Flexible material rewinding slitting system and rewinding slitting mechanism thereof

A flexible material, rewinding roller technology, applied in thin material handling, sending objects, transportation and packaging, etc., can solve the problems of affecting flexible material belts, increasing the labor intensity of operators, and occupying a large space, reducing labor intensity, The effect of improving the efficiency of rewinding and slitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

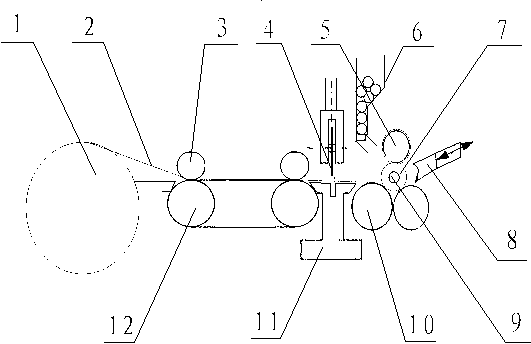

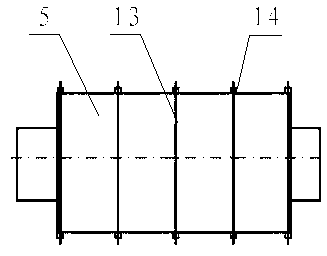

[0018] Embodiments of the flexible material rewinding and cutting system of the present invention: as Figure 1-2 As shown, including the frame (not shown in the figure), the frame is provided with a discharge mechanism, and the right side of the discharge mechanism is provided with a rewinding and cutting mechanism. The rewinding and slitting mechanism includes two rewinding rollers 10 arranged side by side and spaced apart on the frame, and a slitting and pressing roller arranged in parallel with the rewinding rollers 10 is rotatably mounted directly above the middle of the two rewinding rollers 10 5. In this way, the slitting and pressing roller 5 and the two rewinding rollers 10 form a triangular distribution state, and the triangular area between the three is the rewinding area for the rewinding mandrel 9 to enter side by side. On the outer peripheral surface of the slitting and pressing roller 5 Annular slitting knives 13 extending circumferentially along the slitting an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com