Patents

Literature

405results about How to "To achieve the separation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

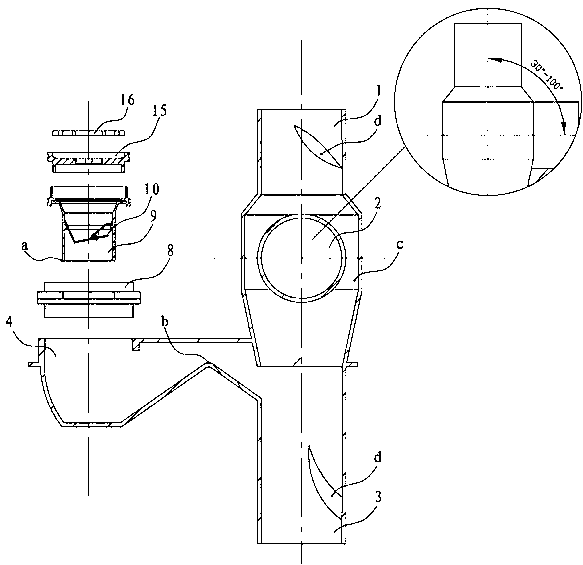

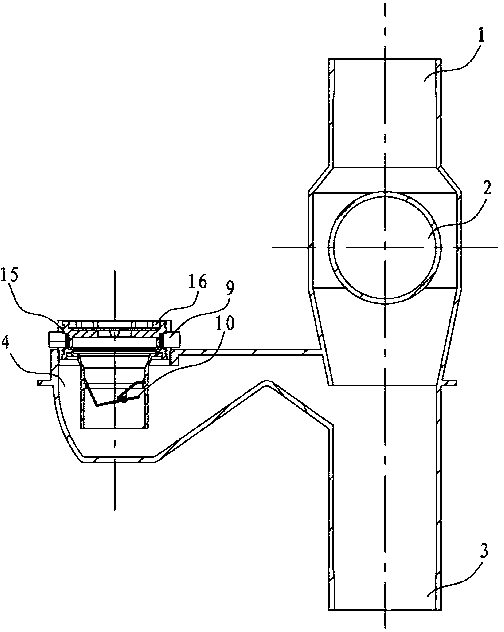

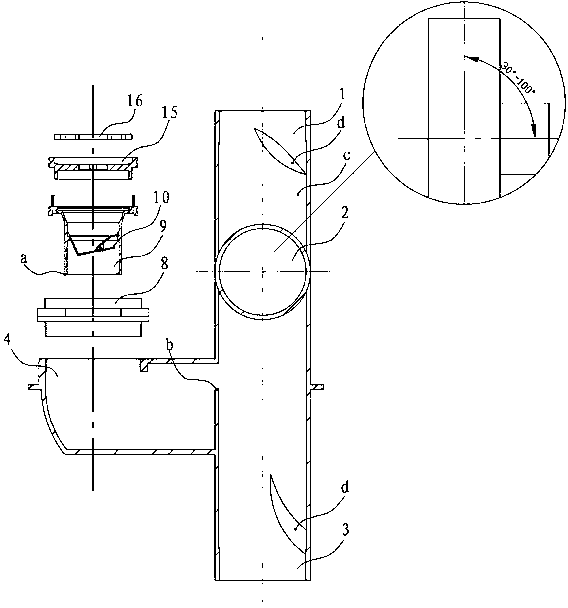

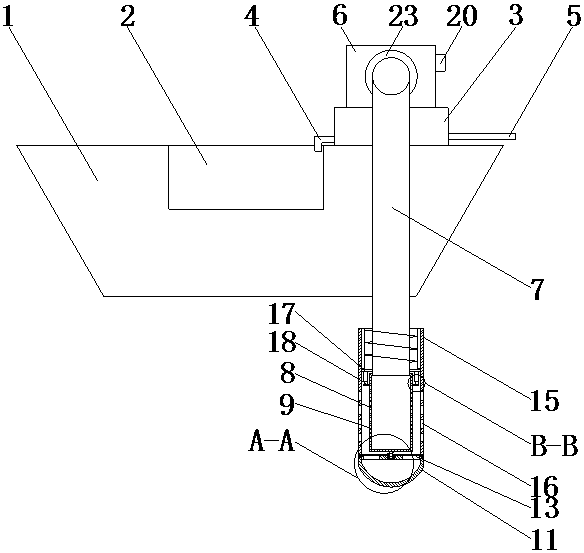

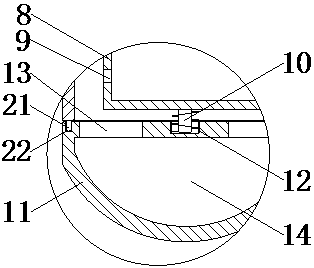

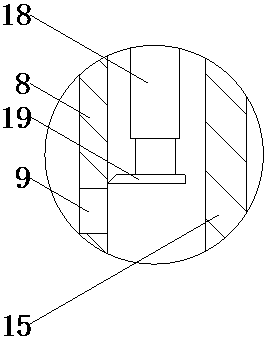

Same floor draining joint for building

InactiveCN102839724AIncrease drainage flowTo achieve the separation effectDomestic plumbingToiletCivil engineering

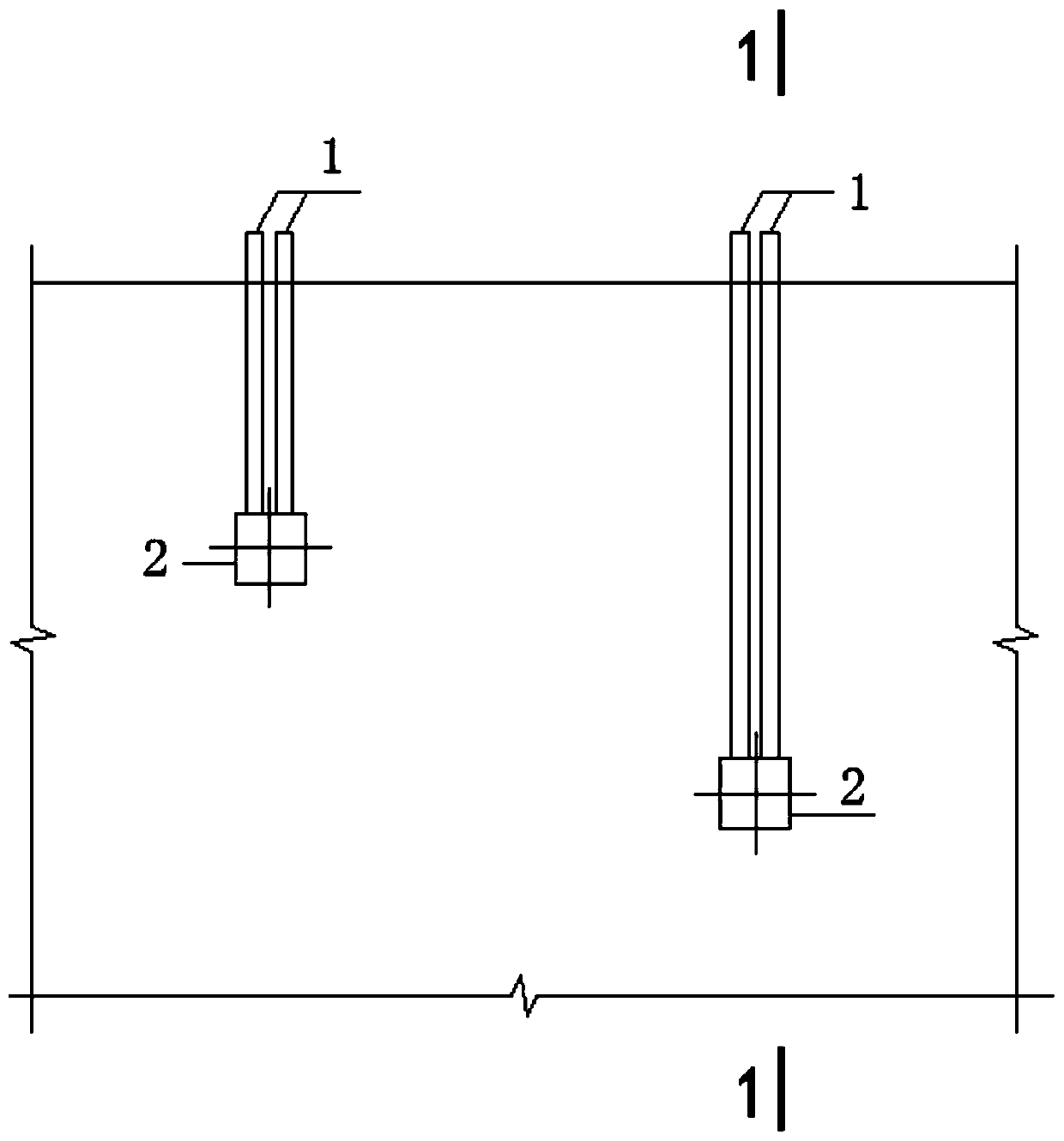

The invention relates to a same floor draining joint for a building, in particular to a same floor draining joint for a toilet, which consists of an upper vertical pipe draining port, a lower vertical pipe draining port and at least two transverse pipe draining ports; the upper vertical pipe draining port is communicated with the upper end and the lower end of the lower vertical pipe draining port; the at least two transverse pipe draining ports are staggered in position and are arranged between the upper vertical pipe draining port and the lower vertical pipe draining port; the orientation of the inlet of at least one of the transverse pipe draining ports is equal to or nearly equal to the orientation of the upper vertical pipe draining port, and the orientation of the inlet of at least one of the transverse pipe draining ports forms an included angle of 30-100 degrees with the orientation of the upper vertical pipe draining port. The same floor draining joint is rational and scientific in structure, and is capable of realizing the same floor draining and the same floor maintenance when the draining joint is adopted in the same floor draining of the non-falling plate or falling plate; the draining is more safe; the water is not easy to accumulate in the falling plate layer even the way of the falling plate is adopted, and the accumulated water is safely and completely discharged, so as to avoid the foreign smell in the room.

Owner:KUNMING QUNZHIYING TECH

Method for preparing pharmaceutics of hydrolysate of brain protein

ActiveCN1562339ATo achieve the separation effectNo pollution in the processPowder deliveryNervous disorderHydrolysateTyrosine

A hydrate of brain protein is prepared from pig's brain through adding purified water, homogenizing, heating, cooling, regulating pH=1.5-2.0, enzymolyzing, regulating pH=7.7-8.0, enzymolyzing, regulating pH=2.5-3.0 freezing, thawing, filter, regulating pH to become neutral, ultrafiltering, concentrating, sterilizing, adding amino acids, regulating peptide map, diluting, and steam sterilizing.

Owner:赛隆药业集团股份有限公司

Method and kit for rapidly extracting nucleic acids from trace clinical samples

InactiveCN101684463ASimple and safe operationLow costMicrobiological testing/measurementDNA preparationBiologyDNA

The invention relates to a method for rapidly processing and extracting nucleic acids from various trace clinical samples. The method comprises the following steps: cracking cells; absorbing by a filter membrane; and leaching and extracting nucleic acids (DNA and RNA). The invention also relates to a kit for rapidly extracting nucleic acids from clinical samples and application thereof.

Owner:USTAR BIOTECHNOLOGIES (HANGZHOU) CO LTD

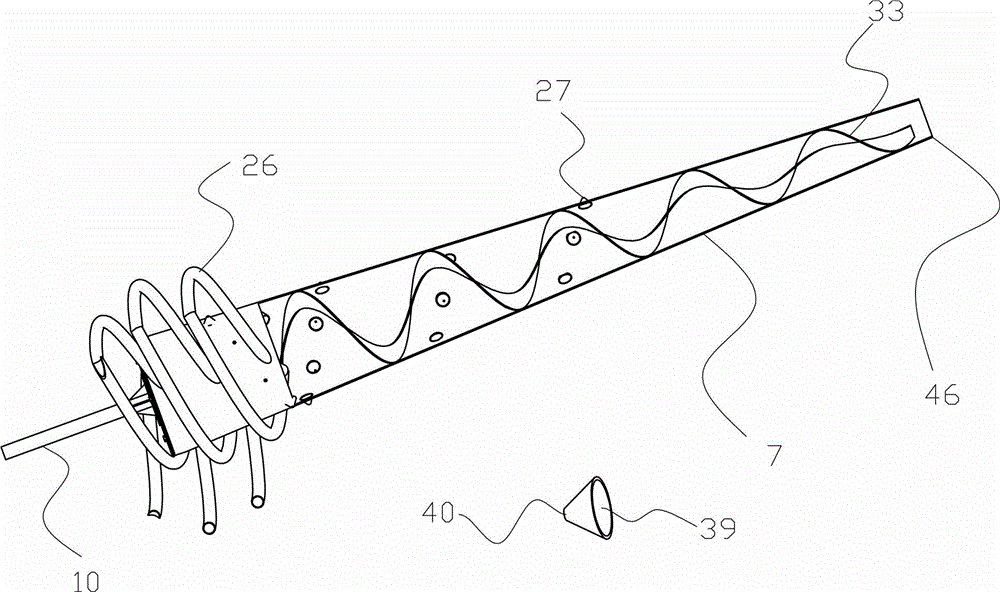

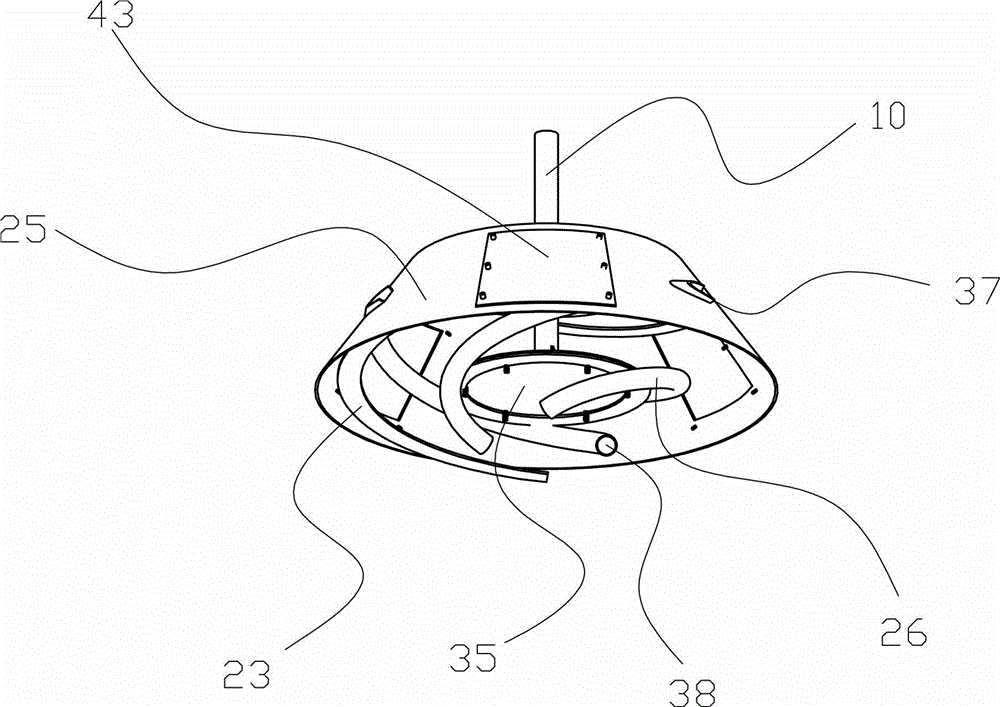

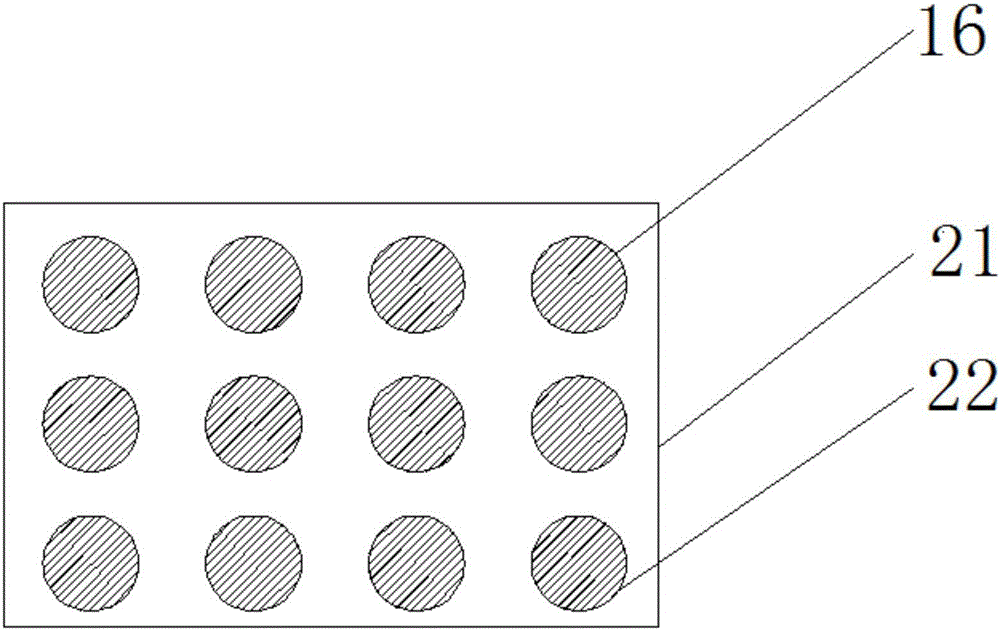

Fishbone separator and separating method thereof

The present invention is small fishbone separator and its separating method with high fish meat yield and high efficiency and suitable for use in restaurant. The fishbone separator includes a pestling unit and a separating unit connected via pipe and set inside the separator frame. The pestling unit includes pestling motor, pestling barrel with material inlet, and pestling shaft in the middle of the pestling barrel and with toothed rods. The separating unit includes separating motor and separating barrel with closely distributed separating holes. The present invention can separate fish meat from fishbone and fish skin effectively and suitable for food producing enterprise and restaurant.

Owner:关健

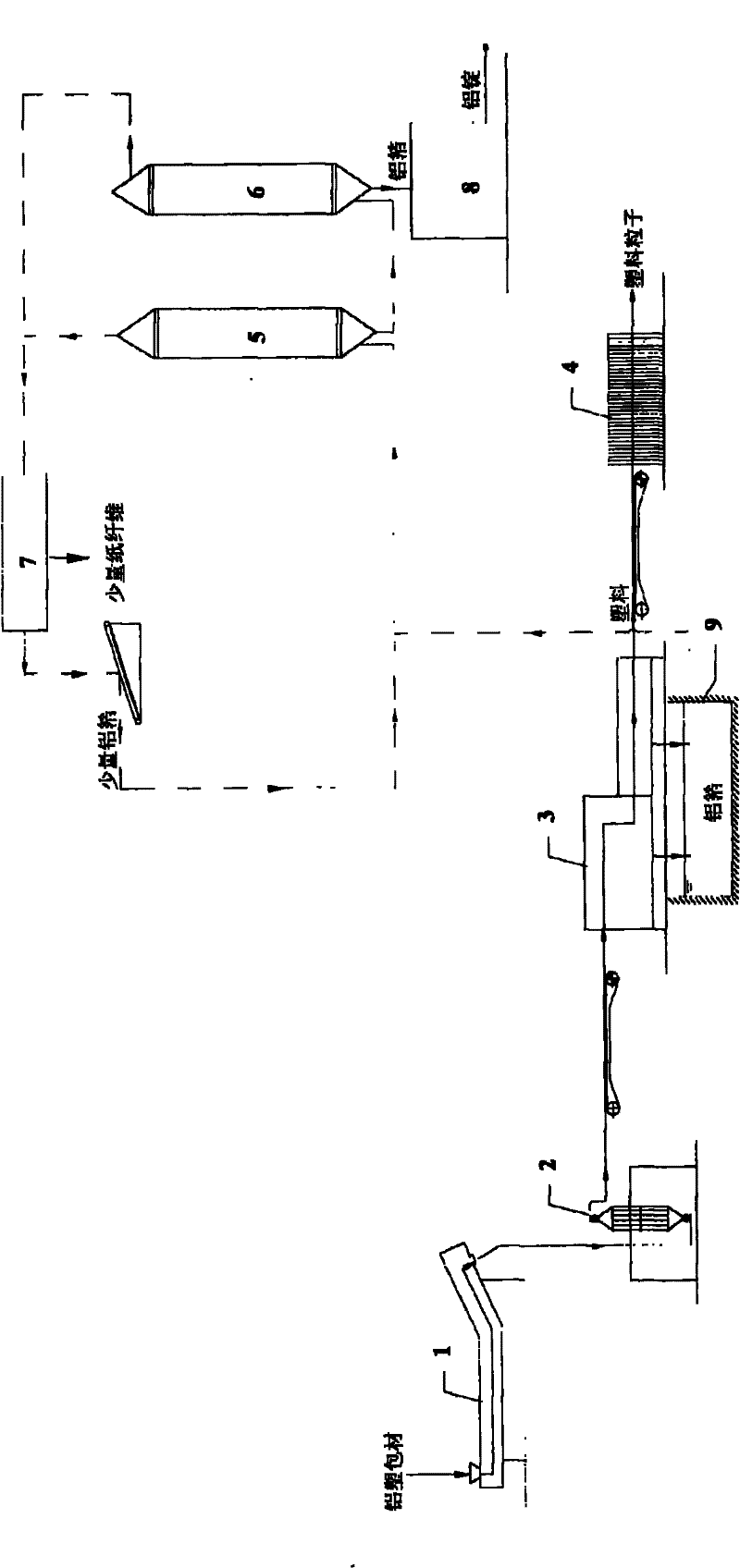

Successive separation method of aluminum-plastic composite packaging materials and device thereof

InactiveCN102206359ASmooth feedingContinuous dischargePlastic recyclingProcess efficiency improvementFormic acidSeparation method

A successive separation method of aluminum-plastic composite packaging materials comprises the following steps of: A) immersing the aluminum-plastic composite packaging materials in a formic acid remover, wherein the formic acid concentration of the formic acid remover is 2-6 mol / L; B) drying the separated aluminium foils and plastic to remove the residual remover; C) centrifuging and sifting thedried aluminium foils and plastic to spall and separate the plastic and aluminium foils, followed by collecting the plastic and aluminium foils. The invention also provides a device to accomplish theabove method. The method provided by the invention accomplishes the purpose of successive feeding and successive discharging with high separation efficiency and high separation speed, saves costs andis of economic and valid industrial value.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

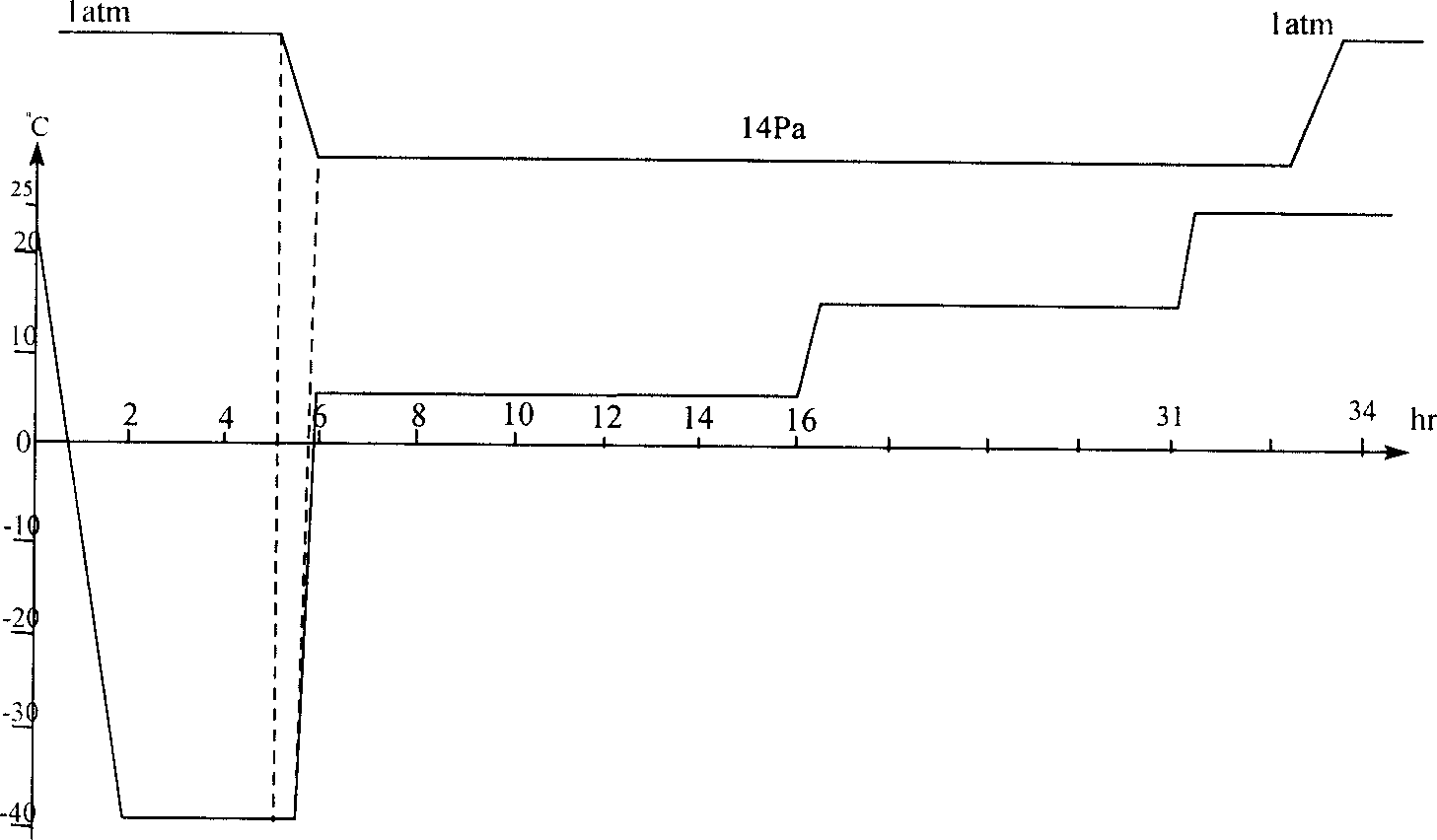

Brain protein hydrolysate and production process of its freeze dried preparation

InactiveCN1857711ANo pollution in the processReduce investmentPowder deliveryNervous disorderFreeze-dryingNitrogen

The present invention relates to a kind of brain protein hydrolysate and the production process of its freeze dried preparation. The brain protein hydrolysate for injection is prepared with pig brain and through the steps of homogenating in a colloid mill to collect slurry, hydrolyzing with pepsase and pancreatin to collect supernatant, filtering with filer paper to collect filtrate, separating and purifying the filtrate with hydroxyapetite column, regulating peptide map and collecting object, ultrafiltering with membrane of intercepting molecular weight 8 KD to collecting filtrate, nitrogen and amino acid analysis and adding amino acid in the required amount, and fine filtering with 0.22 micron filtering membrane. The brain protein hydrolysate for injection may be further freeze dried to obtain freeze dried brain protein hydrolysate preparation. The production process is environment friendly, high in yield and low in cost.

Owner:HAINAN JINXING PHARMA

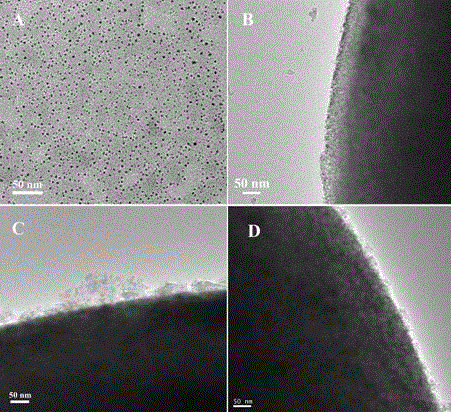

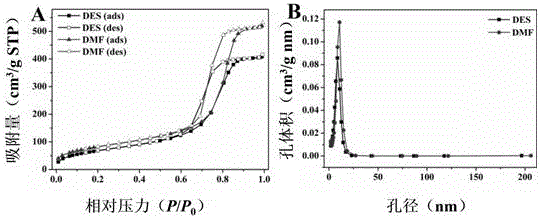

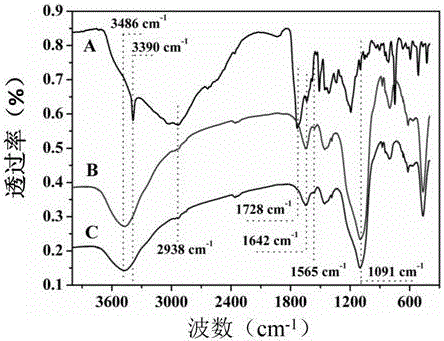

A green synthesis method for carbon quantum dot bonded silica gel chromatography filler

InactiveCN106268715AEnhanced bondingHigh bonding capacityIon-exchange process apparatusComponent separationEpoxySynthesis methods

This invention has discloses a green synthesis method for carbon quantum dot bonded silica gel chromatography filler, which comprises the concrete steps of: mixing the solid powder of aconitic acid and tryptophan to be ground evenly, letting the mixture react under the temperature of 180oC- 200oC for 3 - 6 hours. Through dissolution, centrifugation and freeze drying of the generated solid, the amino-functionalized carbon quantum dots (NCDs) are obtained; After that, NCDs are dispersed in DES and added with gamma-glycidoxypropyl trimethoxy siloxane(GPTMS). Under the protection of N2 and the temperature of 55oC- 65oC, the mixture is stirred to react for 22 - 25 hours, then the silica gel (SiO2) is added to react for another 12 - 48 hours. Water and absolute ethyl alcohol are alternatively used to wash the raw product generated from the reaction. Silica gel chromatography filler modified by carbon quantum dots will be generated after drying. This green synthesis method realizes the surface bond of carbon quantum dots and silica gel through epoxy group and amino. DES used in the process of reaction is reaction solvent, which serves as an excellent dispersing agent for carbon quantum dots and silica gel, ensures higher bonded amount, and at the same time, meets the requirements of green chemistry.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

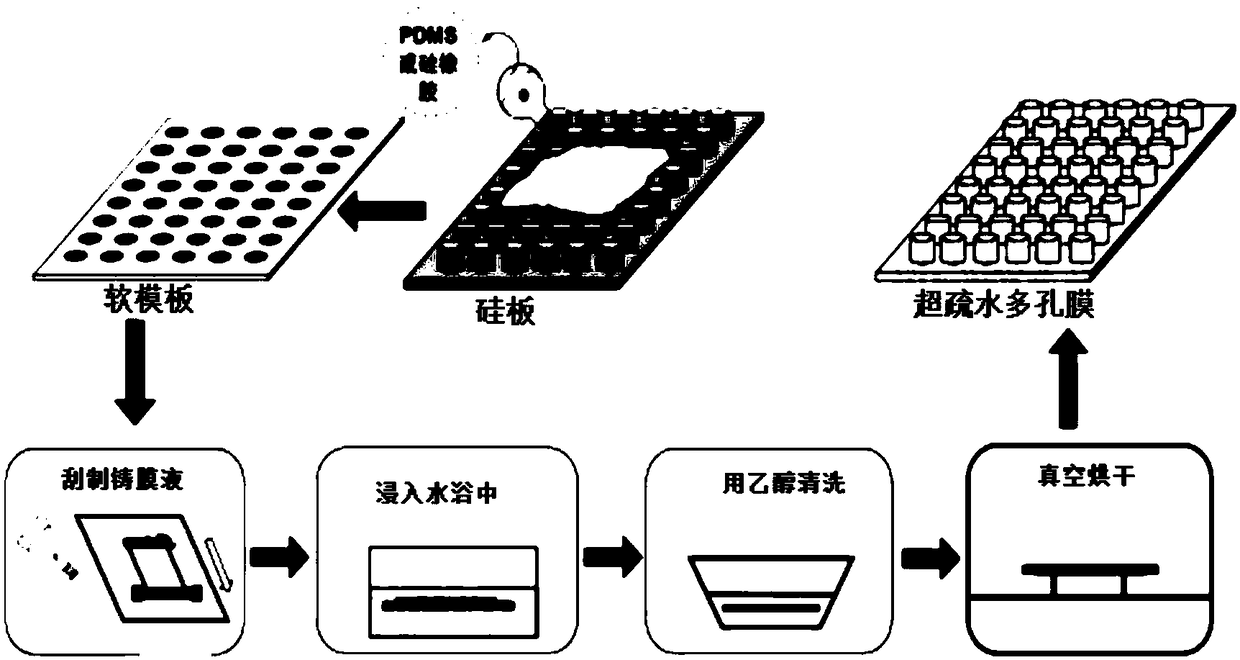

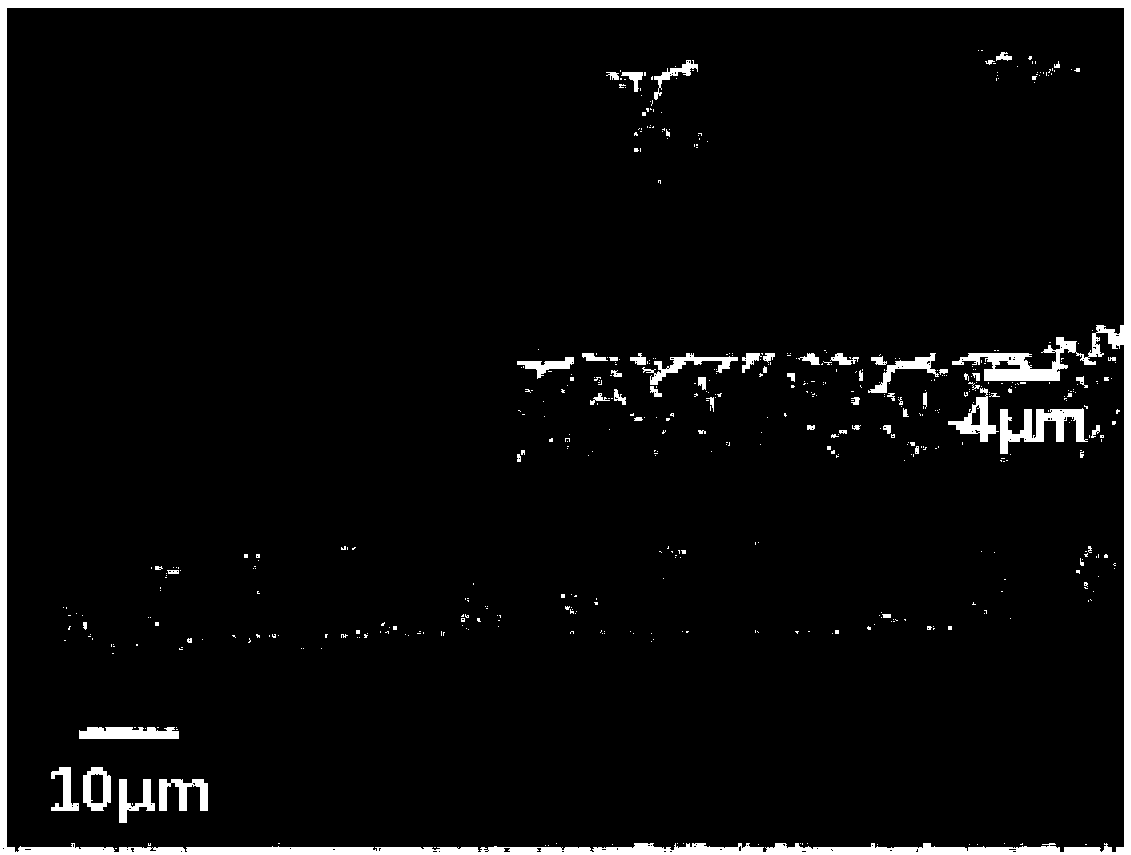

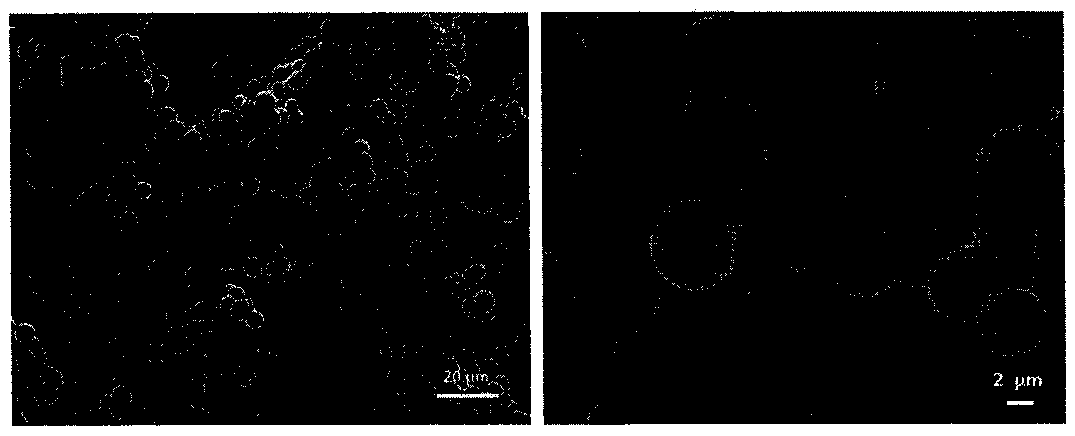

Super-hydrophobic porous membrane as well as preparation method and application thereof

InactiveCN108421418AImprove hydrophobicitySimple preparation processDistillationSalt resistanceWater baths

The invention discloses a super-hydrophobic porous membrane as well as a preparation method thereof. A micro molding technology and a phase separation technology are combined, a membrane scraping bottom plate on which a membrane casting solution is scraped is placed in a water bath at the preset temperature for phase separation membrane formation, a formed membrane material is stripped, and the super-hydrophobic porous membrane is obtained. The membrane scraping bottom plate is a grooved soft template produced with a reverse mold process, the super-hydrophobic porous membrane produced throughthe grooved soft template comprises micron-size surface bulges which are consistent in size and arranged regularly, and the distance between adjacent surface bulges is micron-sized. The surface morphology of the membrane material is reconstructed, the super-hydrophobic porous membrane with multiple scales is prepared while additional modifiers are not added, and the super-hydrophobic porous membrane can be applied to a membrane distillation technology, has the advantages of high hydrophobicity, pollution resistance, wetting resistance and the like and thus has high salt resistance, and a novelmembrane production technology is provided for industrialization of membrane distillation and is low in cost and prone to mass production.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

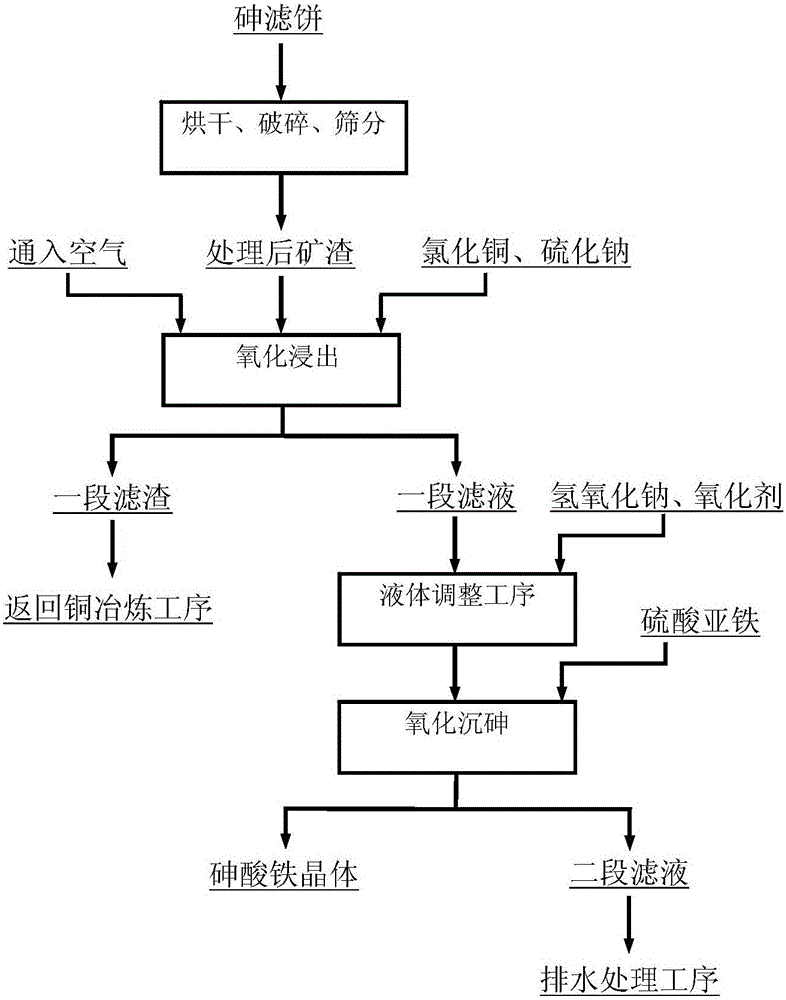

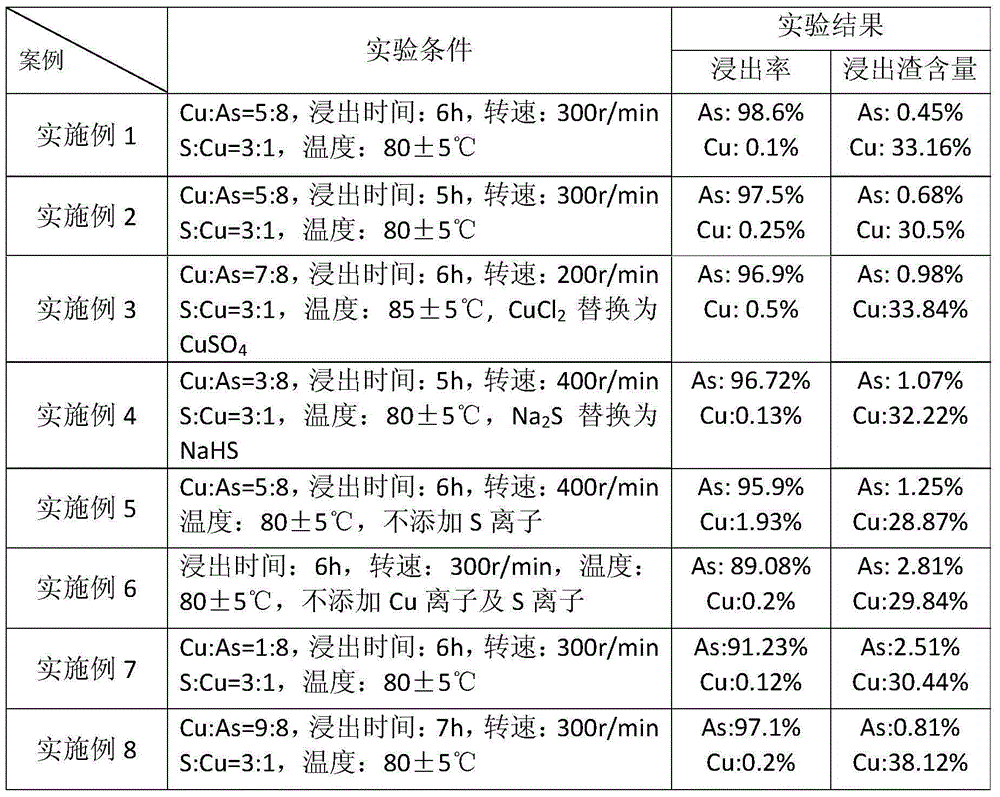

Treatment method for separating copper and arsenic in arsenic filter cakes

ActiveCN105154679AAchieve stabilizationImprove separation rateProcess efficiency improvementWater bathsPregnant leach solution

The invention discloses a treatment method for separating copper and arsenic in arsenic filter cakes. The method comprises the following steps: (1) drying, grinding and sieving raw residues of the arsenic filter cakes; (2) mixing the sieved residues with water and pulping; (3) adding copper chloride into a solution; (4) placing the solution in a water bath stirrer at 80-85 DEG C and simultaneously introducing air and reacting for 6 hours; and (5) reacting for 1-3 hours, then adding sodium sulfide into the solution, introducing the generated sodium sulfide into leaching residues, wherein a leaching solution is an arsenic-containing solution. According to the treatment method for separating copper and arsenic of the arsenic filter cakes, the purpose of separating copper and arsenic can be effectively achieved; the leaching residue is returned to the smelting process and is used; then the leaching solution is oxidized; the pH is regulated; ferrous sulfate is used for depositing arsenic to generate scorodite crystals. The method effectively reaches high recovery rate of copper and harmless treatment of arsenic in the arsenic filter cakes with low cost.

Owner:CENT SOUTH UNIV

Preparation method and application of three-element siloxane sponge

ActiveCN104194028ALow densityExcellent compression resistanceFatty/oily/floating substances removal devicesLiquid separationSilanesHydrolysis

The invention relates to a preparation method and application of three-element siloxane sponge, belonging to the technical field of preparation and application of environmental functional materials. The method comprises the following steps: alkoxy silane hydrolysis, gelation, product washing and drying. Compared with the traditional two-element siloxane sponge, the three-element siloxane sponge contains abundant non-polar groups and higher roughness on the surface, and is endowed with the superhydrophobic and superoleophylic effects; the contact angle with water exceeds 160 degrees; and the material has excellent mechanical properties. The preparation method is simple to operate, has the advantages of cheap raw materials and the like, and can easily implement large-scale preparation. The three-element siloxane sponge has the advantages of low density, excellent compression resistance, high oil absorption speed, high oil absorption power and the like, has wide application prospects in the fields of organic chemical solvent treatment, oily wastewater treatment, oil spillage treatment and the like, and is a novel efficient oil-water separation material.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

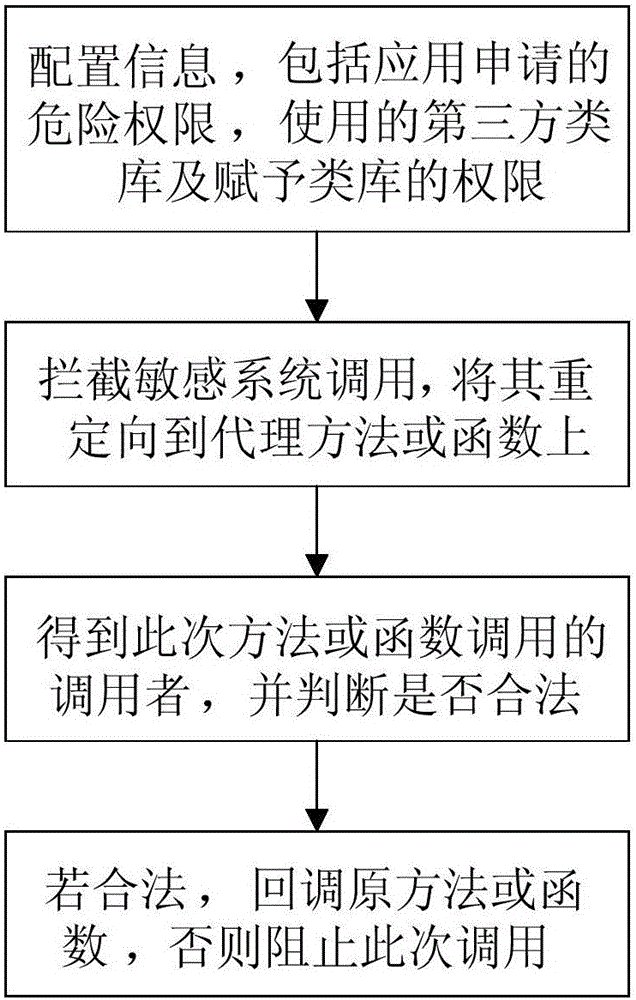

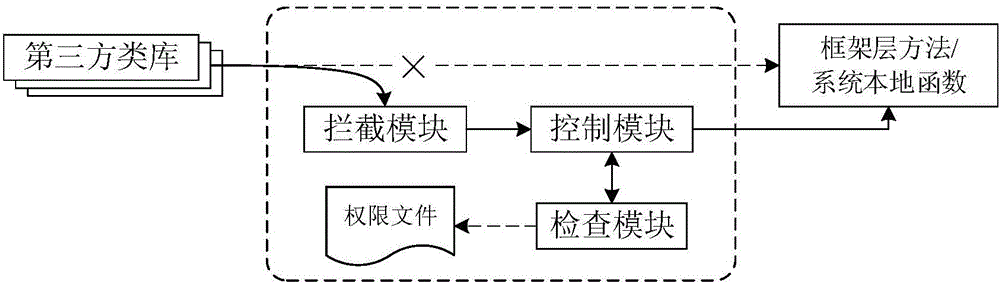

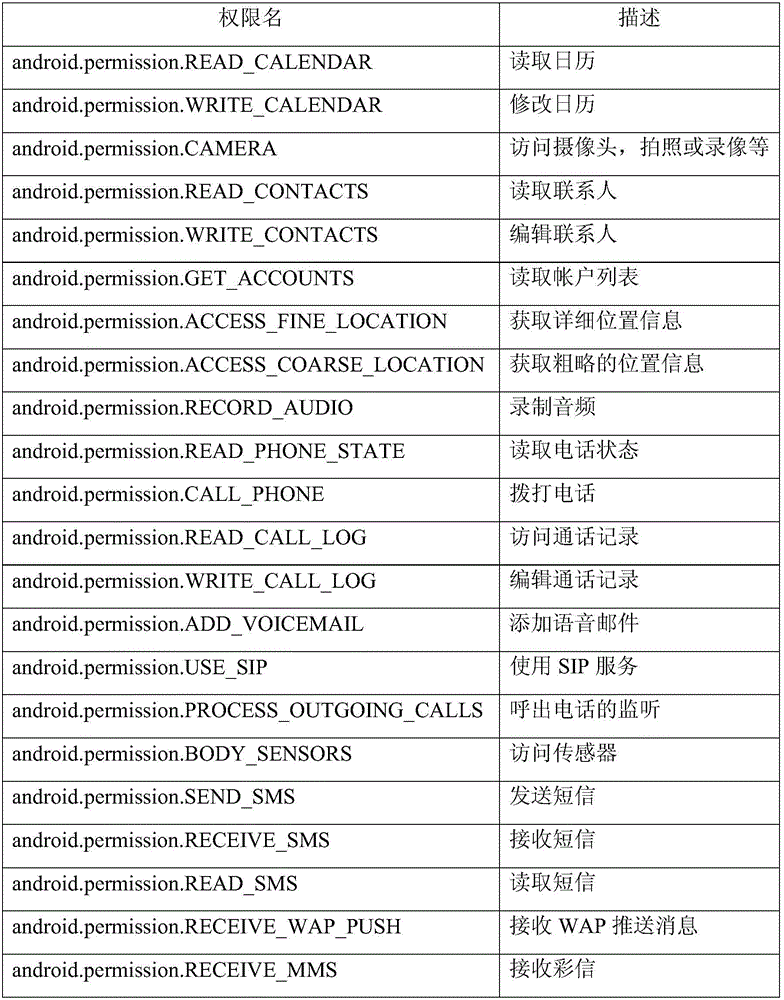

Privilege isolation method and device of Android third-party class library

InactiveCN106446672ATo achieve the separation effectEasy to useInternal/peripheral component protectionPlatform integrity maintainanceThird partyProgramming language

The invention relates to a privilege isolation method and device of an Android third-party class library. The method comprises the following steps of: configuring the privilege information of an application, wherein the privilege information comprises adopted third-party class library information and the privilege endowed to the third-party class library; when the application is started, replacing a sensitive method or function, and calling and redirecting the sensitive method or function to an agent method or function; and obtaining the caller of the sensitive method or function, judging whether the calling is legal or not, if the calling is legal, calling back an original method or function, and otherwise, stopping the calling. The device comprises an interception module, a control module, a checking module and a privilege file. By use of the privilege isolation method and device of the Android third-party class library, the privileges of the Android third-party class library and a host application during operation can be effectively isolated, and therefore, the third-party class library can not use the privilege of the host application.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES +1

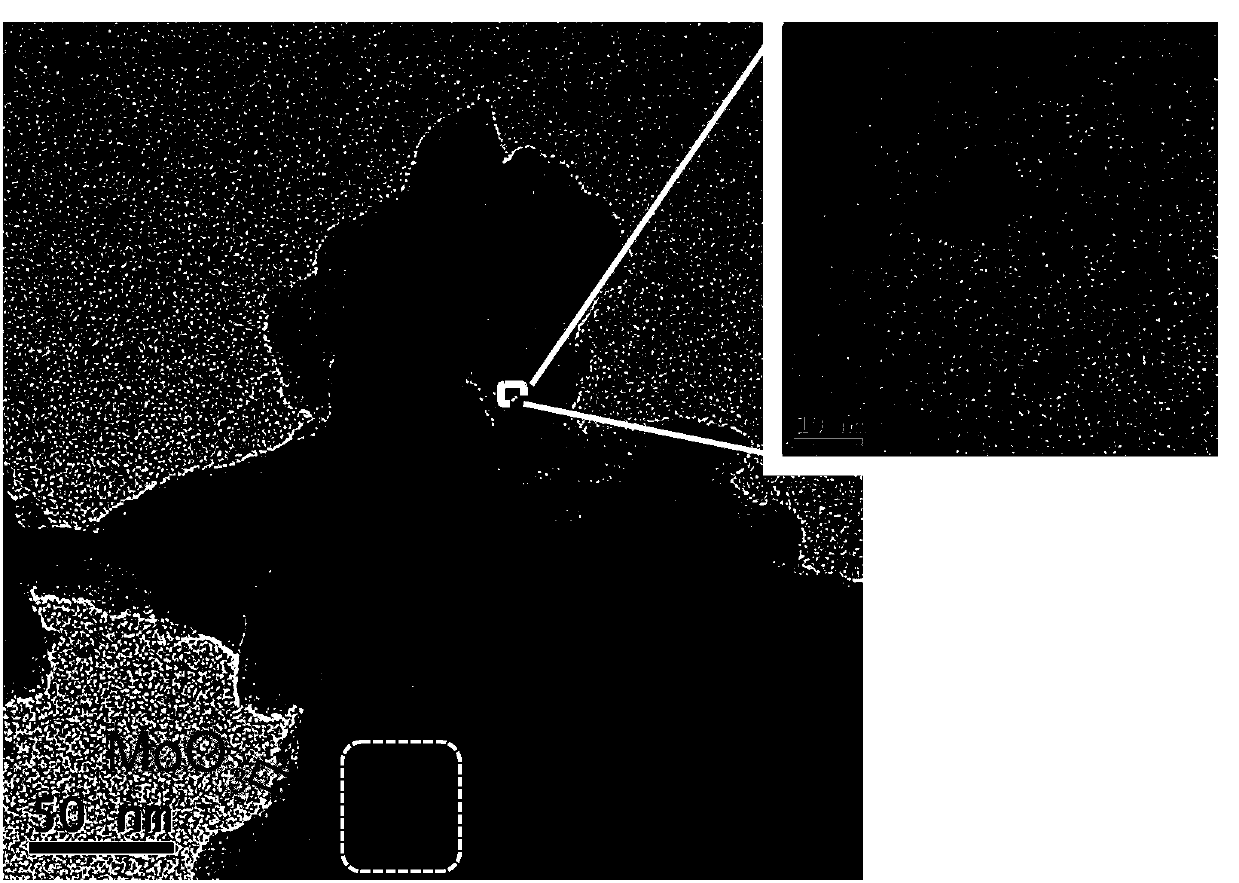

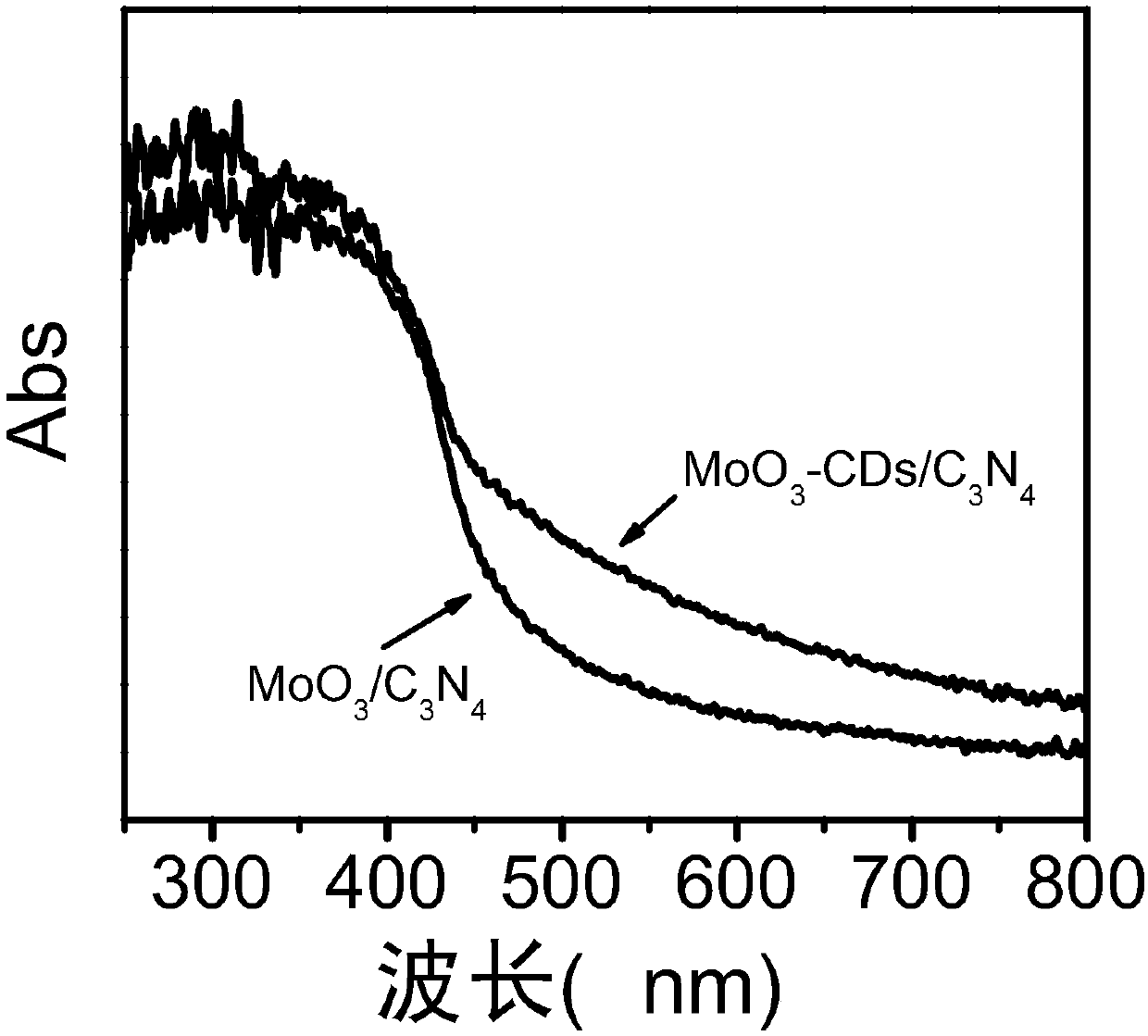

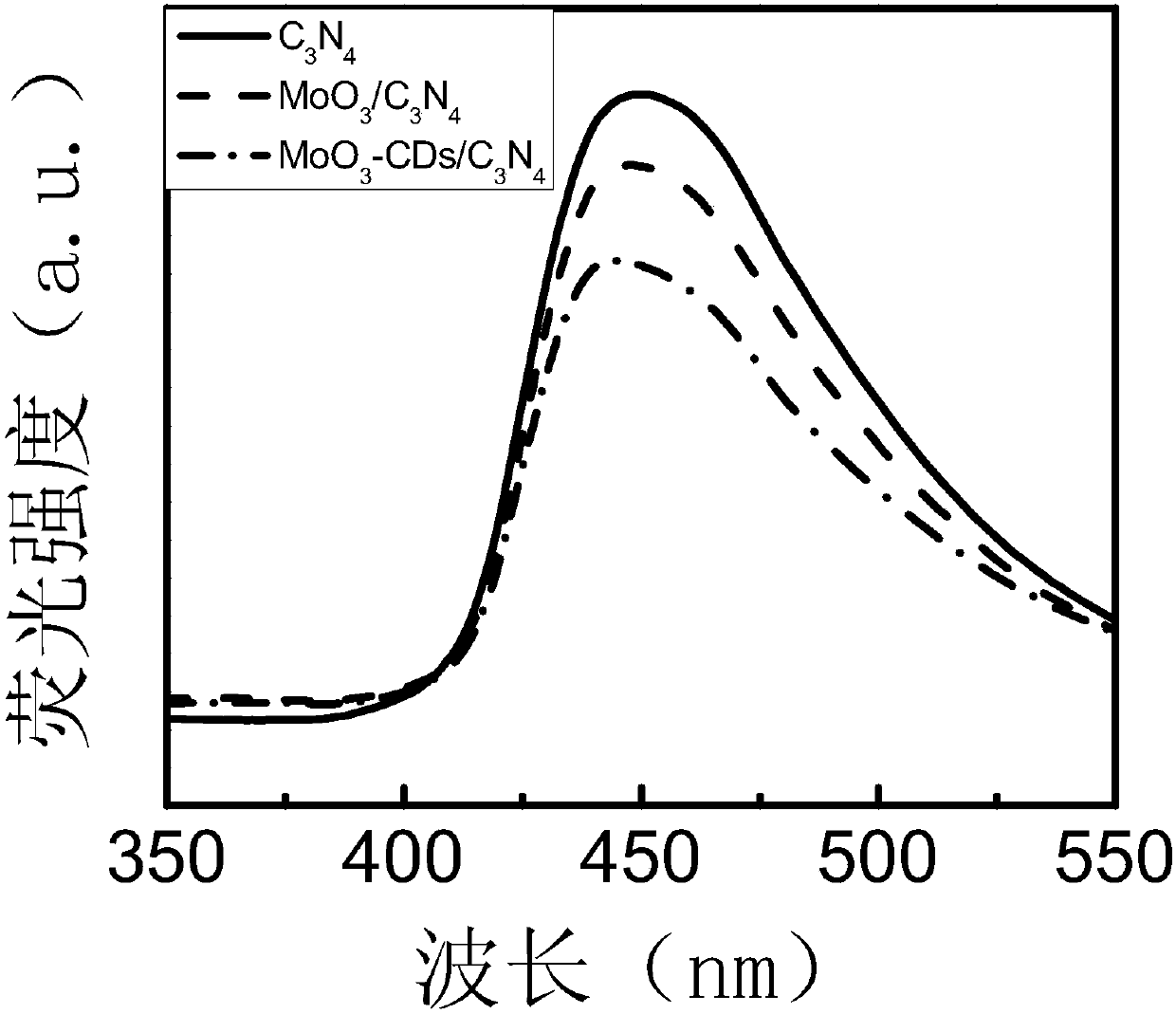

Carbon dot-molybdenum trioxide and carbon nitride composite catalyst, preparation method and applications thereof

InactiveCN107803215AImprove photocatalytic efficiencyGood controllability and repeatabilityWater/sewage treatment by irradiationWater treatment compoundsMuffle furnaceControllability

The invention belongs to the field of photocatalysis, and discloses a preparation method and applications of a carbon dot-molybdenum trioxide co-composite carbon nitride catalyst. The preparation method comprises the following operation steps: S1, preparing MoO3 powder; S2, preparing CDs powder; S3, preparing C3N4 powder; and S4, preparing a MoO3-CDs / C3N4 composite catalyst: weighing C3N4 powder,MoO3 powder and CDs powder, mixing, adding anhydrous ethanol, carrying out ultrasonic dispersion, increasing the temperature of the mixed solution to 75 DEG C, carrying out stirring evaporation, transferring into an oven, drying at a temperature of 100 DEG C, cooling, taking out the powder solid, uniformly grinding, transferring into a muffle furnace, carrying out a reaction, cooling to a room temperature, grinding, and screening to obtain the carbon dot-molybdenum trioxide and carbon nitride composite catalyst. According to the present invention, the preparation method has advantages of goodrepeatability, good controllability, good material stability, high application prospect and high use value, and can well meet the mass production requirements.

Owner:GUANGDONG UNIV OF TECH

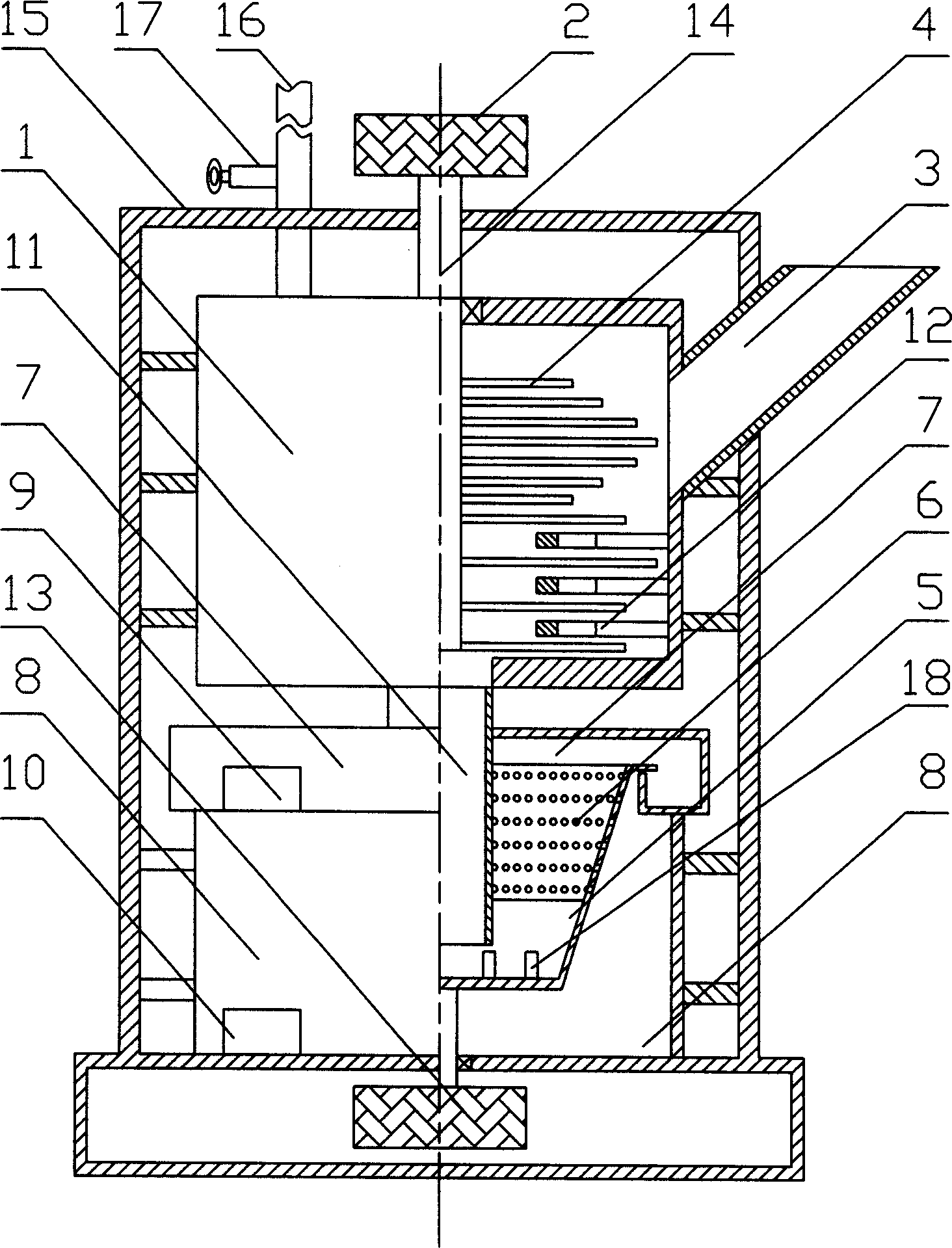

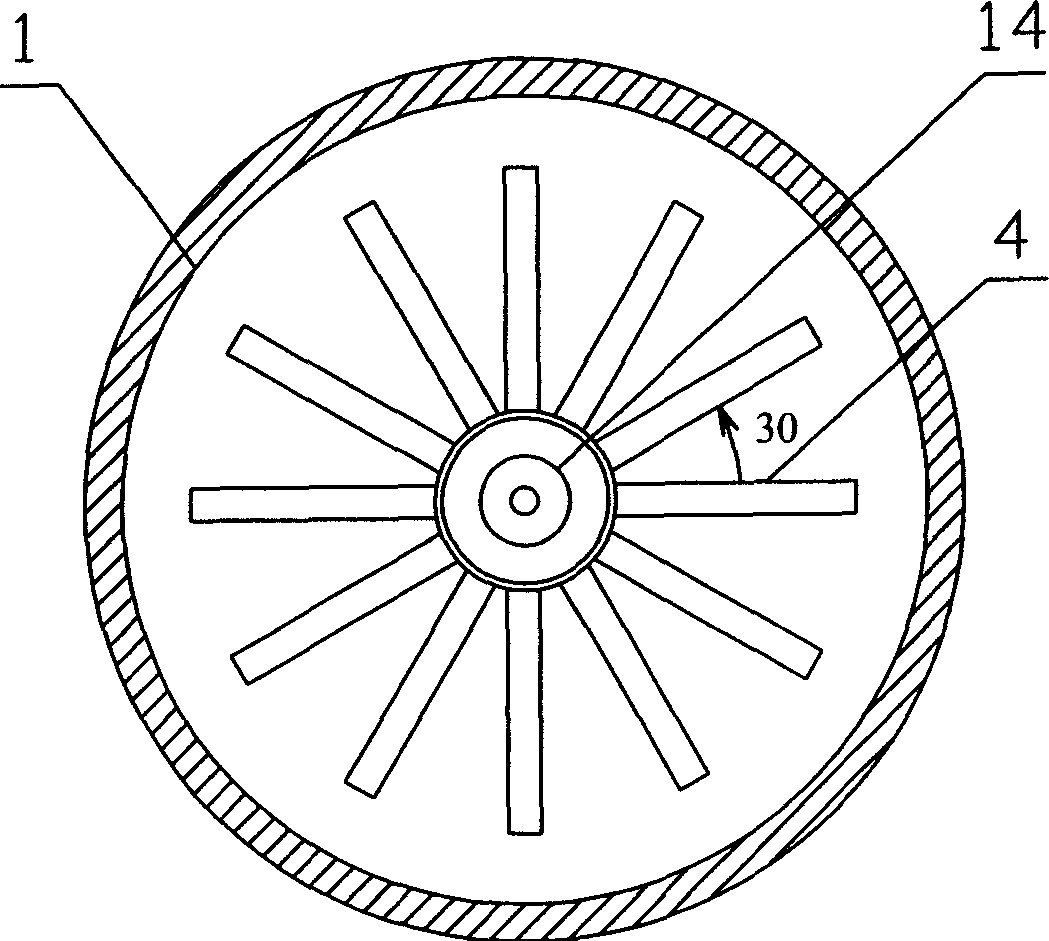

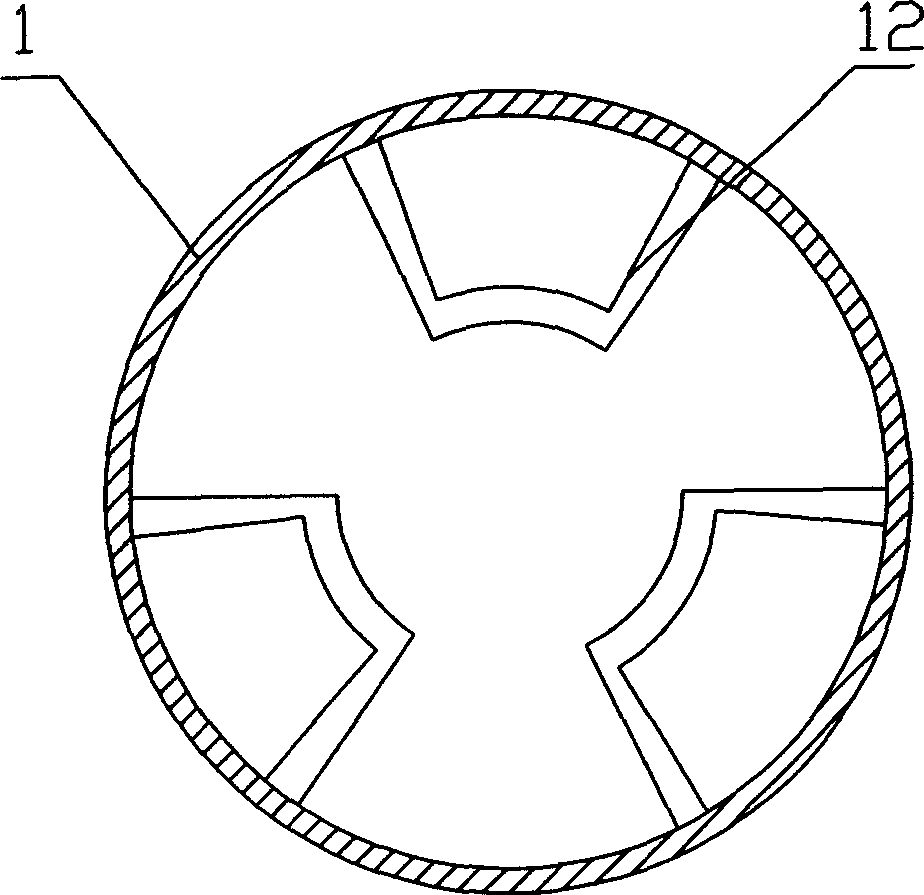

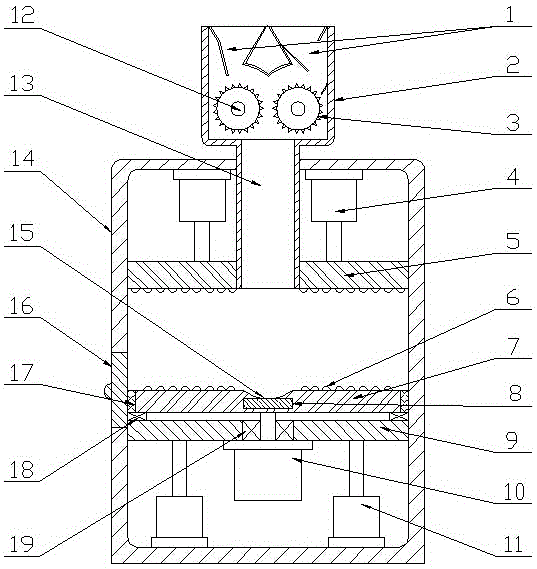

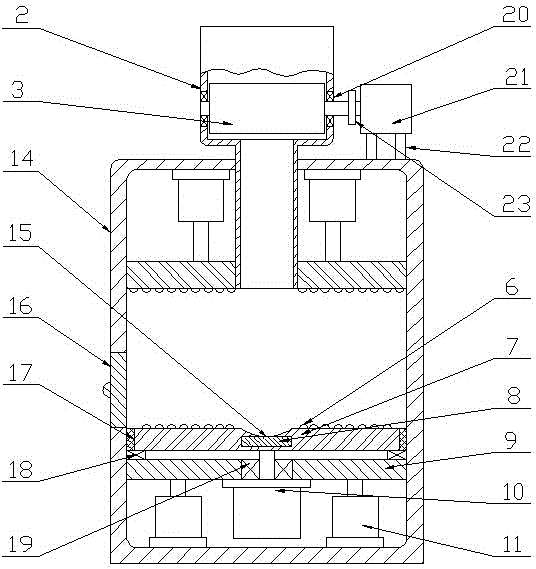

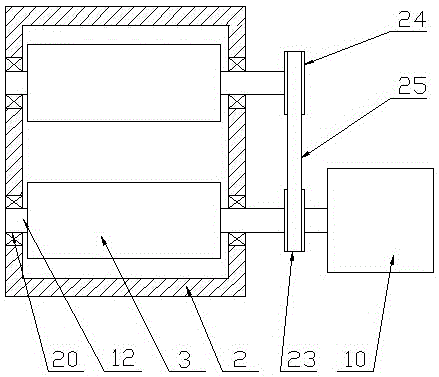

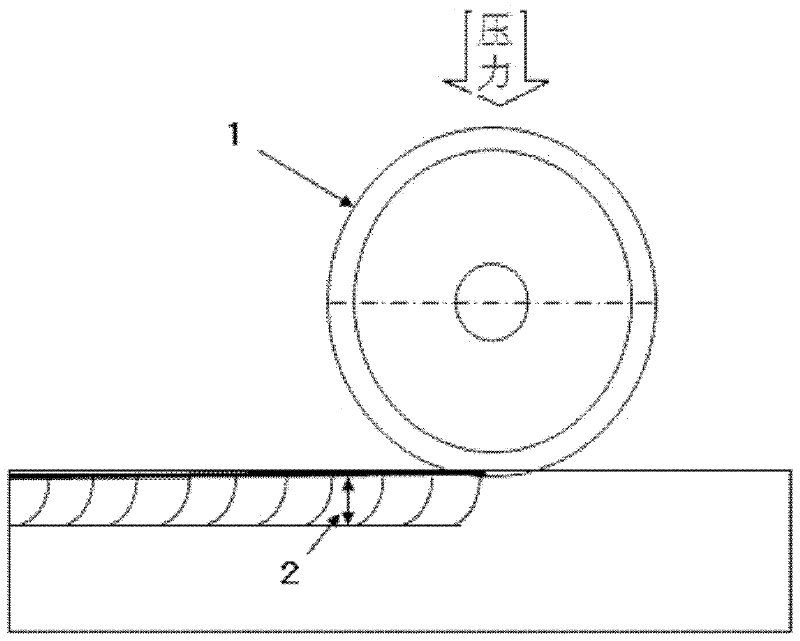

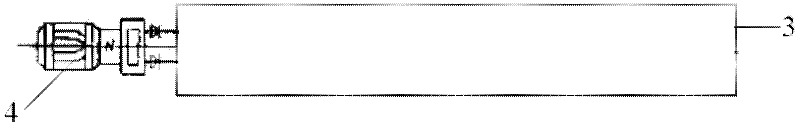

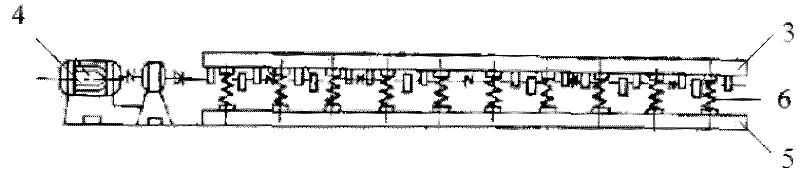

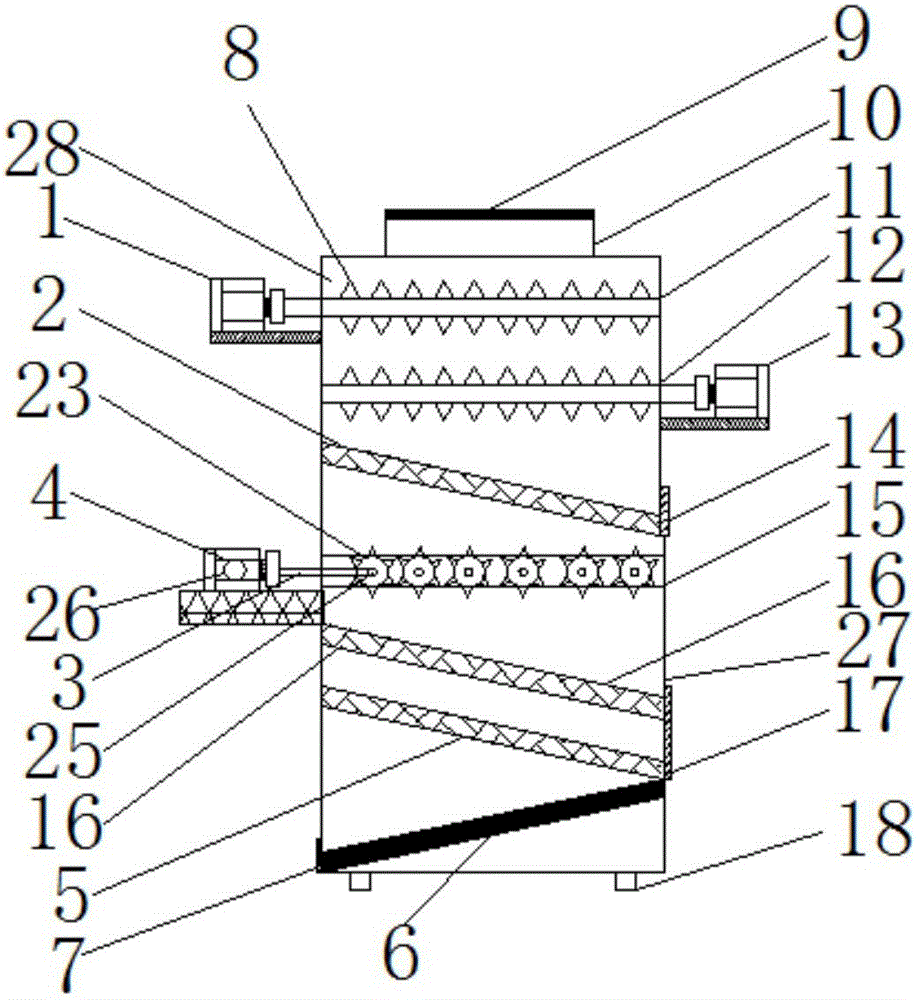

Coarseness and fineness integrated iron ore hydraulic pulverizer

InactiveCN106423379AImprove crushing effectTo achieve the separation effectCocoaGrain treatmentsIronstoneGranularity

The invention provides a coarseness and fineness integrated iron ore hydraulic pulverizer. The coarseness and fineness integrated iron ore hydraulic pulverizer is provided with an upper coarse pulverizing chamber and a lower fine grinding pulverizing chamber. The discharge port end on the bottom of the coarse pulverizing chamber communicates with the fine grinding pulverizing chamber through a discharge channel. The fine grinding pulverizing chamber is internally provided with an upper pressure cylinder, a lower pressure cylinder, an upper pressing plate, a lower pressing plate, a grinding rotary table and a grinding motor. The upper pressing plate is an annular pressing plate, the inner edge of the upper pressing plate is matched with the outer wall of the discharge channel, and the outer edge of the upper pressing plate and the outer edge of the lower pressing plate are matched with the inner wall of the fine grinding pulverizing chamber. At least one side of the fine grinding pulverizing chamber is provided with a discharge door. The upper pressure cylinder is installed between the upper side wall of the fine grinding pulverizing chamber and the upper pressing plate, and the lower pressure cylinder is installed between the lower side wall of the fine grinding pulverizing chamber and the lower pressing plate. The grinding motor is installed on the lower pressing plate, an output shaft of the grinding motor penetrates the lower pressing plate to be fixedly connected with the grinding rotary table, and grinding teeth are arranged on the lower surface of the upper pressing plate and the upper surface of the grinding rotary table in a staggered manner. The coarseness and fineness integrated iron ore hydraulic pulverizer is simple in structure and can achieve coarseness and fineness integrated pulverizing conveniently to meet machining requirements of iron ore produces with different grain size grades.

Owner:国龙寿

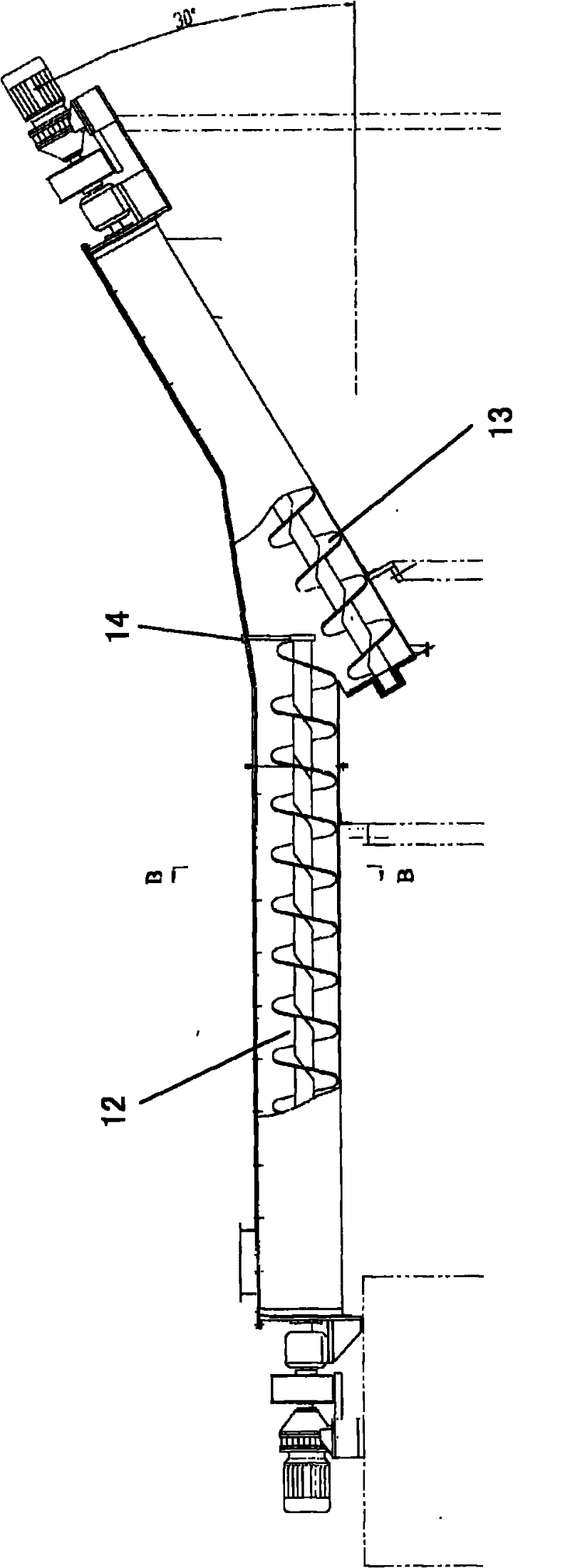

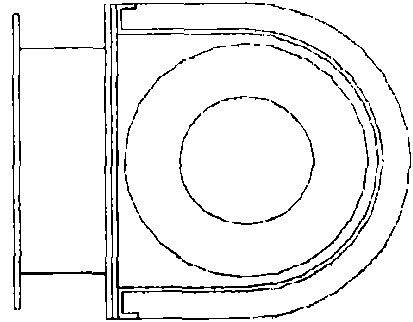

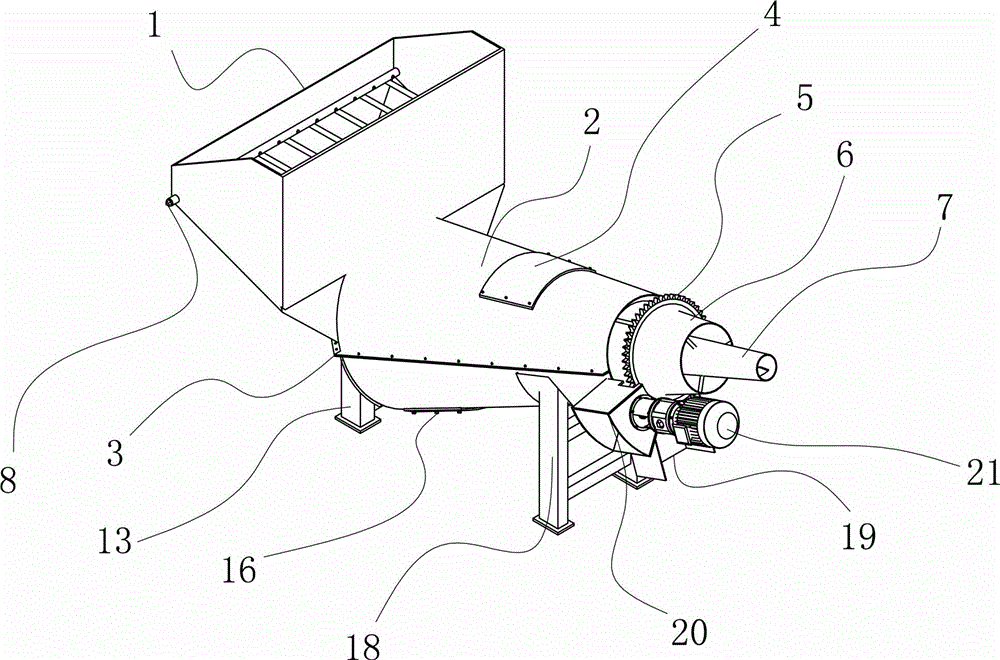

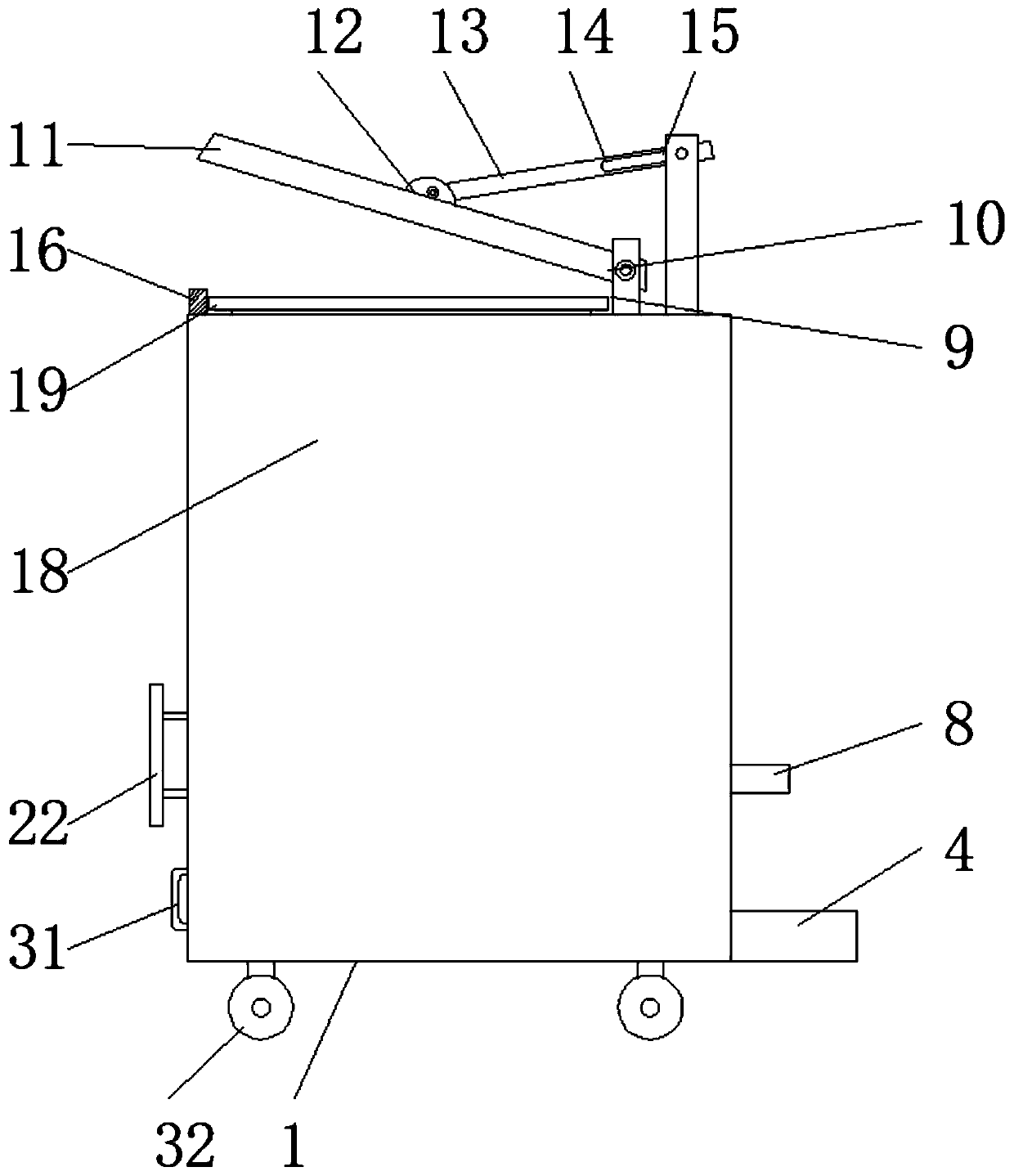

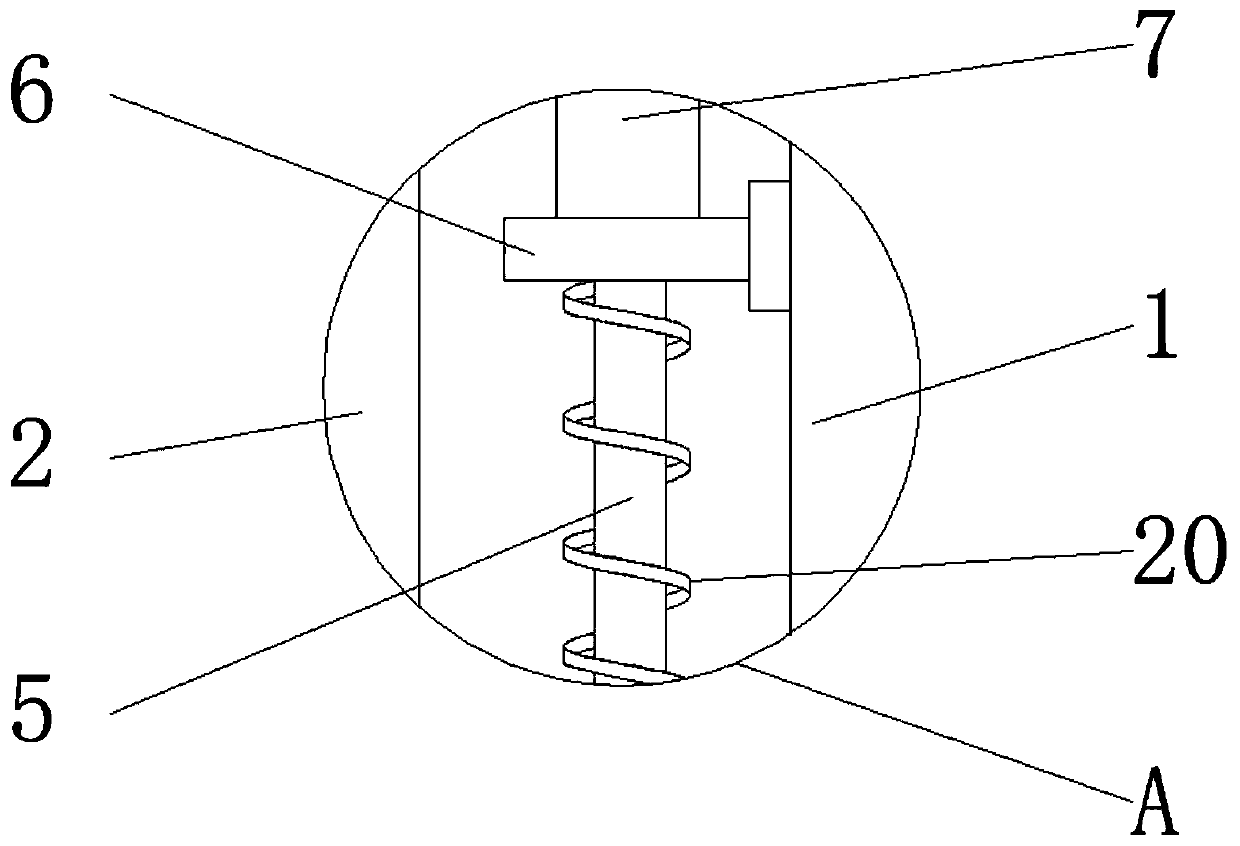

Wet concrete recycling and screening machine with automatic sewage pumping and transporting function and application method thereof

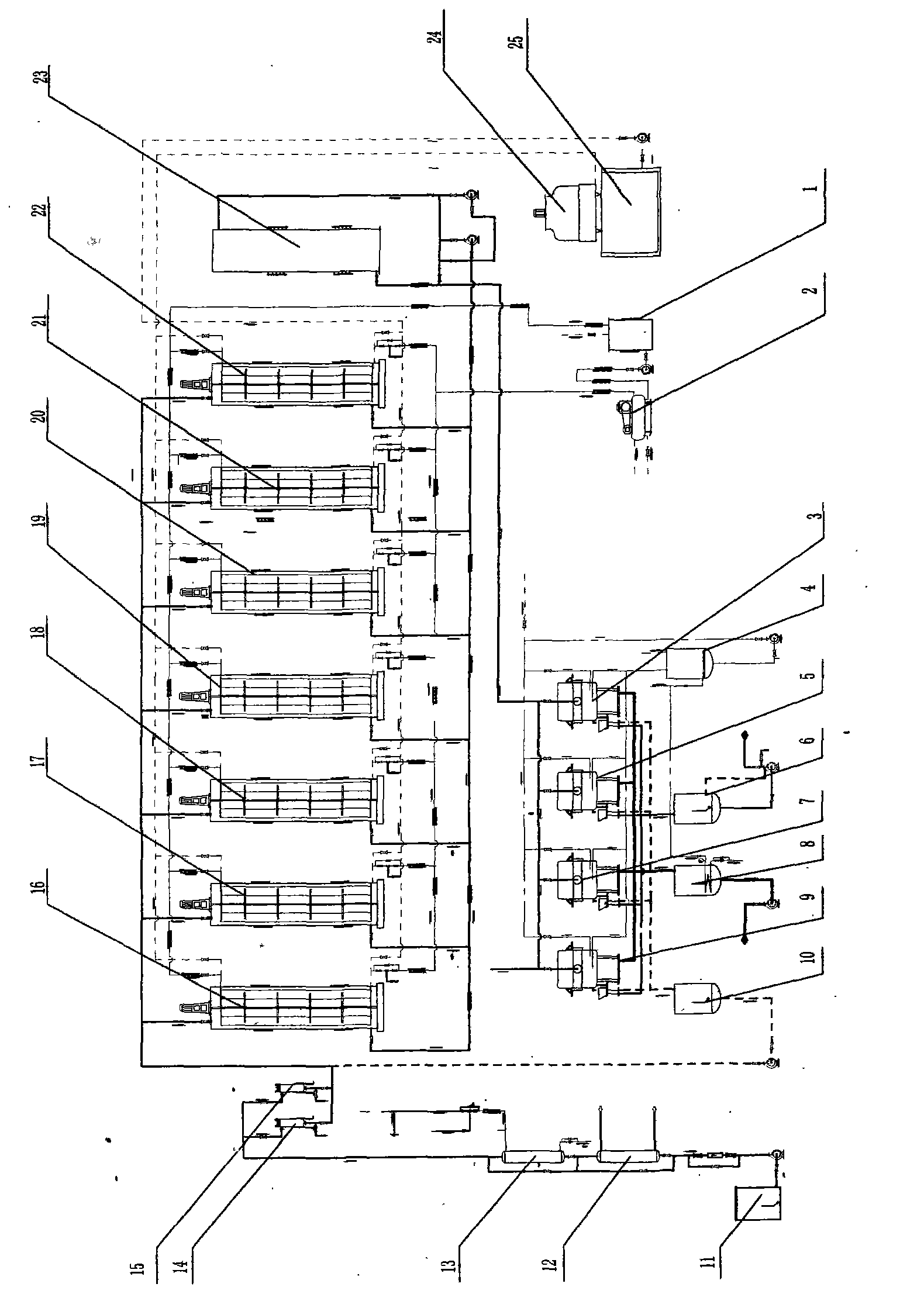

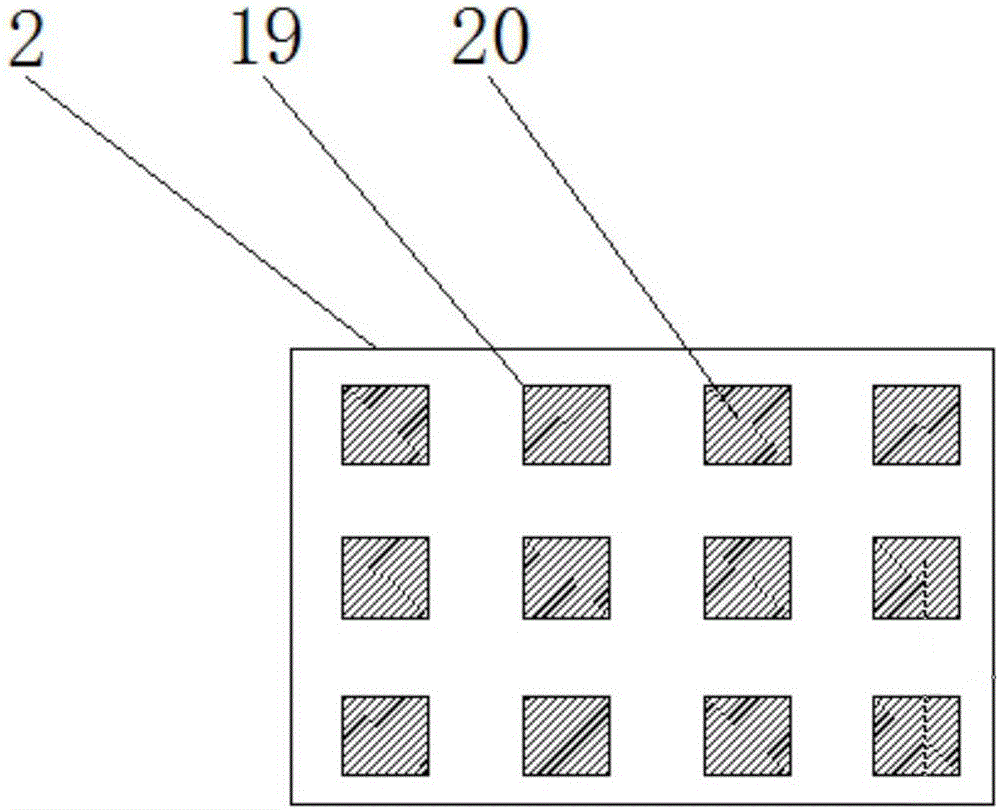

The invention belongs to the technical field of wet concrete recycling, and relates to a wet concrete recycling and screening machine and an application method thereof. The machine has an automatic sewage pumping and transporting function and an automatic fine sand filtration function. The provided screening machine has the advantages of small material transportation resistant force, controllable sewage flow, easy separation between fine sand from sewage, and reduction on energy and water. The screening machine comprises screening and transporting devices for sewage, stones, and sand materials. The application method comprises steps of pre-mixing, transportation, screening on stones and sand materials, and transportation of stones and sand materials. The recycling and screening machine has the following advantages: (1) the material is fed in a higher place and discharged in a lower position, and thus the transportation resistant force is greatly reduced; (2) the sewage in the recycling and screening machine is pumped and transported, and changed is the conventional sewage recycling method through a sewage overflowing opening; (3) the filtration of sewage containing fine sand and automatic screen net cleaning are realized; (4) the vehicle washing tank is clean without washing, the fine sand in sewage can be completely filtered and removed without a swirl separation system, and the screen net can be maintained a clean state without washing during vehicle cleaning.

Owner:铜陵亚摩管业有限公司

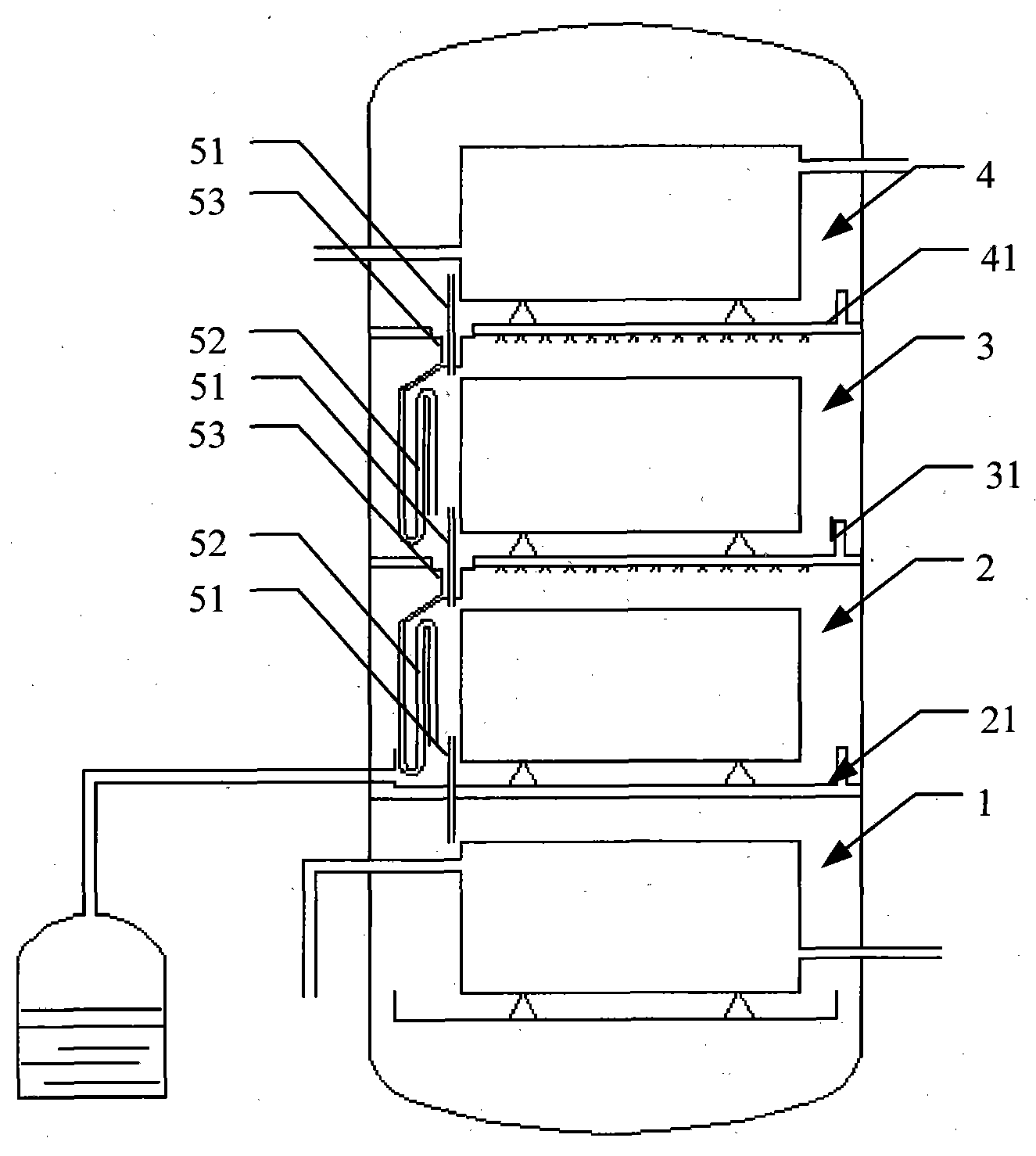

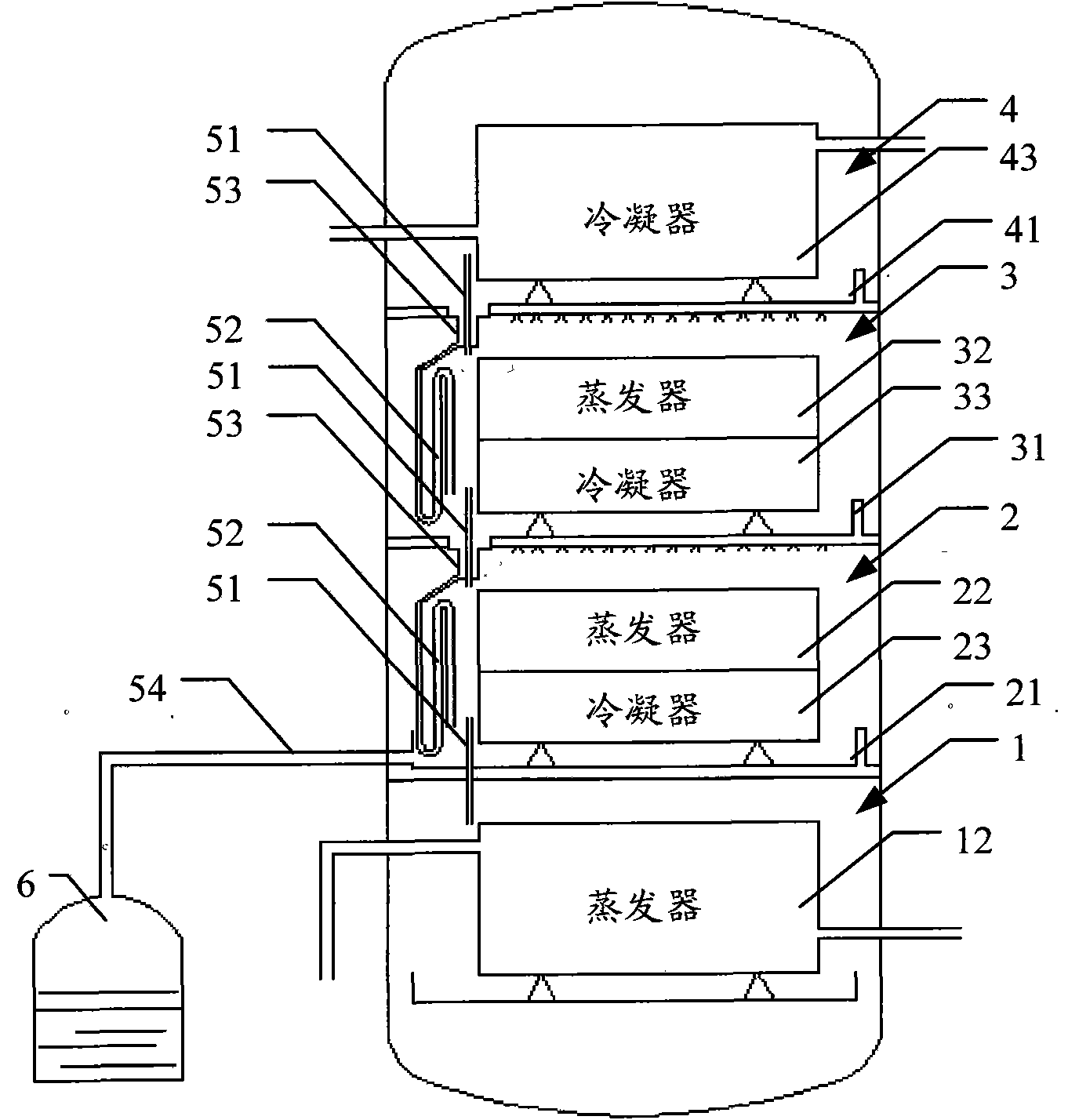

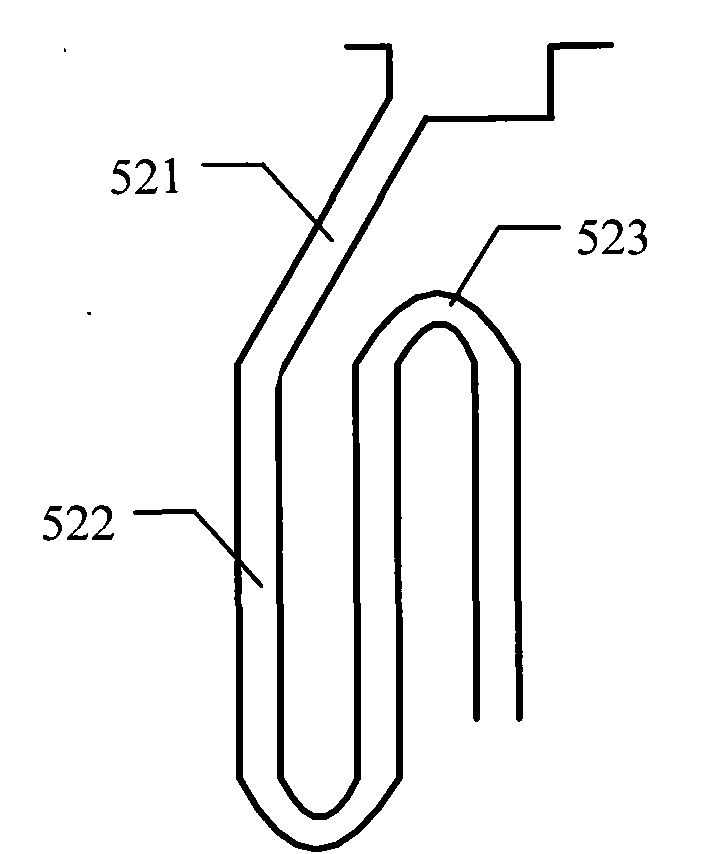

Multi-level solar sea water desalting plant

InactiveCN101885515AImprove collection efficiencyTo achieve the separation effectGeneral water supply conservationSeawater treatmentWater vaporEvaporation

The embodiment of the invention discloses a multi-level solar sea water desalting device. The device comprises at least four layers: an evaporation layer at the bottom, a condensation layer on the top and two levels of fresh water collecting layers in the middle, wherein fresh water collecting grooves are formed in the condensation layer and the fresh water collecting layers and used for collecting the condensed fresh water; a clapboard between layers is provided with a vapor communicating pipe for communicating the water vapor in an upper layer and a lower layer so as to keep the same pressure between the layers; fresh water drainage pipes communicated with the fresh water collecting grooves through connecting grooves are arranged between the fresh water collecting layers and the condensation layer and between the fresh water collecting layers and used for guiding the fresh water collected in the top layer into the bottom layer. Through the embodiment of the invention, liquid in the fresh water collecting groove on the upper part of the device can be guided into the fresh water collecting groove on the bottom part level by level through the fresh water drainage pipe, and the fresh water is collected and gathered and flows into a fresh water tank for use. Meanwhile, the device realizes double functions of fresh water collection and vapor water separation by using the characteristics of the fresh water drainage pipe and the vapor communicating pipe.

Owner:SHENZHEN HEPING WOLONG SCI & TECH

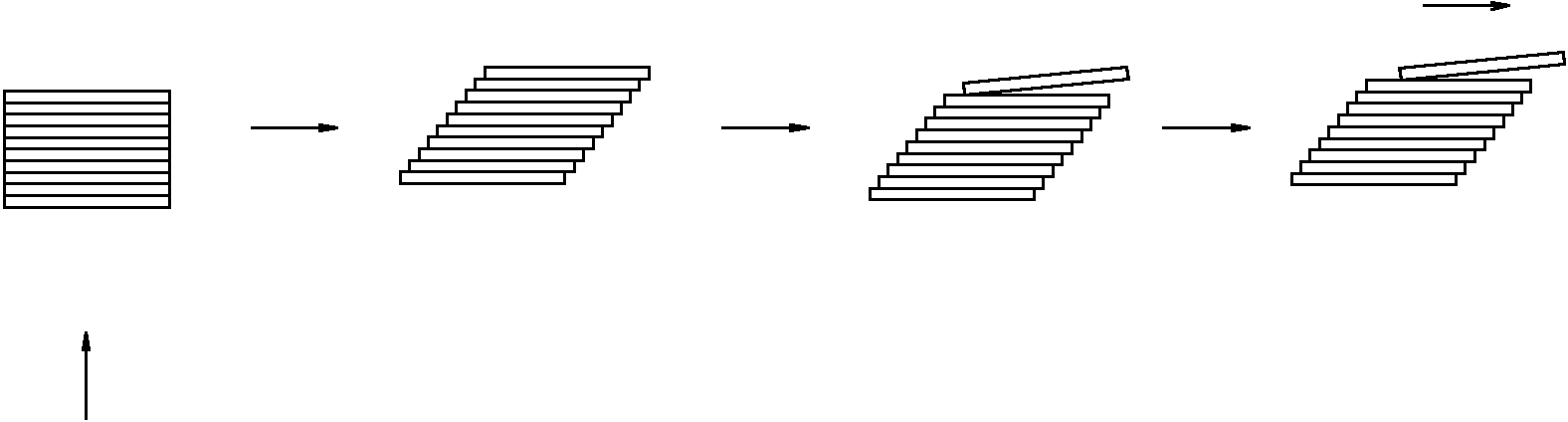

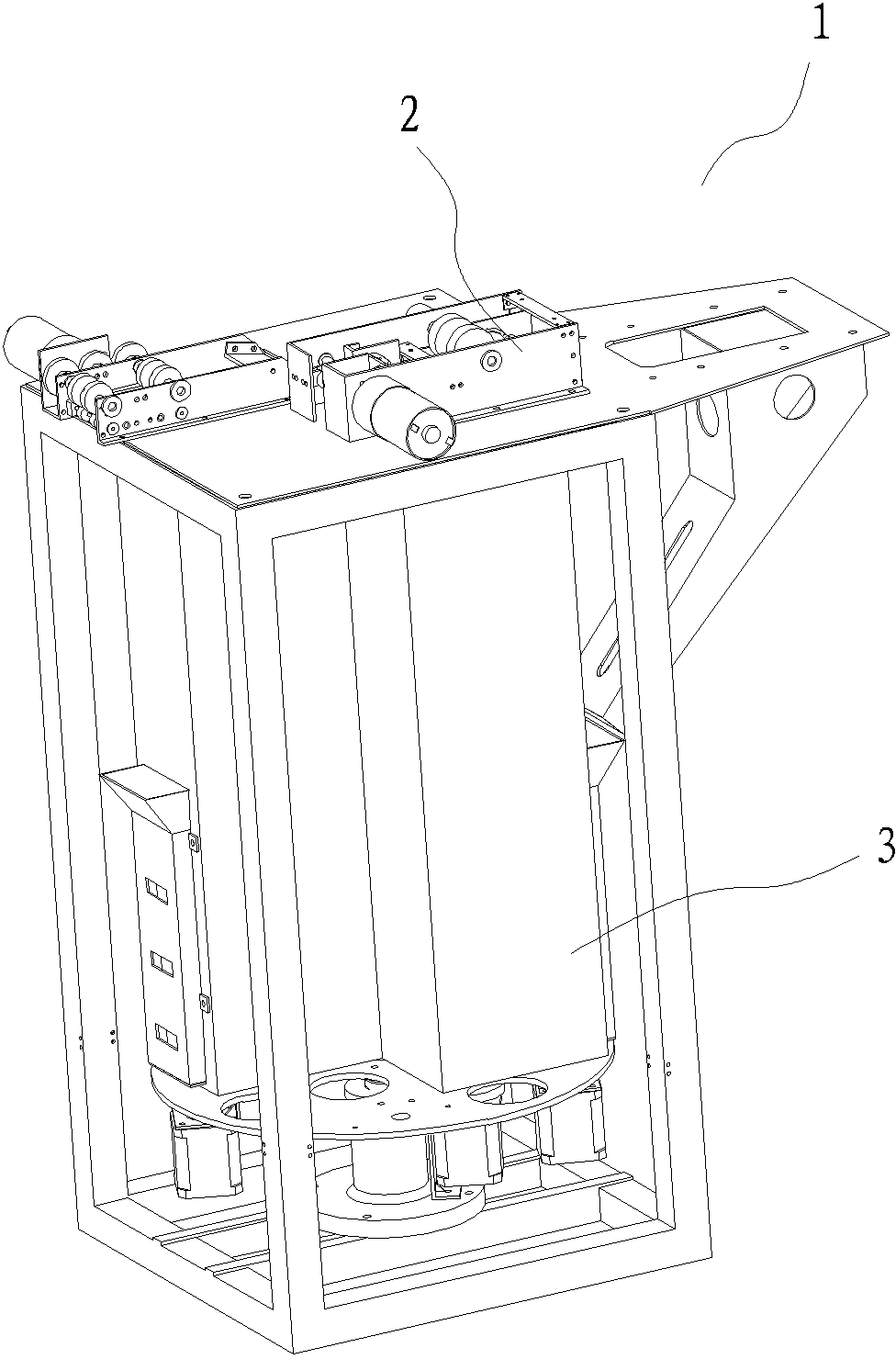

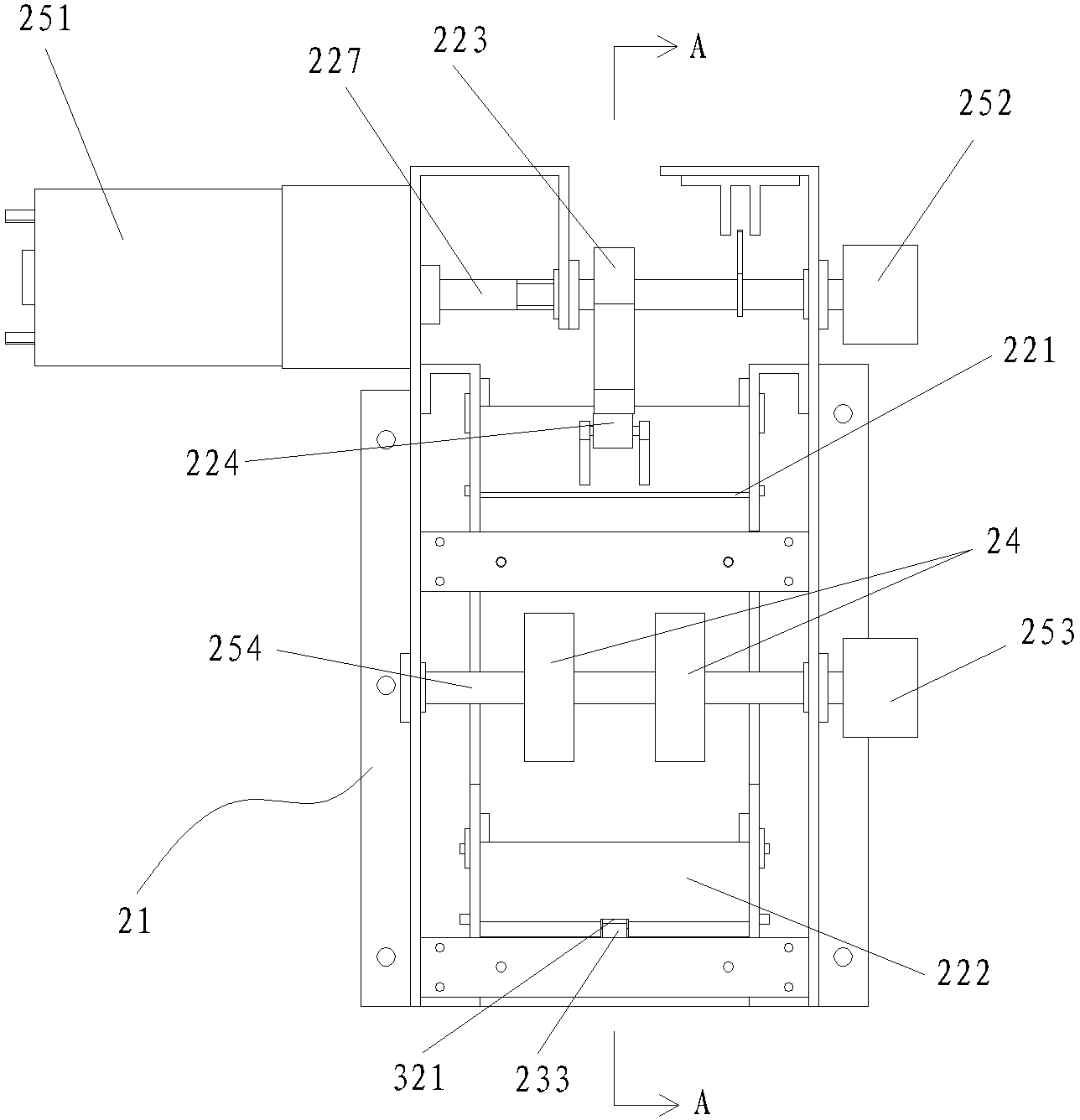

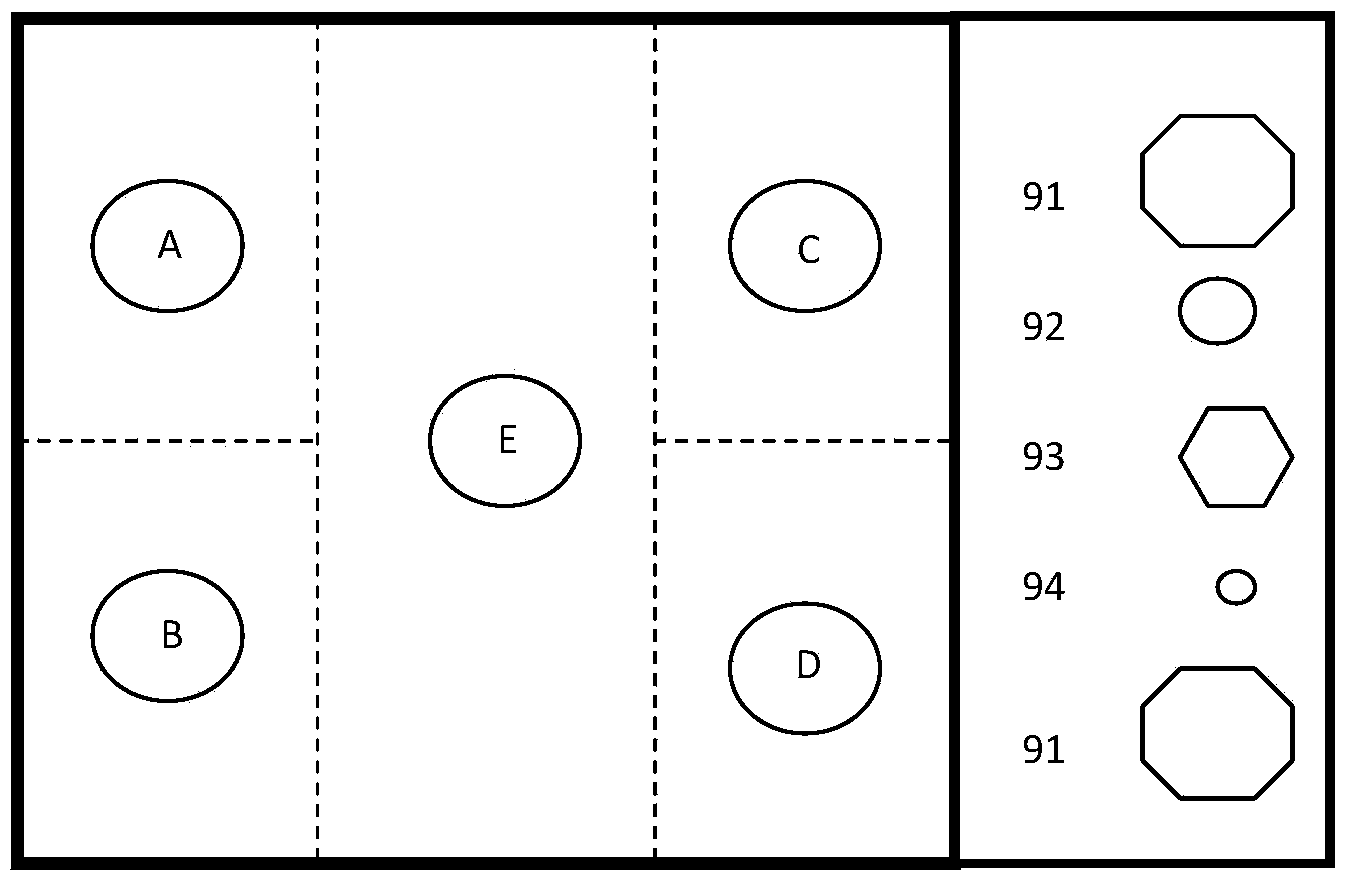

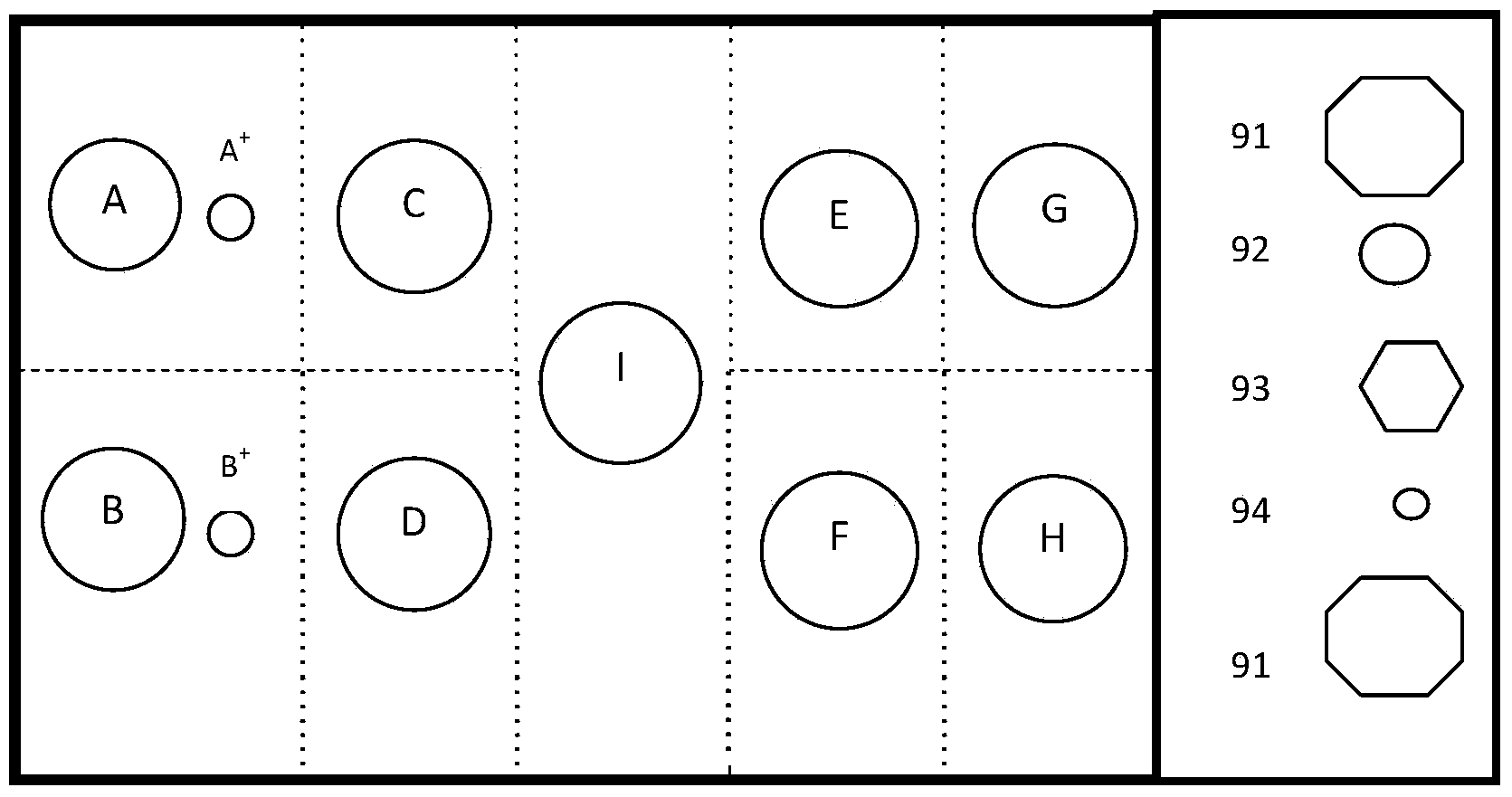

Card outlet method and device of card machine

ActiveCN103020663AReduce card rateLow failure rateConveying record carriersComing outComputer hardware

The invention discloses a card outlet method of a card machine. The card outlet method of the card machine includes the steps that (1) vertically superposed cards are distributed in a staggered mode by a card staggering mechanism, so that the cards are distributed in a stair-step shape; (2) one end of the uppermost card is jacked up and separated from the adjacent lower card so as to avoid adhesion; and (3) the uppermost card is fed into a card read-write area through a dragging mechanism so as to achieve card distributing operation. Simultaneously, the invention further provides a device using the card outlet method. By means of the method and the device, undesirable phenomena that the cards get stuck and excessively come out are mainly prevented, effects of separating the cards are achieved, thereby the card stuck rate of a card dispenser is greatly lowered, the fault rate of the card dispenser is reduced, maintaining times are reduced, the using efficiency is improved, and maintenance costs are lowered.

Owner:XIAMEN SAIMO JISHUO TECH CO LTD

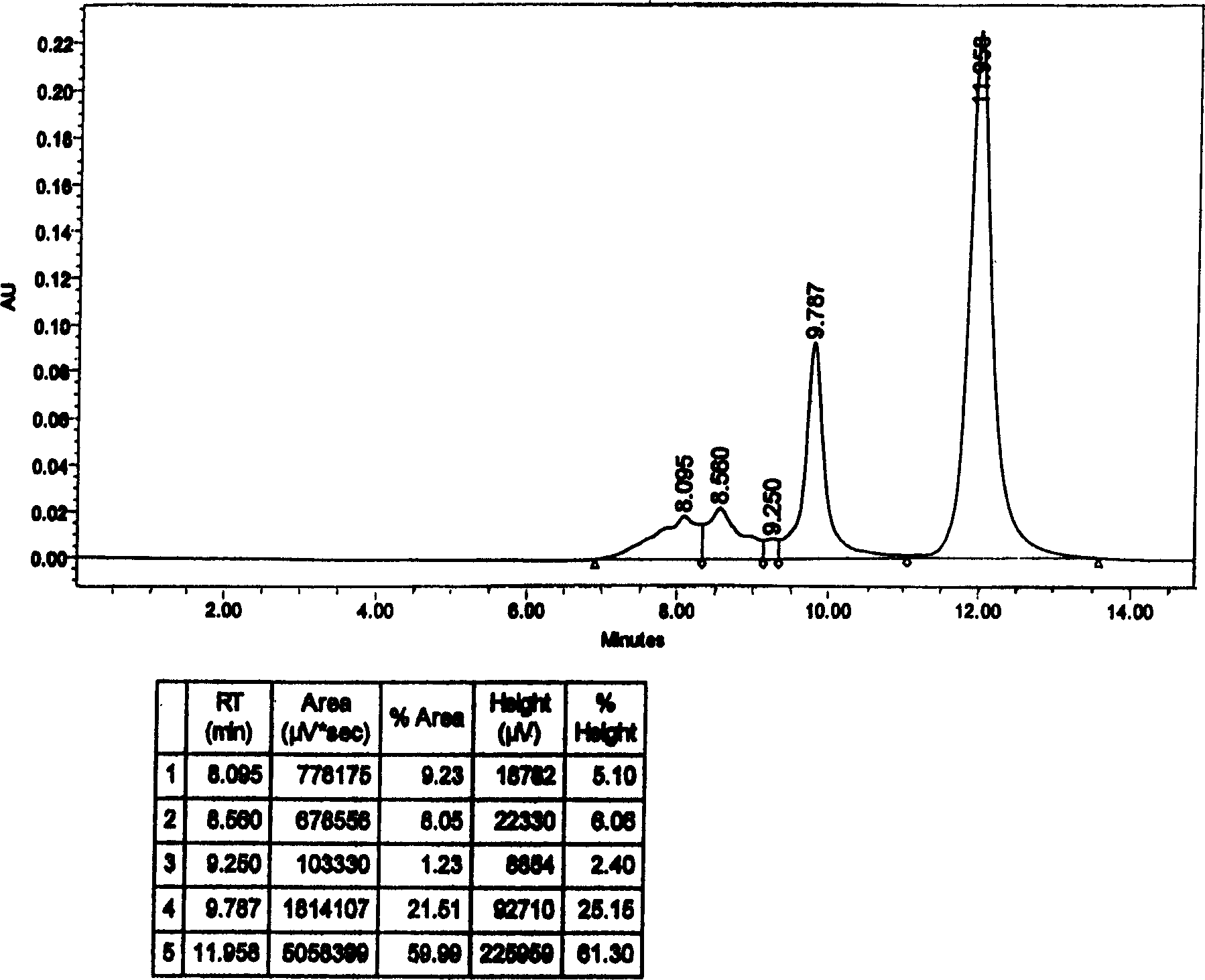

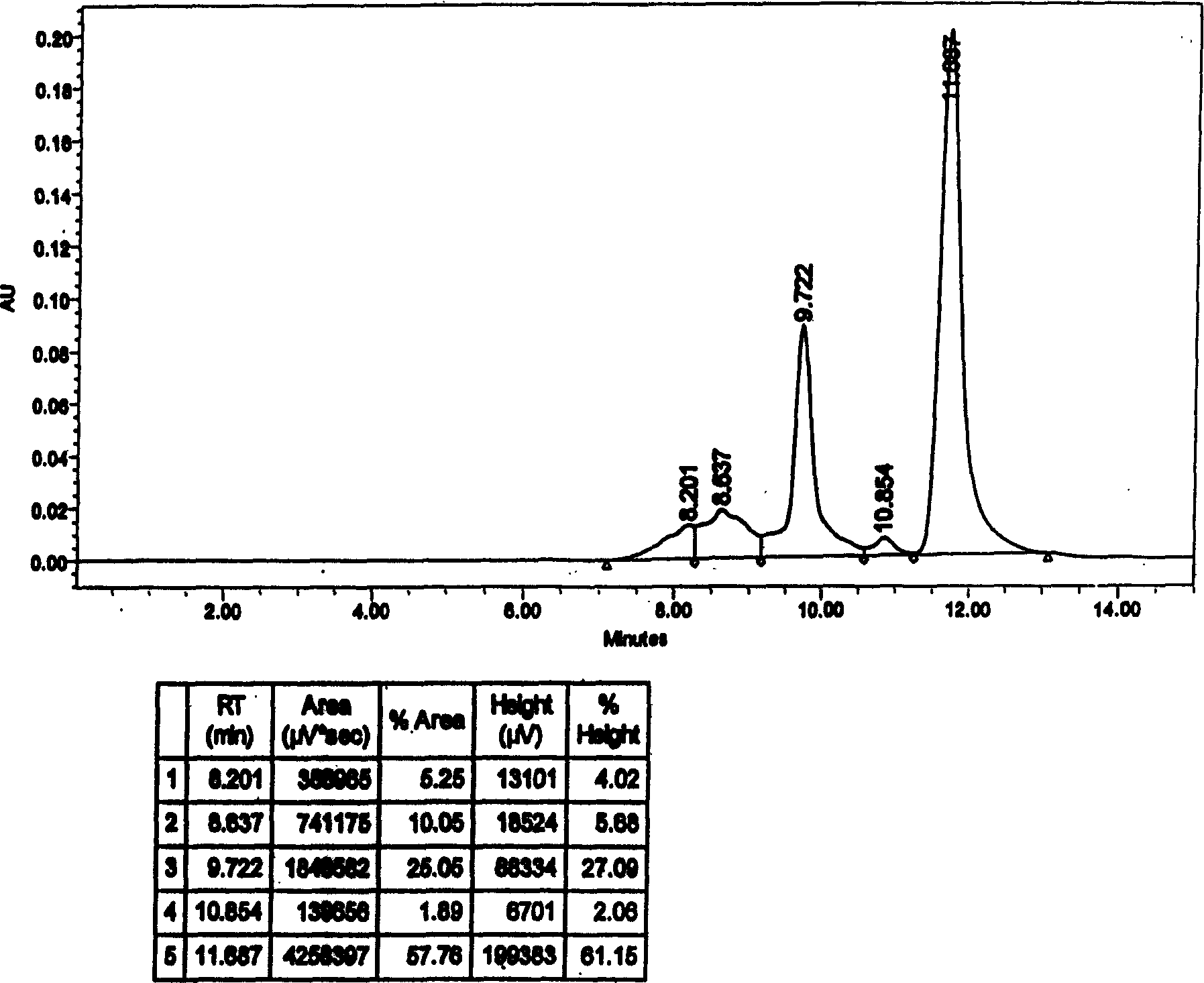

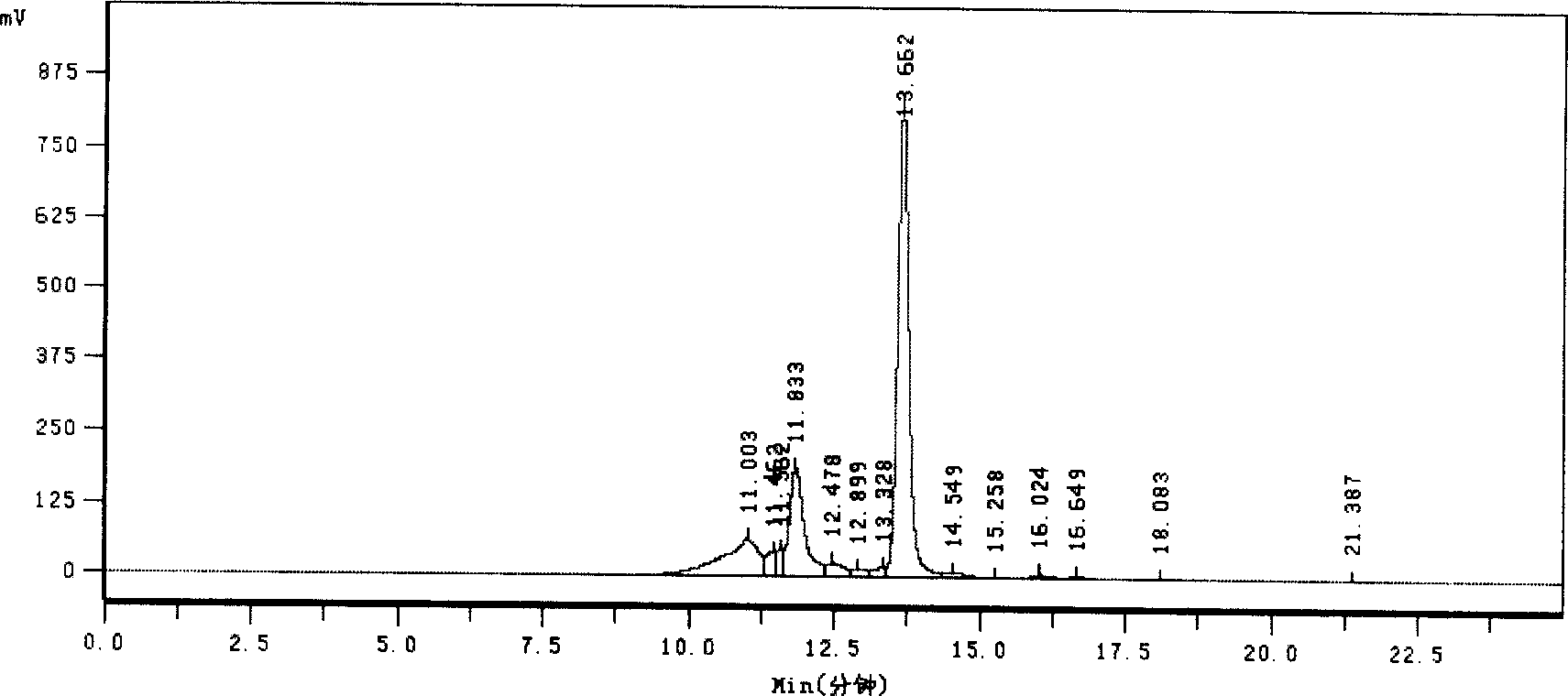

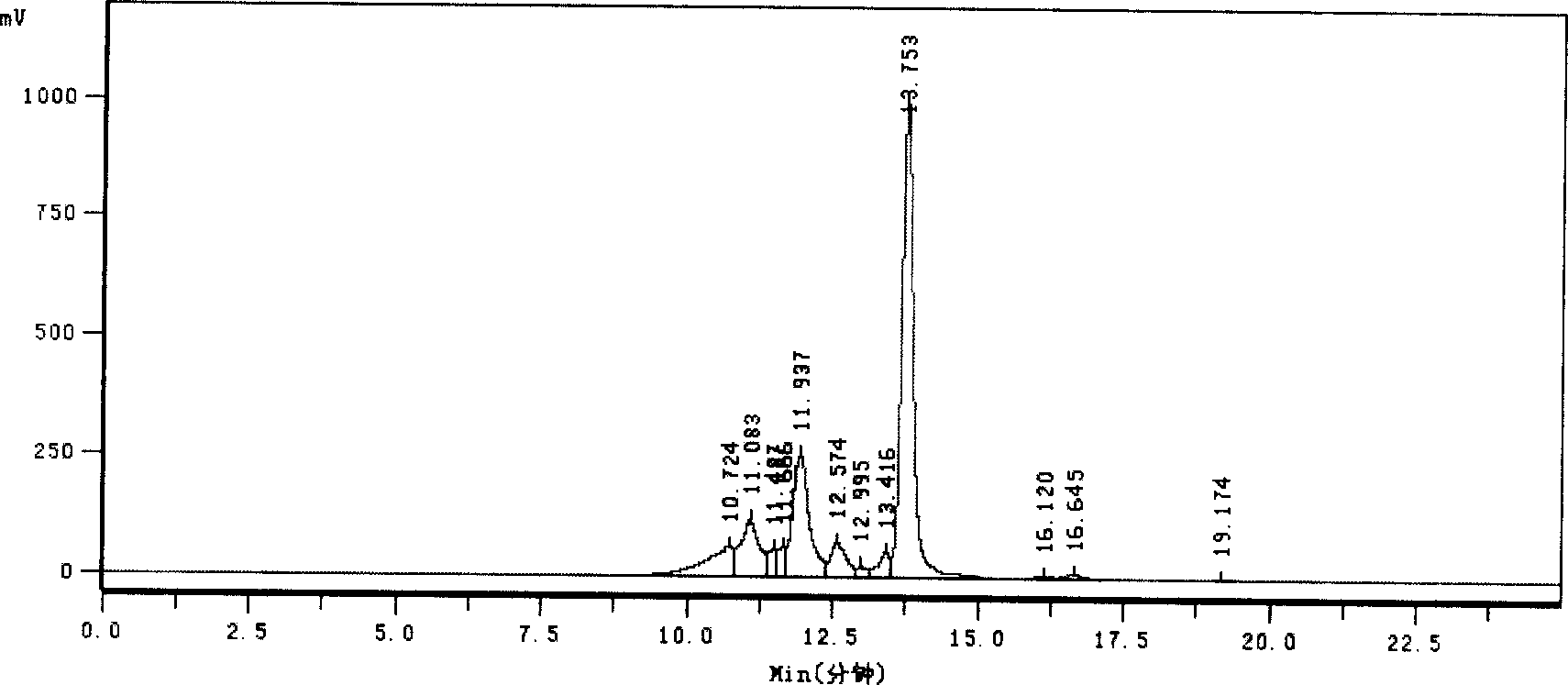

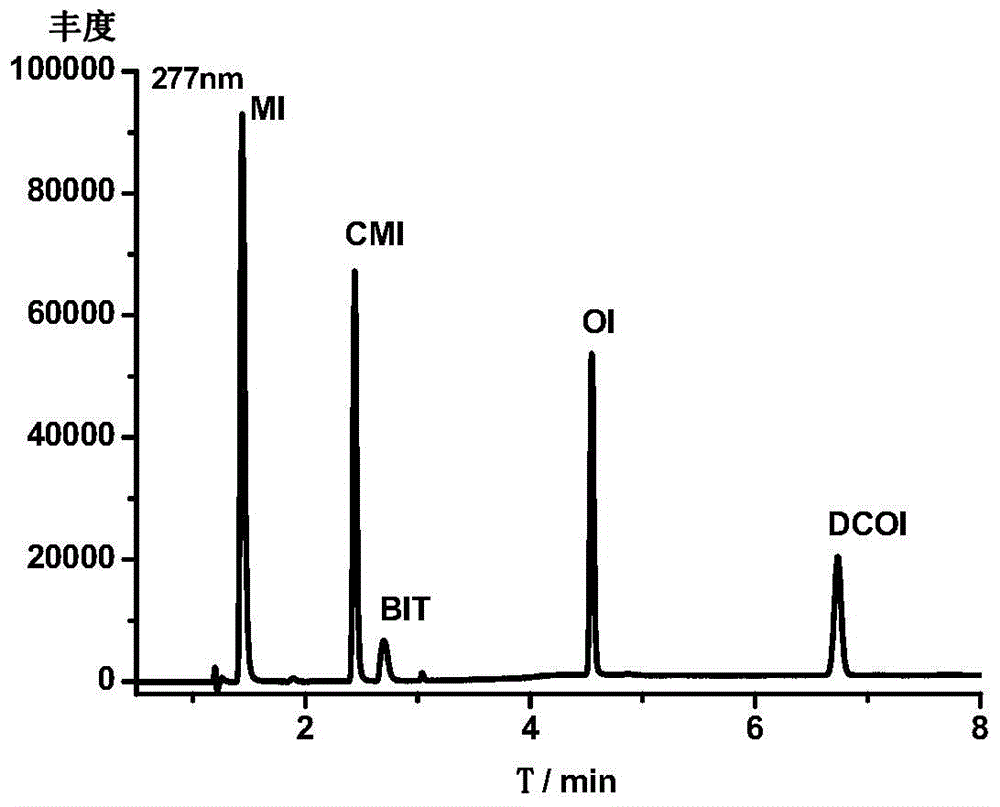

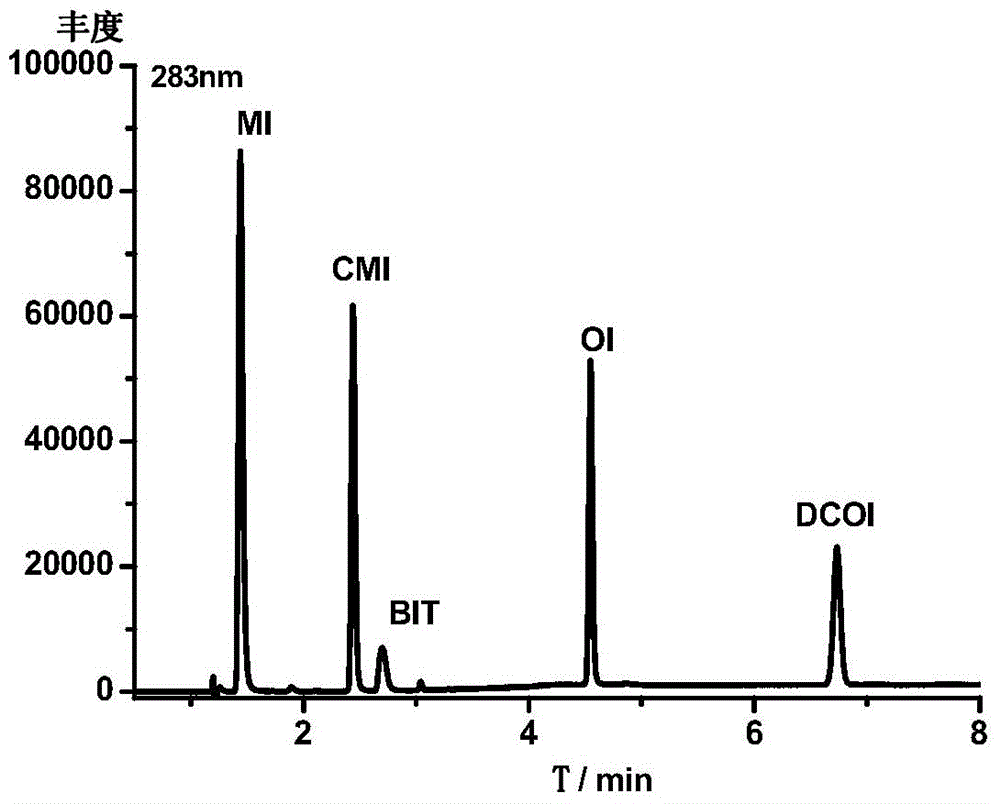

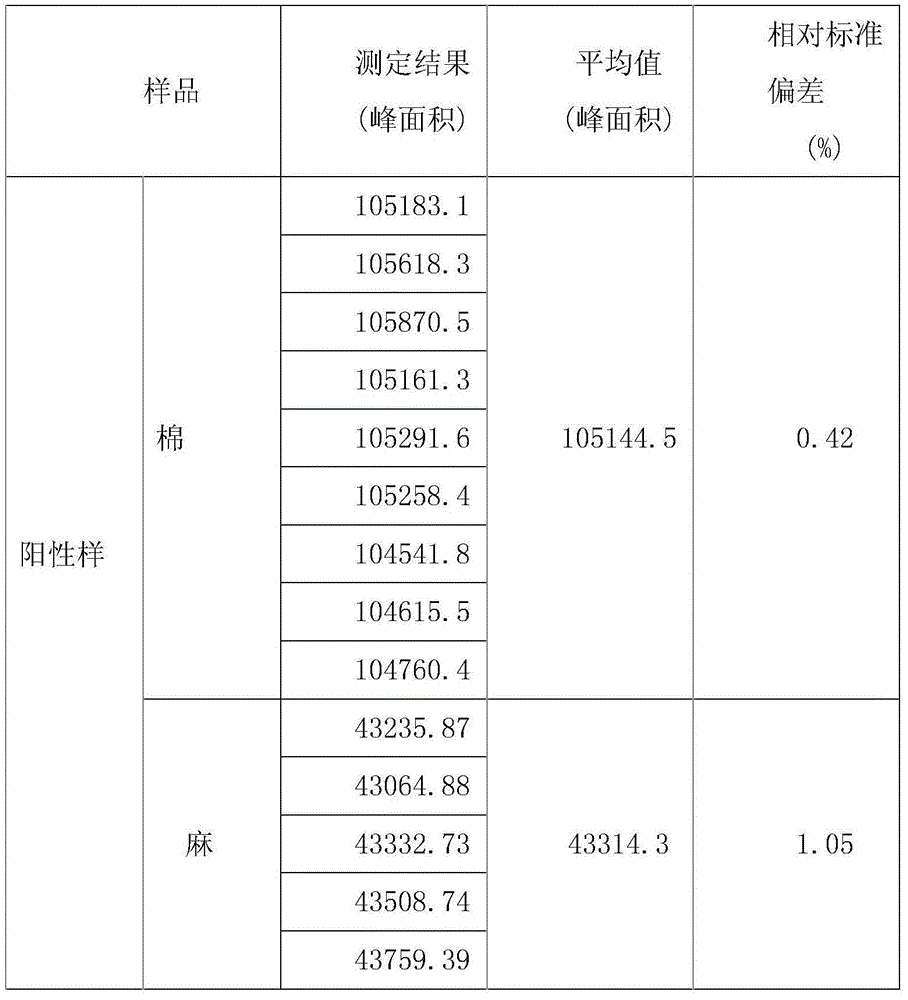

Method for measuring isothiazolinone antibacterial finishing agents in textiles

ActiveCN104991003AEfficient extractionGuaranteed reliabilityComponent separationIsothiazolinoneColumn temperature

The invention provides a method for measuring isothiazolinone antibacterial finishing agents in textiles, and relates to the field of product quality analysis, and discloses a method for separating and detecting the five isothiazolinone antibacterial finishing agents. The following liquid phase chromatographic conditions are adopted, and according to the liquid phase chromatographic conditions, a chromatographic column is XR-ODS (2.2 microns), the inner diameter is 100 mm*3.0 mm, column temperature is 40 DEG C, column flow speed is 0.4ml / min, a diode array detector is adopted, and detection wavelengths are 277 nm and 283 nm. According to the gradient elution conditions, the volume ratio of methanol to water is 40 to 60 for 0.00 min; the volume ratio of methanol to water is 90 to 10 for 1.90 min; the volume ratio of methanol to water is 90 to 10 for 6.00 min; the volume ratio of methanol to water is 40 to 60 for 6.01 min; 9.00 min. The five isothiazolinone antibacterial finishing agents are separated, a good baseline separation effect can be achieved, and peak types are sharp and symmetric.

Owner:SHENZHEN ENTRY EXIT INSPECTION & QUARANTINE BUREAU INDAL PROD INSPECTION TECH CENT

ZSM-5 molecular sieve filled silicon rubber/cellulose acetate composite membrane and preparation method thereof

InactiveCN101816897ALow priceTo achieve the separation effectSemi-permeable membranesCellulose acetateEvaporation

The invention relates to a ZSM-5 molecular sieve filled silicon rubber / cellulose acetate composite membrane and a preparation method thereof. In the composite membrane, a cellulose acetate support membrane is used as a support layer, and the composite membrane also comprises the following components in parts by weight: 2-20 parts of ZSM-5 molecular sieve, 3-15 parts of cross-linking agent and 100 parts of silicon rubber. The preparation method comprises the following steps of: preparing materials, pretreating the molecular sieves, preparing a membrane casting solution, pretreating the support membrane and forming a membrane. Compared with the prior art, a penetration and evaporation membrane is prepared by adopting the ZSM-5 molecular sieves, the silicon rubber and the cellulose acetate, and the composite membrane preferentially permeates aldehyde and can be used for removing the aldehyde in waste water by a pervaporation method so as to achieve a separation effect. The composite membrane has the advantages of small pollution, low energy consumption, high efficiency, and the like, and meanwhile, the composite membrane has higher selectivity and flux. Moreover, the membrane preparation process is reasonable and simple, and the selected materials have low price and low production cost, thus the composite membrane has wide application range.

Owner:TONGJI UNIV

Lobe separation equipment and method

ActiveCN102643018ATo achieve the separation effectSeparation process is easy to controlConveyorsGlass severing apparatusLiquid-crystal displayEngineering

The invention discloses lobe separation equipment and a lobe separation method and relates to the technical field of preparation of liquid crystal displays. The lobe separation equipment comprises a vibrating platform; and the vibrating platform is used for fixing at least one liquid crystal panel for lobe separation and drives the liquid crystal panel to vibrate, so that a glass substrate of the liquid crystal panel is cracked along a cutting crack. The equipment and the method have the beneficial effects that according to a vibration principle, the cutting crack on the glass substrate for forming the cutting crack fully extends along the thickness direction of the glass substrate to achieve the lobe separation efficiency, the separation process is easy to control, and no pollution and no damage can be caused to the liquid crystal panel.

Owner:BOE TECH GRP CO LTD +1

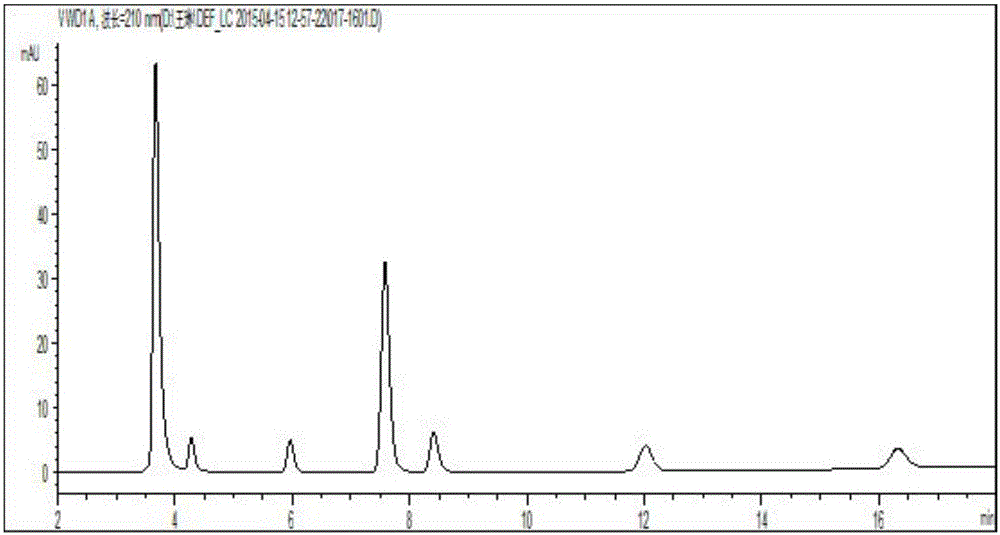

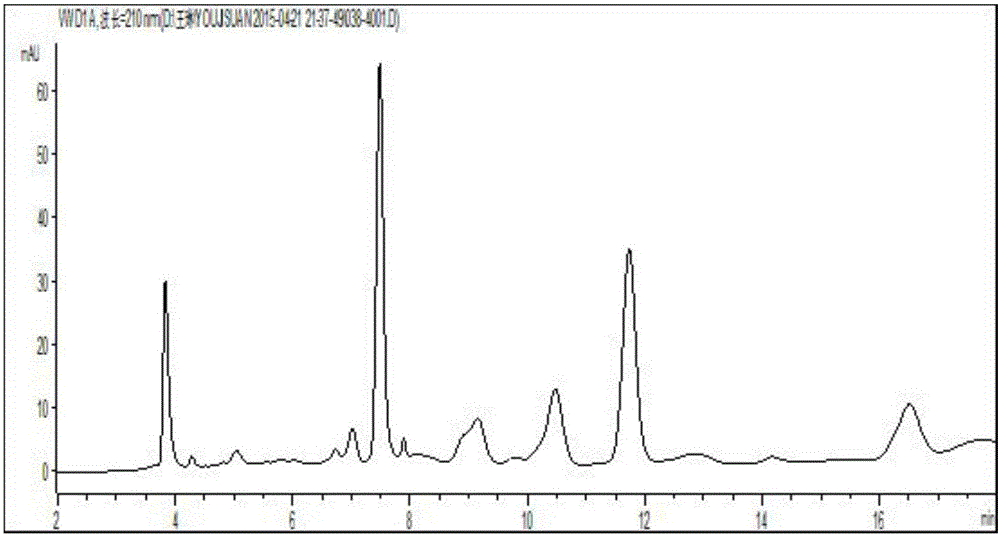

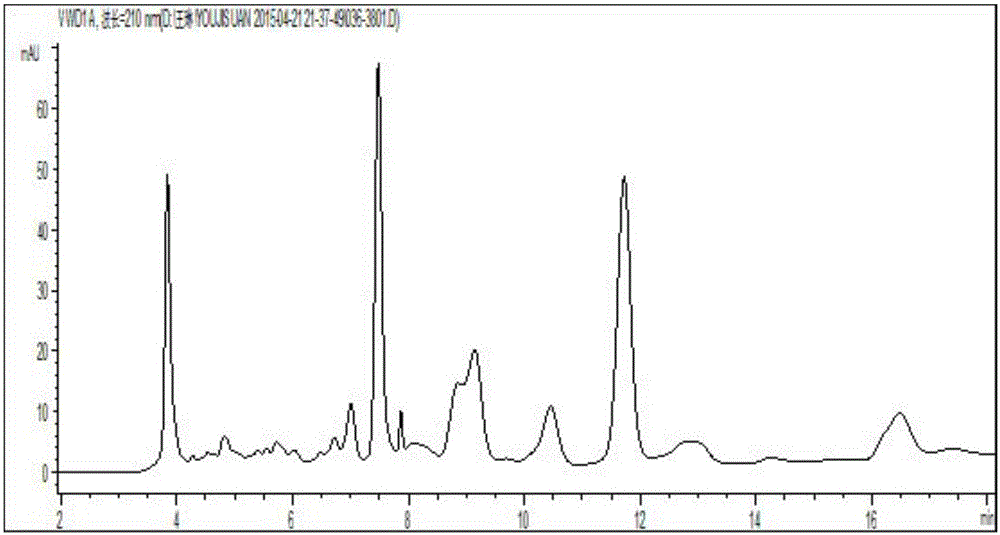

Method for measuring seven kinds of organic acid in rice wine by adopting solid-phase extraction-liquid-phase chromatogram method

ActiveCN105092739AEfficient removalTo achieve the separation effectComponent separationPreparing sample for investigationSolid phase extractionChromatography column

The invention discloses a method for measuring seven kinds of organic acid in rice wine by adopting a solid-phase extraction-liquid-phase chromatogram method and belongs to the technical field of rice wine detection. The method comprises the following steps that small positive ion solid-phase extracting columns are adopted for purifying samples to be measured, a moving-phase organic acid standard substance is adopted for carrying out preparation and treatment, before the samples are fed, a 0.22-micrometer or 0.45-micrometer filter membrane is adopted for filtering to obtain liquid to be measured. High-performance liquid chromatography detection is applicable to chromatographic columns of Xselect HSS T3(Waters) and IC PAKTM ION Exclusion types. The method can effectively eliminate interference to accurate analysis of the organic acid from impurities such as protein, amino acid, polysaccharide and pigment in a rice wine matrix, has the advantages of being high in measuring speed, high in accuracy and good in repeatability, and can be used for flavor quality control and analysis of the rice wine.

Owner:JIANGNAN UNIV

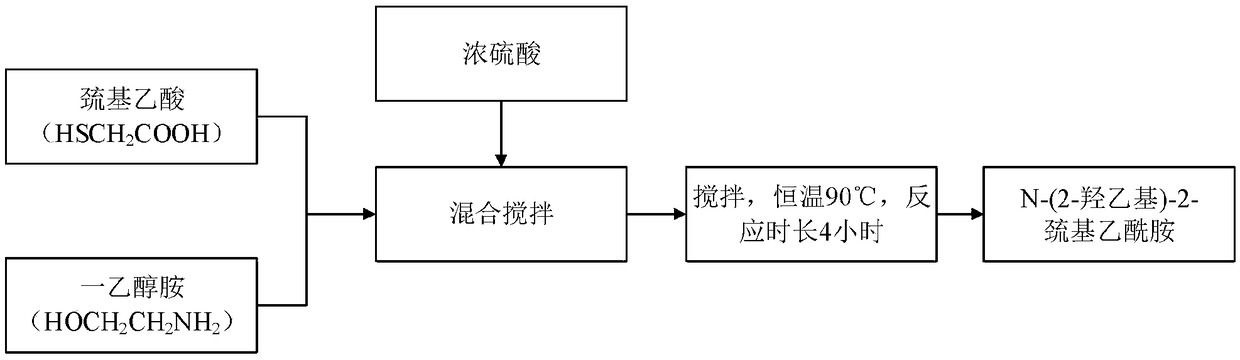

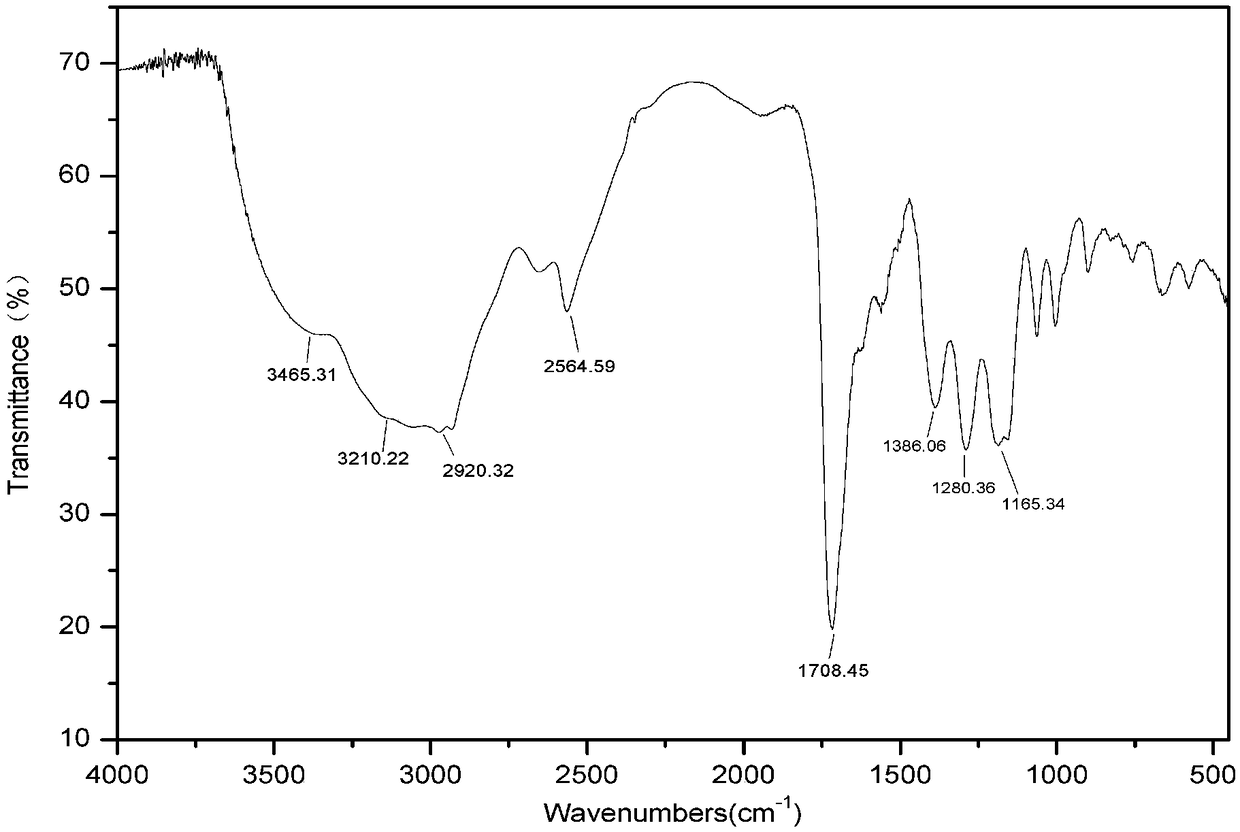

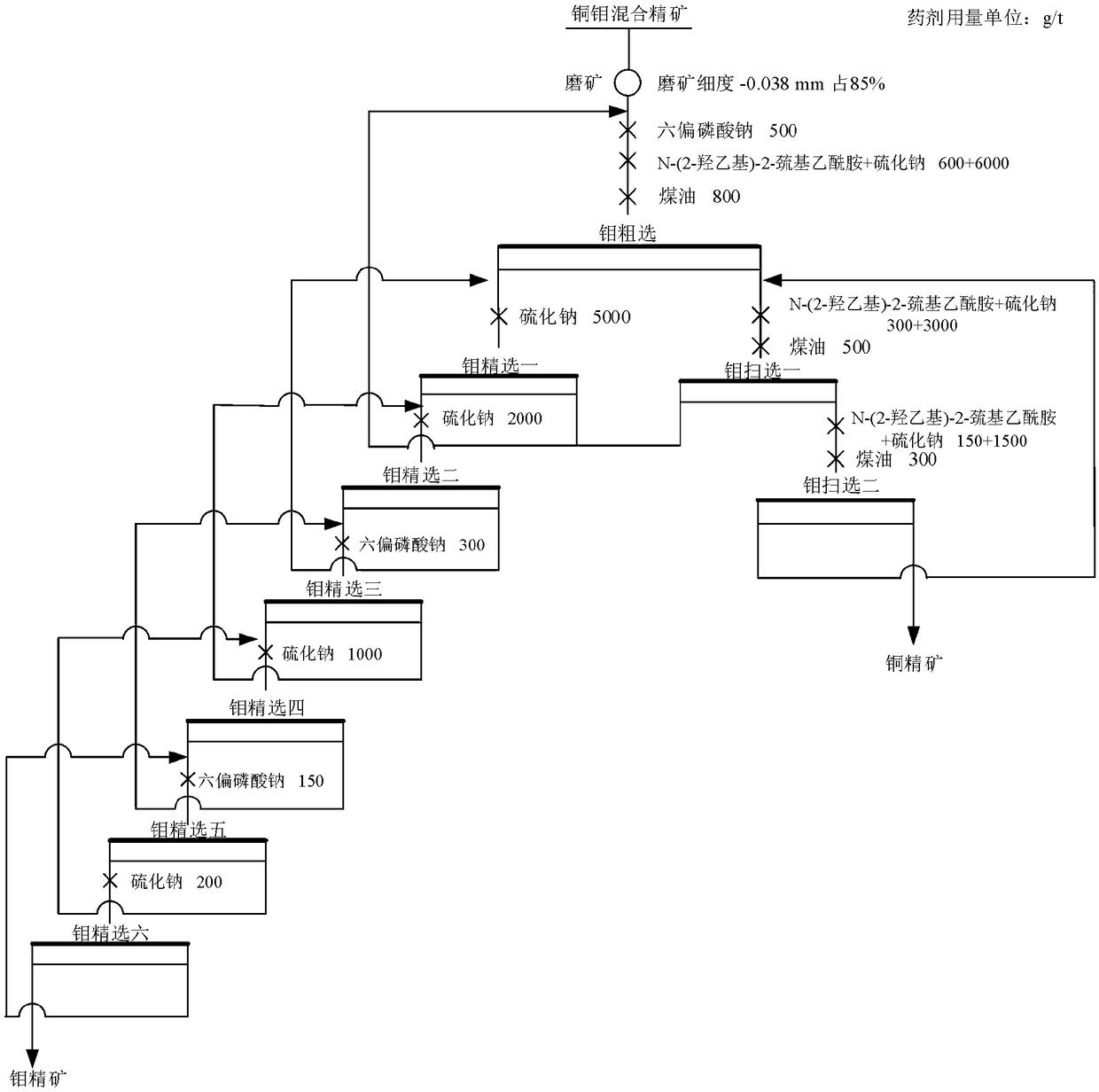

Preparation and application of copper-molybdenum separation inhibitor

The invention relates to preparation and application of a copper-molybdenum separation inhibitor. The preparation method of the inhibitor comprises the following steps that under a catalytic stirringcondition, the reaction of mercaptoacetic acid with monoethanolamine is carried out at the temperature of 90-100 DEG C, the reaction time is 4-5 hours, and the copper-molybdenum separation inhibitor,specially, N-(2-hydroxyethyl)-2-mercaptoacetamide which is subjected to dehydration condensation kneading is obtained; the application of the prepared copper-molybdenum separation inhibitor is characterized in that the copper-molybdenum separation inhibitor is applied to flotation separation of copper-molybdenum mixed concentrate, the N-(2-hydroxyethyl)-2-mercaptoacetamide is prepared, and strongparent-mine polar group (-SH) and hydrophilic polar group (-OH and -CONH) are provided, so that the copper ore can be effectively inhibited, and the copper and molybdenum separation is achieved; the inhibitor is simple in preparation method, remarkable in inhibition effect, less in use amount, free of pungent smell, stable in property, safety in addition and convenient to use; and the N-(2-hydroxyethyl)-2-mercaptoacetamide is matched with sodium sulfide to use so that the synergistic effect can be brought into full play, the copper-molybdenum separation precision is improved, and the method isparticularly suitable for flotation separation application of molybdenite and copper sulfide ore in the copper-molybdenum mixed concentrate.

Owner:ZIJIN MINING GROUP +2

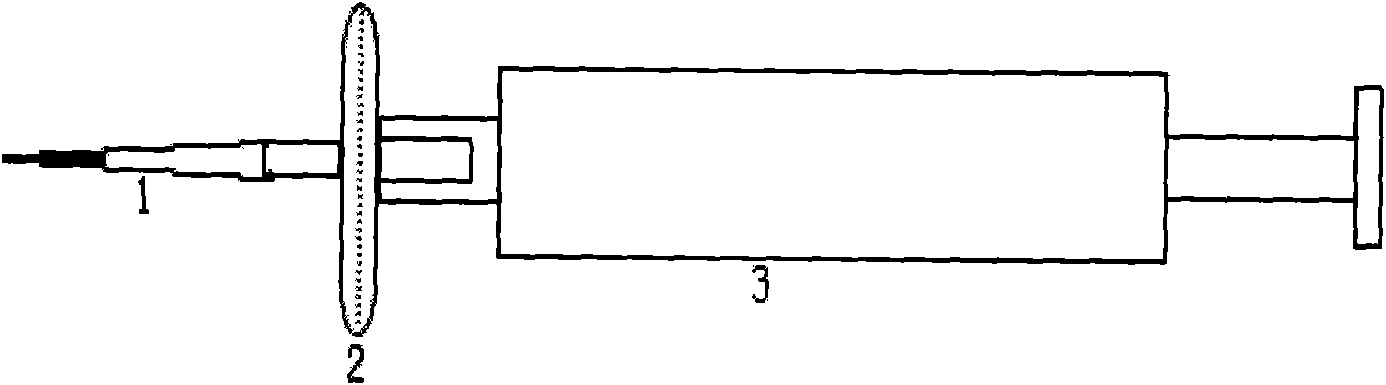

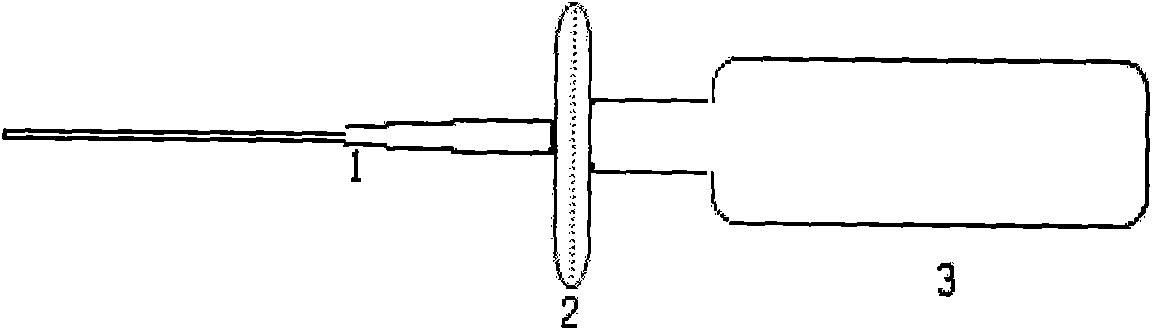

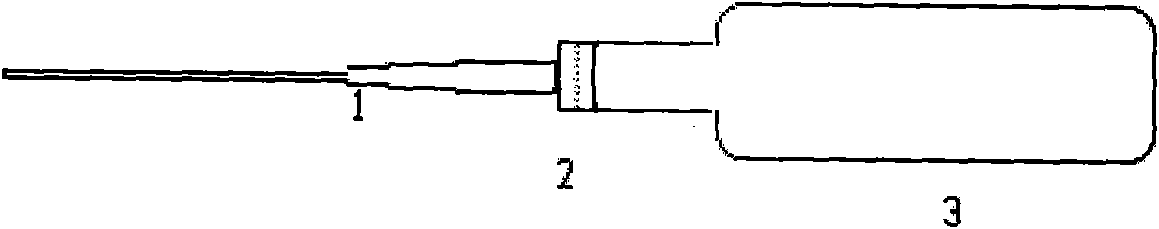

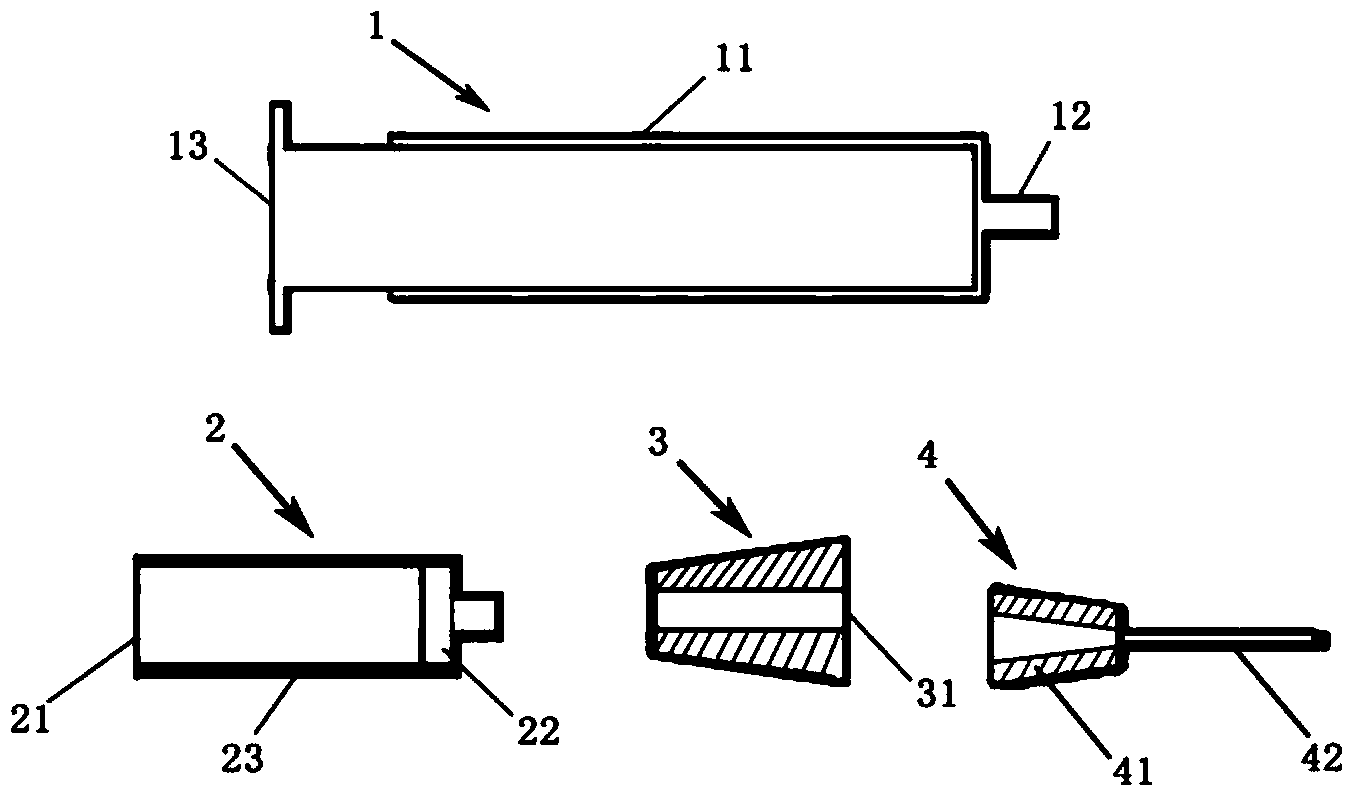

Tool box and kit for rapid extraction of nucleic acid, and method for rapid extraction of nucleic acid

ActiveCN104073429ASuitable for on-site operationTo achieve the separation effectBioreactor/fermenter combinationsBiological substance pretreatmentsLysisElution

The invention provides a tool box and a kit for rapid extraction of nucleic acid, and a method for rapid extraction of nucleic acid, which are mainly used for rapidly extracting nucleic acid (including RNA and DNA) from various clinical samples. According to the invention, a nucleic acid extraction device and a reagent are combined as an integrative device which mainly comprises an injection syringe, a hollow adaptor, a nucleic acid adsorbed film tube, a sample adding needle, various pipes for accommodating different reagents, a pipe frame and other parts; a pure nucleic acid solution for downstream experiments can be obtained through the following steps of lysis treatment on a clinical sample, suction by the injection syringe, adsorption of nucleic acid by a nucleic acid adsorbed film, rinse of the nucleic acid adsorbed film with a rinse liquid, elution of nucleic acid with an eluant, and the like.

Owner:INST OF PLA FOR DISEASE CONTROL & PREVENTION

Polyester for adhesive with adjustable viscosity and preparation method thereof

ActiveCN106928406ATo achieve the separation effectHigh glass transition temperatureGraft polymer adhesivesPolyesterPolymer science

The invention provides polyester for an adhesive with adjustable viscosity and a preparation method thereof. The number-average molar mass of the polyester for the adhesive is 10000-50000, the acid value is 1-5mg KOH / g and the hydroxyl value is 10-50mg KOH / g. The preparation method thereof comprises the following steps: firstly, performing esterification reaction on the combination of saturated dicarboxylic acid and unsaturated dicarboxylic acid and dihydric alcohol, and then performing decompression polycondensation, thereby acquiring a matrix resin, and lastly, performing grafting reaction on the matrix resin, namely, performing grafting reaction on the acquired matrix resin and the monomer containing an azobenzene structure, thereby acquiring the polyester. According to the invention, the photoinduced heterogeneous characteristic of azobenzene is utilized, so that the adhesion strength of the end product is reduced, the separating effect of the compound layer is achieved and the repeated reversible adhesion is realized.

Owner:中瀚新材料科技有限公司

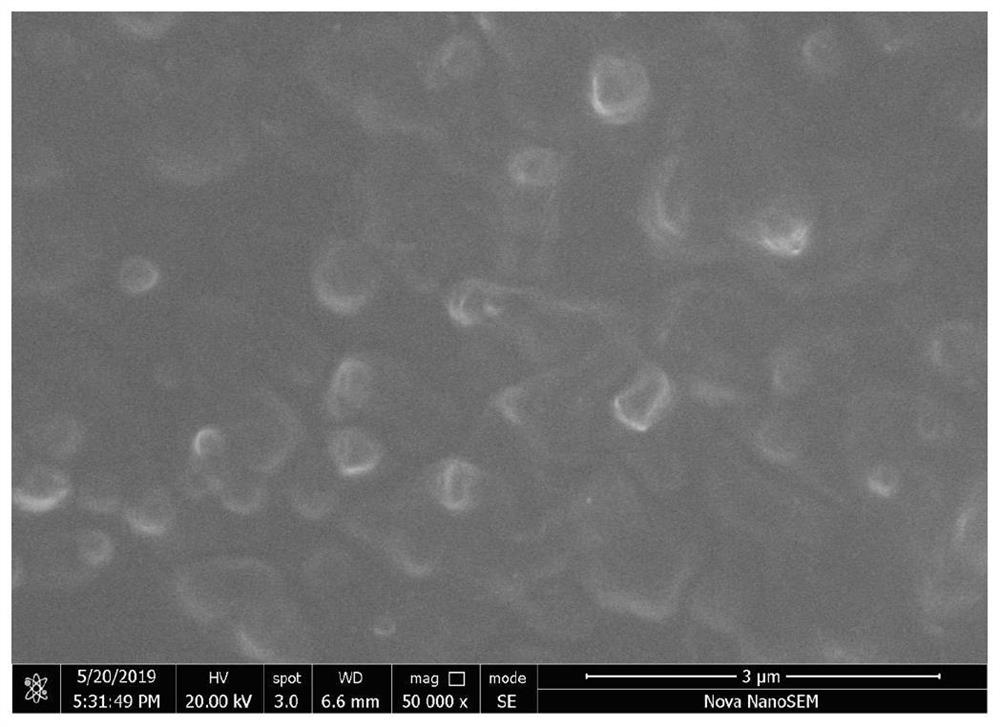

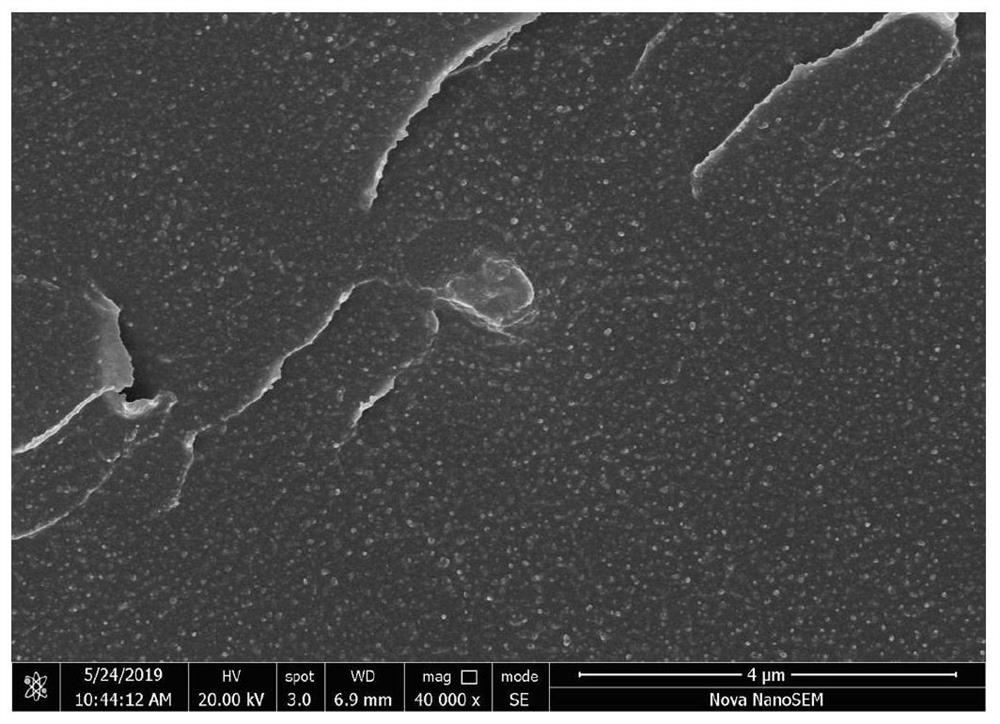

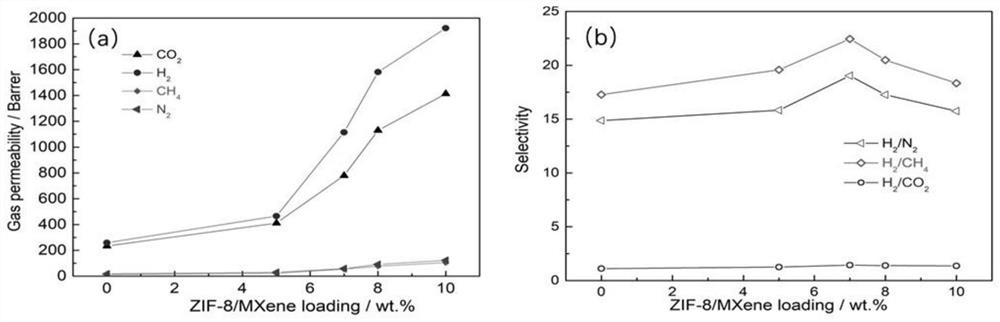

Mixed matrix membrane based on MXene/ZIF-composite material and preparation method

ActiveCN113083042AImprove permeabilityHigh selectivitySemi-permeable membranesDispersed particle separationPolymer sciencePolymer solution

The invention relates to the field of preparation of new materials, in particular to a mixed matrix membrane based on an MXene / ZIF-composite material and a preparation method, and the preparation method comprises the following steps: preparing an MXene material, preparing a ZIF-8 material, preparing a polymer solution and preparing the mixed matrix membrane. The invention provides a preparation method of the mixed matrix membrane for gas separation, which comprises the following steps: firstly compounding an MXene material and a ZIF-8 material to prepare a composite material, and then blending the composite material with a polymer to prepare the mixed matrix membrane. High selectivity and dimensional stability of an inorganic material and high permeability, mechanical stability and simplicity of a preparation process of a polymer material are combined.

Owner:DALIAN UNIV OF TECH +1

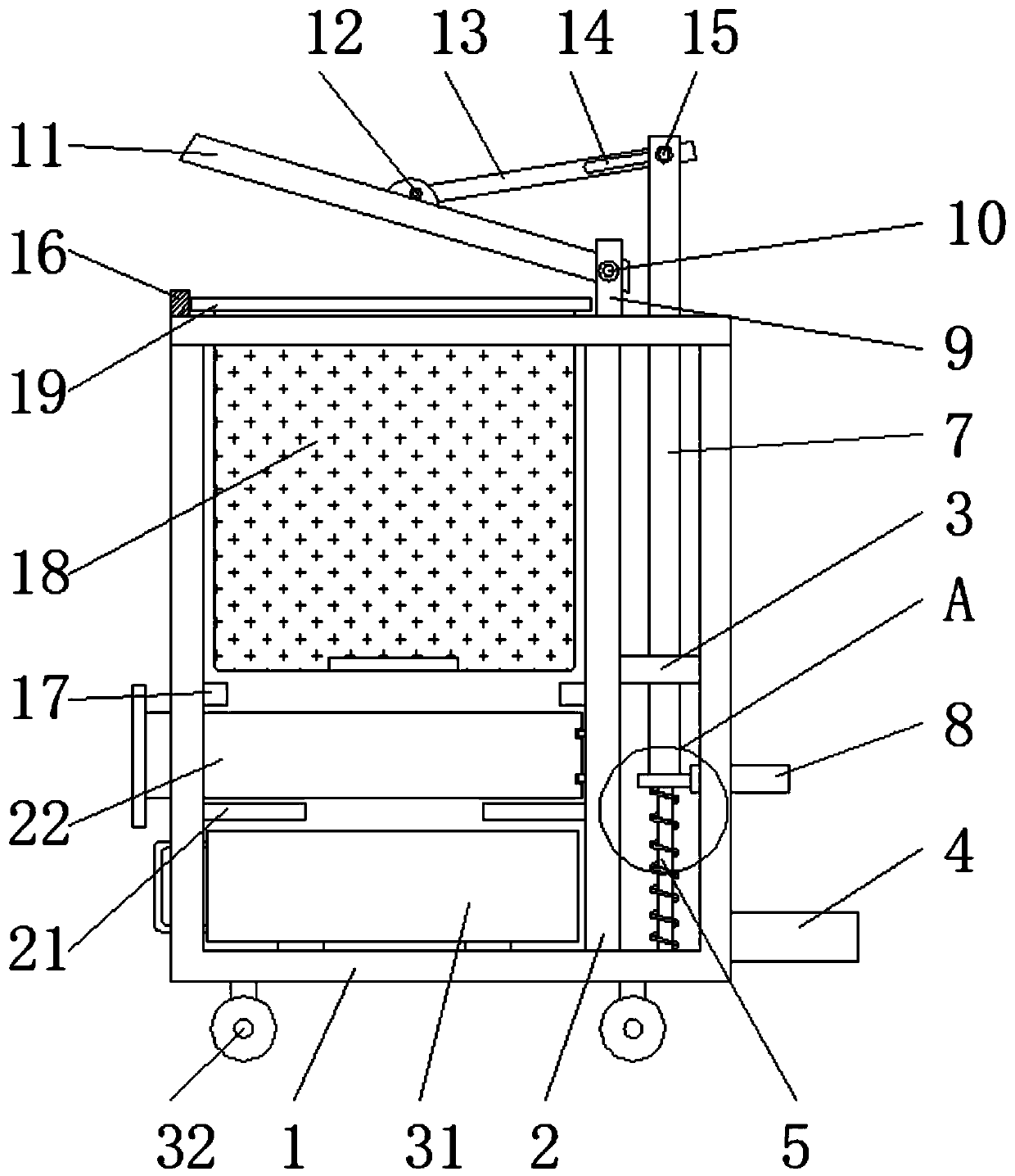

Garbage collecting and putting device for municipal construction

The invention relates to the technical field of municipal construction, and discloses a garbage collecting and putting device for municipal construction. A device partition board is fixedly arranged in a garbage outer box, the top and the bottom of the device partition board are fixedly connected with the top and the bottom of the inner wall of the garbage outer box, a limiting casing plate is fixedly arranged on the right side of the device partition board, and a positioning pedal plate is fixedly arranged on the bottom of the right side of the garbage outer box. According to the garbage collecting and putting device for municipal construction, the outer casing rod is driven by the pedal plate to carry out downward pressing, then, the length of an inner shrinkage rod inserted into the outer casing rod is increased, a sliding groove and a box cover plate are driven to pull a can cover open, the contact with garbage equipment through hands can be avoided, the bacterium pollution on thegarbage in a garbage device is reduced, safety of the garbage device is improved, meanwhile, the phenomenon that the hand of a worker is full of garbage, and cannot open the garbage device is avoided,the defect that a worker needs to open the can cover through the hand, and sanitation is poor is avoided, and the effect that the garbage collecting and putting device is tread, and the can cover isopened can be achieved.

Owner:徐超

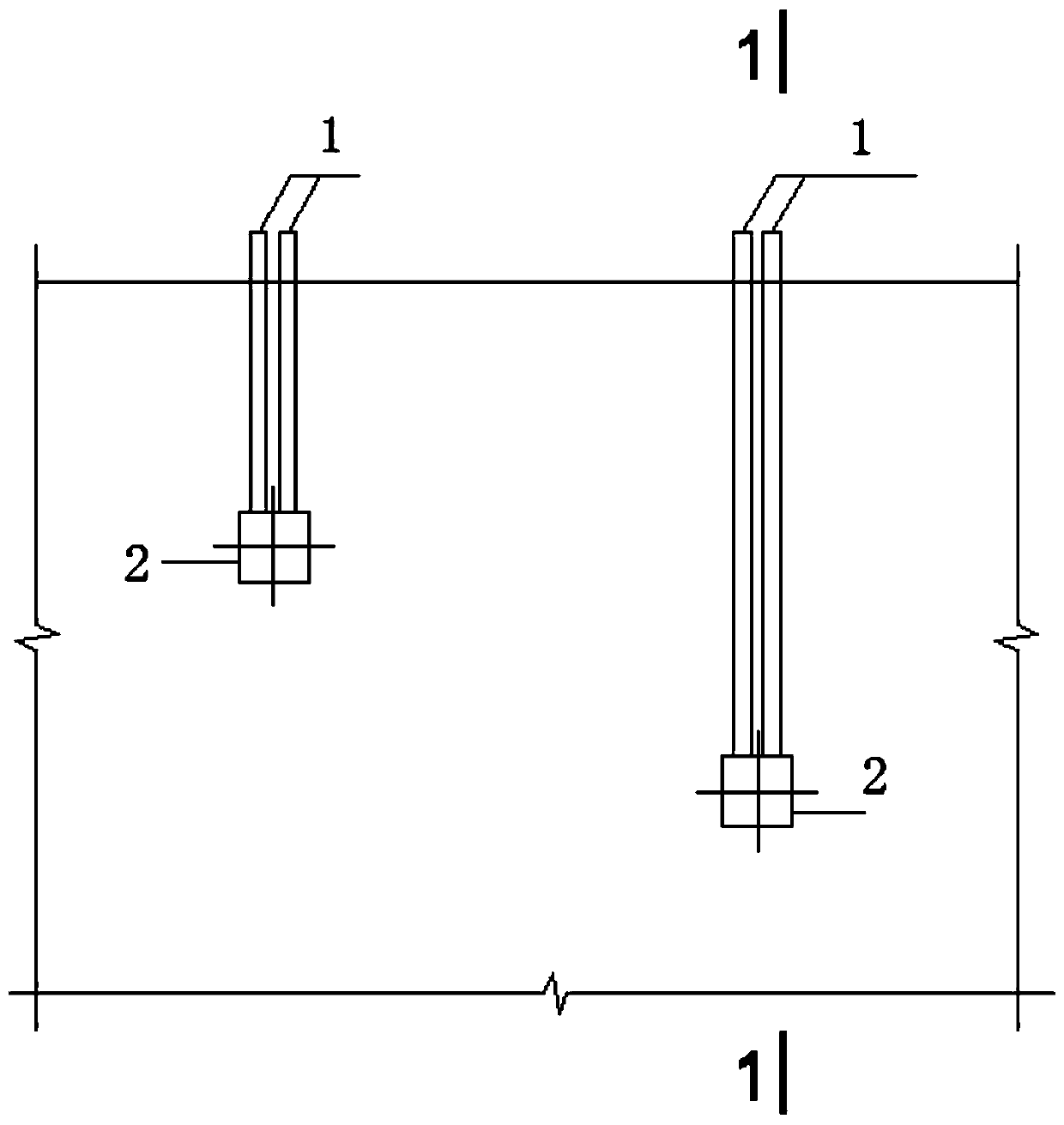

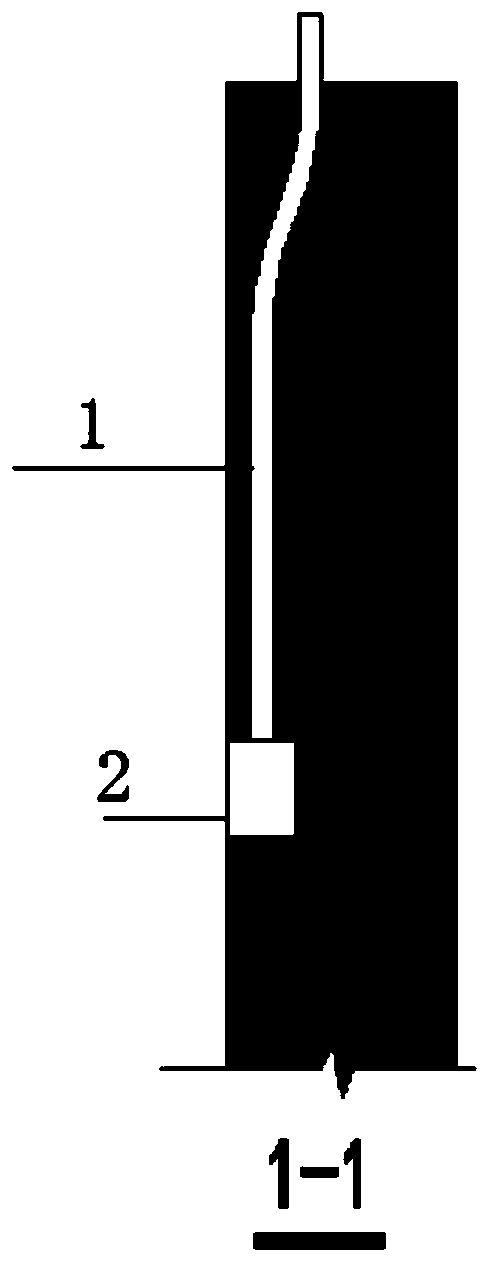

Embedded machine wire box structure and method of prefabricated panel

PendingCN111441531AAvoid misalignmentAvoid the situationElectrical apparatusCeramic shaping apparatusLine tubingStructural safety

The invention relates to an embedded machine wire box structure of a prefabricated panel. The structure comprises a casing pipe and at least one pipeline, the pipeline penetrates through the side wallof the casing pipe and extends into the casing pipe, a combined embedded part is formed, the combined embedded part is embedded in a prefabricated panel, the casing pipe is transversely mounted, thepipeline is longitudinally mounted, the casing pipe connects with the inner side of the prefabricated panel, the inner diameter of the casing pipe is larger than the outer diameter of a wire box prepared to be connected with the pipeline, a system finished product embedded part composed of the pipeline and the casing pipe is adopted, the casing pipe can avoid conditions of wire box deviation and inclining and the like during factory embedding, wire box positioning can be effectively adjusted in the casing pipe area on site, positioning accuracy is ensured, meanwhile, the casing pipe can ensurethat the construction site does not need to do work of wall chiseling and the like, it is ensured that during construction, a main structure is not damaged, and structure safety is ensured.

Owner:上海紫宝住宅工业有限公司

Rice bran oil dewaxing process

InactiveCN103773602AHigh wax contentTo achieve the separation effectFatty-oils/fats refiningEdible oils/fatsFiltrationPressure difference

The present invention discloses a rice bran oil dewaxing process, wherein the rice bran oil has the high wax content, and a dewaxing and degreasing double-stage winterization process is adopted. According to the process, the dewaxing process temperature is about 16-18 DEG C, and the degreasing process temperature is about 5 DEG C, such that the bran wax has the low oil content; after crude oil is heated, the solid impurity is removed through filtration with a fine filter, and the obtained material enters a crystallization tank to carry out crystallization and crystal cultivating; and the heat of the edible oil is replaced through a refrigerant with a freezer so as to achieve solid-liquid separation of the bran wax crystal and the edible oil, the high position tank high position pressure difference is adopted so as not to break the crystal grains, and the press-in thermal unloading type filter is adopted to carry out solid-liquid separation so as to achieve the large-scale production mode.

Owner:BEIJING ZHONGTIAN JINGU GRAIN OIL ENG TECH

Solid-liquid separator

The invention discloses a solid-liquid separator which comprises a first separation box and a second separation box, wherein a feeding pipeline is arranged at the top of the first separation box; a top cover is arranged at the top of the feeding pipeline. The solid-liquid separator provided by the invention achieves the separation effect by arranging the first separation box, in which a first separation shaft and a second separation shaft are arranged to separate water possibly contained in solid; the solid and the liquid can be separated secondarily through a pinion wheel arranged inside the second separation box, to achieve a better separation effect; the solid and the liquid in the first separation box can be separated by arranging a first filter plate; the first filter plate is inclined, so that the solid is preferably discharged from a first outlet and filter residues cannot block a filter opening; the solid and liquid can be separated more thoroughly by arranging a second filter plate and a third filter plate in a machine body in a beveling manner, so that the filter residues do not block filter holes.

Owner:成都君华睿道科技有限公司

Water conservancy desilting device with high using efficiency

InactiveCN108203998AGuaranteed efficiencyPrevent fallingMechanical machines/dredgersSlurry pumpEngineering

The invention discloses a water conservancy desilting device with the high using efficiency. The water conservancy desilting device comprises a ship body, a silt storing tank is arranged at the axis of the top of the ship body, a silt and water separating device is fixedly connected to the right side of the top of the ship body, a silt outlet pipe is connected to the bottom of the left side of thesilt and water separating device in a communicating mode, and the end, far away from the silt and water separating device, of the silt outlet pipe extends into the silt storing tank. According to thewater conservancy desilting device with the high using efficiency, the effect of removing silt in an adsorption mode can be achieved by arranging a slurry pump, the effect of separating the silt andwater is achieved through the silt and water separating device, the effect of removing the silt and sundries in an adsorption mode can be achieved through a second adsorption pipe and a second adsorption port, the effect of removing the silt in an adsorption mode can be achieved through a first adsorption pipe and a first adsorption port, the effect of removing the sundries is achieved through anelectric telescopic rod, the effect of collecting the sundries is achieved through a collecting block and a collecting cavity, therefore, the condition that the silt and the sundries block a pipelineis avoided, and the desilting efficiency is guaranteed.

Owner:WUXI AOYUTE NEW TECH DEV

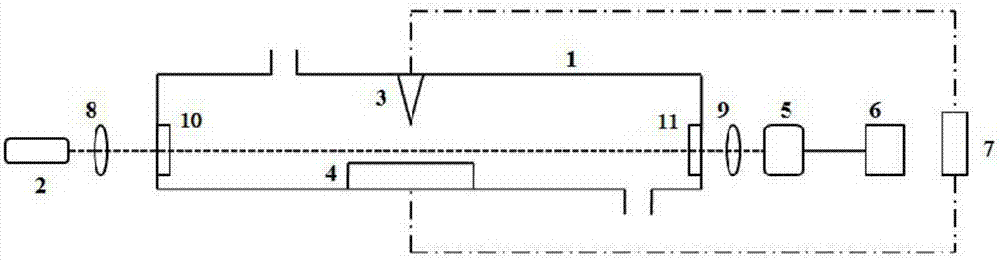

Device for real time online monitoring concentration of SO3 gas in flue gas

ActiveCN107976403ATo achieve the separation effectReal-time online analysisColor/spectral properties measurementsElectrical field strengthFlue gas

The invention discloses a device for real time online monitoring the concentration of SO3 gas in flue gas. A light source, a collimation lens, a gas absorption pool, a focusing lens, a photoelectric detector and data processing equipment are arranged in sequence from left to right, wherein the top inner wall of the gas absorption pool is provided with a first electrode; the bottom inner wall of the gas absorption pool is provided with a second electrode; the first electrode and the second electrode are connected with a power supply. The device has the beneficial effects that a non-uniform electric field is coupled into the gas absorption pool, and SO2 and H2O molecules are enriched in an area with high electric field intensity, so that the effect of separating the SO3 gas is achieved. Theabsorption characteristic peaks of the SO3 gas in the flue gas under a non-uniform electric field environment are scanned by laser light of corresponding wavebands to obtain a high-fineness absorptionspectrum of the gas, and high-accuracy real-time online analysis of the SO3 gas is performed by relevant technical means such as TDLAS (Tunable Diode Laser Absorption Spectroscopy).

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com