Nut shelling device with tapered millstone

A technology for grinding discs and dried fruits, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of high labor intensity, low production efficiency, and unsatisfactory shelling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A specific embodiment of a cone-type grinding disc dried fruit shelling device will be described below in conjunction with the accompanying drawings.

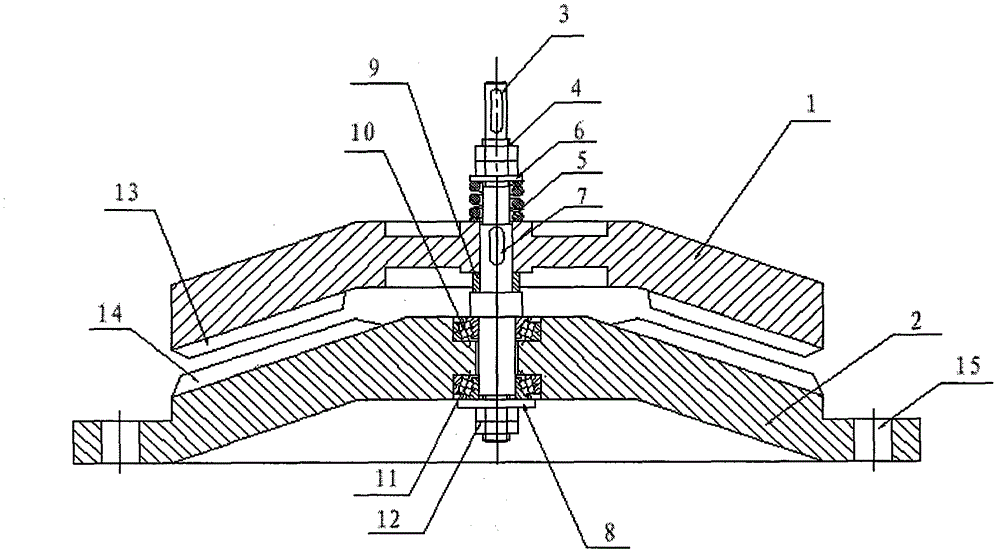

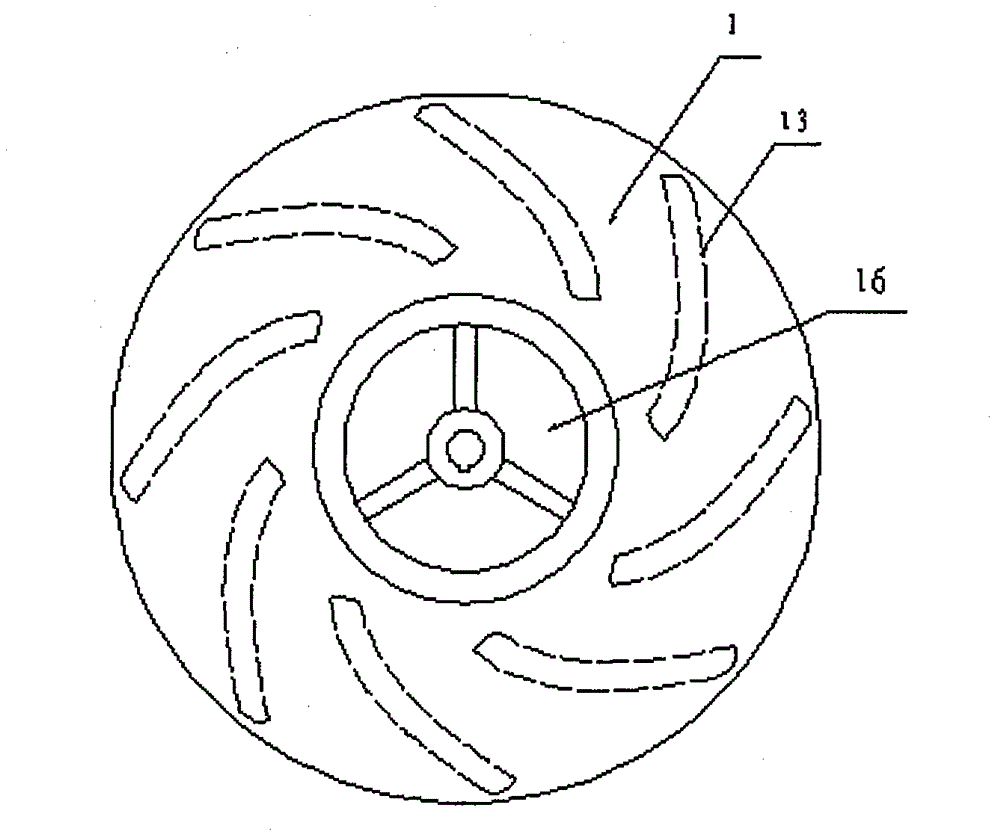

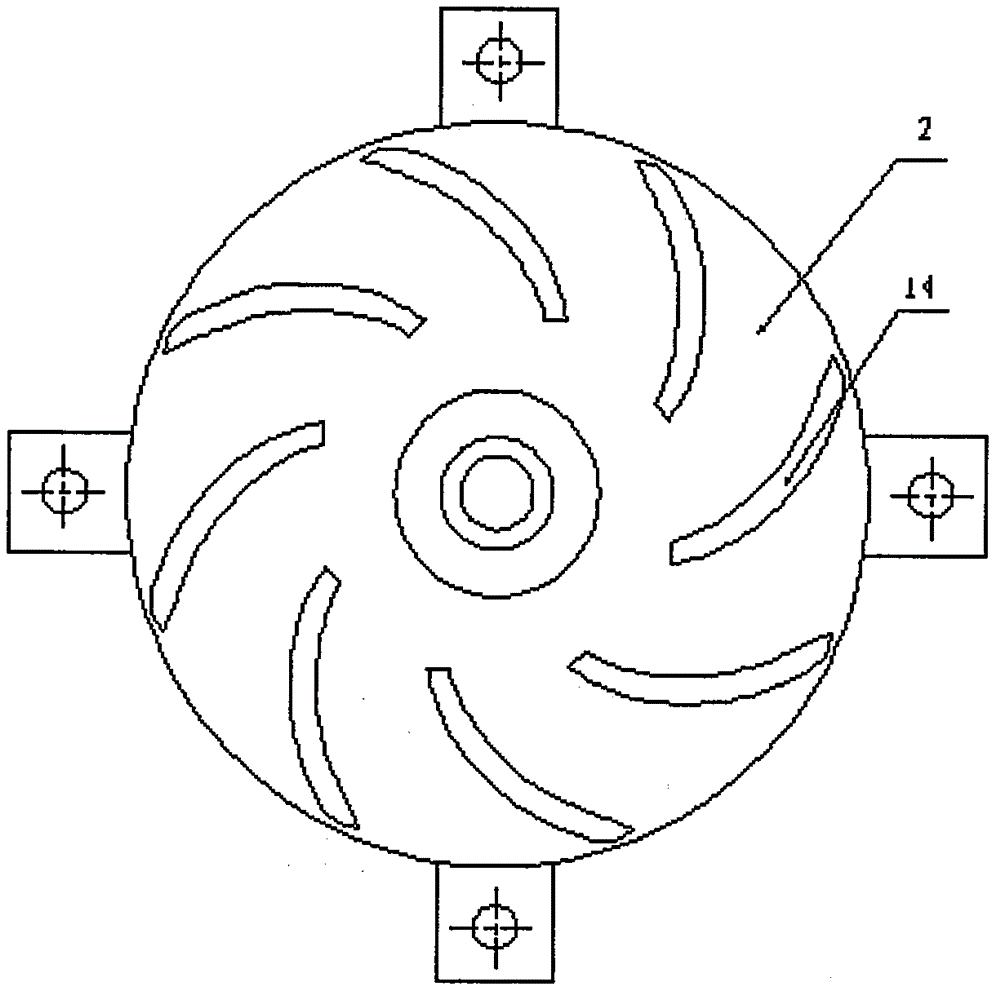

[0017] Such as figure 1 As shown in to 3, a dried fruit shelling device of a conical grinding disc, comprising: a rotating grinding disc 1, a fixed grinding disc 2, a transmission shaft 3, a positioning nut 4, a spring 5, a washer 6, a flat key 7, a washer 8, and an adjusting washer 9 , the upper tapered roller bearing 10, the lower tapered roller bearing 11, the fastening nut 12, and the upper rib 13 fixed on the rotating grinding disc 1 and the lower rib 14 fixed on the fixed grinding disc 2. The transmission shaft 3 is designed with two threads and two keyways; the transmission shaft 3 is sequentially installed with two fastening nuts 12, washers 8, and a fixed grinding disc 2, and an upper tapered roller is installed in the bearing hole of the fixed grinding disc 2. Sub-bearing 10 and lower tapered roller bearing 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com