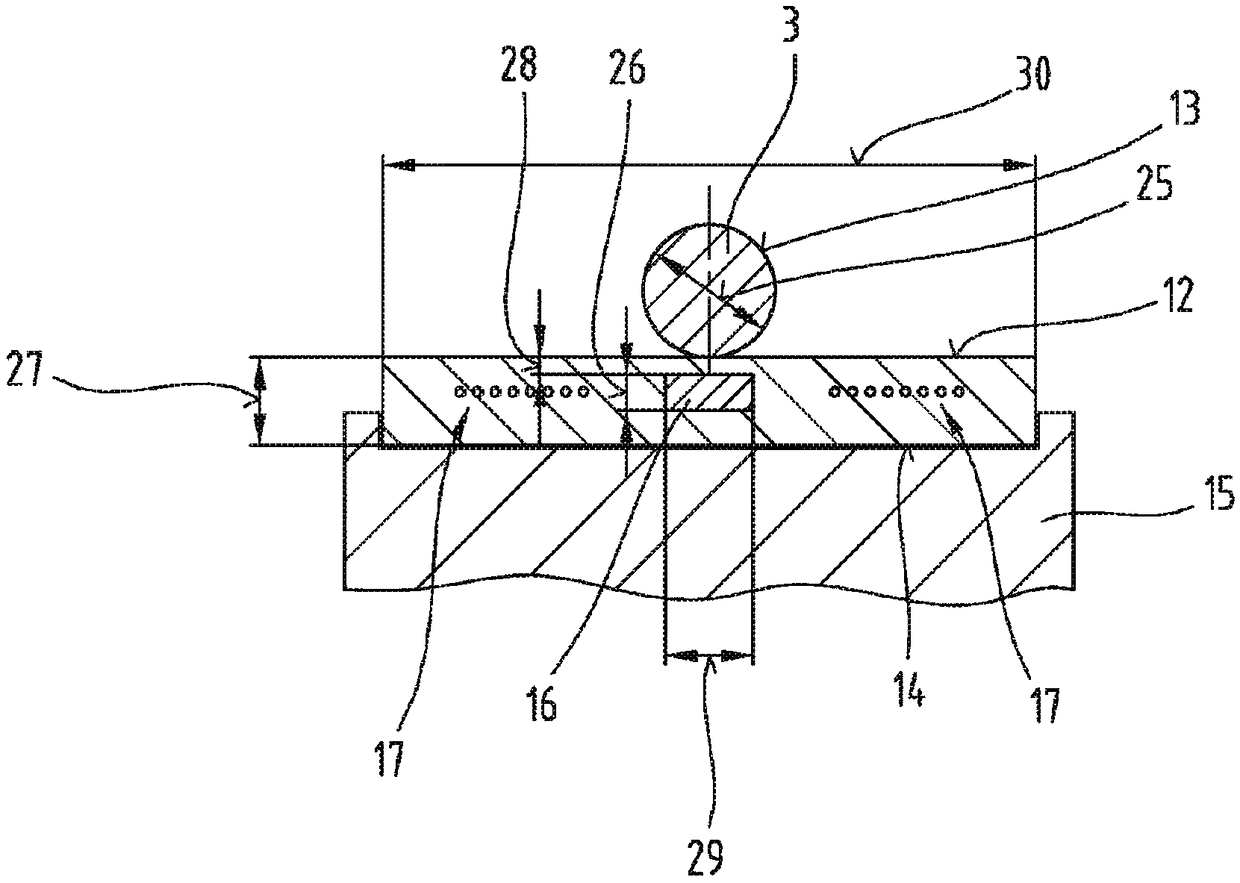

[0032] The manufacturing device 1 comprises a receiving device 4 for receiving the wire reel 2 . Furthermore, an unwinding device 5 is formed, by means of which the wire 3 wound on the reel 2 can be p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com