Patents

Literature

221results about How to "Guaranteed cut" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

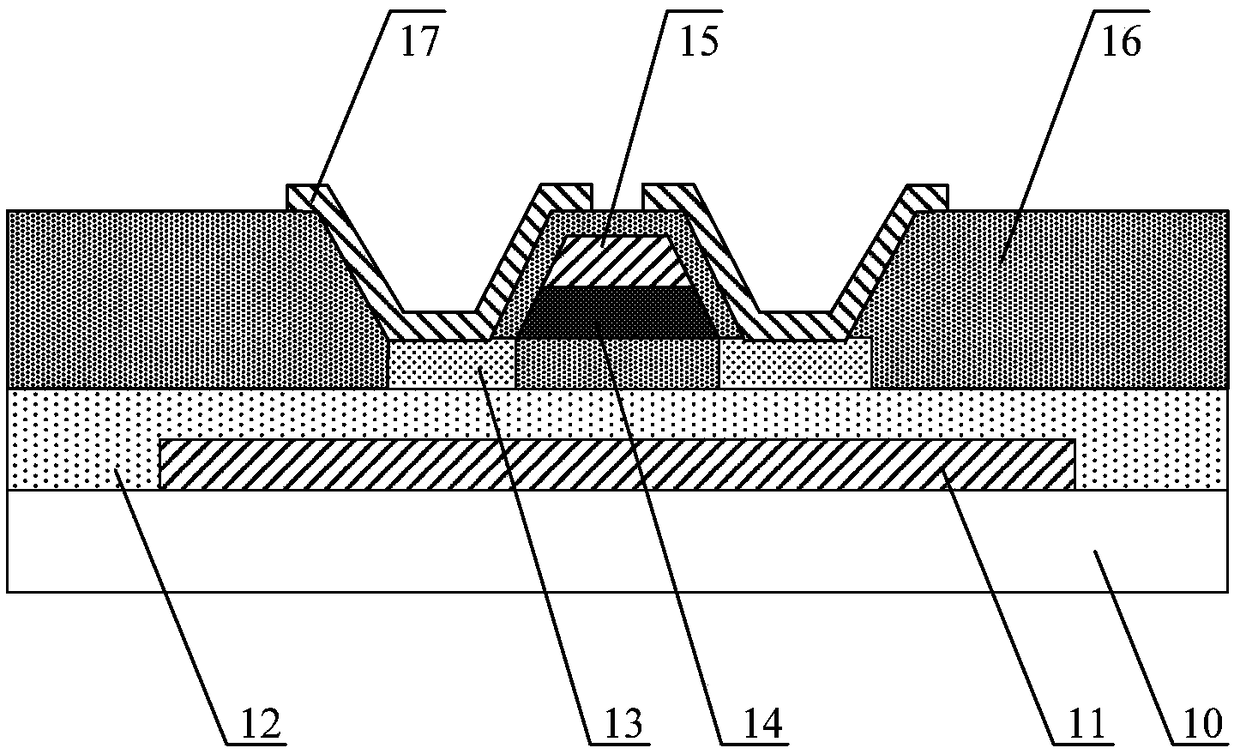

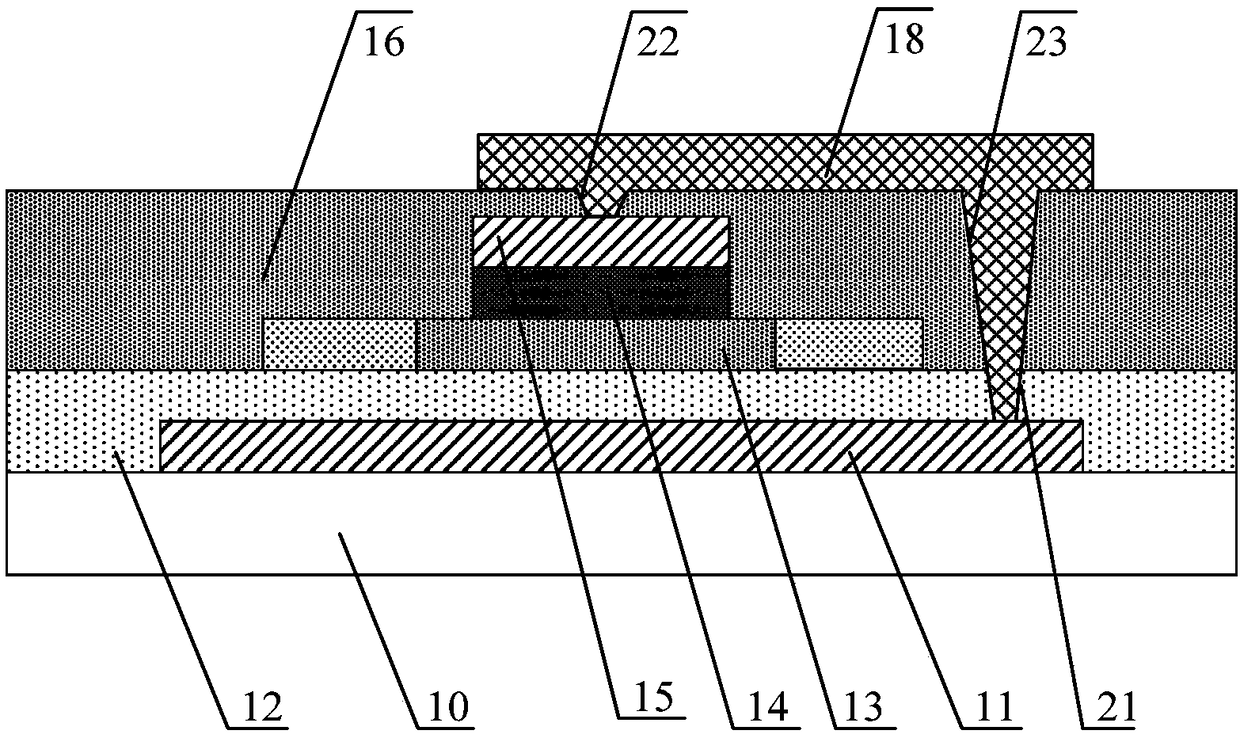

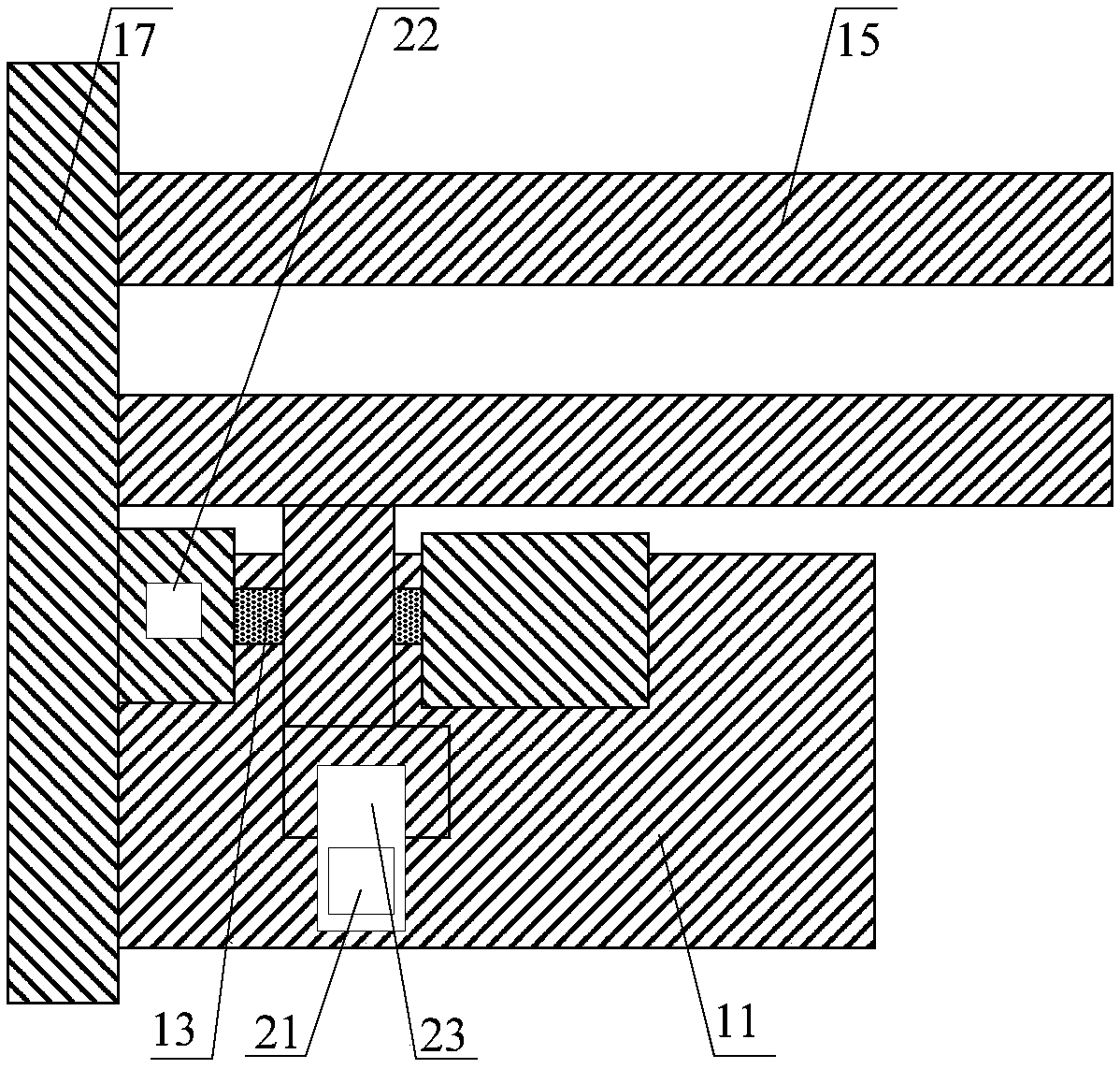

Thin film transistor and method for fabricating the same, array substrate, and display device

ActiveCN108767016AAvoid Negative Threshold Voltage DriftReduce leakage currentTransistorSemiconductor/solid-state device detailsPower flowSignal-to-noise ratio (imaging)

Embodiments of the invention disclose a thin film transistor and a method for fabricating the same, an array substrate, and a display device, wherein the thin film transistor includes: a first gate disposed on one side of a substrate, an active layer, a second gate, and a source / drain electrode; the active layer is disposed on one side of the first gate away from the substrate; the second gate isdisposed on one side of the first gate away from the substrate; the source / drain electrode is disposed on one side of the second gate away from the substrate; and an overlapping area exists between the orthographic projection of the source / drain electrode on the substrate and the orthographic projection of the second gate on the substrate. The embodiments of the invention avoid hydrogen atoms fromentering the active layer in the subsequent process, avoid the threshold voltage negative drift of the thin film transistor, and reduce the leakage current of the thin film transistor, thereby ensuring the dark current decrement and the signal-to-noise ratio during optical detection, and optically compensating the display accurately.

Owner:BOE TECH GRP CO LTD

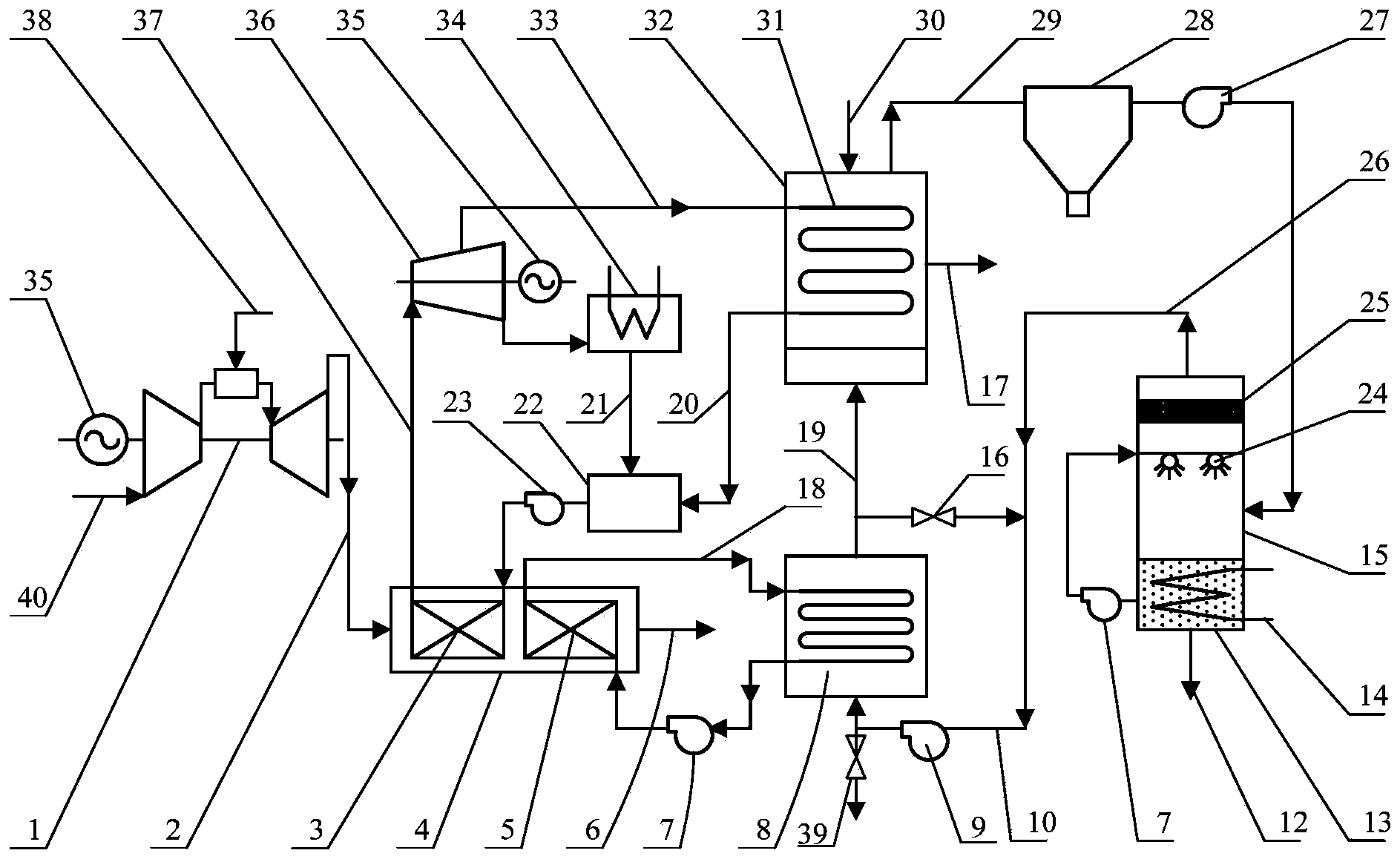

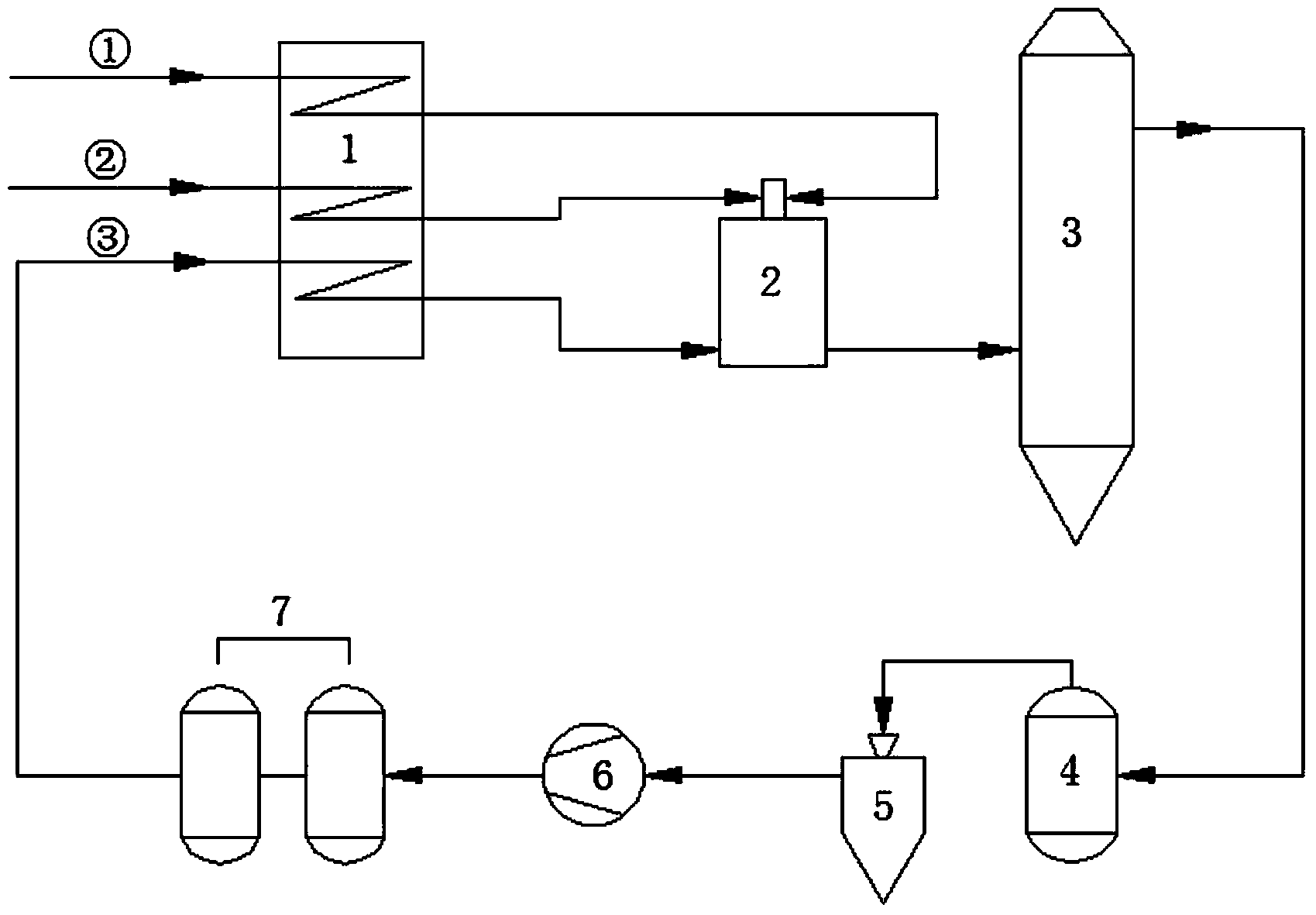

System and method for drying sludge through waste heat of gas turbine

ActiveCN103539333ALower fuel costsSolve the emission problemSludge treatment by de-watering/drying/thickeningSteam useFluidized bed dryingSludge

The invention provides a system and a method for drying sludge through the waste heat of a gas turbine. The gas turbine is connected with a generator; a flue gas outlet of the gas turbine is communicated with a waste heat boiler; a steam outlet of the waste heat boiler is communicated with a steam turbine; the steam turbine is connected with the generator; a steam extraction pipe of the steam turbine is communicated with an inlet of a heated surface pipe of an internal thermal type fluidized bed dryer; an air outlet of an air heater is communicated with an air inlet of the internal thermal type fluidized bed dryer; wet sludge enters the internal thermal type fluidized bed dryer through a wet sludge pipe, flows outside the heated surface pipe, is dried and then is discharged into a dry sludge pipe from a discharging hole. Steam is produced through the flue gas waste heat of the gas turbine to push a steam turbine generator set to generate power, and the waste heat of the steam turbine is taken as a heat source for drying the sludge, so that gradient energy utilization is realized, the heat efficiency is high, and a peculiar smell is not discharged; the fluidization air of the fluidized bed dryer is preheated by hot water, so that the energy utilization rate is further improved, and the environmental problems of groundwater pollution and the like caused by sludge burying and soil utilization are effectively solved.

Owner:凤阳县经济发展投资有限公司

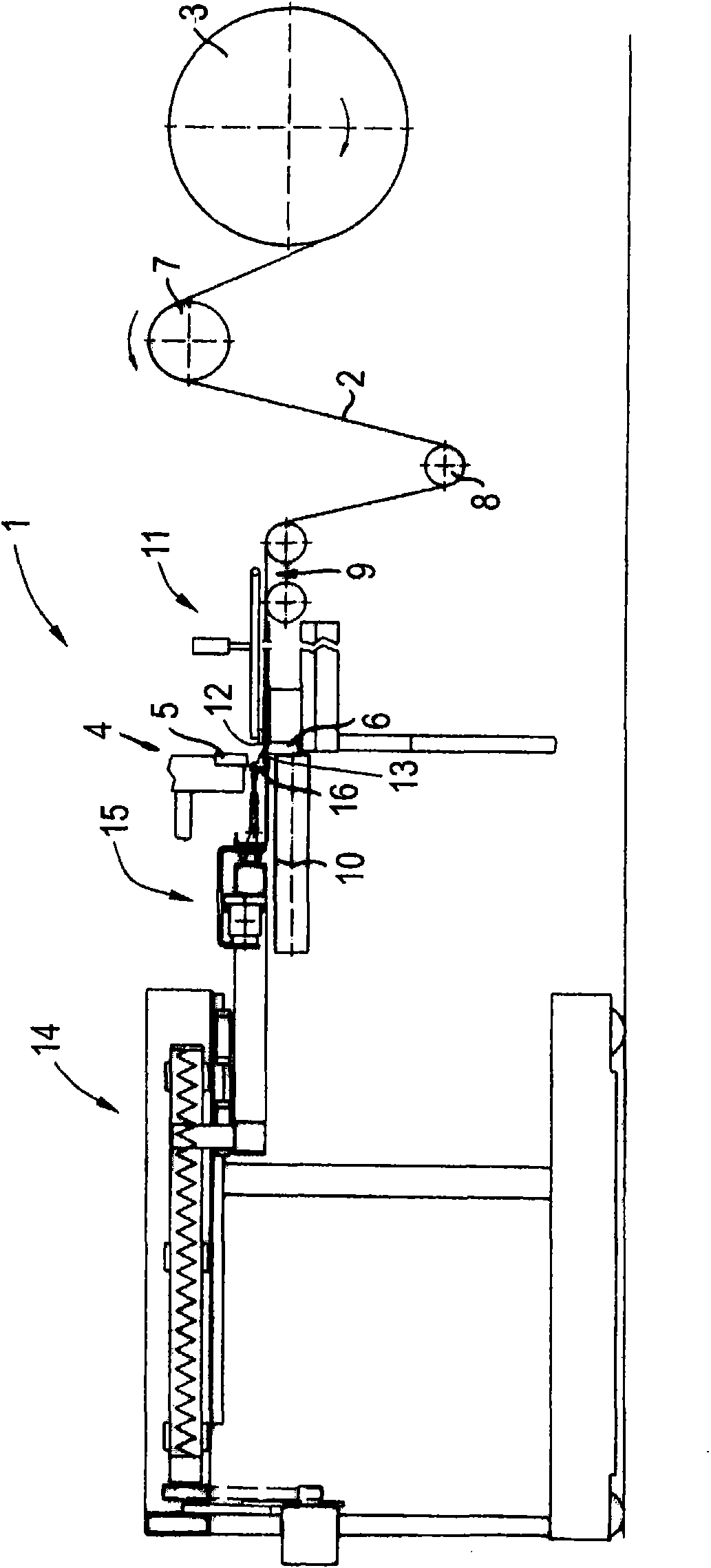

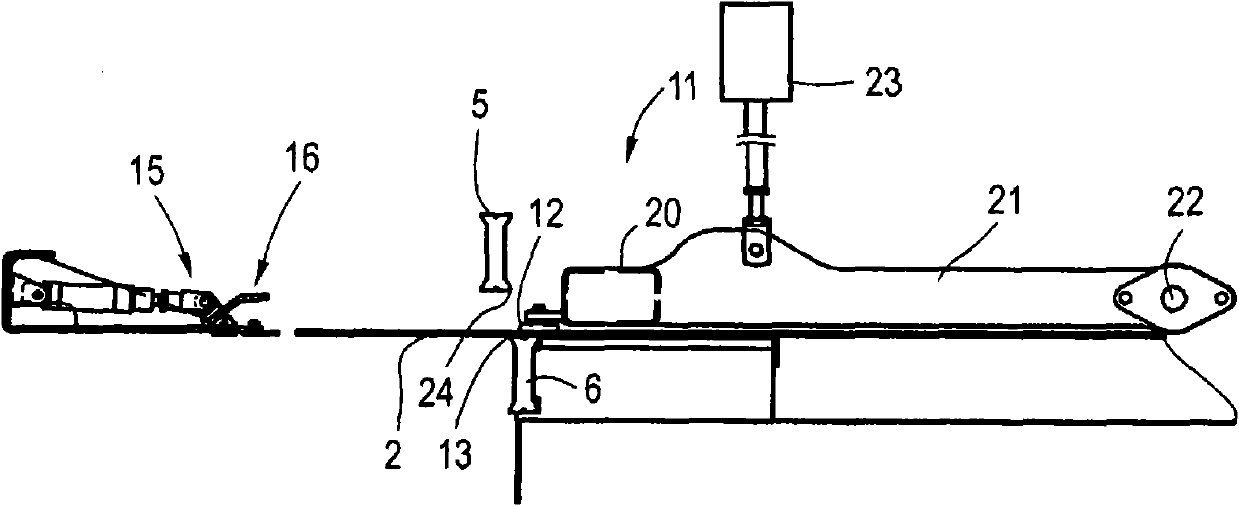

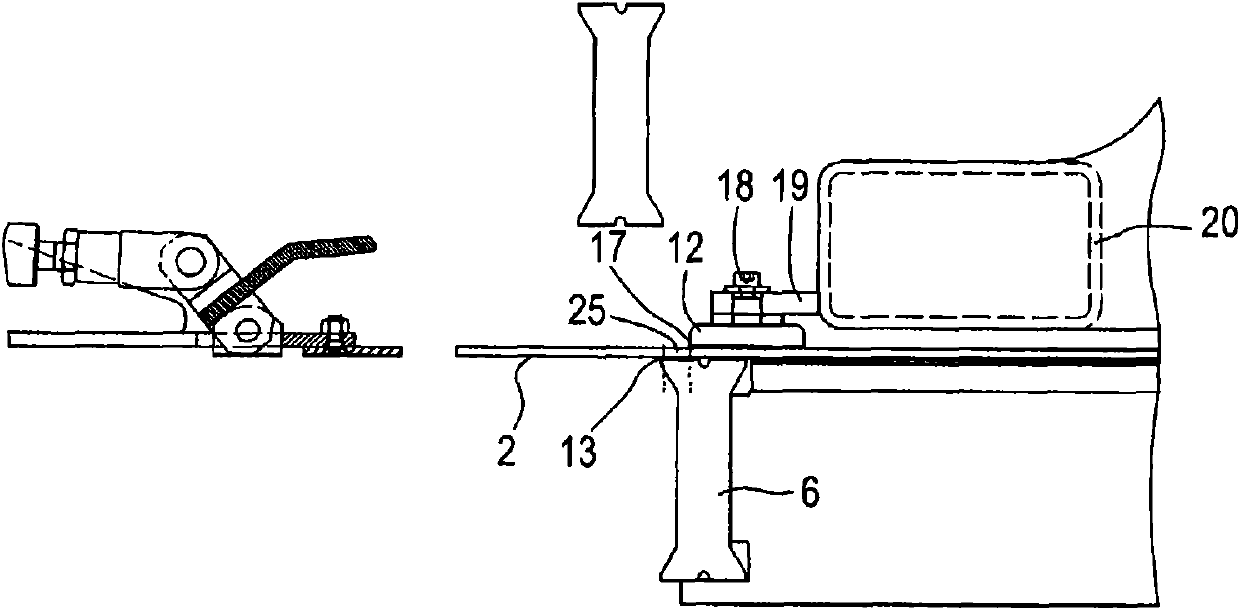

Cutting device for cutting a thin and adhesive belt, in particular a cord belt

ActiveCN101992559ASimple structureShort free lengthTyresMetal working apparatusEngineeringFront edge

Owner:KARL EUGEN FISCHER

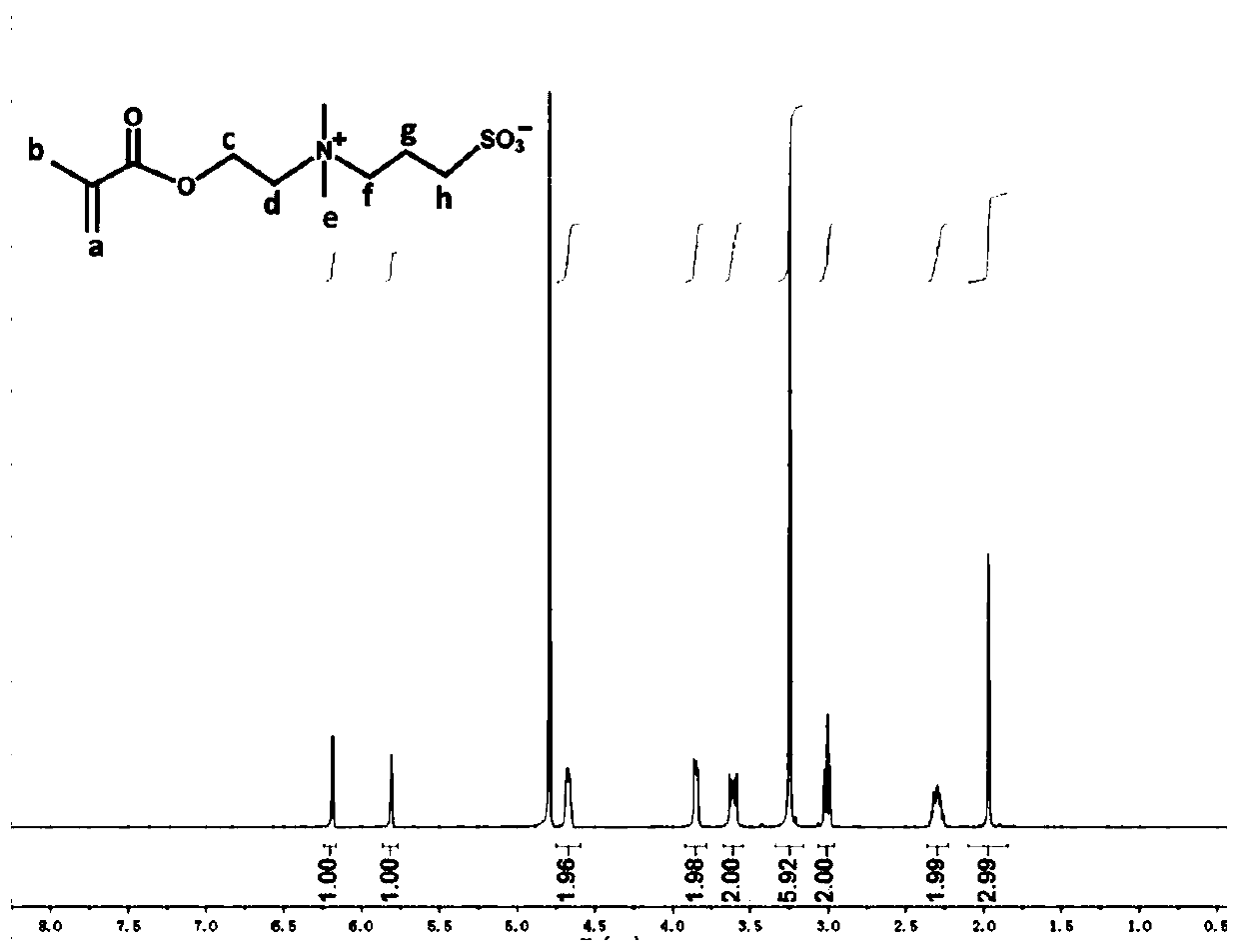

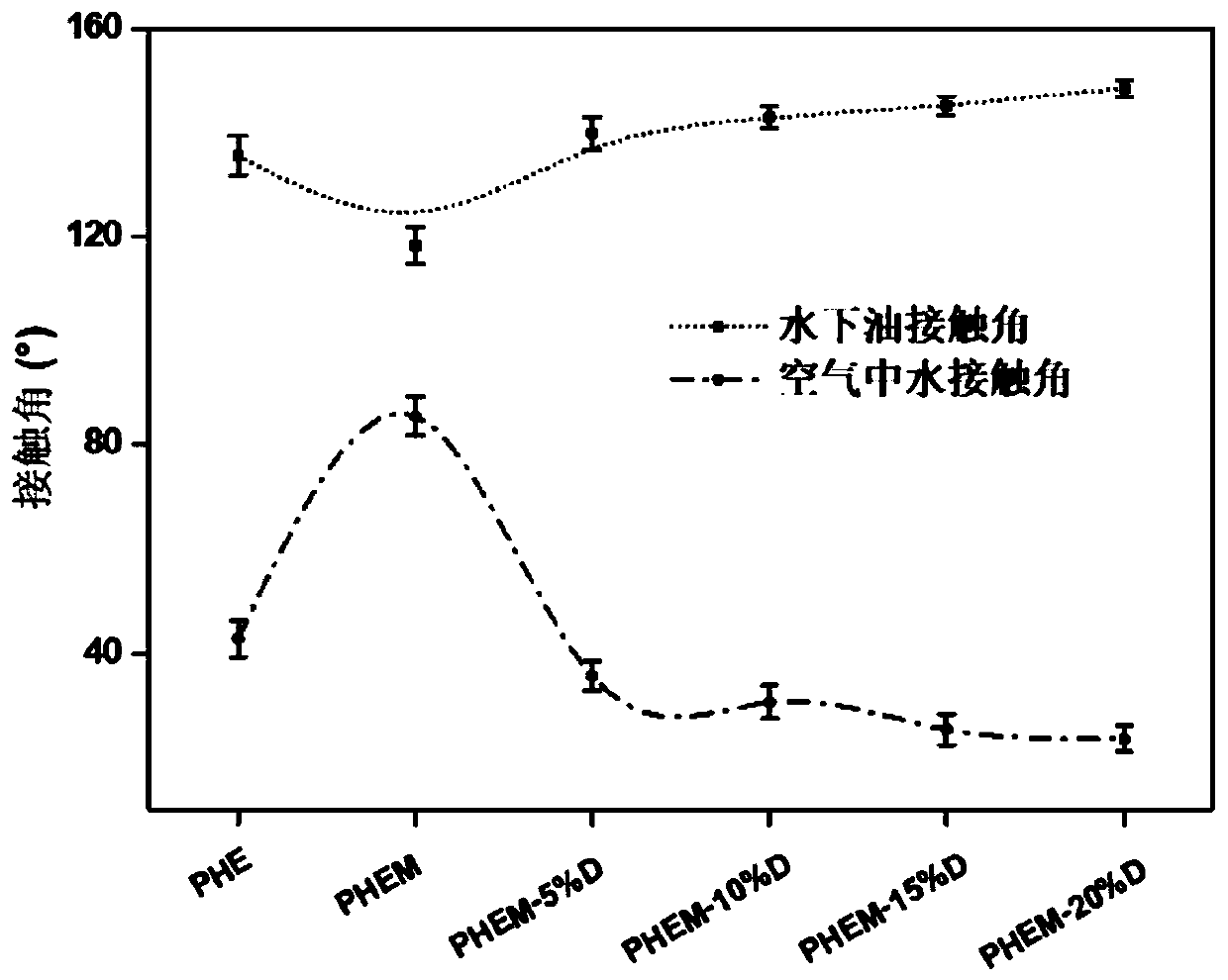

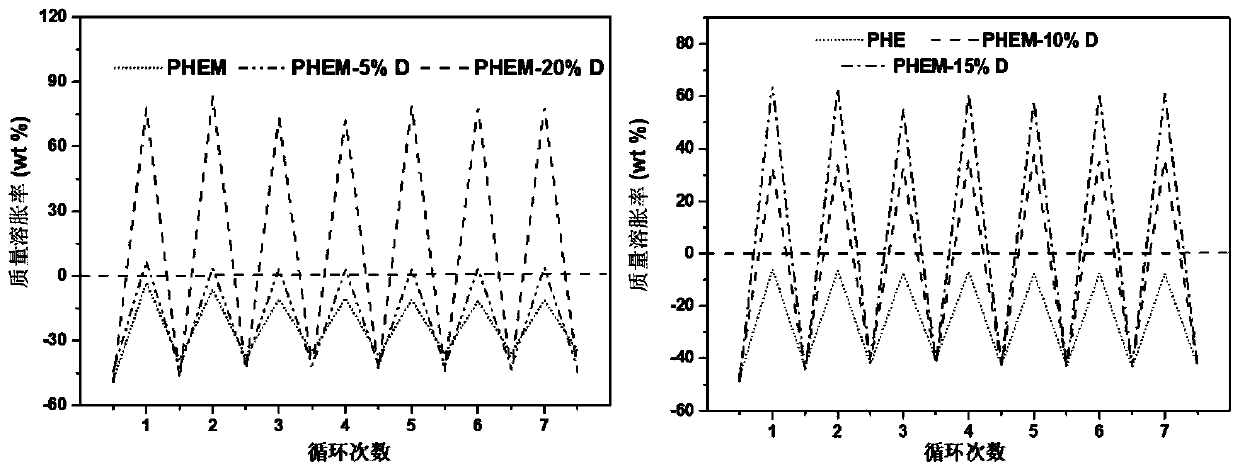

Hydrogel capable of being used for marine antifouling, preparation method and uses thereof

ActiveCN110358006ANo change in compression resistanceExcellent anti-biofouling performanceAntifouling/underwater paintsPaints with biocidesDehydration rehydrationBiofouling

The present invention provides a hydrogel capable of being used for marine antifouling, a preparation method and uses thereof. According to the present invention, the hydrogel does not swell while other gels such as acrylic acid, clay, acrylamide and the like swell heavily; the hydrogel can completely restore to the original state after water loss while other hydrogels such as a PVA gel cannot berecovered; the compression resistance of the gel of the present invention can remain unchanged after dehydration-rehydration circulation, the gel of the present invention has good stability under different shear frequencies at different temperatures, and the hydrogel is transparent while other oil hydrogels are less transparent; and the gel of the present invention has excellent biofouling performance.

Owner:INST OF CHEM CHINESE ACAD OF SCI

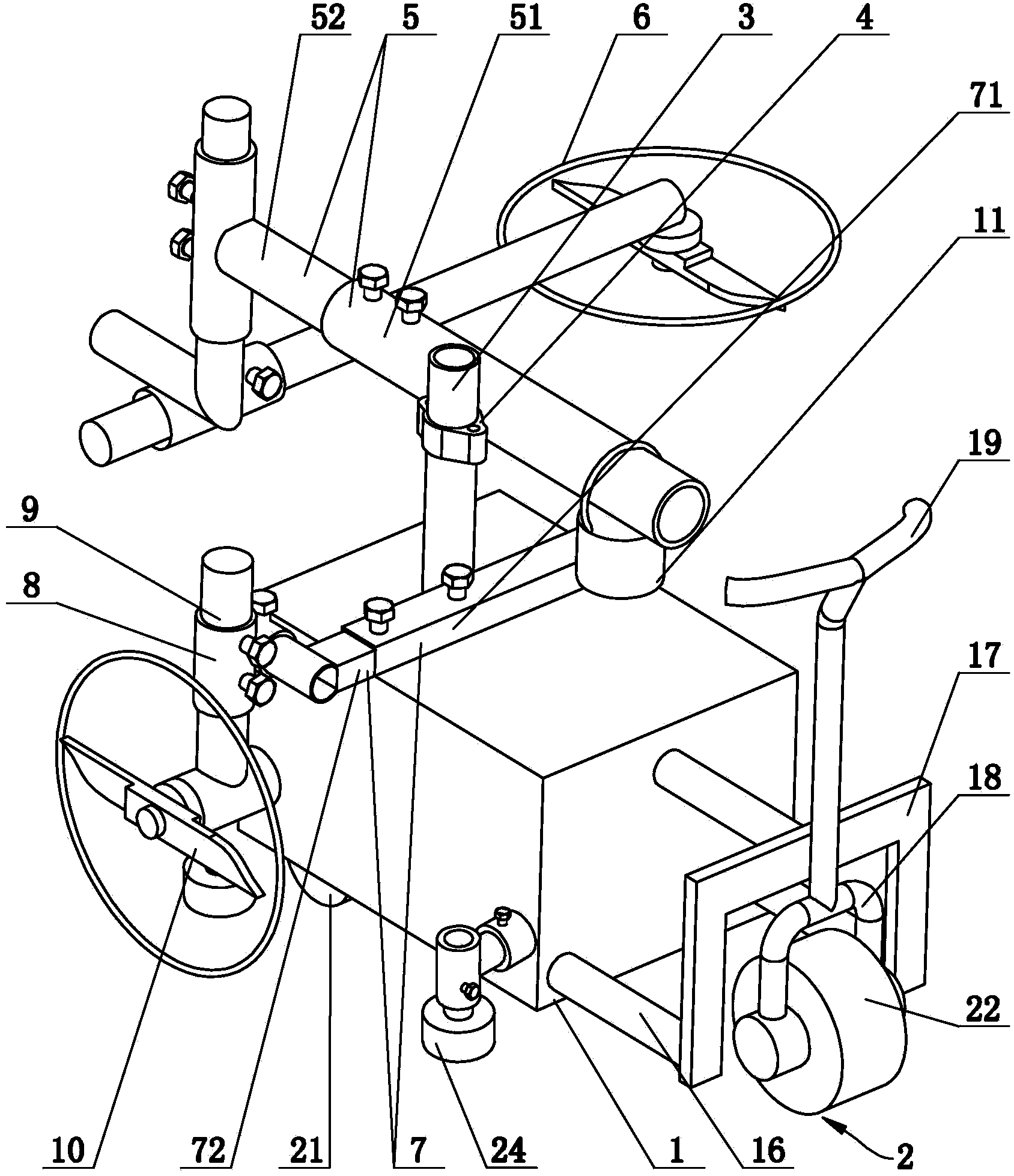

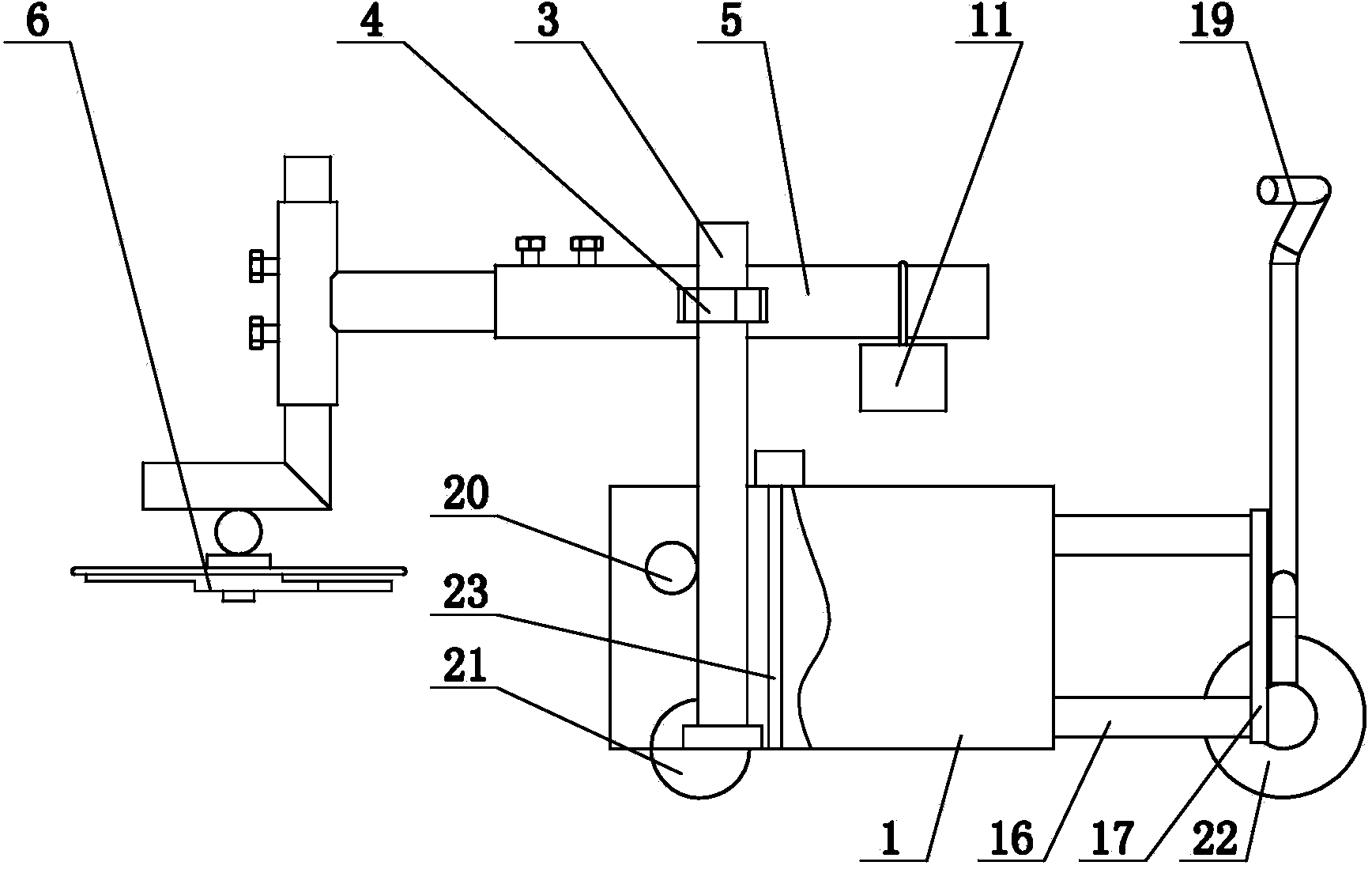

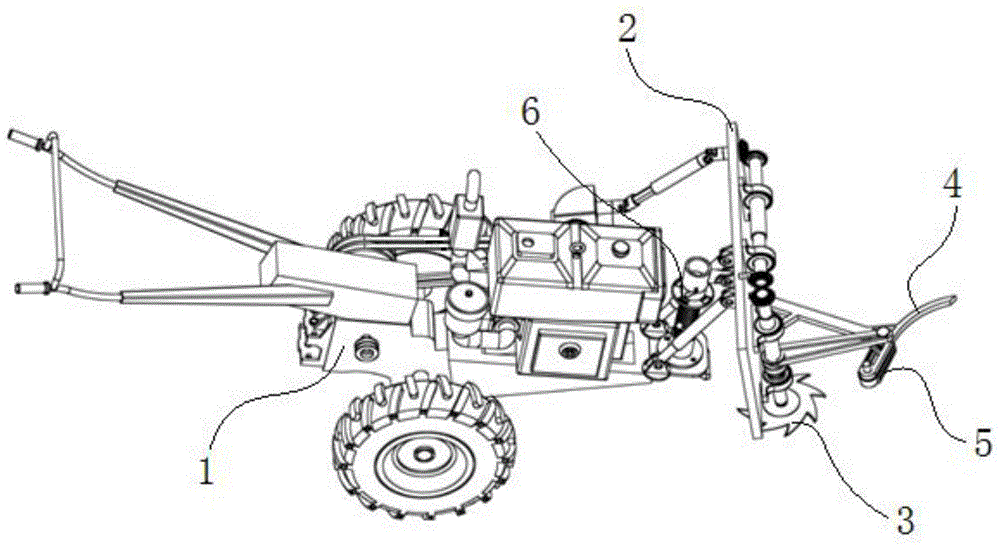

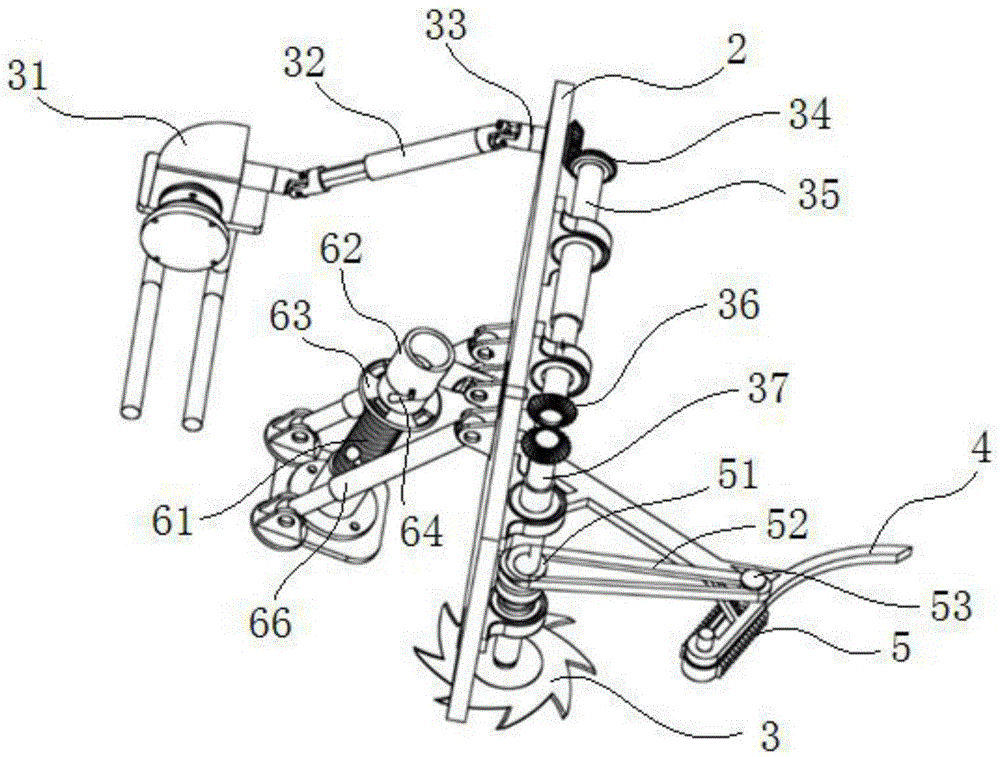

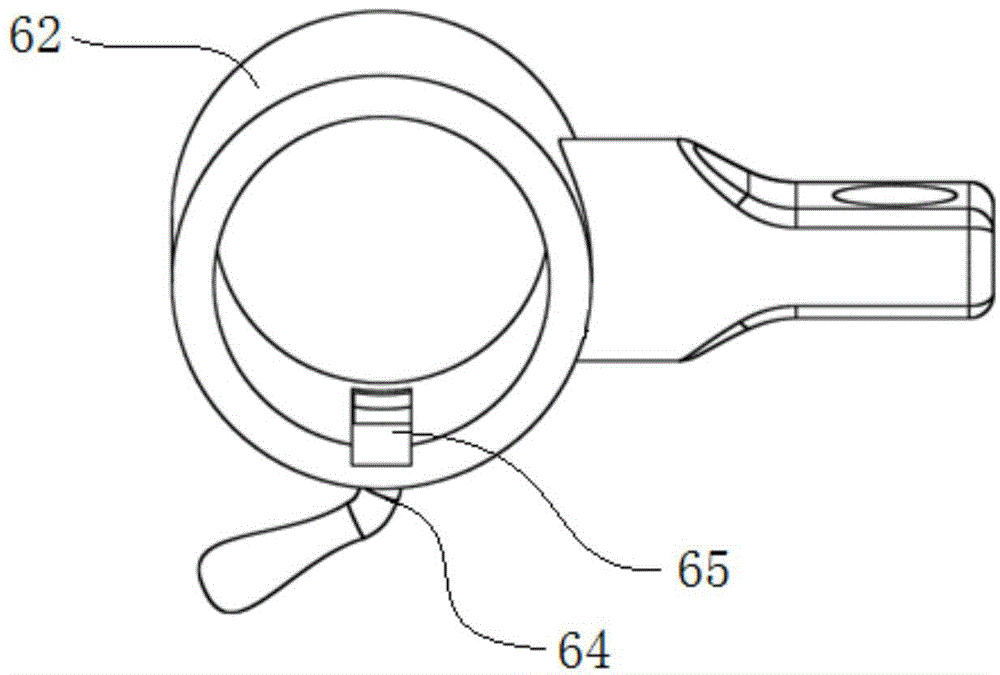

Hedgerow trimmer

ActiveCN103404378AReduce labor intensityAvoid fatigueHedge trimming apparatusVertical planeEngineering

The invention discloses a hedgerow trimmer and belongs to the technical field of trimmers. The hedgerow trimmer comprises a machine body which is provided with a walking mechanism. A rotary column positioned in a vertical plane is rotatably arranged on the machine body, a regulation seat for regulating the height position is installed on the rotary column through fasteners, an oscillating rod is fixedly arranged on the regulation seat, the axial direction of the oscillating rod is perpendicular to the axial direction of the rotary column, and a top surface trimming cutter driven by a first power device and used for trimming the top surface of a hedgerow is fixedly arranged at one end of the oscillating rod. A fixed seat is arranged at the top of the machine body, a connection sleeve positioned in a vertical plane is arranged on the fixed seat, a connection rod is fixedly arranged in the connection sleeve, and a lateral surface trimming cutter driven by a second power device and used for trimming lateral surfaces of the hedgerow is arranged at the end portion of the connection rod. By means of the hedgerow trimmer, the trimmed hedgerow top surface is flat, attractive and uniform, work efficiency is improved, and labor intensity of workers is reduced.

Owner:山东绿美生态环境工程集团有限公司

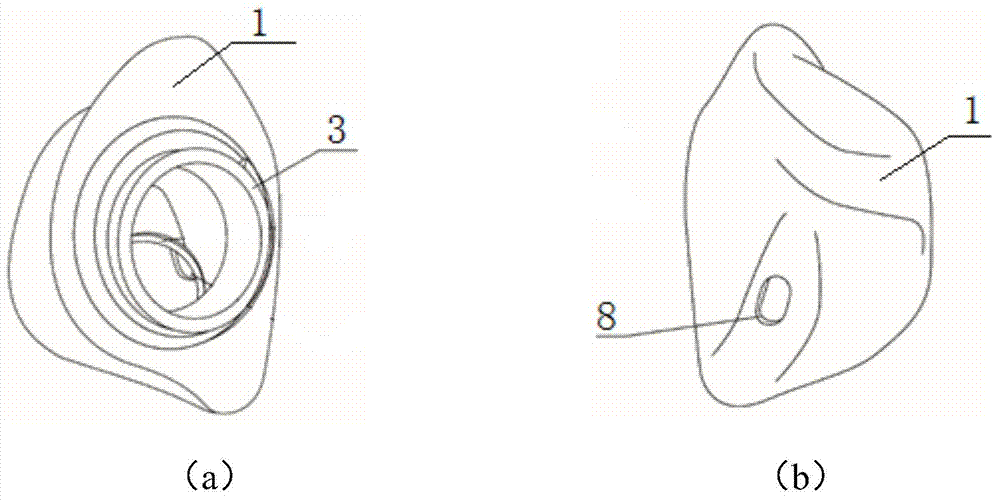

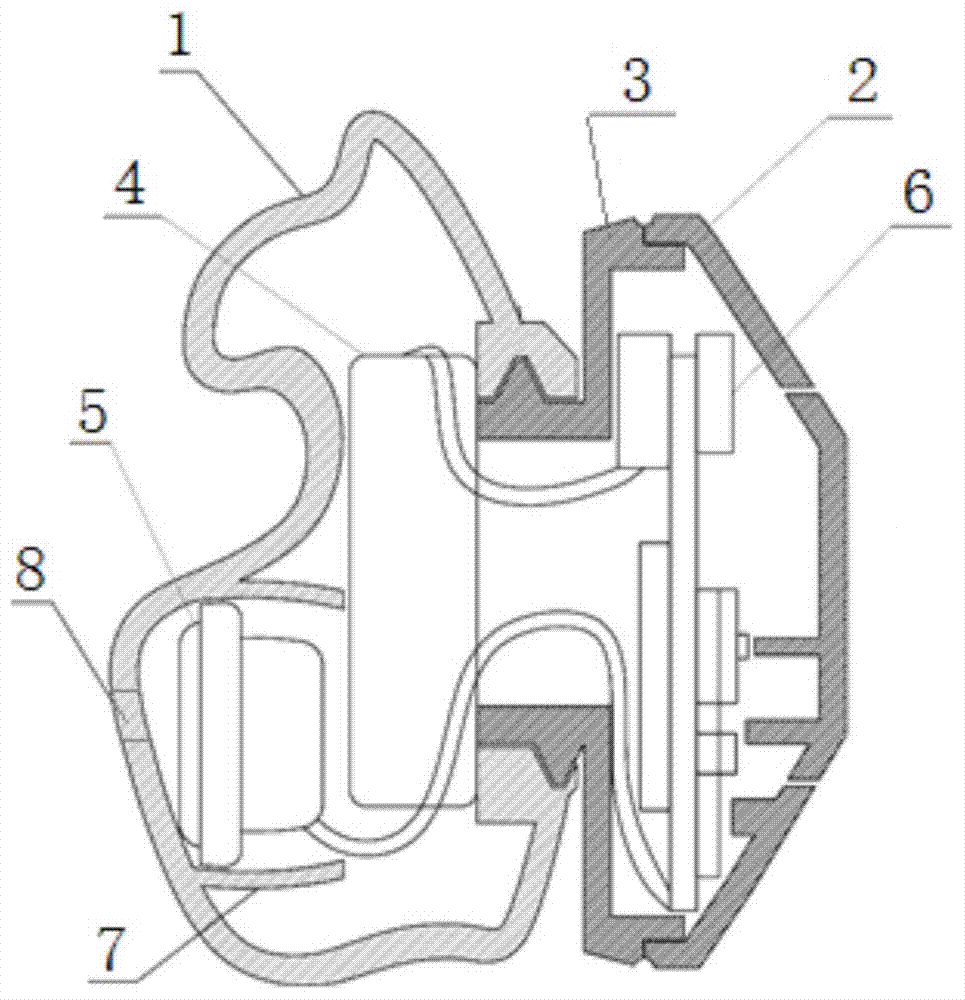

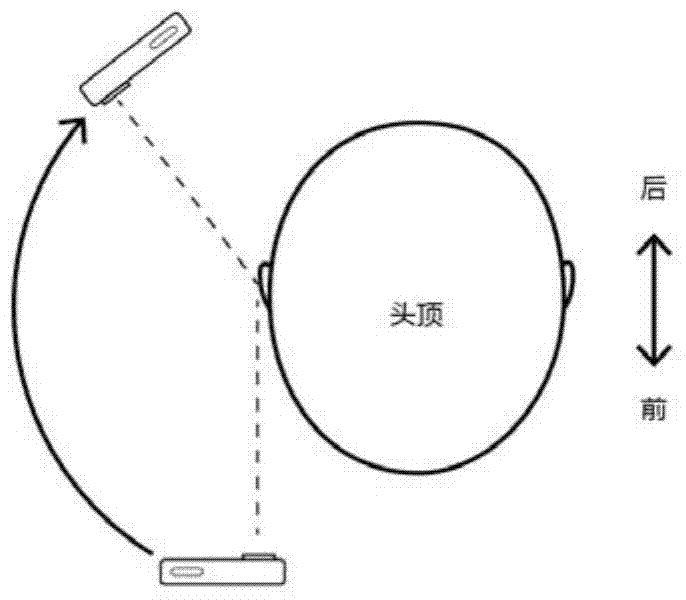

Customized Bluetooth earphone and manufacturing method thereof

InactiveCN104853273AImprove good experienceSave manpower and material resourcesEarpiece/earphone attachmentsIntegrated circuitMicrophone

The invention relates to a customized Bluetooth earphone and a manufacturing method thereof. The customized Bluetooth earphone comprises an ear cavity inner shell, a connection component, an ear cavity outer shell, a lithium battery, a sounding unit and an integrated circuit board, wherein the ear cavity inner shell is molded integrally through a 3D printing process; the ear cavity inner shell is connected with the ear cavity outer shell through the connection component; a sound cavity structure is arranged at a position corresponding to the cavity of auricular concha in the ear cavity inner shell; the sounding unit is arranged in the sound cavity structure; the side wall of the ear cavity inner shell is provided with a sound guide hole; the lithium battery is arranged in the ear cavity inner shell; the integrated circuit board comprises an antenna, a Bluetooth module, a decoding chip, a power amplifying module and a microphone which are arranged in the ear cavity outer shell and a switch, an answering button, a charging port and an LED (Light-Emitting Diode) indicating lamp which are arranged on the side wall of the ear cavity outer shell; and the lithium battery and the sounding unit are connected with the integrated circuit board respectively. The customized Bluetooth earphone and the manufacturing method thereof have the beneficial effects that customized delivery is not limited by regions anymore; the user experience can be enhanced; and a large amount of labor force and materials is saved.

Owner:长兴悦瑞三维科技有限公司 +3

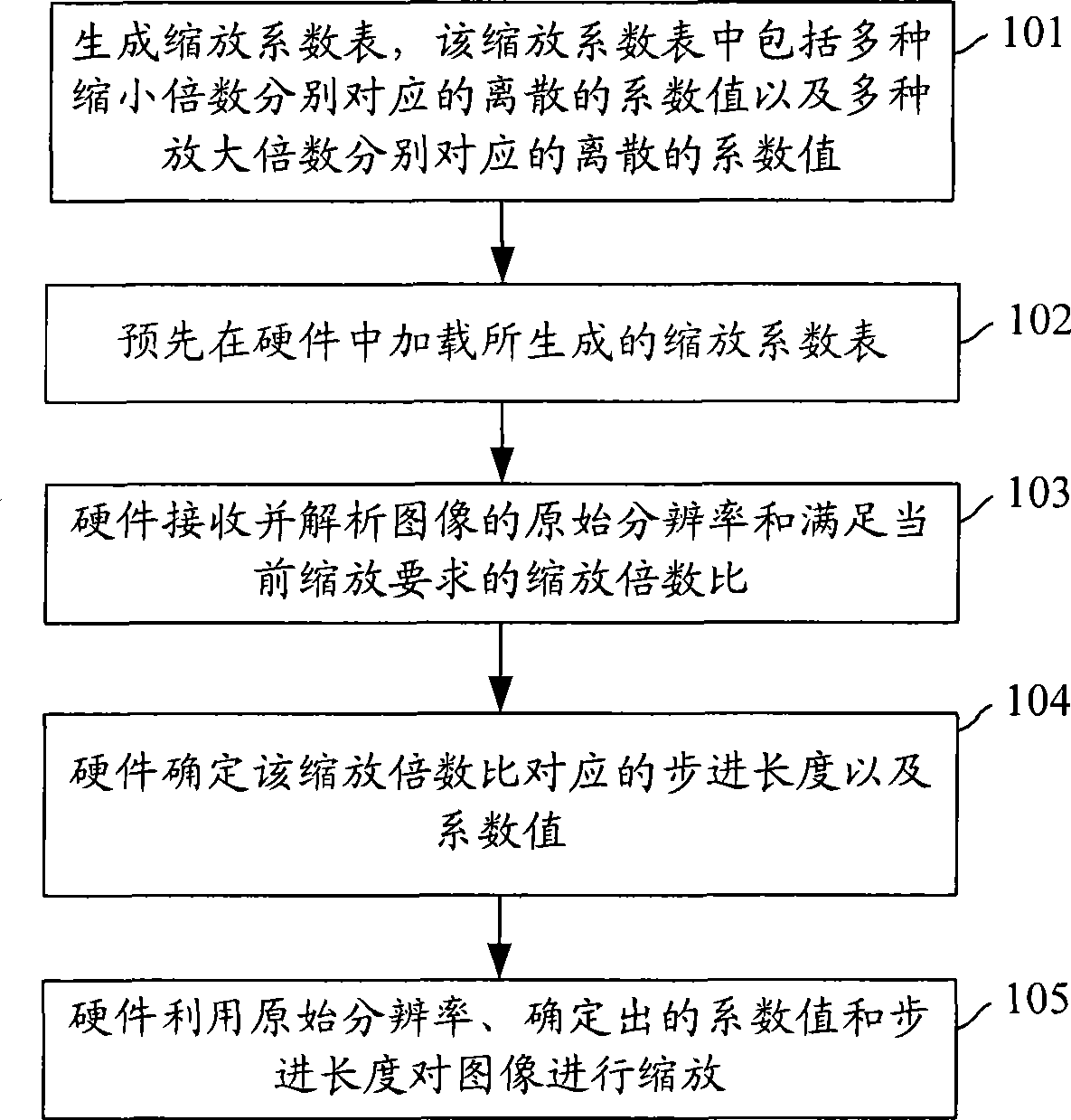

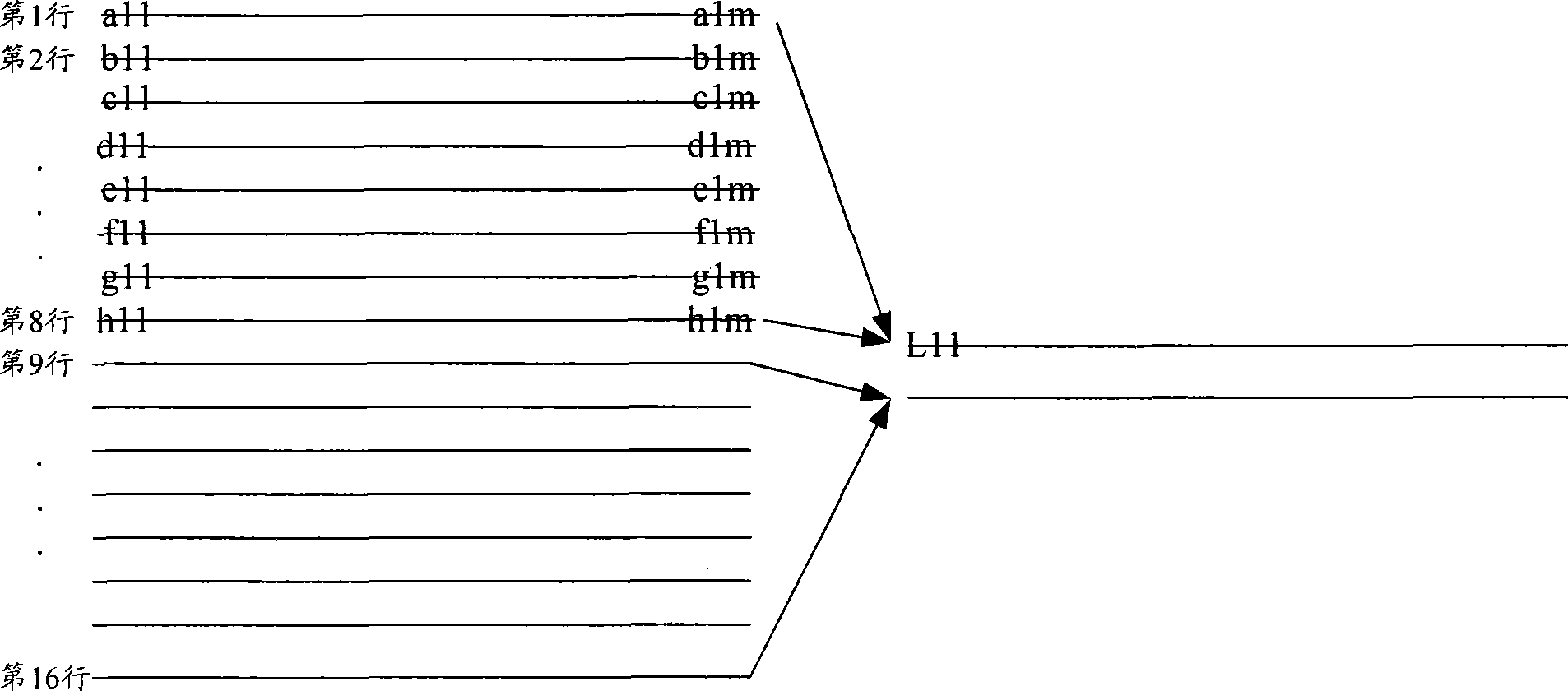

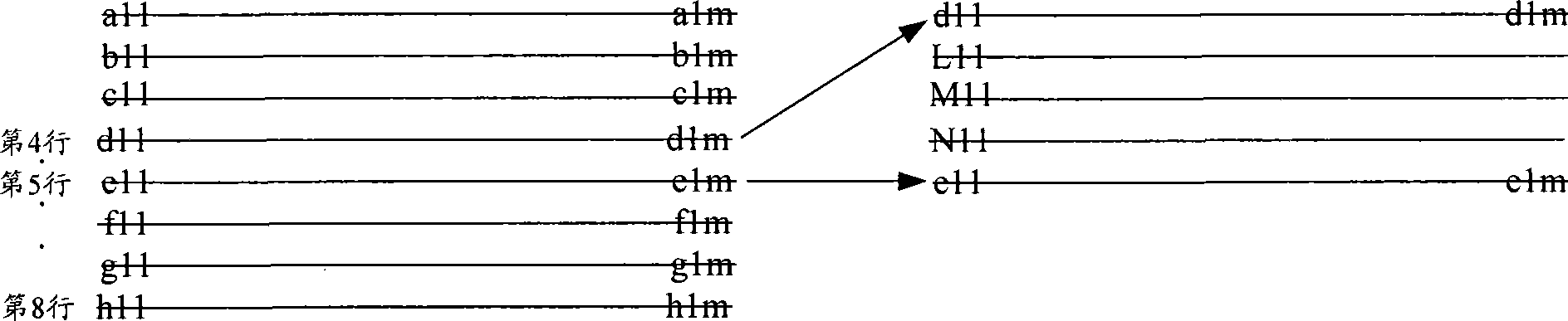

Method and device for zooming image

ActiveCN101465954AImprove practicalityMeet flexibility requirementsTelevision system detailsColor television detailsImage resolutionTime ratio

The invention discloses an image zooming method and device. The method comprises: a pre-generated zooming coefficient table is loaded and the zooming coefficient table comprises discrete coefficient values respectively corresponding to a plurality of reduction times and the discrete coefficient values respectively corresponding to a plurality of magnification times; the original resolution rate is received and a zooming times ratio required by the present zooming is satisfied; according to the zooming times ratio, the zooming coefficient table is searched and the stepping length as well as the coefficient value corresponding to the zooming times ratio are determined; by utilizing the determined stepping length, rows or columns of the original pixel which participates in each zooming are controlled, the pixel value of the original pixel in the rows or columns of the original pixel which participates in the zooming is multiply-accumulated with the determined coefficient value, the zoomed rows or columns are obtained, and the zooming is finished until the present image is determined according to the original resolution rate.

Owner:ZHEJIANG UNIVIEW TECH CO LTD

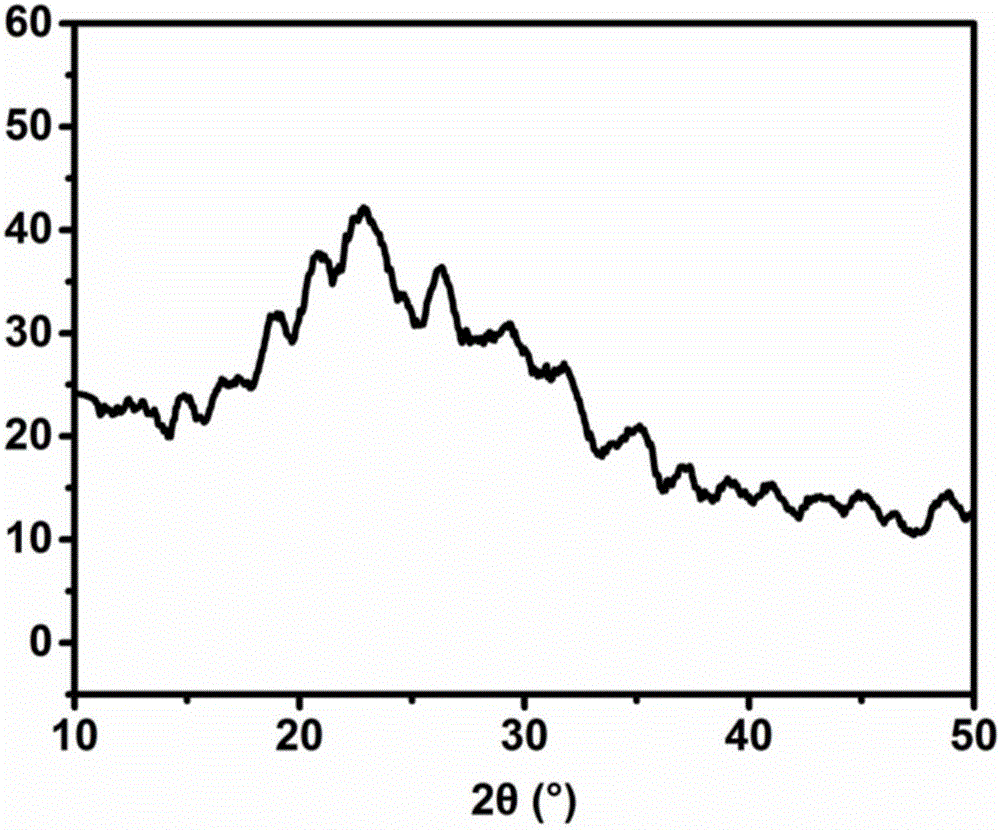

Polytetrafluoroethylene millipore membrane for purifying PM2.5

InactiveCN103212308AUniform fiber thicknessUniform film thicknessSemi-permeable membranesDispersed particle filtrationChemistryMembrane configuration

The invention provides a polytetrafluoroethylene millipore membrane for purifying PM2.5. The polytetrafluoroethylene millipore membrane is characterized in that the polytetrafluoroethylene millipore membrane is formed by a fiber of a three dimensional cross structure, wherein the polytetrafluoroethylene millipore membrane formed by the fiber of the three dimensional cross structure comprises following parameters: 5-8mum of thickness, 0.2-0.5mum of aperture, 80-90% of amount of porosity, 25-30MPa of intensity, 50-90% of resilience, 2-12m3 / (m2.min) of ventilating amount, and +-1.5mum of thickness tolerance. The polytetrafluoroethylene millipore membrane for purifying PM2.5 in the invention, has advantages of uniform fiber thickness, high amount of porosity, good resilience, uniform membrane thickness, multi-layer filtration, high filtrating efficiency, high and low temperature resistance, and high chemical resistance, can effectively filtrate dust with 2.5mum of particle diameter. The polytetrafluoroethylene millipore membrane for purifying PM2.5 in the invention, is suitable for application in a membrane coated filtrating material.

Owner:LINGQI ENVIRONMENTAL PROTECTION EQUIP FACTORY SHANGHAI

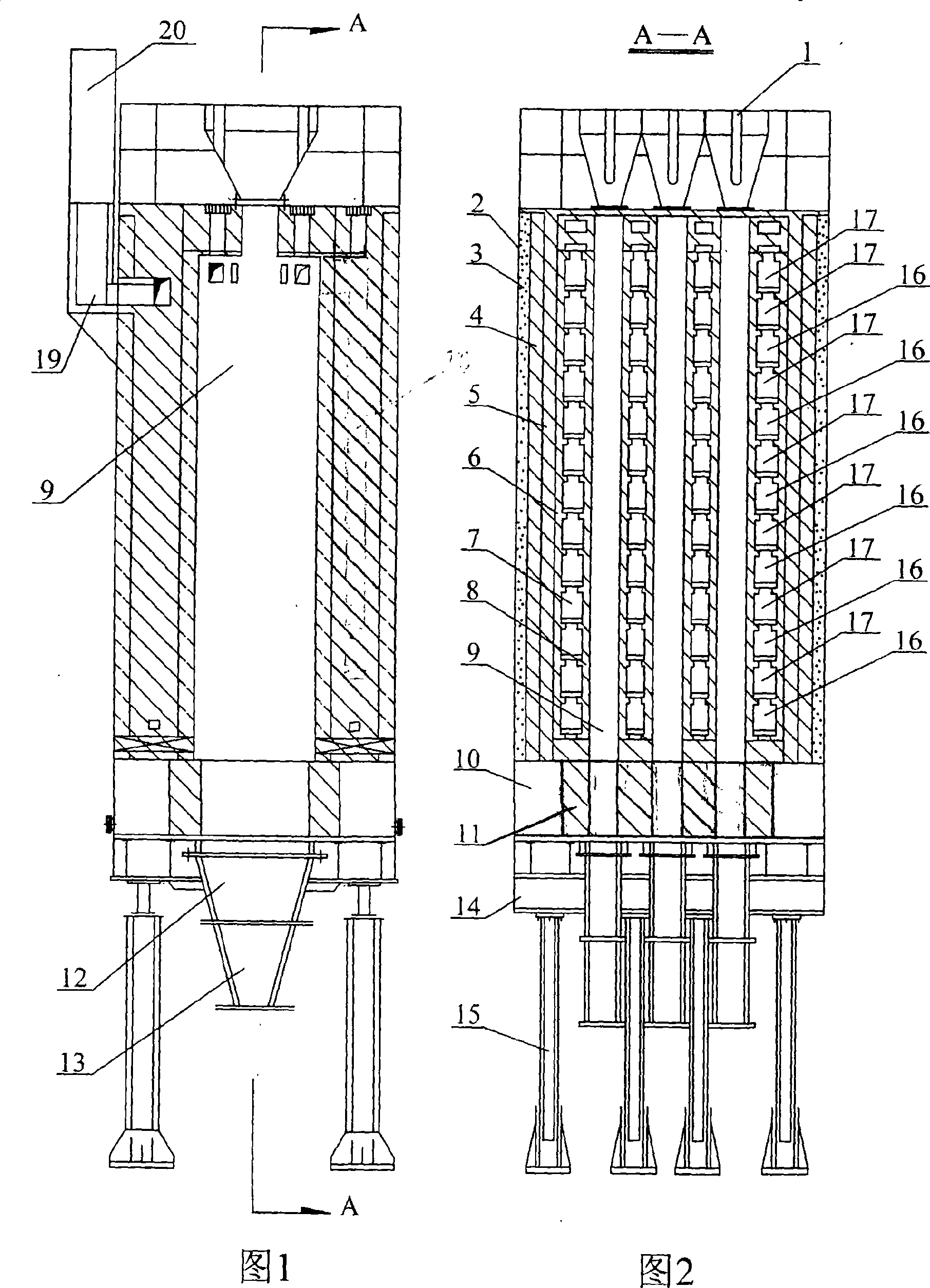

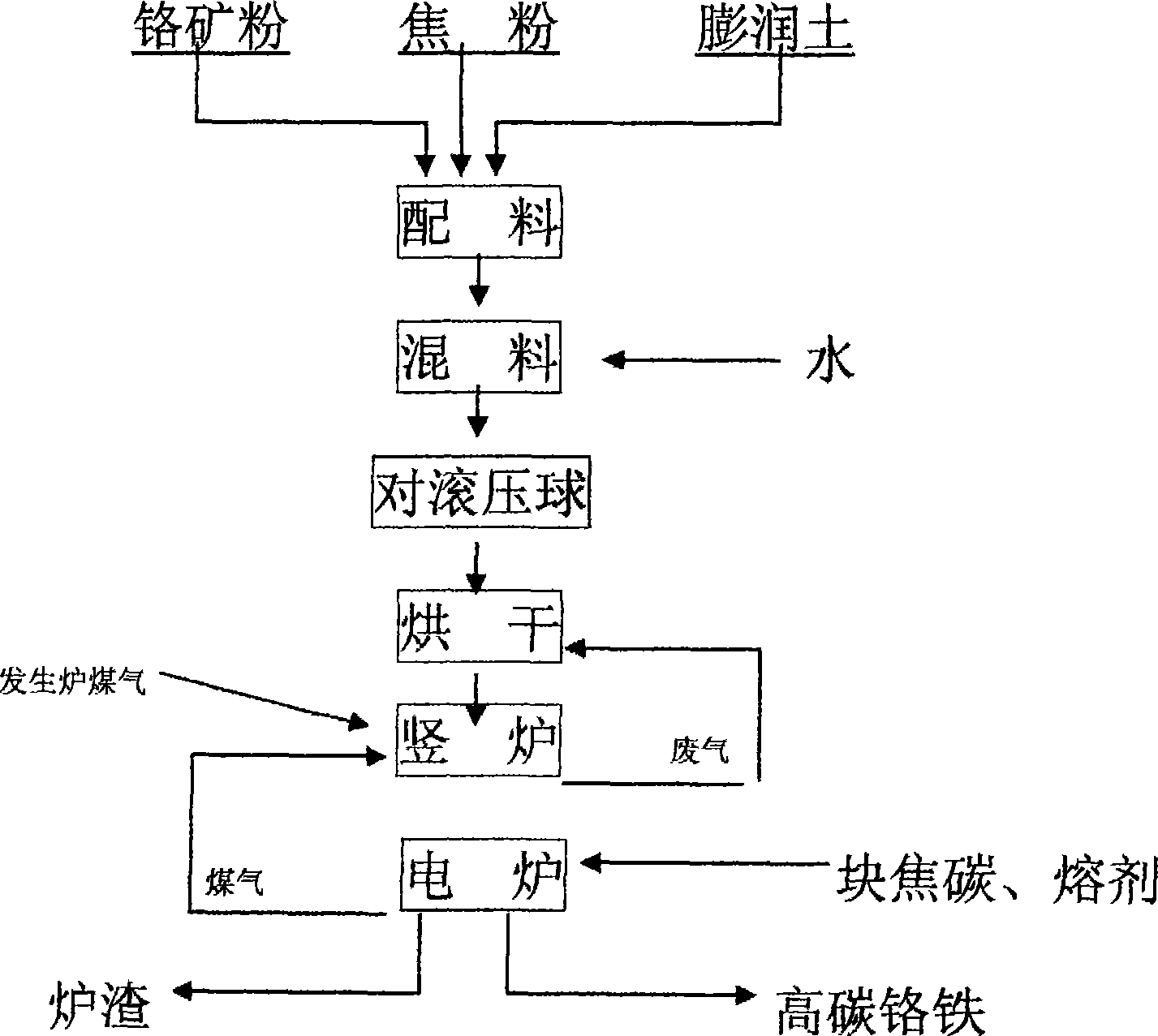

Production of pre-reduced chrome ore pellet by external heated shaft furnace

InactiveCN101418372AOvercome the difficulty of controlling the reducing atmosphereOvercome Kiln DifficultiesVertical furnacesCombustion chamberHigh carbon

The invention discloses a chrome ore prereduction external heating type shaft furnace, which is characterized in that multilayer gas burner flame paths arranged on both sides of reduction reaction chambers with a rectangular cross section indirectly supply heat under the condition of air separation. The shaft furnace consists of a plurality of independently working reaction reduction chambers; the reduction reaction chambers and the gas burner flame paths are built by tailored high aluminium special-form refractory bricks; and the shaft furnace body is vertically arranged on a bearing girder. Dried carbon-contained chrome ore pellets are added into a bin on the top end of the shaft furnace and are discharged out of the furnace through the preheating section, the reduction section and the cooling section of the shaft furnace. The temperature of the reduction reaction is 1,300 to 1,400 DEG C; the material stays at the reduction section for 3 to 4 hours; and the comprehensive reduction degree is 60 to 70 percent. The prereduced pellet ore is used for producing high carbon ferrochrome in a closed electric furnace. The cold pellet ore which is charged into the closed electric furnace can reduce the power consumption for ferrochrome by above 25 percent, improve the yield by above 40 percent, reduce the emission by above 20 percent, and improve the chrome recovery rate by above 3 percent. The chrome ore prereduction external heating type shaft furnace can be used for continuous production, and has the advantages of circulation, high economical efficiency, environmental protection, energy conservation, emission reduction, and the like.

Owner:李志忠

Circuit board splitting machine

The invention discloses a circuit board splitting machine. The technical problems of coarse cuts and welding spot crazing or part breakage caused by cutting stress of a circuit board in the prior art is solved. The circuit board splitting machine comprises a cutting table, a tool rest and guide rails, wherein the guide rails are fixed on the cutting table through a liftable support. A blade for cutting the circuit board is arranged on the tool rest, the tool rest is in sliding connection with the guide rails through slide blocks, and a control device for controlling left-right walking of the tool rest along the guide rails is arranged on the cutting table. When the circuit board splitting machine works, a driving motor drives a lead screw to rotate and accordingly drives a nut seat to run vertically to achieve lifting of the guide rails and further achieve lifting and descending of the blade, and an air cylinder pushes the blade to walk in a left-right mode so as to achieve circuit board cutting. Compared with the prior art, the circuit board splitting machine has the advantages that feeding type advance cutting is adopted, the stress can be thoroughly decreased, smooth cuts can be ensured, and welding spot crazing and part breakage can be prevented; the tool rest can freely lift with the guide rails, the cutting depth is controllable, and cutting of different circuit boards in thickness is achieved.

Owner:SUZHOU BECHENLAI ELECTRONICS

Medical waste crushing treatment device and treatment process adopting same

PendingCN107030091AGuaranteed stabilityGuaranteed safetyGas current separationSolid waste disposalMedical wasteEnvironmental engineering

The invention provides a medical waste crushing treatment device which comprises a feeding conveyer belt, a feed opening, a crushing chamber, a sorting room, a compression chamber and a moving chamber, wherein the feeding conveyer belt is mounted at the right end of the feed opening; a feeding hopper is arranged on the feeding conveyer belt; the invention further provides a treatment process adopting the medical waste crushing treatment device. Compared with the prior art, the medical waste crushing treatment device and the treatment process adopting the same have the benefits as follows: wastes can be compressed and stored in a classified manner and wait to be transferred to different garbage disposal plants, expenses spent on garbage disposal are reduced for the society, environmental requirements of medical wastes on stabilization, securitization, reduction and harmlessness are ensured, and meanwhile the conformity to the development tendency of modern medical waste treatment is achieved.

Owner:SHANDONG JINGHUA ENVIRONMENTAL SCI & TECH

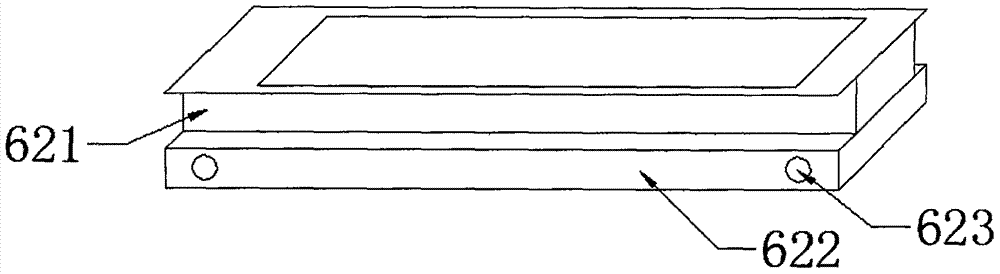

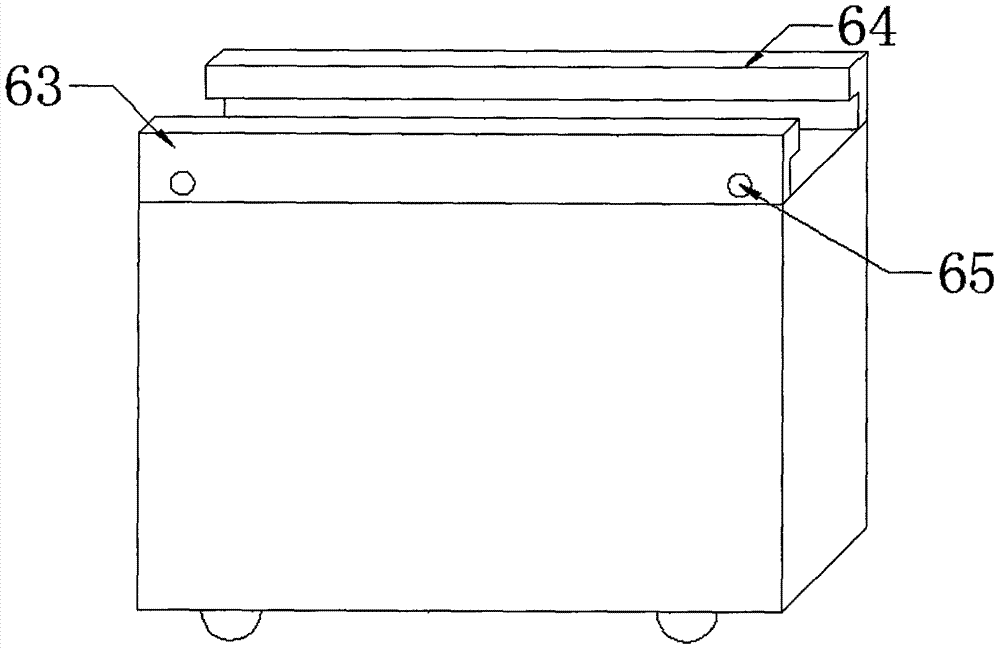

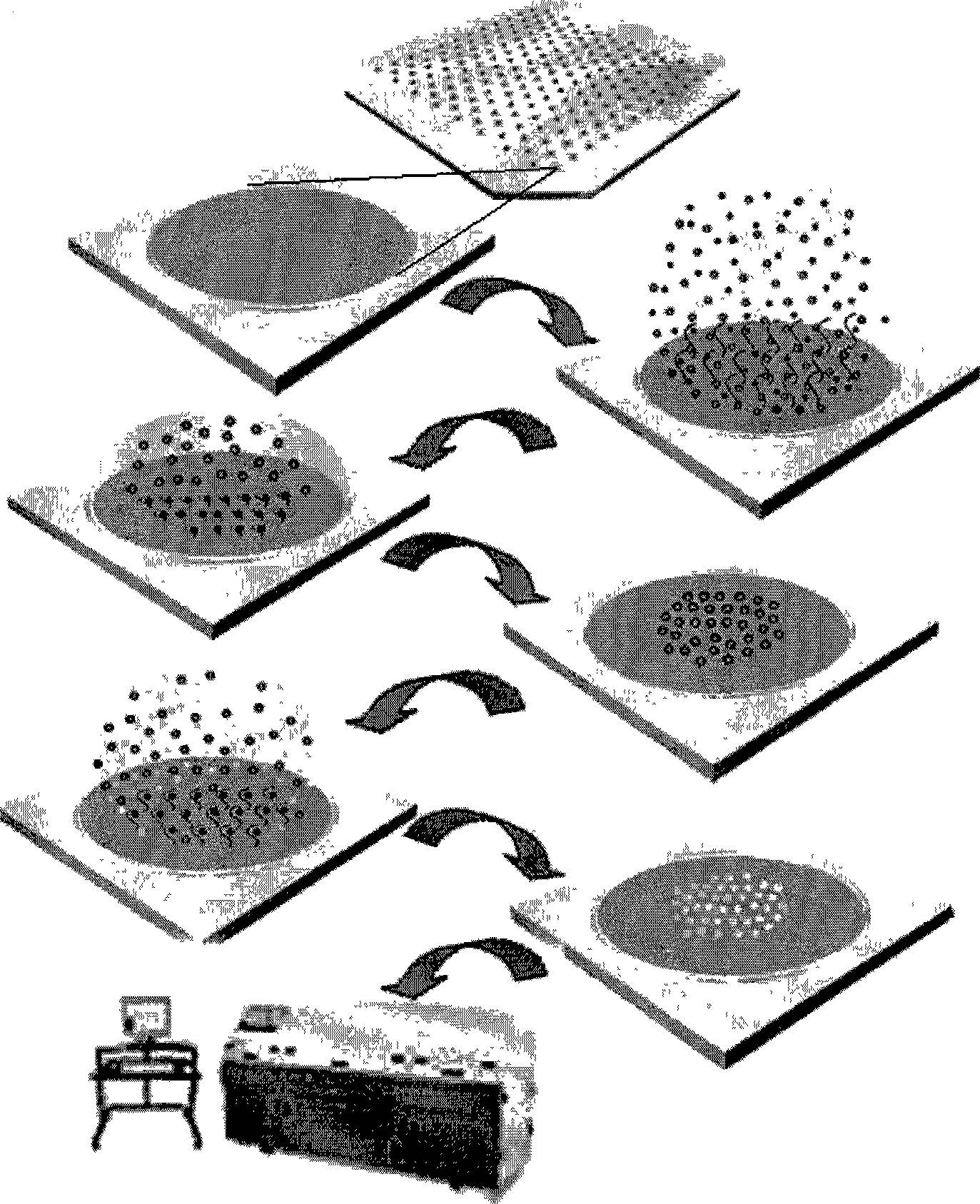

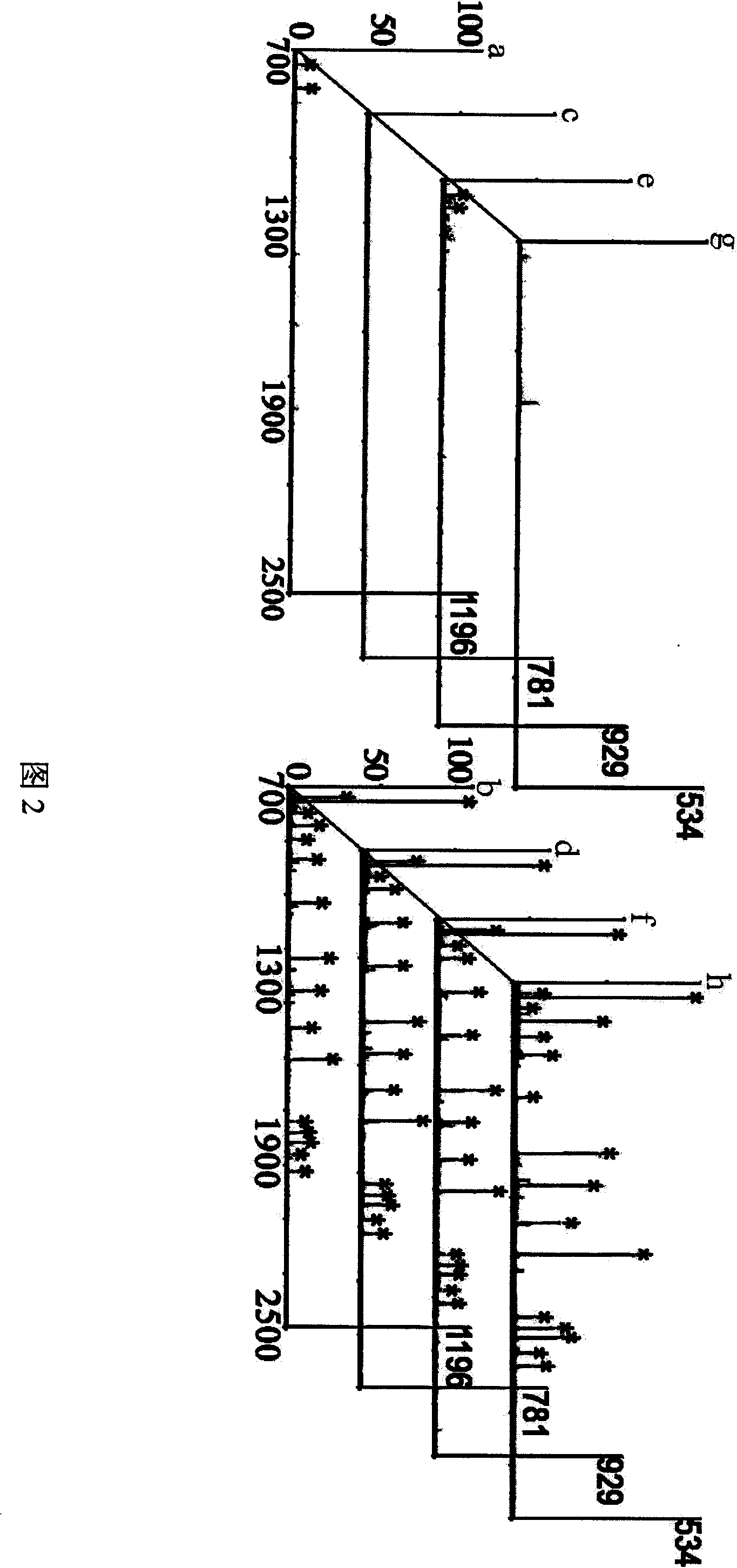

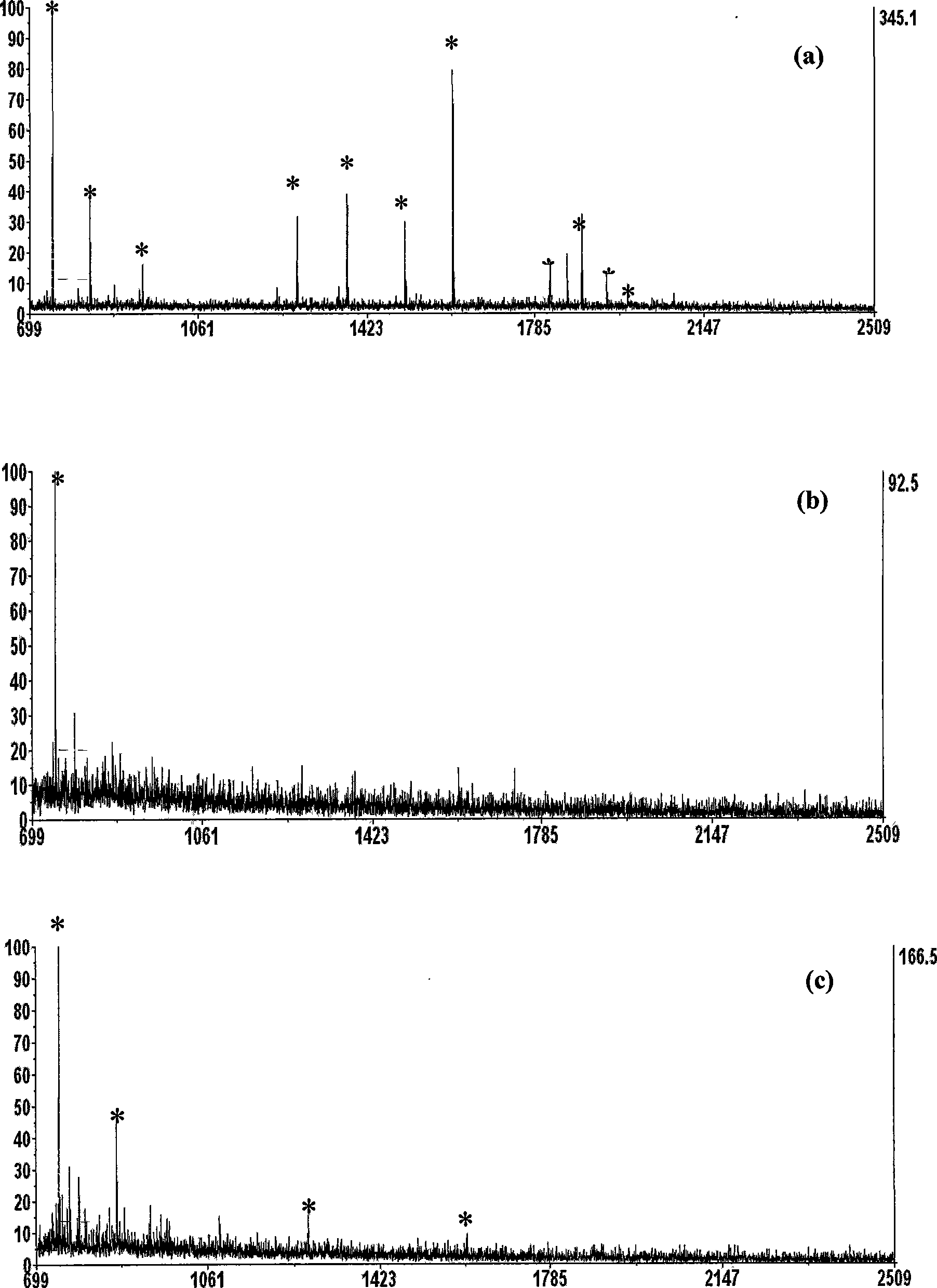

Method for in-situ desalination and enrichment on trace amount of protein or polypeptide target

InactiveCN101368890AHigh sensitivityHigh reproducibilityPreparing sample for investigationMaterial analysis by electric/magnetic meansMass spectrum analysisMass spectrometry

The invention belongs to the biochemical analysis field and relates to a method which makes use of the block polymer coating with a micro-phase separation structure to carry out on-target elution-free in-situ desalting and synchronous enrichment on the peptide and protein samples to avoid samples loss and can directly carry out matrix-assisted laser analysis ionization mass spectrometry analysis and identification on the enriched samples. The invention can realize desalting dispensing with extra eluted desalting step and excessive matrix solution and can directly make MALDI MS analysis; the invention successfully achieves the characteristics of sample on-target in-situ elution-free desalting and enrichment at the first time and has the advantages of high sensitivity, high reproducibility, high flux and strong salt-tolerant ability, which is economical and time-saving; the invention can be widely used in the field of proteomics and also greatly expands the application scope of the polymer coating technology.

Owner:FUDAN UNIV

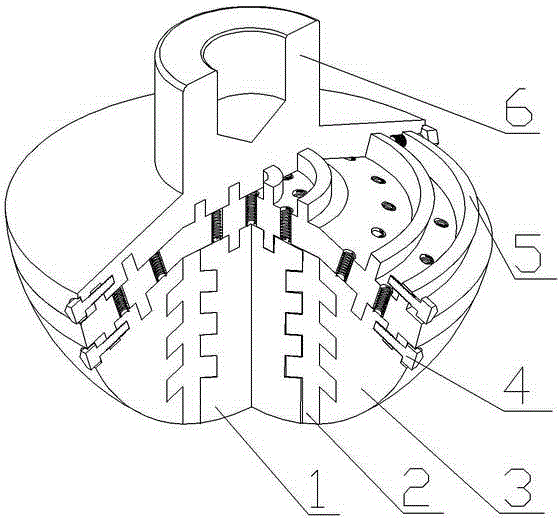

Rigid-flexible coupling buffer bionic foot

ActiveCN104401416AWork lessGuaranteed stabilityNon-rotating vibration suppressionVehiclesCouplingEngineering

The invention discloses a rigid-flexible coupling buffer bionic foot which comprises a coupling foot bottom, an upper-portion flexible layer, a foot top cover plate, a torsion spring and a compression spring. The meshing faces of a radial foot base plate, a bottom flexible layer and a lateral foot base plate form a rigid-flexible coupling buffer interface, and the upper-portion flexible layer, the compression spring and the torsion spring and the foot top cover plate and the coupling foot bottom form a rigid-flexible coupling buffer interface. By means of ingenious matching of a rigid split structure and flexible connection, a coupling body structure is formed through rigid-flexible-rigid organic combination, and ground impact forces in the radial direction and the lateral direction are effectively absorbed and weakened. The whole rigid-flexible coupling buffer bionic foot has the advantages of having rigid supporting and flexible absorption functions and accordingly has good buffering performance.

Owner:JILIN UNIV

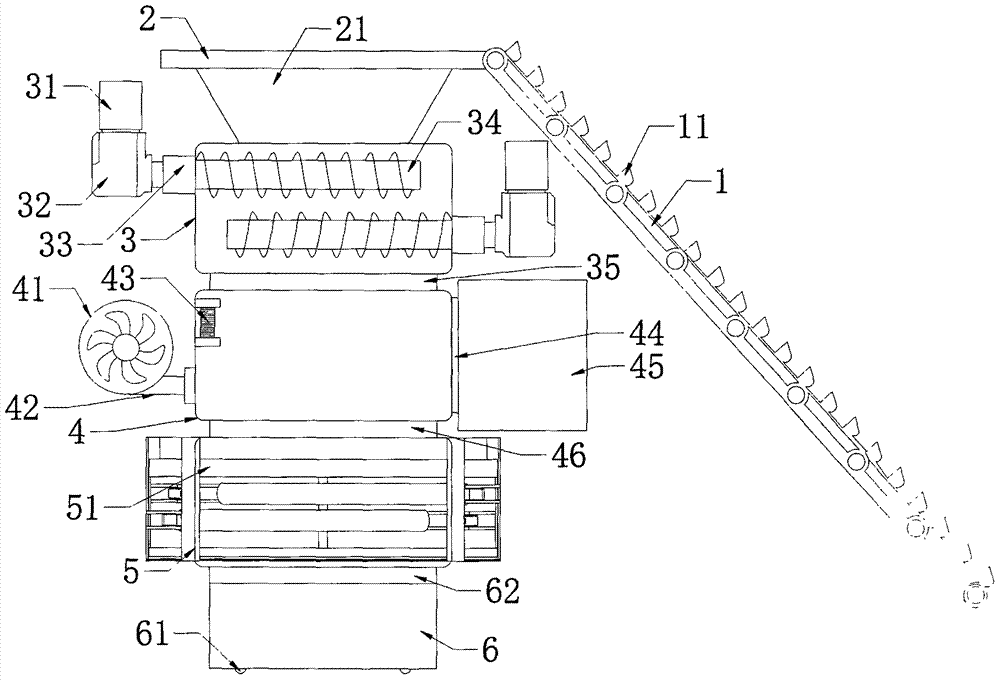

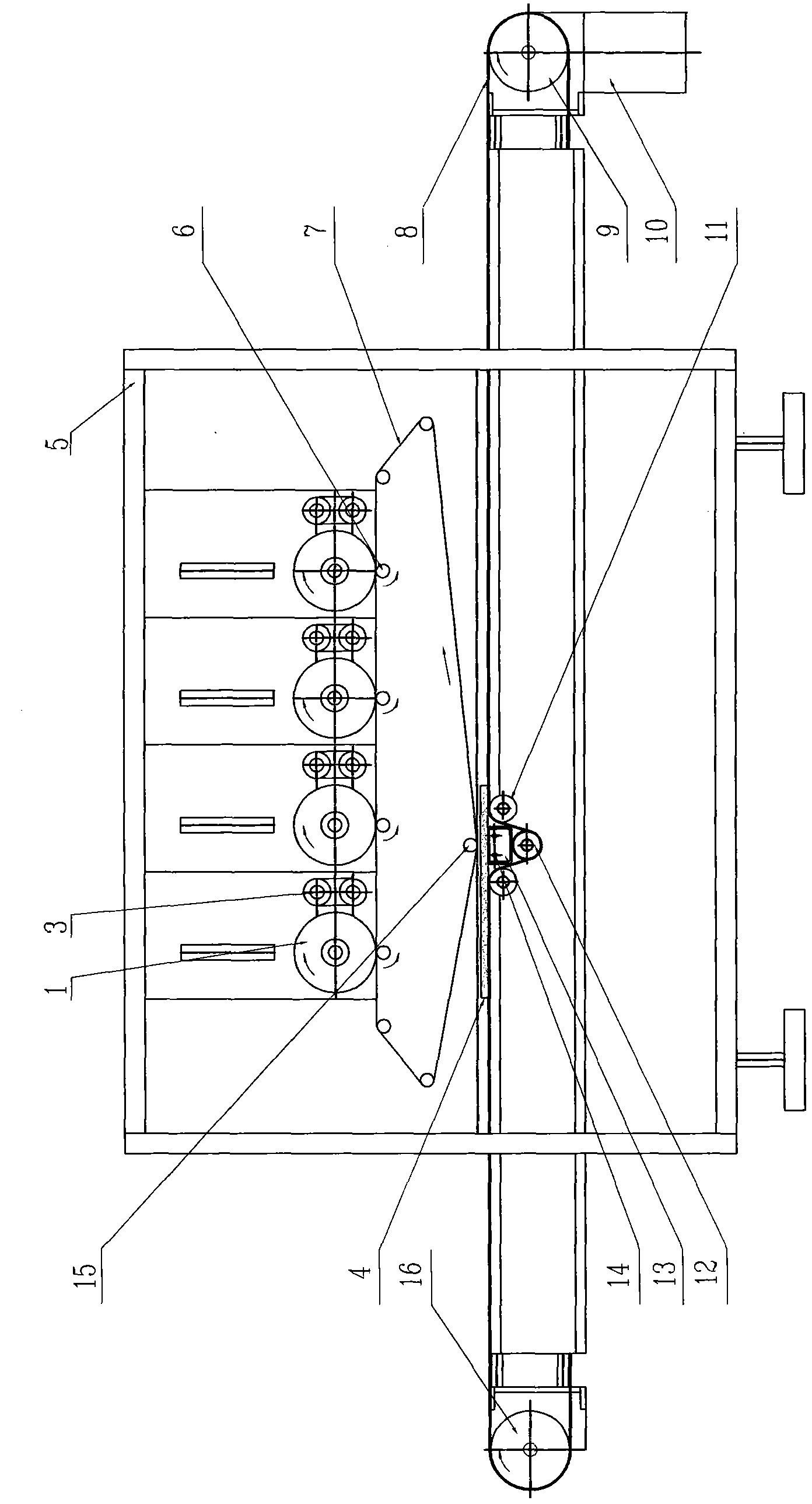

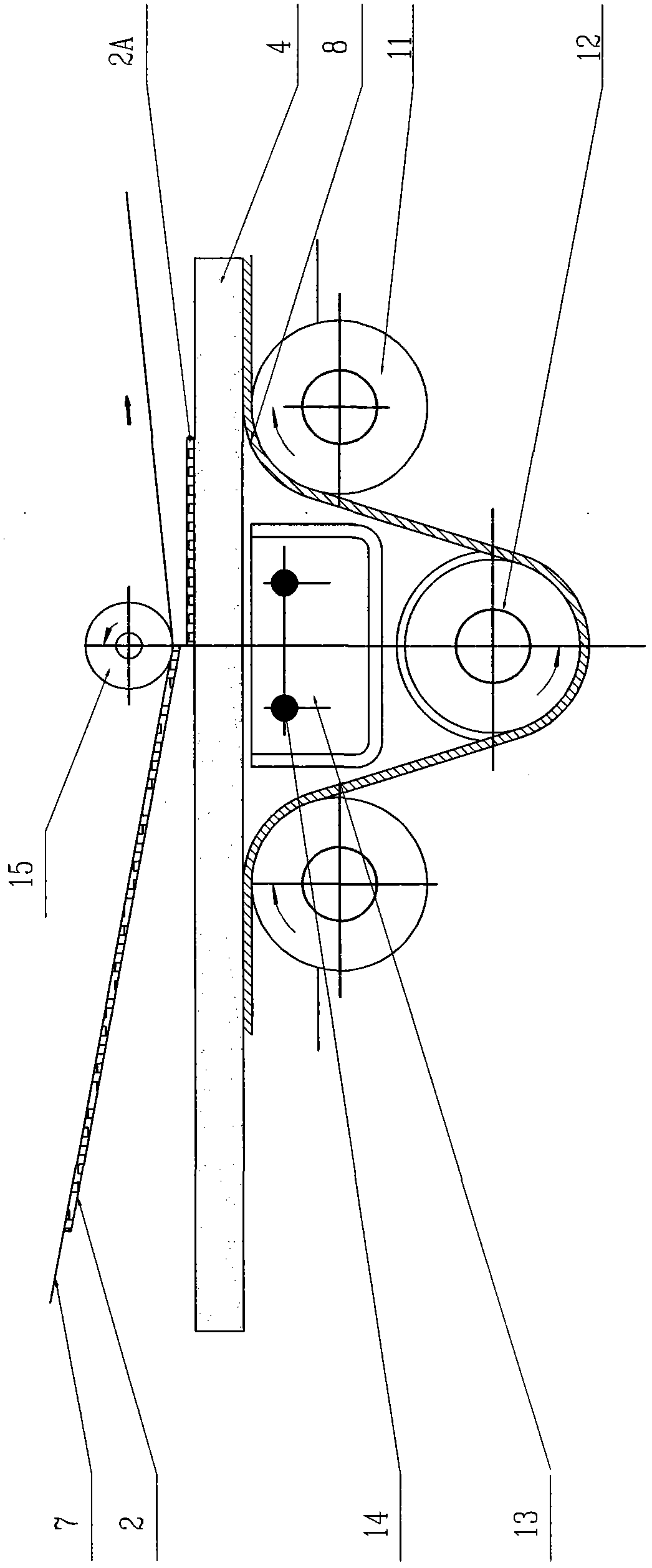

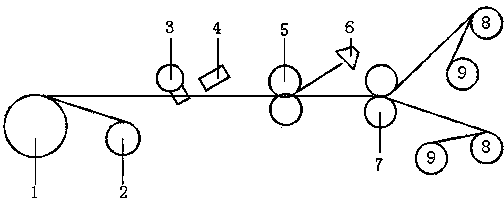

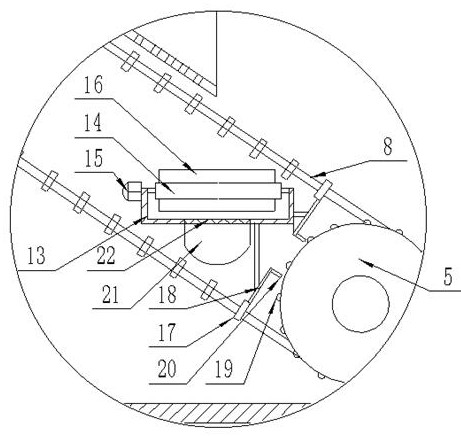

Mulberry shoot cutter

The invention discloses a mulberry shoot cutter which comprises a tractor, a rack, a cutter head, a curbed bar and a shoot pushing track, wherein the rack is arranged at the front end of the tractor; the cutter head is arranged on the rack and is driven by a first driving mechanism to rotate; the curved bar is erected on the right side in front of the rack and is positioned in front of the cutter head; the front end of the curved bar is bent towards the right side; the shoot pushing track is arranged at the rear part of the curved bar and is driven by a second driving mechanism to circularly rotate. Preferably, the rack is arranged at the front end of the tractor through a lifting mechanism. According to the mulberry shoot cutter disclosed by the invention, shoots of mulberries can be mechanically cut and can be centrally pushed towards one side, so that missed cutting is avoided and the cut-off shoots are conveniently picked up. The mulberry shoot cutter has the advantages of simple structure, convenience to use and high shoot cutting efficiency.

Owner:GUANGXI UNIV

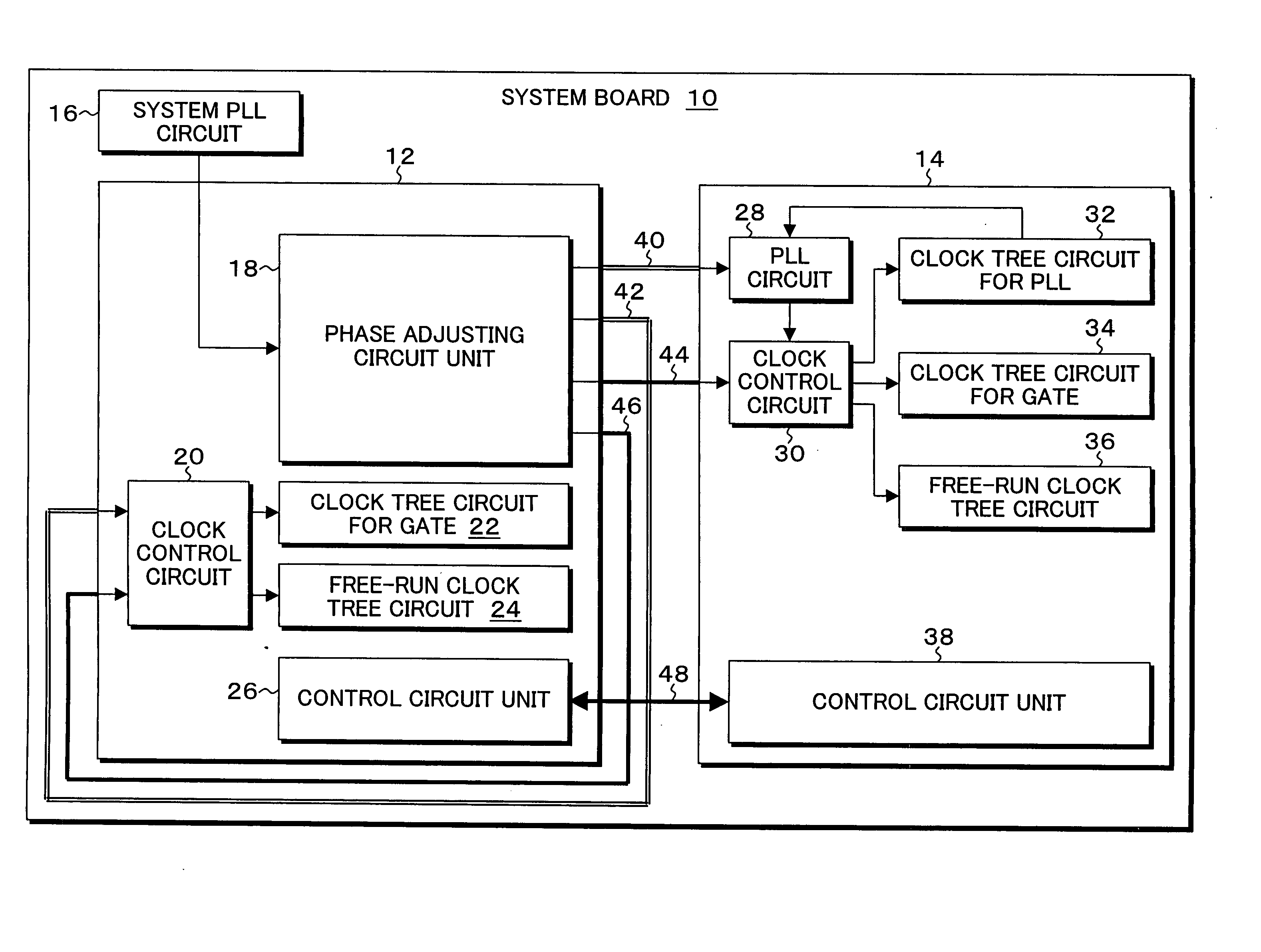

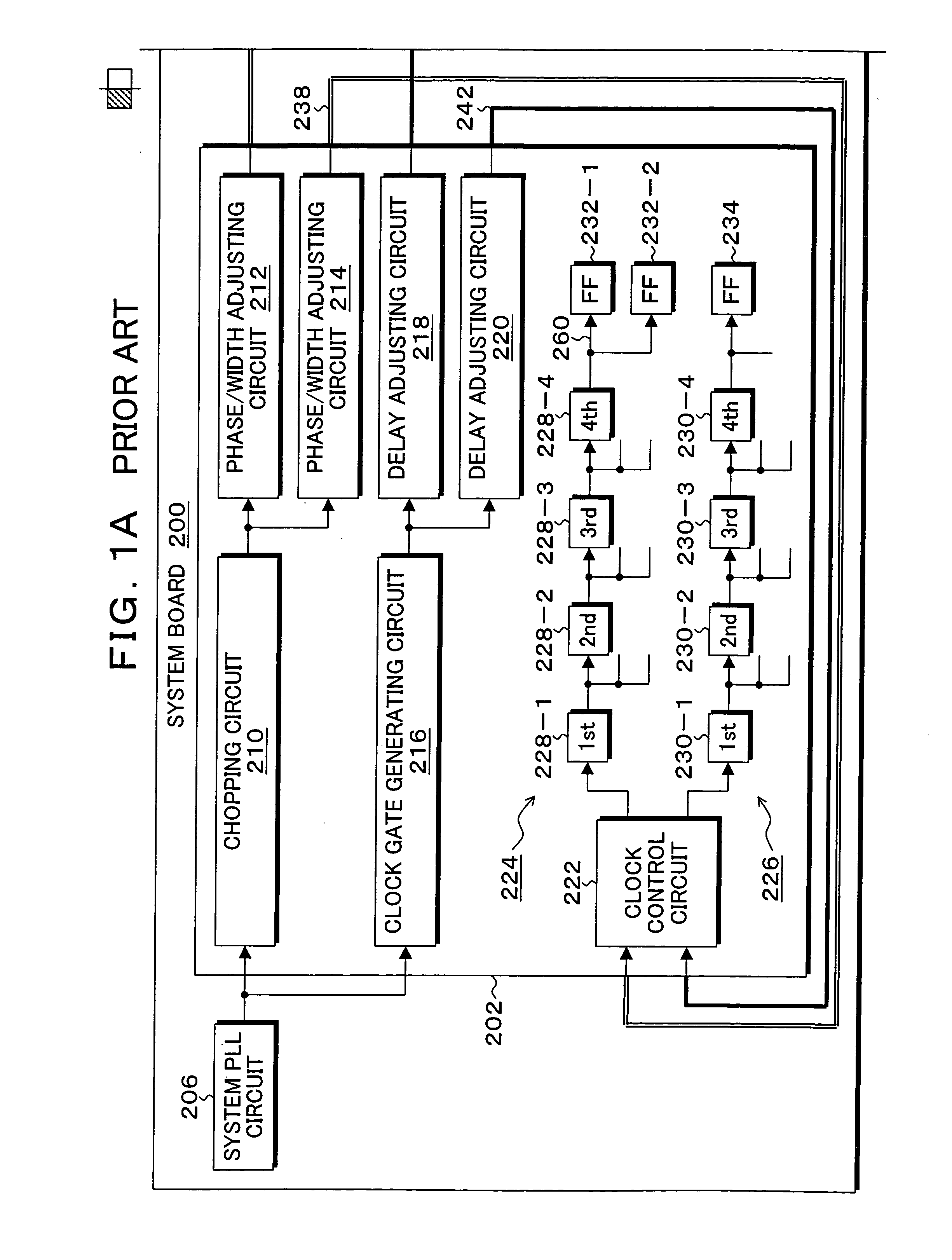

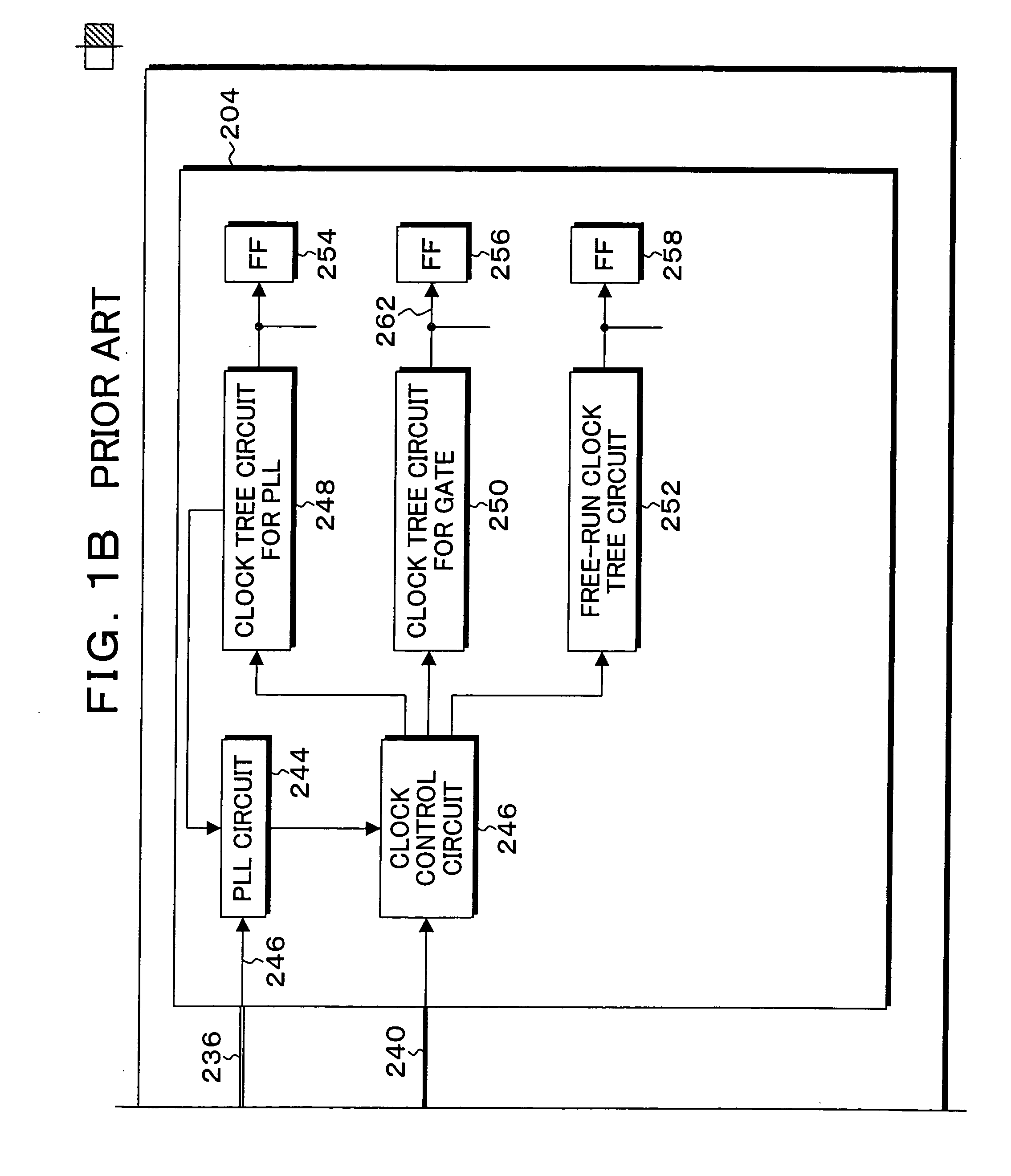

Information processing apparatus

InactiveUS20050156648A1Easy to operateImprove reliabilityPulse automatic controlSingle output arrangementsInformation processingClock tree

An information processing apparatus is constructed by a system PLL, a first unit, a second unit, and a system board on which they are mounted. A delay setting circuit in which a variation and delay elements (a gate delay and a line delay) which are equivalent to those of a clock tree circuit for a gate have been set at the designing stage is provided on a signal line of a system clock in the first unit to the second unit. A delay setting circuit in which a variation and delay elements which are equivalent to those of the clock tree circuit for the gate have been set at the designing stage is provided on a signal line of a clock gate signal to the second unit.

Owner:FUJITSU LTD

Laser printing machine for ceramic

The invention relates to a laser printing machine for ceramic. The laser printing machine comprises a stander, a first transfer printing system and a ceramic green brick conveying system, wherein the first transfer printing system comprises at least one selenium photosensitive drum, a ceramic toner with negative static electricity, a laser head and a transfer printing roller; a circulating rotating transfer printing band is arranged between the first transfer printing system and the ceramic green brick conveying system; a closest point to the ceramic green brick conveying system is formed on the lower part of the transfer printing band and is not in contact with the upper surface of a ceramic green brick passing through the closest point, and a clearance of 0.5-3 mm is reserved between the closest point and the upper surface of the ceramic green brick; a positive static electric field capable of adsorbing the ceramic toner with the negative static electricity on the transfer printing band to the surface of the ceramic green brick is arranged just under a position, through which the ceramic green brick corresponding to the closest point passes; the voltage of the positive static electric field is 2,000-20,000 V. Due to the design, the definition and the vividness of pattern lines printed on the surface of the ceramic green brick can be greatly improved, and the color quality of a ceramic brick is improved; meanwhile, after-sale productive maintenance of equipment is reduced, the production efficiency is improved, and the production cost is lowered.

Owner:陆永添

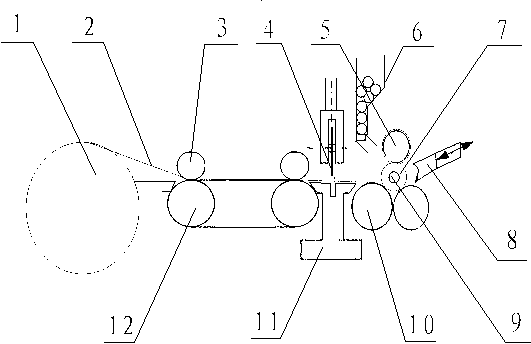

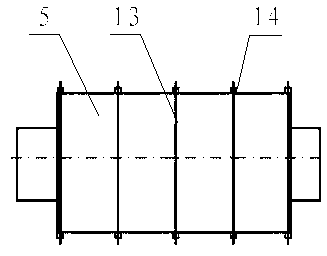

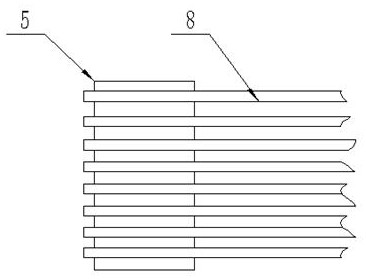

Flexible material rewinding slitting system and rewinding slitting mechanism thereof

InactiveCN103121603AAutomate the processReduce labor intensityArticle deliveryEngineeringMechanical engineering

The invention discloses a flexible material rewinding slitting system and a rewinding slitting mechanism thereof. The mechanism comprises a machine frame and two rewinding rollers which are assembled on the machine frame in a rotation mode. A slitting pressing roller is assembled above the middle portions of the two rewinding rollers in the rotation mode. The slitting pressing roller moves along the radial direction of a rewinding core shaft so that the rewinding core shaft is pressed between the slitting pressing roller and the two rewinding rollers. At least one rewinding roller is a driving roller for achieving rotation of the rewinding core shaft. Annular slitting cutters are distributed on the outer periphery of the slitting pressing roller in the radial direction in a spaced mode and extend along the circumferential direction of the slitting pressing roller, and flexible material rolls are slit by the annular slitting cutters. A working mode of slitting while rewinding is adopted by the rewinding slitting mechanism, compared with the prior art, the inter-related phenomenon of the flexible materials is avoided, the positions of the slitting pressing roller, the rewinding core shaft and the rewinding rollers are relatively closer, occupied space of the whole rewinding slitting mechanism is compressed, the length of the rewinding slitting system of the rewinding slitting mechanism is compressed, and the flexible material rewinding slitting system and the rewinding slitting mechanism of the flexible material rewinding slitting system are simple and compact in structure.

Owner:HENAN UNIV OF SCI & TECH

Preparation method of complex-shaped large cemented carbide wear-resistant block

The invention relates to a preparation method of a complex-shaped large cemented carbide wear-resistant block. The method comprises the following steps of S1, carrying out powder pressing on a cemented carbide mixture, and pressing to form a square pre-blank; S2, carrying out first cold isostatic pressing on the square pre-blank to obtain a pressing blank; S3, carrying out mechanical machining onthe pressing blank to obtain the machined pressing blank; S4, carrying out second cold isostatic pressing on the machined pressing blank to obtain the treated pressing blank; and S5, carrying out pressure sintering on the treated pressing blank to obtain the complex-shaped large cemented carbide wear-resistant block. According to the method, the complex-shape large cemented carbide product can bestably and reliably manufactured, the prepared complex-shape large cemented carbide wear-resistant block is complex in shape, high in dimensional accuracy and uniform in density, stress concentrationinside the material is remarkably reduced, the impact resistance is good, and wear resistance is high.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

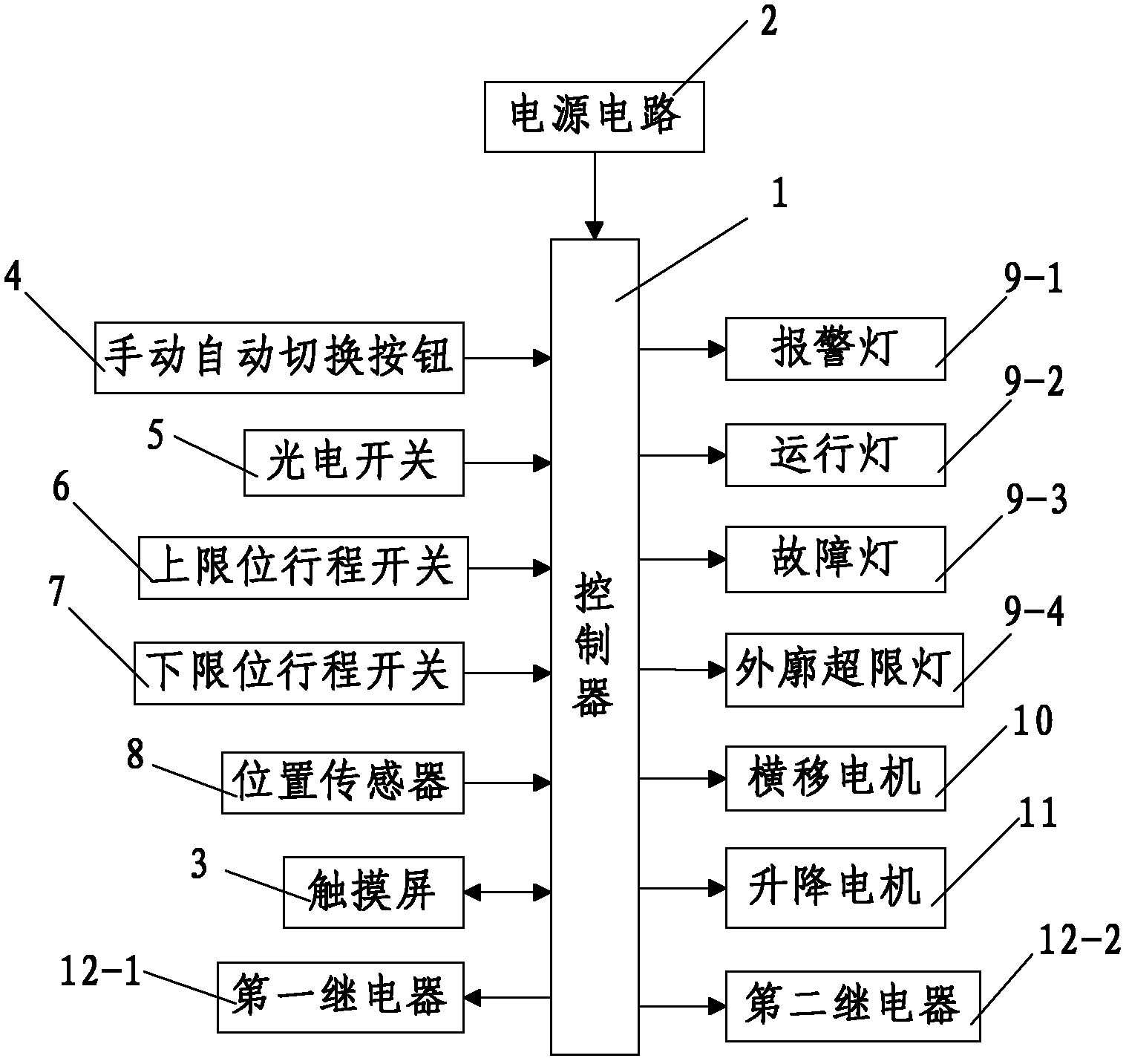

Control system of lifting and lateral moving stopping device

InactiveCN103161337ASimple structureReasonable designProgramme control in sequence/logic controllersParkingsLateral moveElectric machinery

The invention discloses a control system of a lifting and lateral moving stopping device. The control system of the lifting and lateral moving stopping device comprises a controller, a power circuit supplying power for each electricity consuming unit and a touch screen connected with the controller. A manual and automatic switching button, an optoelectronic switch, an upper limit travel switch, a lower limit travel switch and a position sensor are connected at the input end of the controller, wherein the optoelectronic switch is used for detecting whether the parking of an automobile on a tray is in place, the upper limit travel switch is used for detecting an elevator ascending to a limit position, the lower limit travel switch is used for detecting the elevator descending to a limit position, and the position sensor is used for detecting the lifting position of the tray in real time. The output end of the controller is connected with a working state indicator, a lateral-moving motor, a lifting motor and relays, wherein the number of the relays is two, and the two relays are respectively a first relay connected in a power supply circuit of the lifting motor in series and a second relay connected in a power supply circuit of the lateral-moving motor in series. The control system of the lifting and lateral moving stopping device is simple in structure, reasonable in design, not high in the requirements of an installation standard, high in automation degree, easy to operate, high in parking efficiency of a parking lot, and high in space utilizing rate.

Owner:XIAN KING TRUCK ELECTRON

Preparation method of monodirectional preimpregnation narrowband for automatic filament placement

A convenient preparation method of a monodirectional preimpregnation narrowband for automatic filament placement belongs to the composite material laying and forming field, and mainly comprises the following steps: width prepreg uncoiling, back lining paper rewinding, prepreg slitting, preimpregnation narrowband coating, and spiral rewinding of a coated preimpregnation narrowband. The preimpregnation narrowband for automatic filament placement can be prepared by the method, and is continuous in length, constant in width, and good in unwinding.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

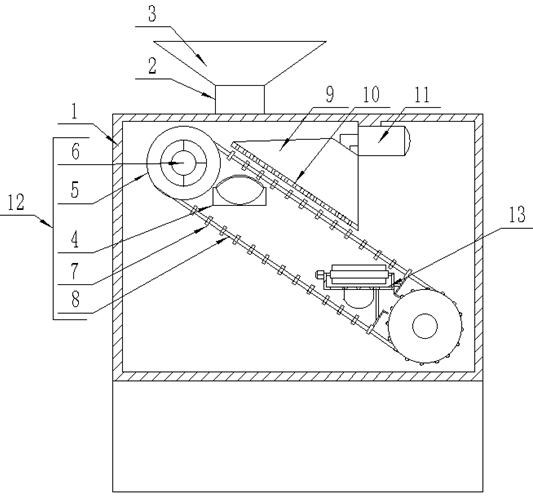

Tea processing machine and processing method thereof

ActiveCN112841331AImprove vibrationEasy to separatePre-extraction tea treatmentWrapper twisting/gatheringCartoning machineElectric machinery

The invention discloses a tea processing machine and a processing method thereof. The tea processing machine comprises a feeding machine box, a feeding pipe is vertically arranged on the rear portion of the upper left side of the feeding machine box, an impurity removing and guiding mechanism is arranged between the lower end of the feeding pipe and the inner side of the feeding machine box, and a rotary weighing mechanism is arranged on the rear side of the lower end of the feeding machine box; and a boxing mechanism is arranged on the lower side of the rotary weighing mechanism. A first driving motor drives a transmission wheel and a transmission rubber rope on the upper left side to rotate, and meanwhile, a high-pressure air pump is started to suck air, so that fine holes in a bottom plate of an air guide hollow body generate strong negative pressure, a suction effect is generated on tea leaves in a feeding transition box, and the tea leaves abut against the side wall of an inner ring of the transmission rubber rope; and then vibration impurity removal is conducted in the transmission process, finally, the materials are discharged to the rotary weighing mechanism, weighing is conducted through a weighing supporting plate, when the corresponding weight is reached, the materials are automatically discharged downwards, fall into a packaging barrel and then are sealed.

Owner:里森食品(广州)有限公司

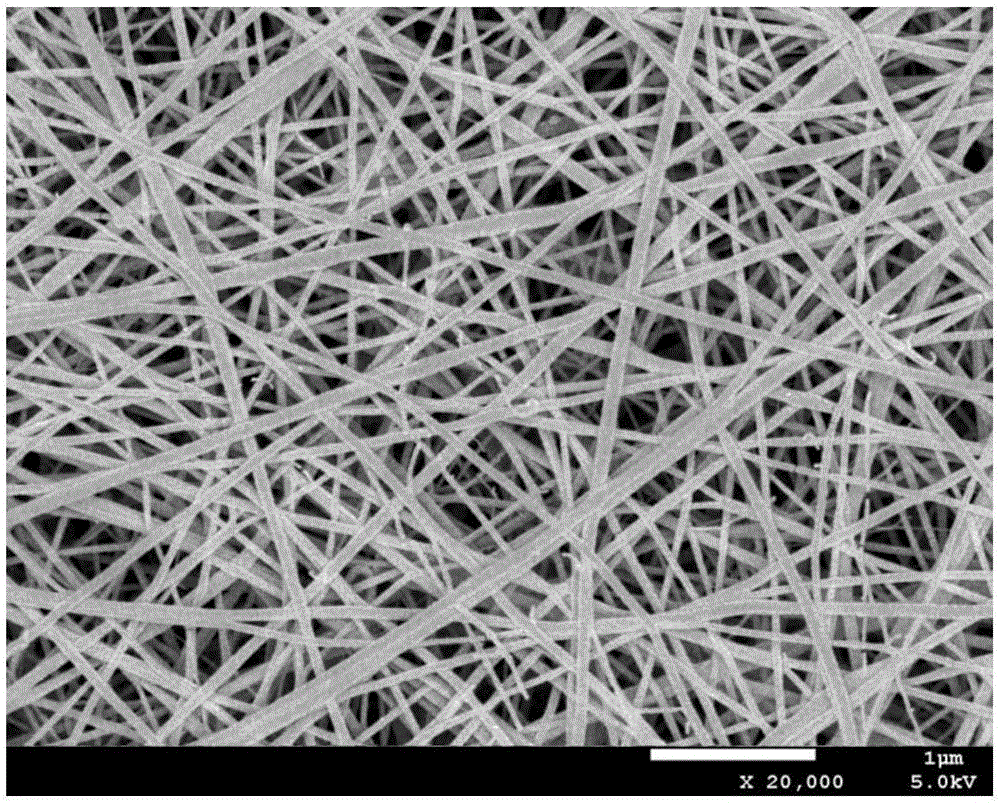

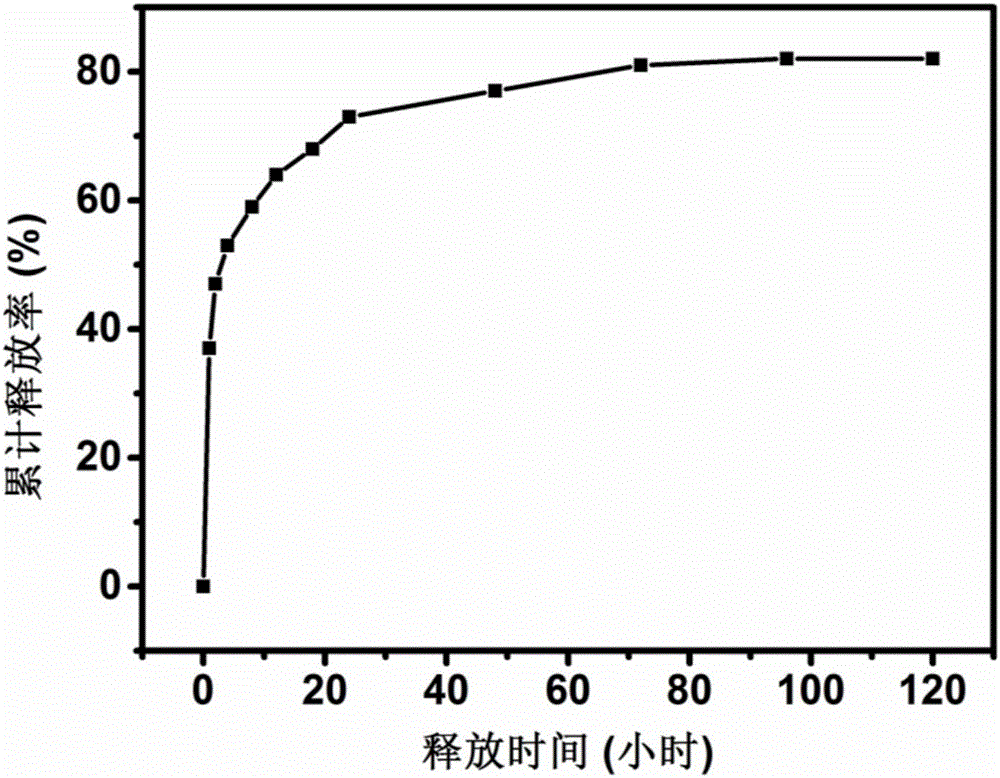

Drug-loaded composite nanofiber membrane used for drug release, and making method thereof

InactiveCN106512013AGood biocompatibilityPromote swellingOrganic active ingredientsPharmaceutical delivery mechanismFiberBiocompatibility Testing

The invention discloses a drug-loaded composite nanofiber membrane used for drug release, and a making method thereof. The method comprises the following steps: mixing polyamide and chitosan, dissolving the obtained mixture in formic acid to obtain a mixed solution, adding a drug to the mixed solution, stirring the drug and the mixed solution to accelerate dissolution in order to obtain a uniform and transparent spinning stock solution, and carrying out an electrostatic spinning technology to obtain the drug-loaded chitosan / polyamide composite nanofiber membrane. The produced nano-fiber membrane adopts polyamide as a main body, chitosan is added to realize a good blending effect, and drug release is regulated through swelling and degradation of chitosan, so the characteristics of good mechanical performance and the chemical stability of the polyamide and the antibacterial and anti-inflammatory property, the degradability and the good biocompatibility of the chitosan are fully shown. The drug-loaded composite nanofiber membrane has a good drug release effect and a high drug accumulative release rate as a novel composite drug slow release carrier material, and can be used in the biomedical fields of wound restoration, oral ulcer treatment and drug controlled release.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

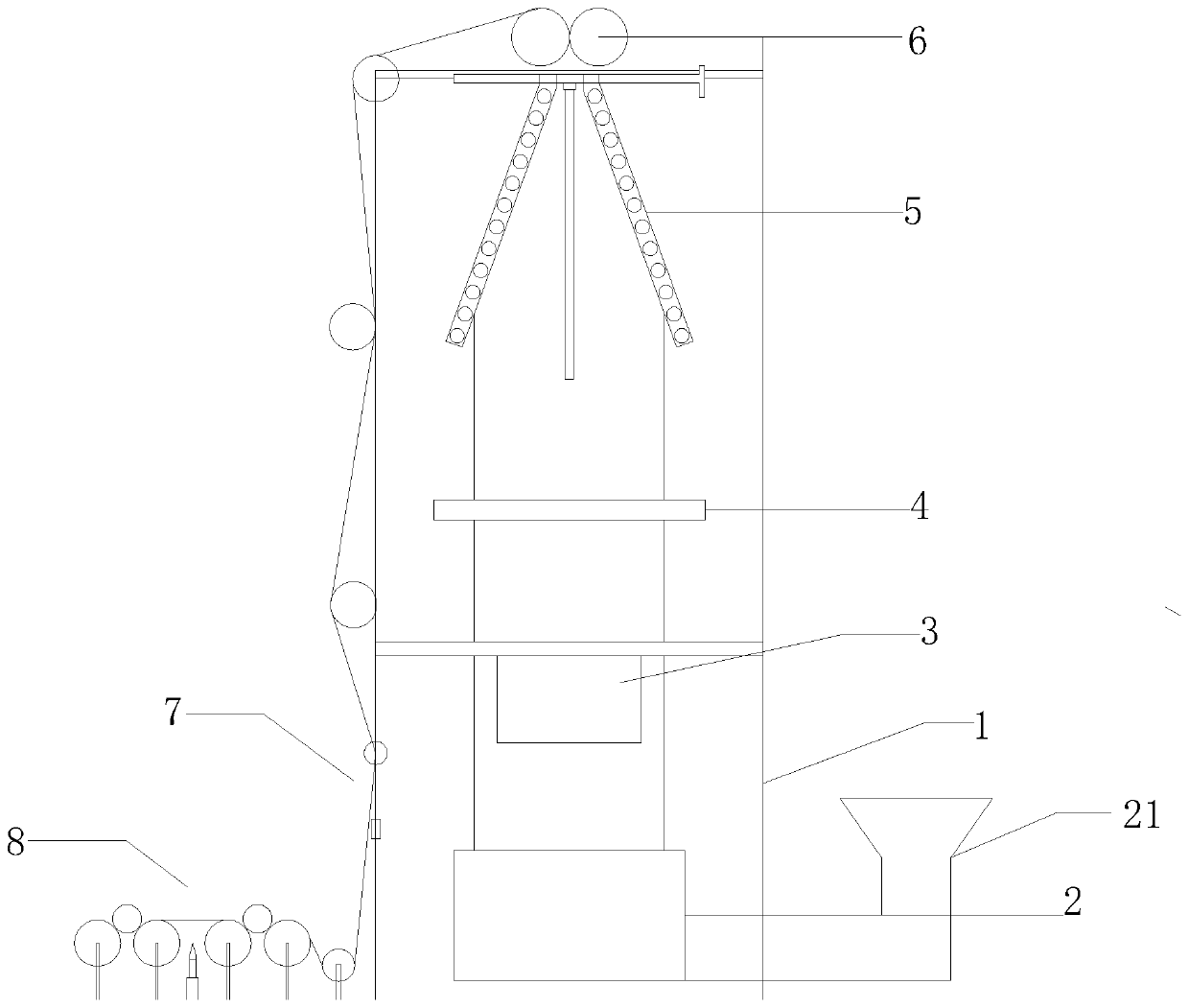

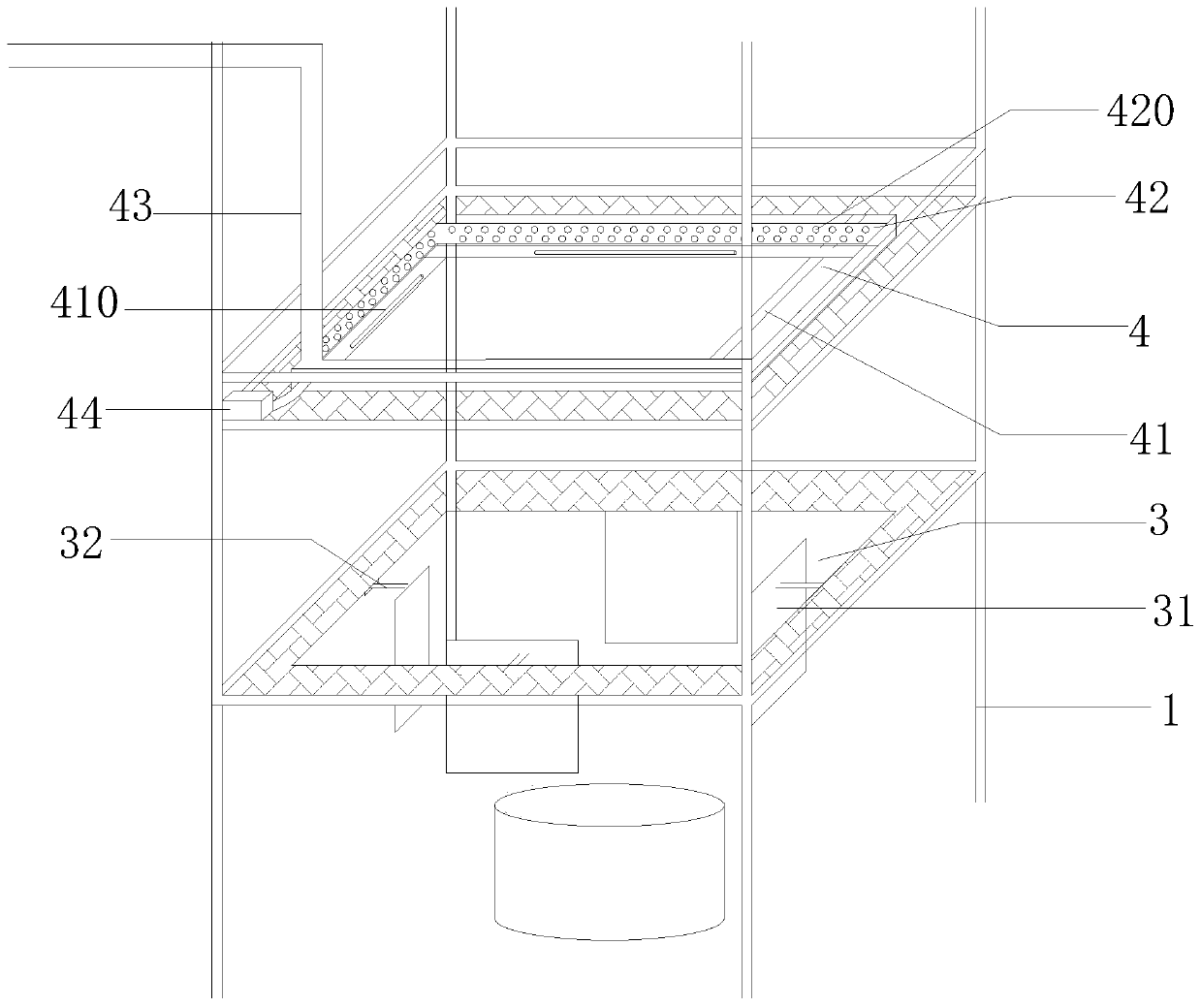

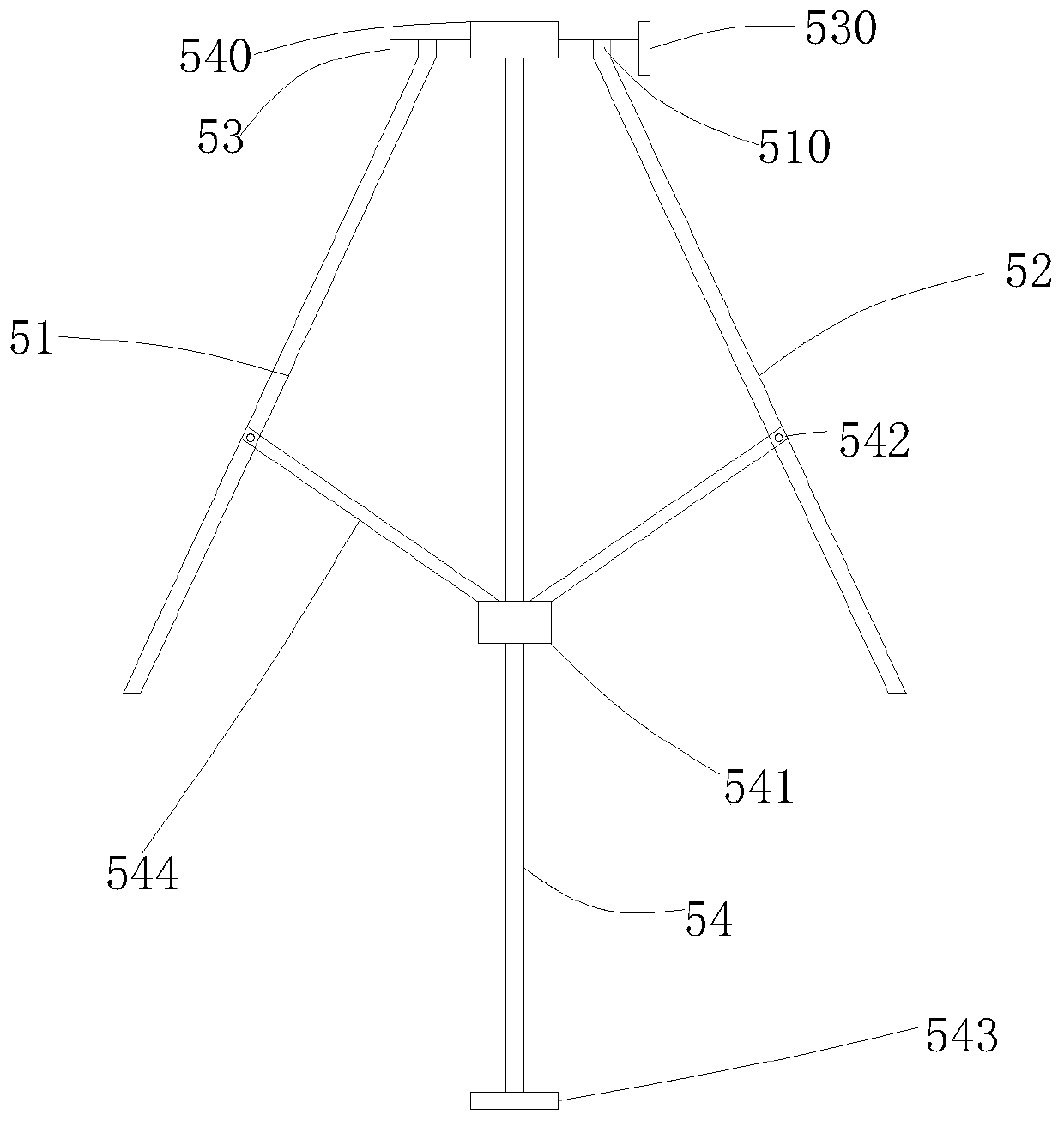

Plastic film production device and process thereof

ActiveCN111113854AReduce exhaust pollutionGuaranteed trimmingTubular articlesPlastic filmManufacturing engineering

The invention discloses a plastic film production device and a process thereof. The production device comprises a machine frame with a hollow structure, a blow molding machine head is installed at theinner center of the frame, a limiting mechanism, an air extraction device, a herringbone plate and a traction device are sequentially arranged on the machine frame above the blow molding machine headaccording to the process of plastic film forming, a movable and adjustable counting device is arranged on the traction device, a cutting device and a winding device are sequentially arranged on the outer side ground of the machine frame at the output end of the traction device, and the winding device further comprises a film breaking device. The process comprises the following steps of (1) extruding molding of a plastic film; (2) setting and exhausting; (3) clamping flattening and pressing; (4) cutting and layering; and (5) winding and packing. According to the plastic film production deviceand the process thereof, through the improvement of the process equipment, in the production process, limiting is conducted on the plastic film protect the plastic film from being scratched, the volatile waste gas of the production plastic film is exhausted, the environment is protected, the length of the plastic film is accurately measured, accurate cutting and breaking of the plastic film are achieved, the plastic film production device is suitable for the production of plastic films of various specifications, and the production efficiency and product quality are improved.

Owner:GUIZHOU TIANXING PLASTIC PRODS

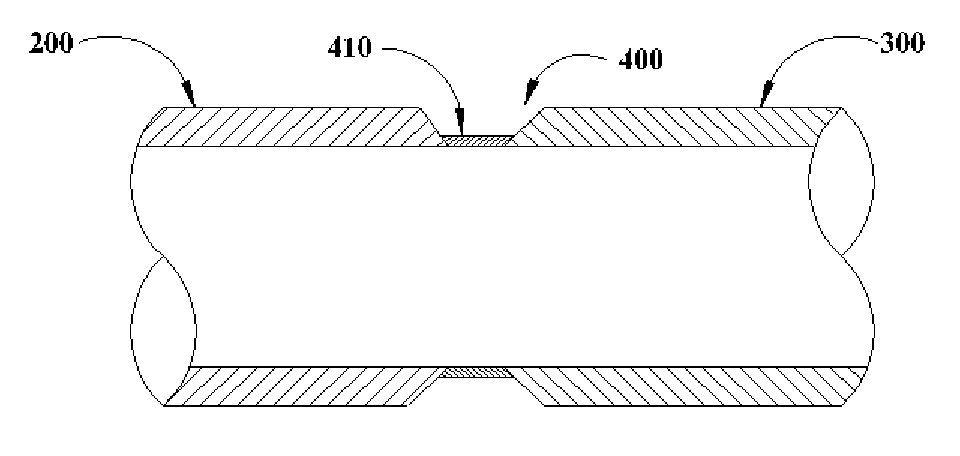

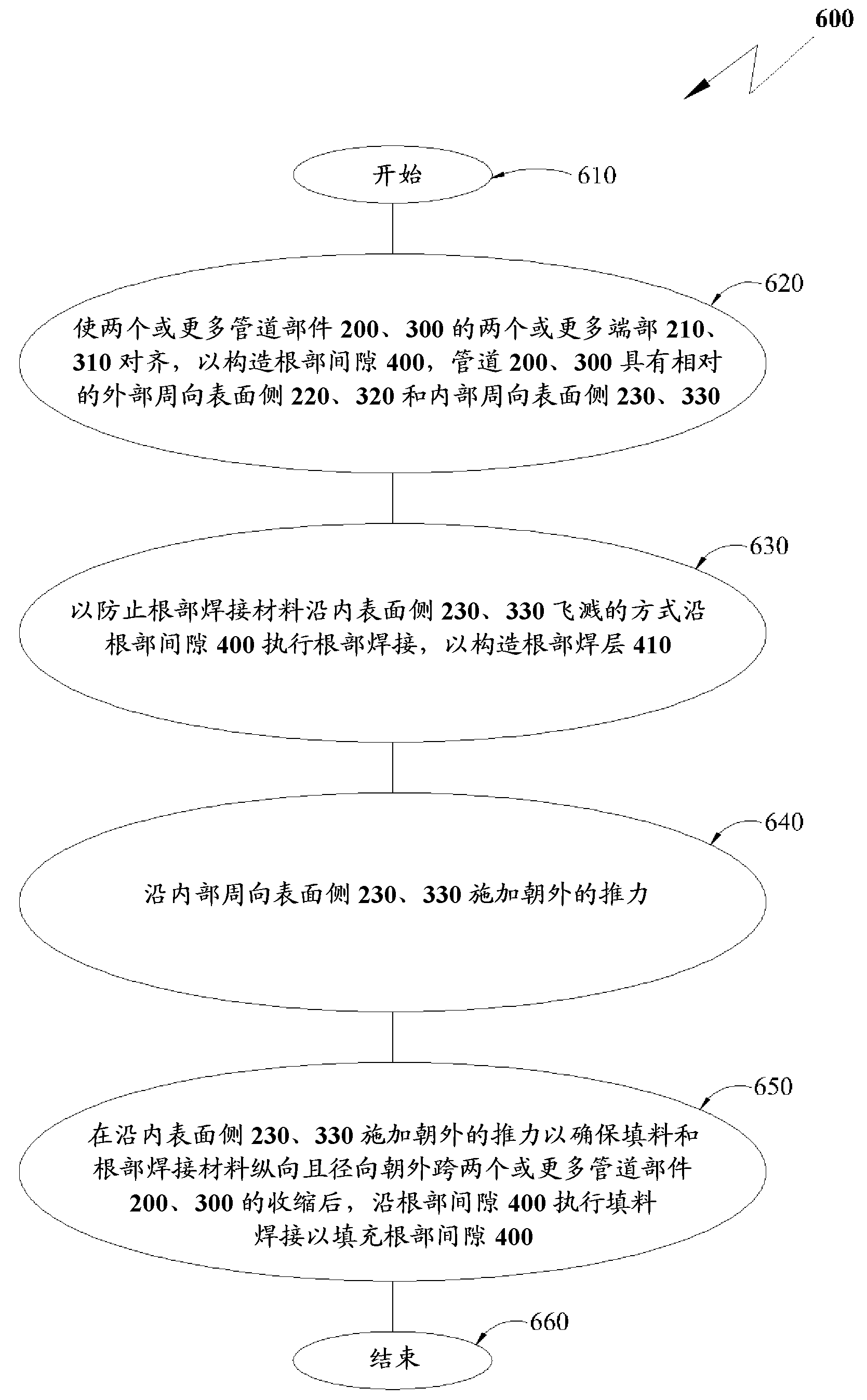

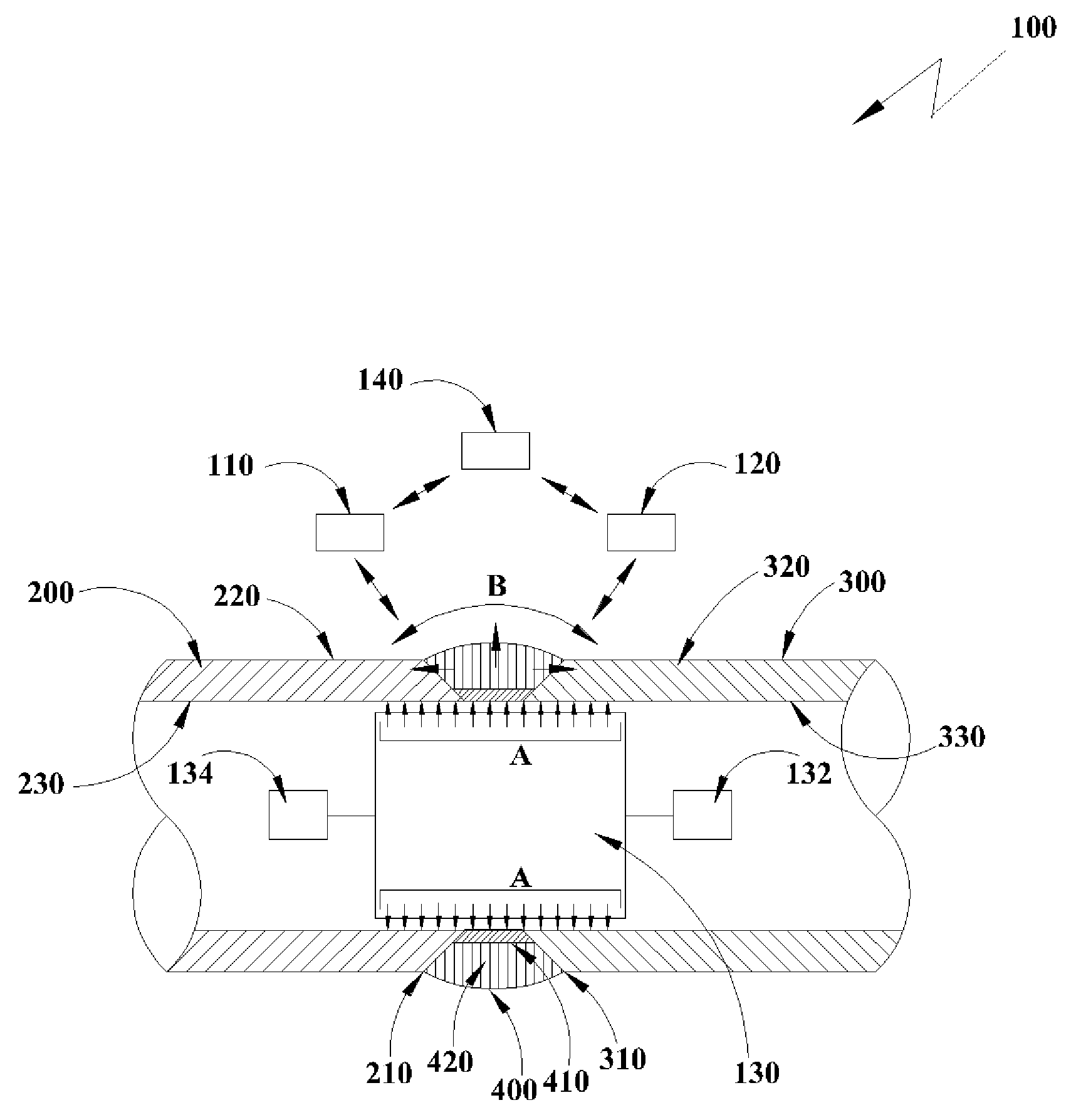

Method and system for welding conduits

ActiveCN103567673AAvoid depositionPrevent extrusionWelding/cutting auxillary devicesArc welding apparatusEngineeringMechanical engineering

A system 100 and a method 600 for welding two or more conduits 200, 300 are disclosed. The system 100 includes a root welding tool 110, a filler welding tool 120 and a support member 130. The root welding tool 110 root weld a gap 400 to form a root layer 410 configured along end portions 210, 310, from outer circumferential surfaces side 220, 320 opposite to inner circumferential surfaces side 230, 330 of conduits 200, 300. The root weld is performed such that spattering of root weld material is prevented. The filler welding tool 120 is utilized to fill the gap 400. The support member 130 is provided for applying an outward thrust to ensure shrinkage of the filler and root weld materials longitudinally and radially outward, preventing pressing out of the filler and root weld materials along the inner circumferential surfaces side 230, 330.

Owner:ARVOS GMBH

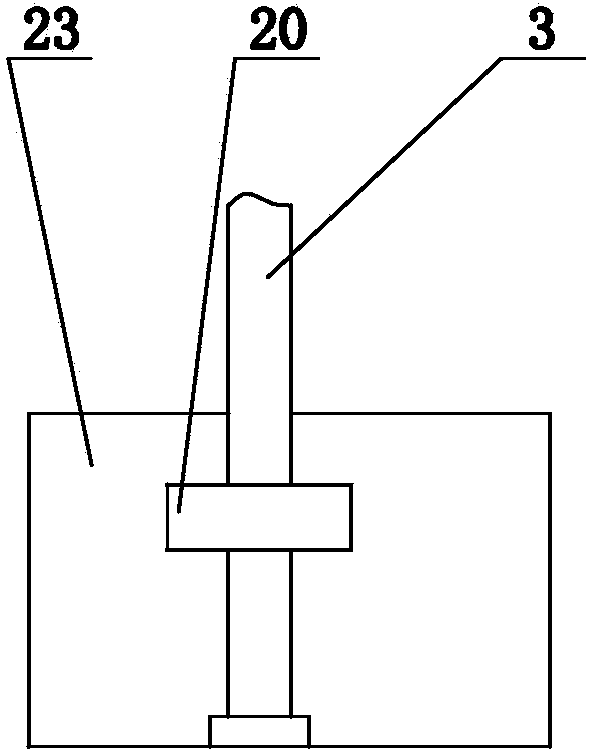

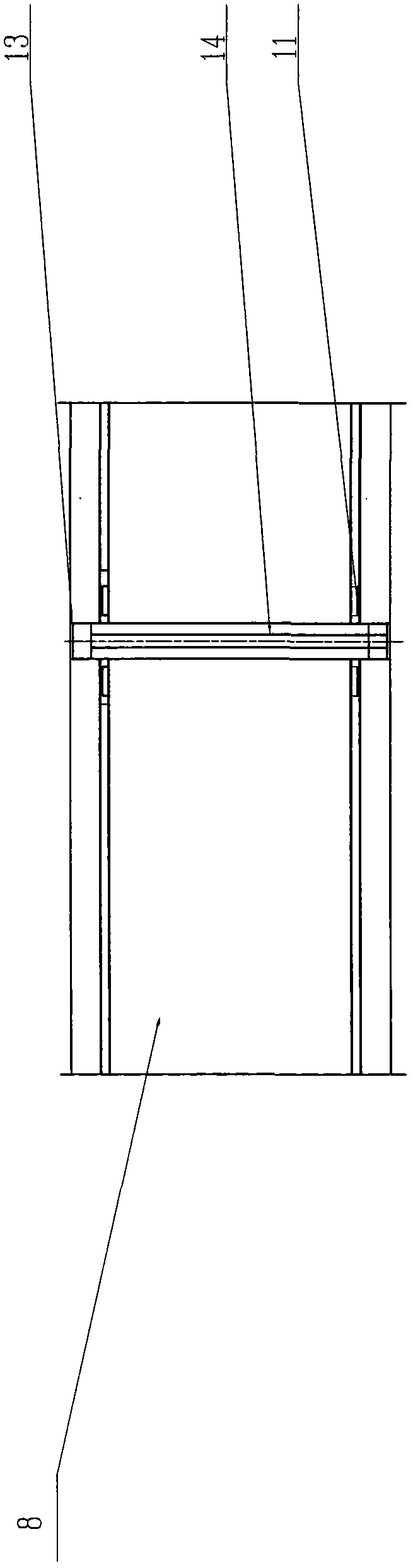

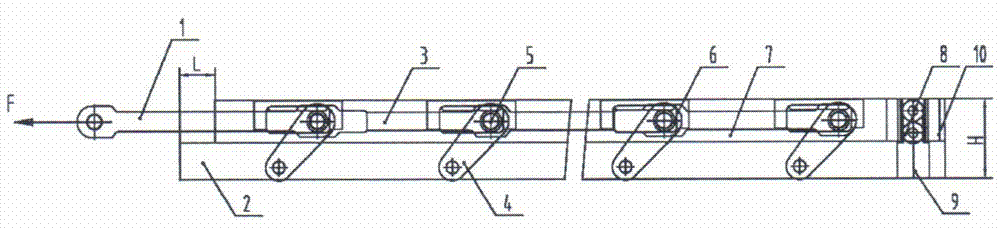

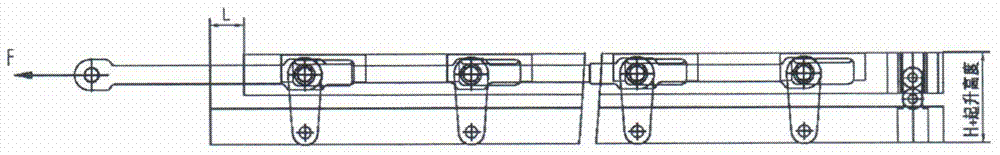

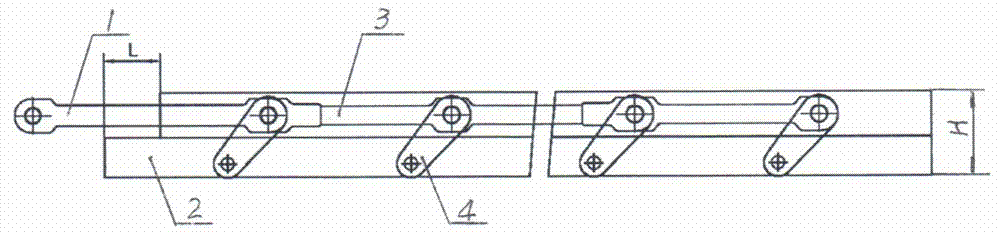

Four-link-type vertical hoisting mechanism

The invention relates to a four-link-type vertical hoisting mechanism. The vertical hoisting mechanism comprises a pull rod, a lower layer trolley, connecting rods, a side link, hinged shafts, idler wheels, an upper layer trolley, a guide wheel, a guide wheel fixing base and a guide groove, wherein the pull rod is hinged to the connecting rods and the side link through the hinged shafts and arranged above the lower layer trolley; each idler wheel is arranged on the corresponding hinged shaft in a sleeved mode and connected with the guide groove in the upper layer trolley in a matched mode; the guide wheel is fixed to the guide wheel fixing base which is fixed to the lower layer trolley. The novel feeding trolley vertical hoisting mechanism is simple in structure, convenient to replace, high in efficiency, low in cost and used for transporting a feeding trolley in front of a furnace.

Owner:LUOYANG LIHE MACHINERY

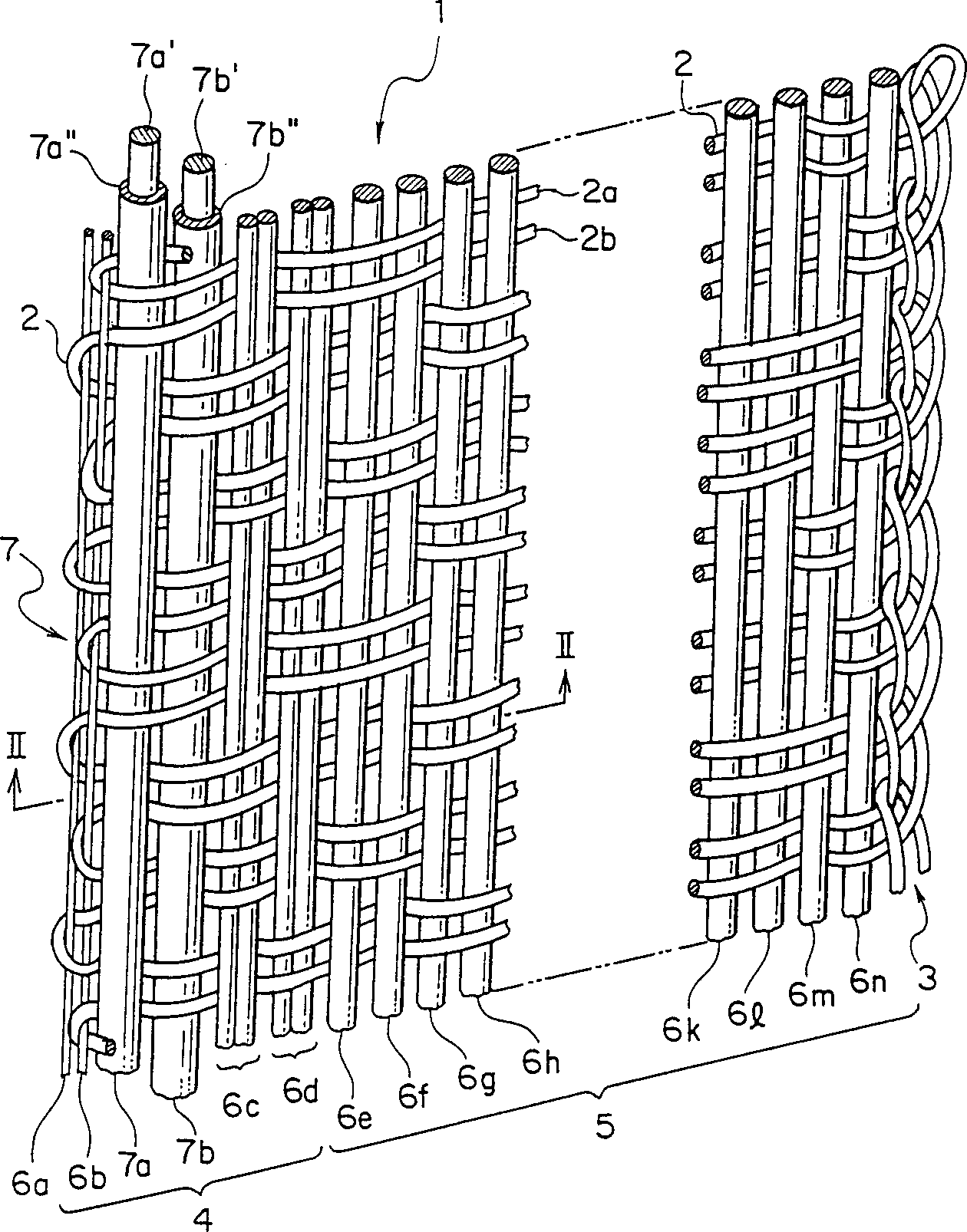

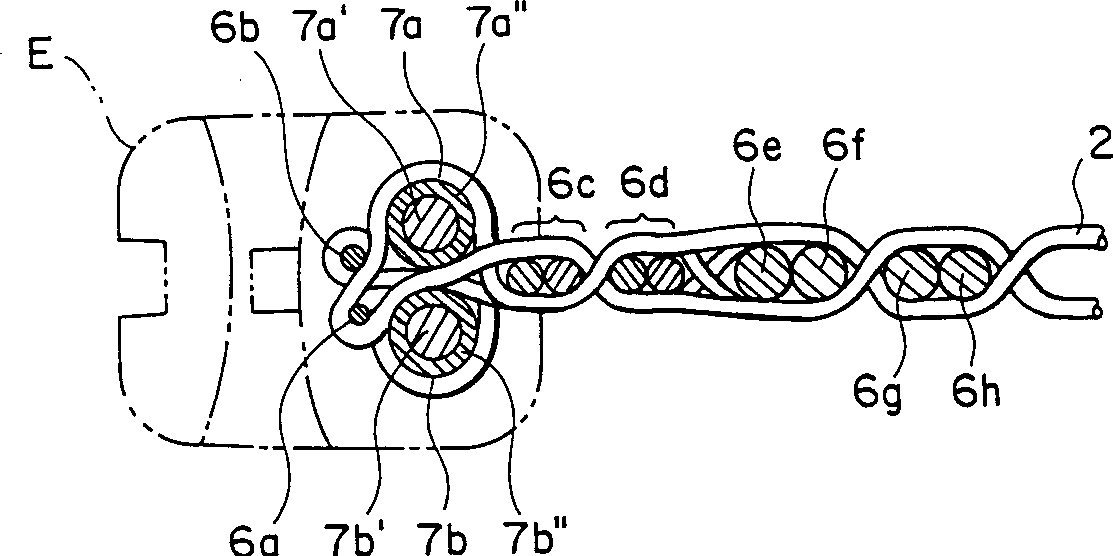

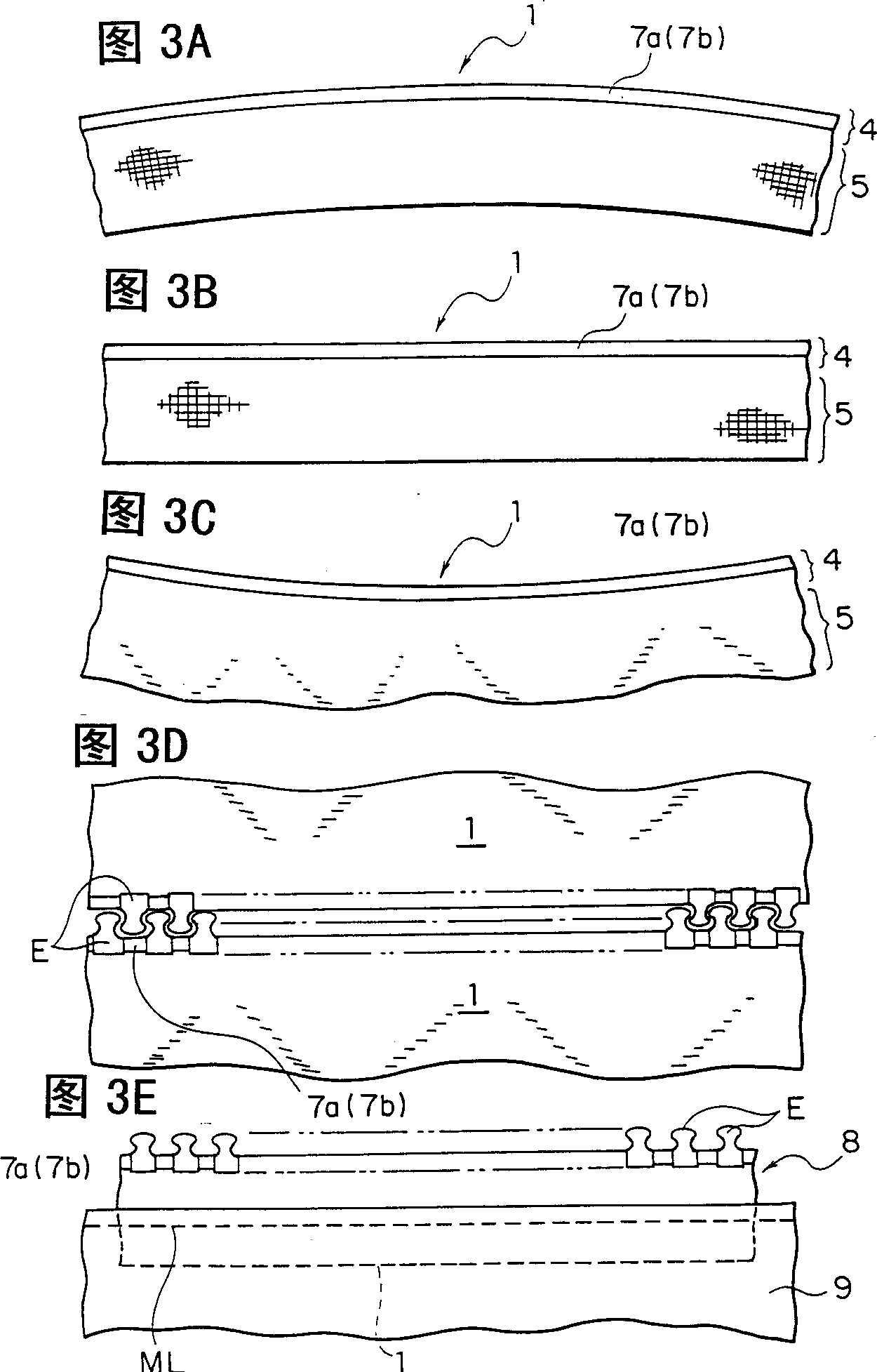

Zip fastener

A zipper tape (1) having a tape main part (5) obtained by weaving and a component mounting edge part (4) in which core threads (7a, 7b) are braided, for the base warp of the tape main part (5) (6e, 6f...6m, 6n) have a lower coefficient of thermal contraction than the other warp yarns (6a to 6d). The core wires (7a, 7b) have a high coefficient of thermal contraction. The warp yarns (6c, 6d) adjacent to the inside of the core wires (7a, 7b) have a lower coefficient of thermal contraction than that of the core wires (7a, 7b). It is thereby possible to obtain a zipper vertical bar (8) in which, even after the component (E) is mounted, wrinkles do not occur in the component mounting edge portion (4), thus ensuring straightness.

Owner:YKK CORP

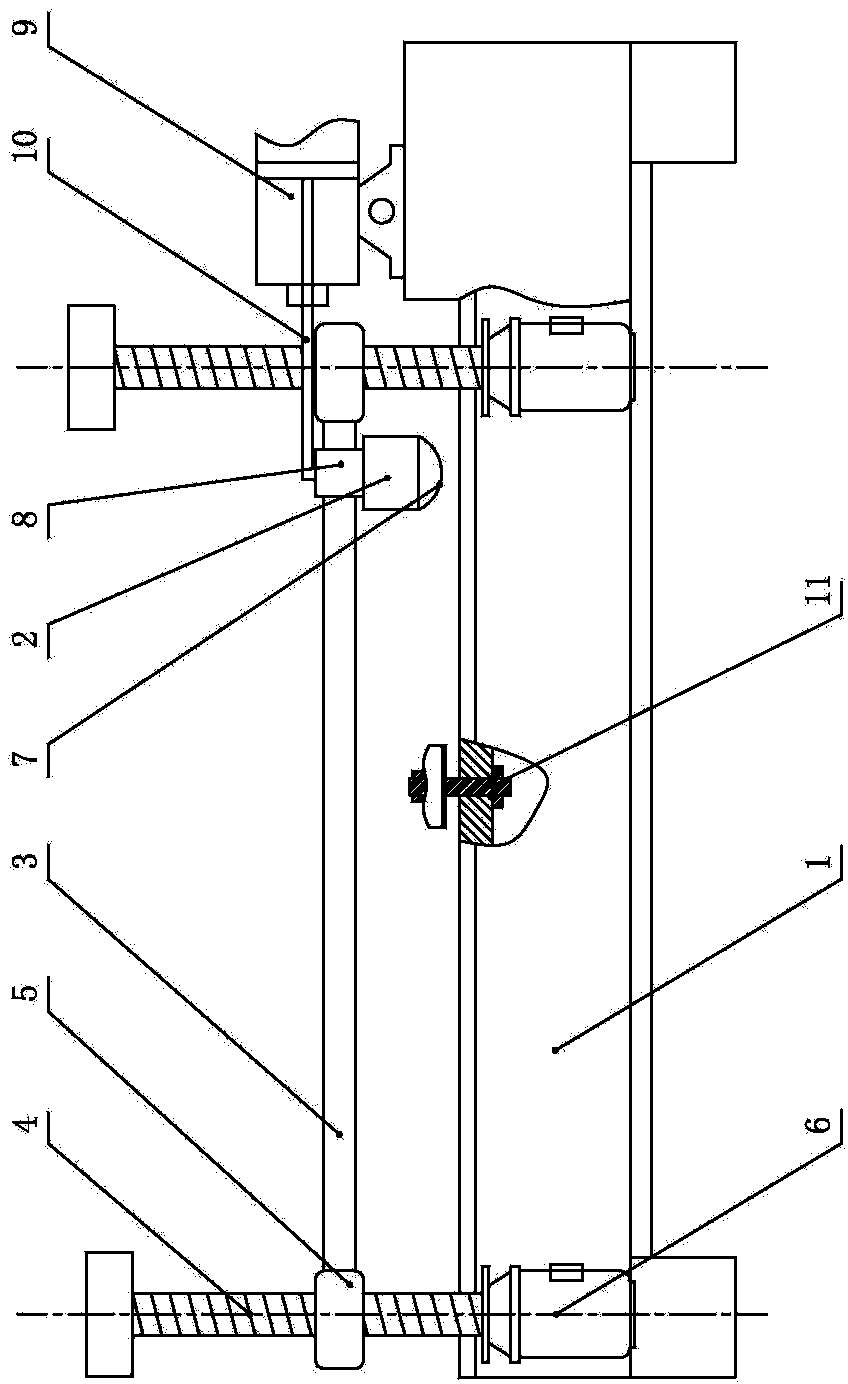

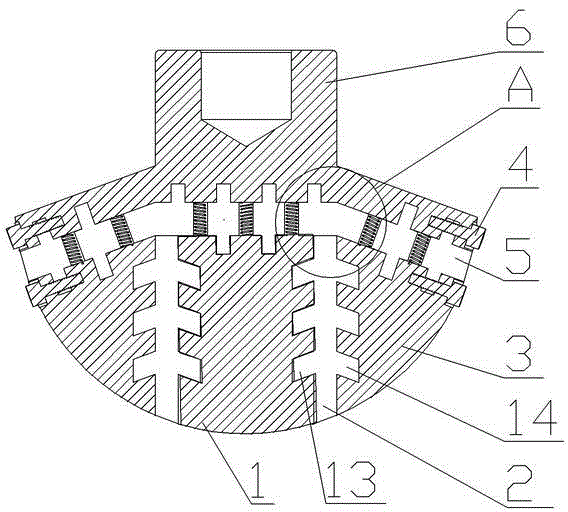

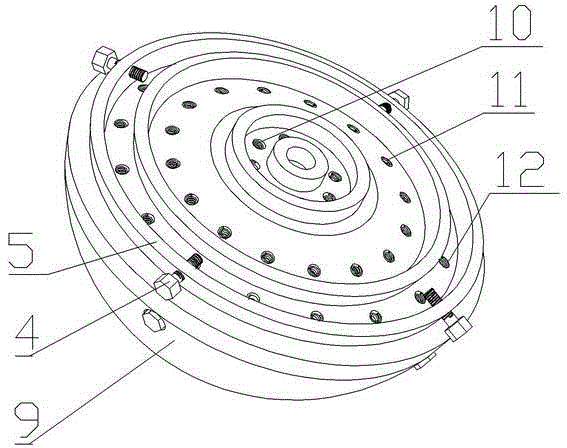

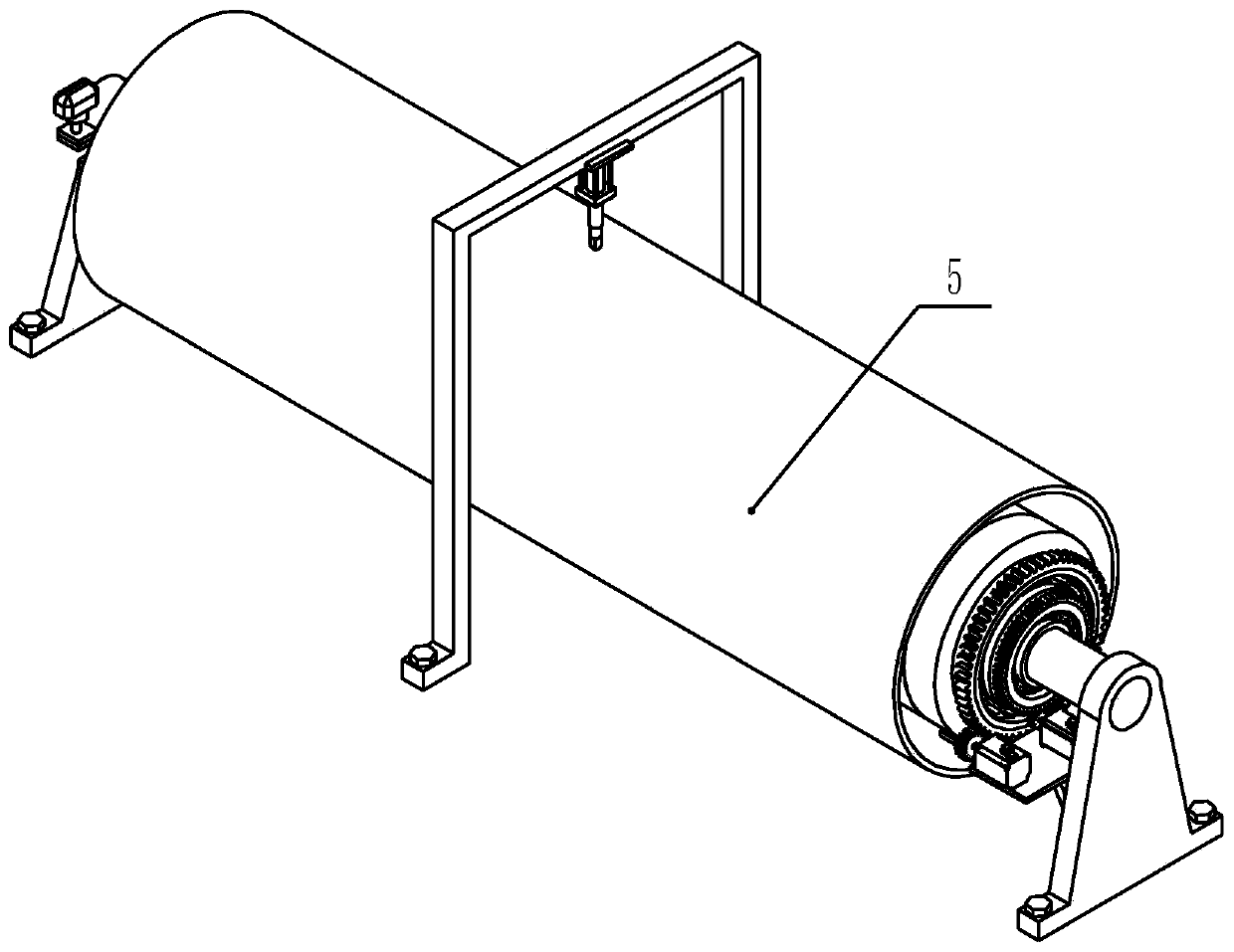

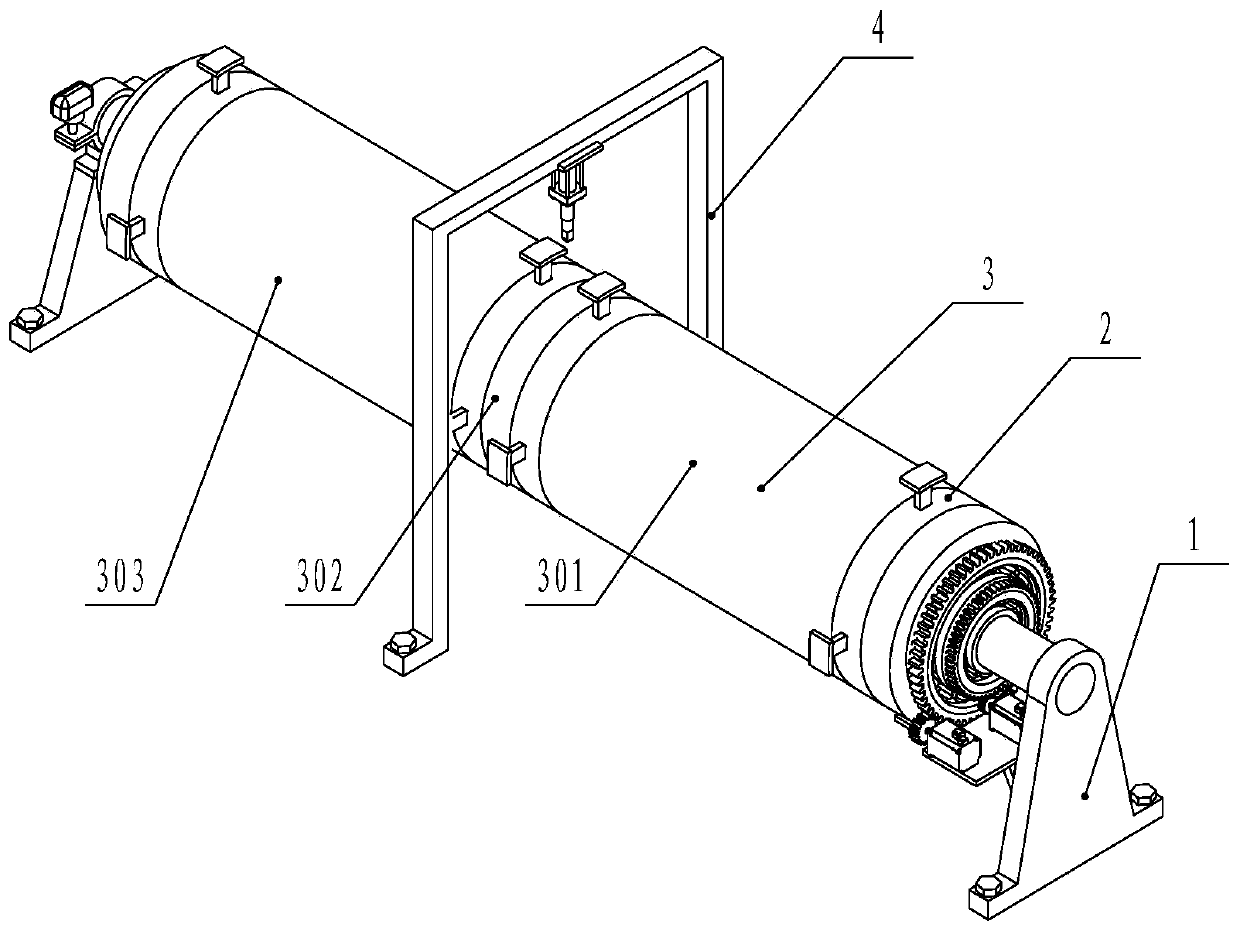

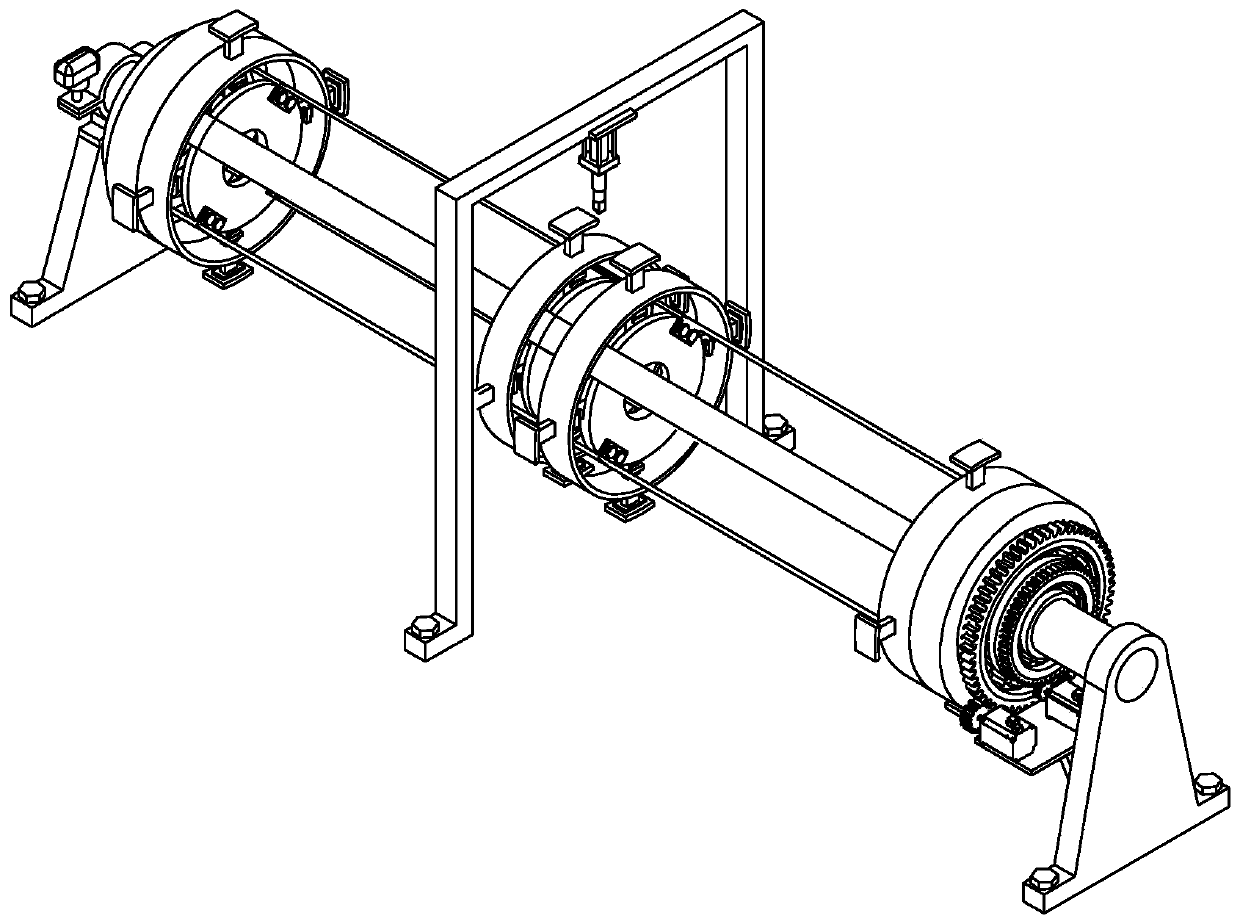

Chuck expansion type metal hard tube rotary cutting machine

InactiveCN110064790AUniform clamping forceAvoid clamping deformationTube shearing machinesShearing machine accessoriesEngineeringGrinding wheel

The invention provides a chuck expansion type metal hard tube rotary cutting machine. The rotary cutting machine comprises a supporting device, a sleeve device, a cutting device and at least four expansion devices, wherein a plurality of expansion devices are sequentially connected and arranged on the same axis through connecting frames, two expansion devices located at two ends are connected withthe supporting device, every two adjacent expansion devices are connected by sleeve pipes of the sleeve device in a sleeving mode, and the cutting device is arranged between two adjacent expansion devices. The expansion devices can expand from the inside of the metal hard tube to achieve the purpose of fixing the metal hard tube, and all lengths of the metal hard tube can be fixed, so that an existing equipment which can only clamp and fix the cut part is replaced, the clamping force is more uniform, and the clamping deformation is prevented; the expansion devices can drive the metal hard tube to rotate together, and then the cutting wall thickness distance can be achieved through feeding movement of a cutting knife, so that the cutting task can be completed, a cutting mode that an existing cutting grinding wheel pieces enter the inner part of the metal hard tube is replaced, and the situation that a cut surface is burned and worn is avoided.

Owner:HEBEI UNIV OF TECH

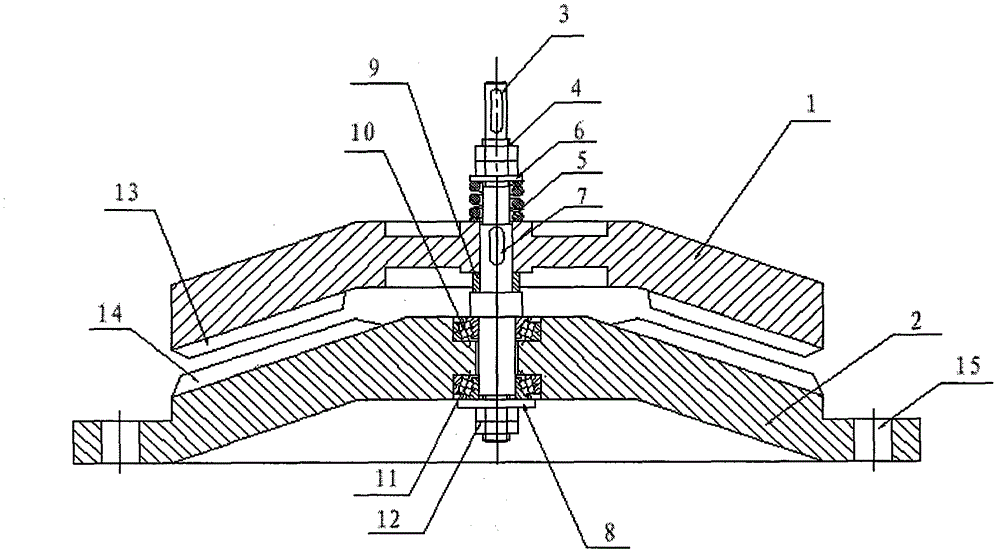

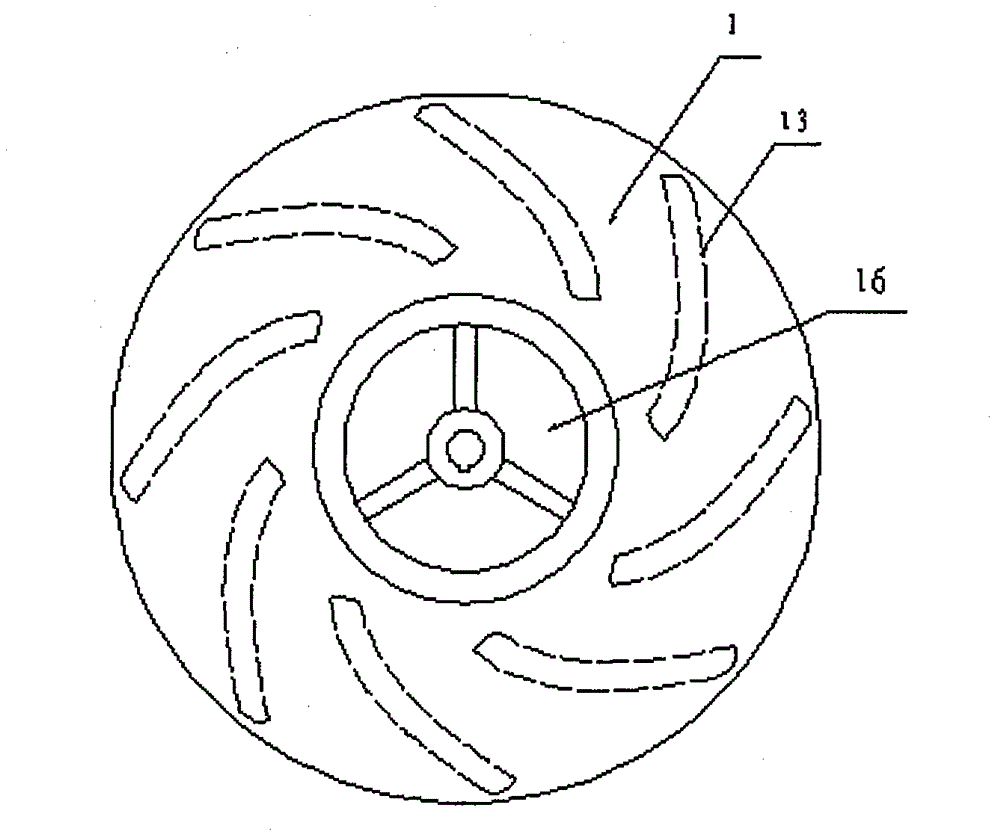

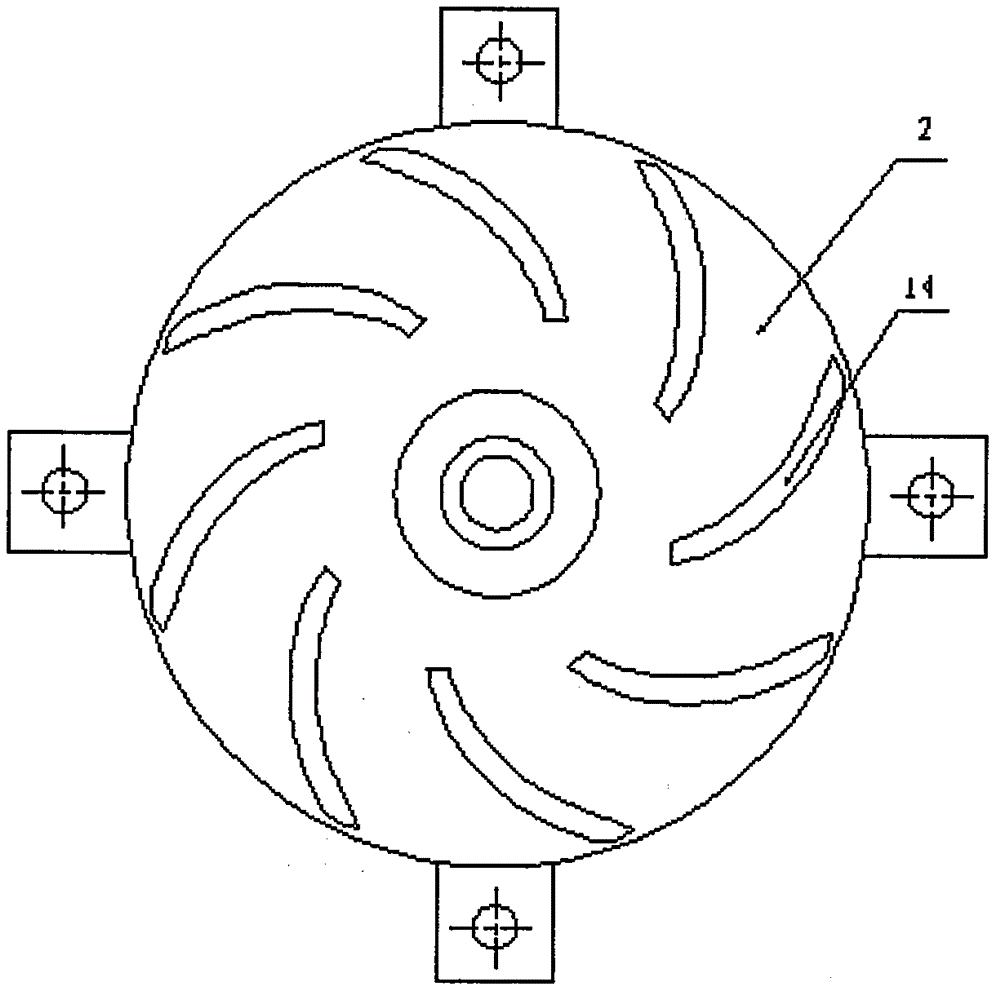

Nut shelling device with tapered millstone

A device for shelling dried fruit with conical grinding discs, including a rotating grinding disc and a fixed grinding disc, the fixed grinding disc is fixed on the frame, and the rotating grinding disc is installed on the fixed grinding disc through a vertically arranged transmission shaft, so that the rotating grinding disc is driven by the transmission shaft, thereby relatively It rotates on the fixed grinding disc, and there is a gap (and adjustable) larger than the outer diameter of the dried fruit between the rotating grinding disc and the fixed grinding disc to form a shelling space. The opposite surface is a downward-sloping conical surface so that a downward passage is formed around the shelling space. There are multiple ribs protruding outward on the opposite surface of the rotating grinding disc and the fixed grinding disc. The ribs are arranged around the transmission shaft and Each rib extends radially along the rotating grinding disc and the fixed grinding disc to cover the glide path of the entire shelling space, and the gap between the rib on the rotating grinding disc and the opposite surface of the fixed grinding disc is smaller than the outer diameter of the dried fruit and larger than the outer diameter of the dried nut. The device has high shelling efficiency, good shelling quality, low damage rate of dried nut kernels and stable discharge.

Owner:HUNAN AGRICULTURAL UNIV

Direct reduction process for producing sponge iron by using CH4 non-catalytic oxygen-enriched transformation

ActiveCN104313228ALower the preheat temperatureLess exhaust smokeShaft furnaceGas emission reductionOxygen enrichmentCaking

The invention relates to a direct reduction process for producing sponge iron by using CH4 non-catalytic oxygen-enriched transformation. A process route comprises the following steps: preheating a CH4-enriched raw gas and oxygen-enriched air which are subjected to purification and pressure regulation, then introducing the CH4-enriched raw gas and the oxygen-enriched air into a non-catalytic oxygen-enriched transformation furnace for a combustion reaction in the non-catalytic oxygen-enriched transformation furnace, and raising the temperature to transform CH4 therein into CO and H2 to form a high-temperature transformation gas; in the meantime, cooling, dedusting and pressurizing a top gas of a shaft furnace, then introducing the top gas into a hydrogen purification device to prepare purified hydrogen, preheating the purified hydrogen, and then introducing the preheated purified hydrogen into the lower part of the catalyst oxygen-enriched transformation furnace to be mixed with the high-temperature transformation gas generated through the combustion reaction to form a reduced coal gas; and introducing the reduced coal gas into the shaft furnace to reduce iron ores into the sponge iron. The direction reduction process disclosed by the invention not only has the advantages of short process flow, availability for energy saving and emission reduction, long service life of a nozzle and low investment cost, and can be used to prevent the sponge iron from caking and avoid carbon formation.

Owner:CISDI ENG CO LTD

Combined medicament for supplementing zinc and calcium and preparation method thereof

ActiveCN101716180AAvoid adverse reactionsPromote absorptionMetabolism disorderCapsule deliverySupplement zincGluconic acid

The invention relates to a combined medicament for supplementing zinc and calcium and a preparation method thereof. Medicament components are released at a fixed part. The preparation method comprises the following steps of: taking zinc gluconate and vitamin D, adding medicinal starch and microcrystalline cellulose and mixing, adding crushed superfine silica gel powder and evenly mixing and sub-packaging into enteric capsules; and mixing water-soluble calcium acetate, the medicinal starch and the microcrystalline cellulose, adding the crushed superfine silica gel powder and evenly mixing and sub-packaging into Muslim capsules. The medicament and the preparation method thereof ensure that the vitamin D cannot be damaged in an acid environment, avoid the direct stimulation of the zinc gluconate to the stomach and block off the direct contact of vitamin E and oxygen. After patients take two kinds of capsules, effective components of the vitamin E and the calcium acetate are rapidly disintegrated and absorbed in the stomach; the vitamin D and the zinc gluconate are disintegrated and absorbed in the intestine; and the invention has the characteristics of taking effect of medicament, high bioavailability, small side effect and the like, and is specially suitable for children, pregnant women, adults and old people for supplement and administration for a long term.

Owner:广西强寿药业集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com