Drug-loaded composite nanofiber membrane used for drug release, and making method thereof

A composite nanofiber, drug-carrying technology, applied in pharmaceutical formulations, drug delivery, non-woven fabrics, etc., can solve the problems of difficult to control drug toxicity, drug efficacy is not long enough, poor stability, etc., to achieve good drug sustained release effect, Good biocompatibility, guaranteed delay and controlled effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

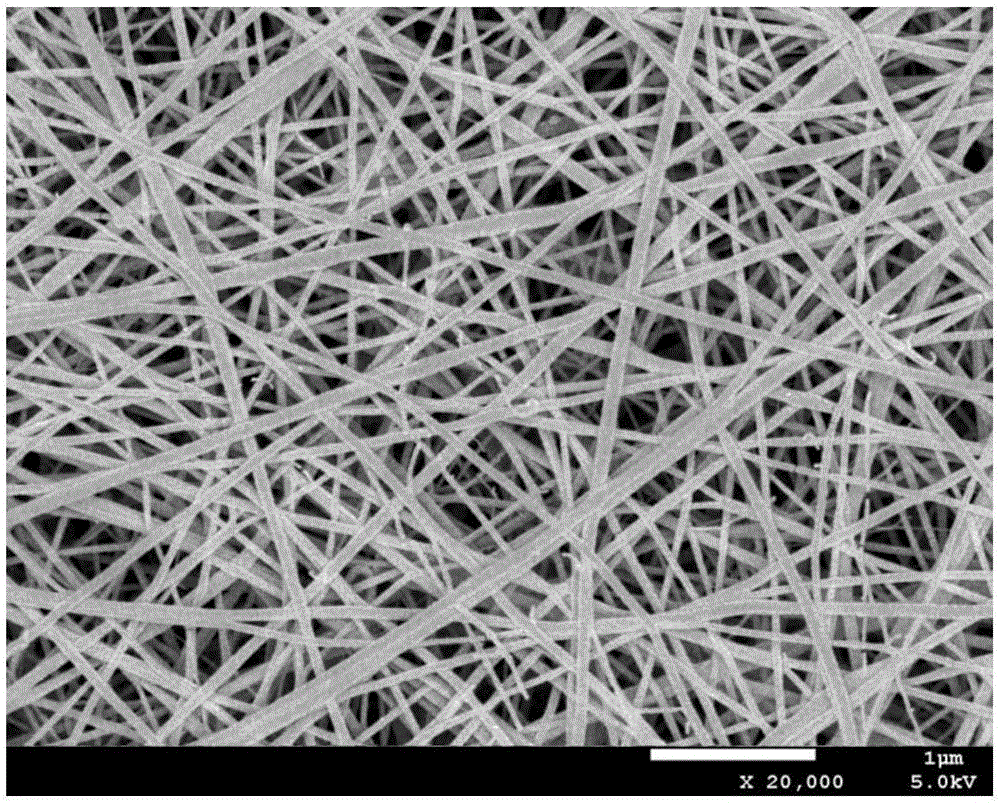

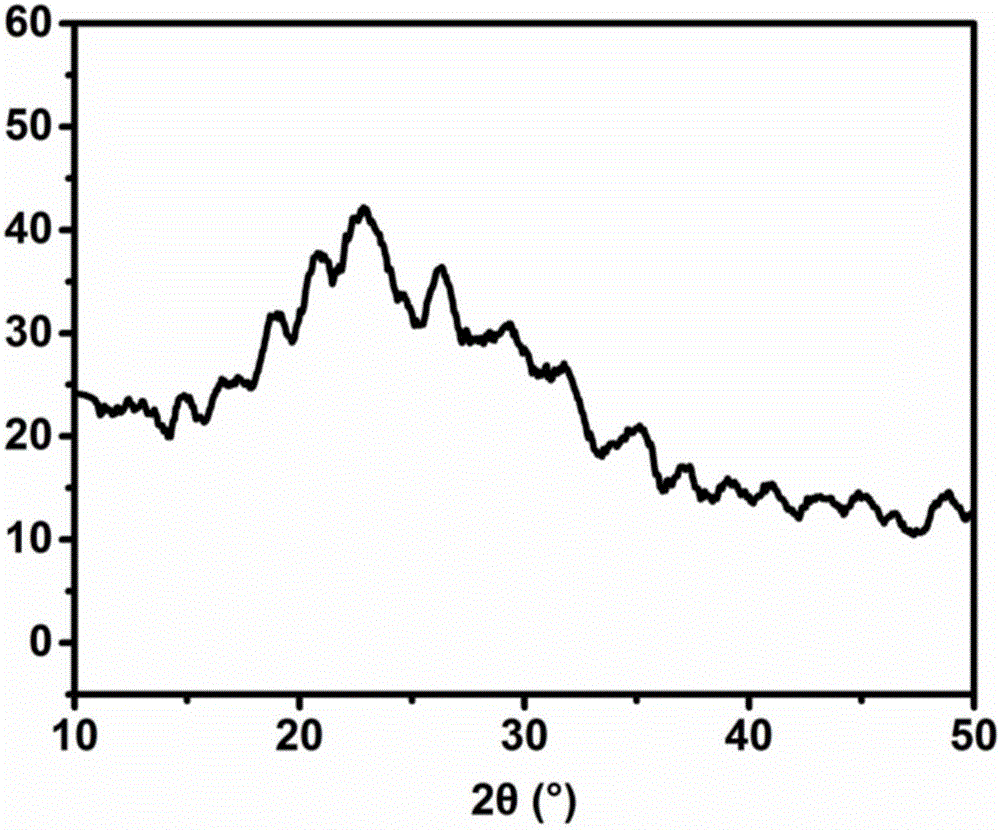

[0023] Weigh 3g chitosan and 7g polyamide respectively, mix the two and dissolve in formic acid to obtain a mixed solution with a concentration of 10wt%; then weigh 1g berberine hydrochloride and add it to the mixed solution. Stir magnetically for 20 minutes and stand still for 2 hours to obtain a uniform and transparent spinning dope. Put the spinning stock solution into the syringe, connect the positive pole of the high-voltage power supply to the needle tip of the syringe, the size of the needle is 12#, and connect the negative pole to the aluminum foil. At room temperature, the electric field was controlled at 7kV, the receiving distance was 13cm, and the electrospinning was performed at a flow rate of 0.4mL / h to obtain the drug-loaded chitosan / polyamide composite nanofiber membrane.

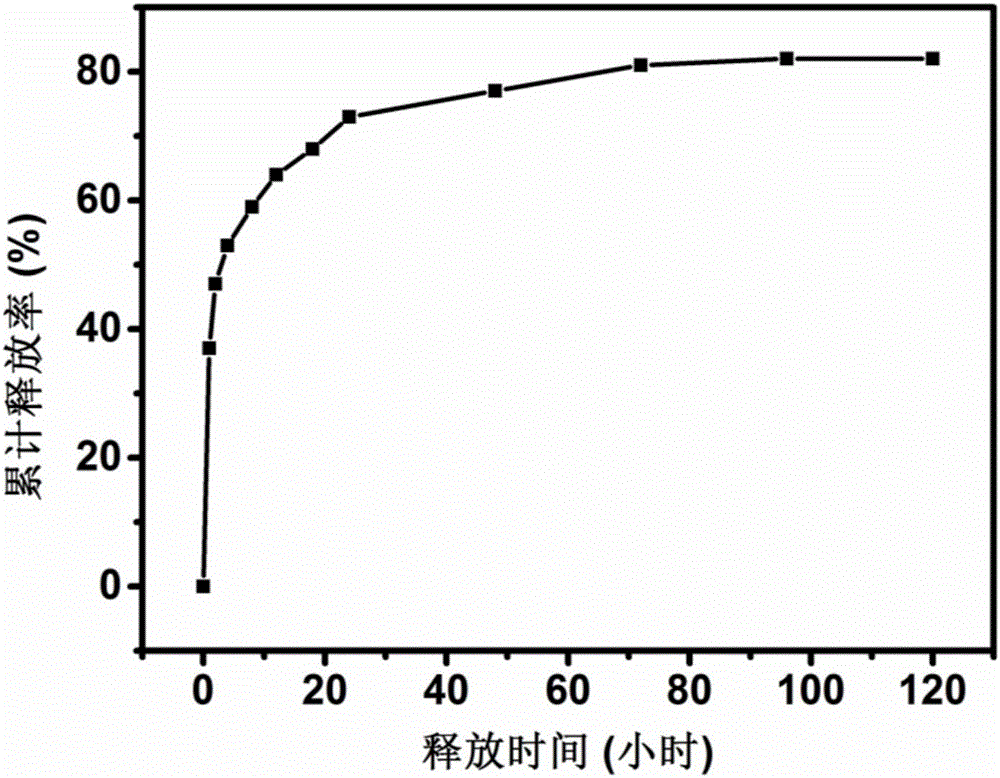

[0024] Take phosphate buffer as simulated body fluid, test the absorbance value of berberine hydrochloride in buffer solution, the absorption wavelength is 263nm, take the sample concentrati...

Embodiment 2

[0029] Weigh 1g chitosan and 9g polyamide respectively, mix the two and dissolve in formic acid to obtain a mixed solution with a concentration of 8wt%; then weigh 0.5g berberine hydrochloride and add it to the mixed solution, at 120r / min Stir under magnetic force for 15 minutes, and obtain a uniform and transparent spinning dope after standing still for 1 hour. Put the spinning stock solution into the syringe, connect the positive pole of the high-voltage power supply to the needle tip of the syringe, the size of the needle is 12#, and connect the negative pole to the aluminum foil. At room temperature, the electric field was controlled at 6.5kV, the receiving distance was 11cm, and the electrospinning was performed at a flow rate of 0.2mL / h to obtain the drug-loaded chitosan / polyamide composite nanofiber membrane.

[0030] Take phosphate buffer as simulated body fluid, test the absorbance value of berberine hydrochloride in buffer solution, the absorption wavelength is 263nm...

Embodiment 3

[0033] Weigh 2g chitosan and 8g polyamide respectively, mix the two and dissolve in formic acid to obtain a mixed solution with a concentration of 9wt%; then weigh 3g berberine hydrochloride and add it to the mixed solution. Stir magnetically for 28 minutes and stand still for 2.5 hours to obtain a uniform and transparent spinning dope. Put the spinning stock solution into the syringe, connect the positive pole of the high-voltage power supply to the needle tip of the syringe, the size of the needle is 12#, and connect the negative pole to the aluminum foil. At room temperature, the electric field was controlled at 7.8kV, the receiving distance was 14cm, and the electrospinning was performed at a flow rate of 0.9mL / h to obtain the drug-loaded chitosan / polyamide composite nanofiber membrane.

[0034] Take phosphate buffer as simulated body fluid, test the absorbance value of berberine hydrochloride in buffer solution, the absorption wavelength is 263nm, take the sample concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com