Preparation method of monodirectional preimpregnation narrowband for automatic filament placement

An automatic wire laying and narrow-band technology, used in metal processing and other directions, can solve problems such as affecting performance, changing the direction of fiber arrangement, and complex mechanisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

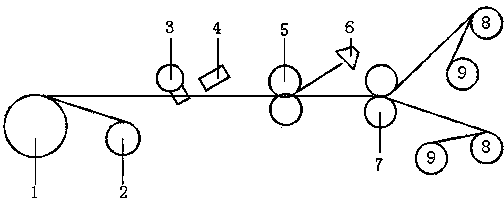

[0022] The present invention will be further elaborated below in conjunction with the schematic diagram of the present invention. After the wide-width prepreg 1 is unrolled, and before entering the razor slitting unit 3 or the circular knife slitting unit 5 where the blades are arranged in parallel, the backing paper on the surface of the wide-width prepreg 1 needs to be peeled off and rewound to the backing On the paper rewinding shaft 2, when the prepreg passes through the razor cutting unit 3 or the circular knife cutting unit 5, it is cut into several prepreg narrow strips with equal width. In view of the fact that during the cutting process of the razor, the cutting edge is fixed, the heat dissipation ability of the cutting tool is poor, and it is easy to generate heat, which will cause resin accumulation and affect the cutting quality. The temperature at the cutting edge is kept within a reasonable range. On the other hand, it also cools down the resin in the prepreg nea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com