Coarseness and fineness integrated iron ore hydraulic pulverizer

An iron ore and pulverizer technology, applied in cocoa, grain processing, food science and other directions, can solve the problems of inability to effectively control the gap of the pulverizing actuator, and the ore pulverization is not uniform and thorough, so as to improve the pulverization effect, increase the The effect of the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

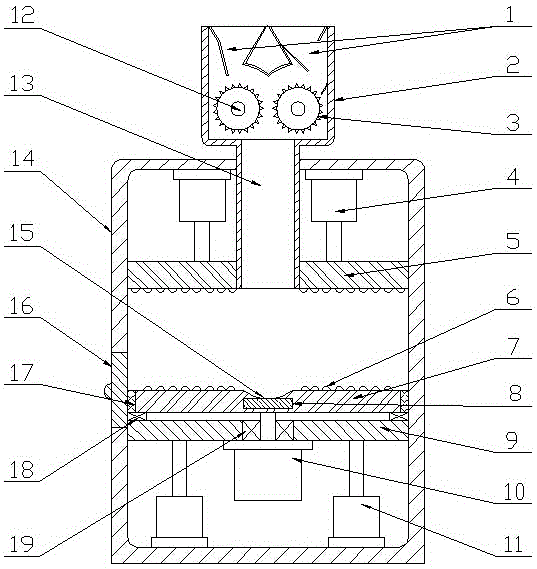

[0027] as attached figure 1 As shown, a coarse and fine integrated iron ore hydraulic pulverizer of the present invention has a structure including a coarse crushing chamber 2 and a fine grinding and crushing chamber 14, the coarse crushing chamber 2 is located at the upper part of the fine grinding and crushing chamber 14, and the top of the coarse grinding chamber 2 is set There are two feed ports 1 and 1, and the bottom discharge port of the coarse grinding chamber 2 communicates with the fine grinding and crushing chamber 14 through the discharge channel 13 .

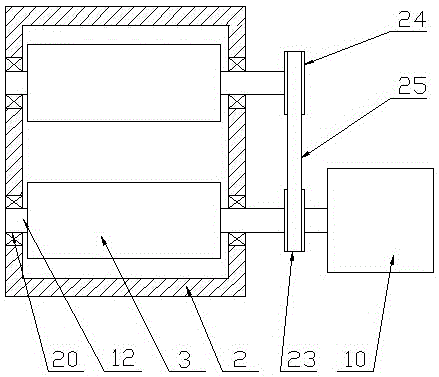

[0028] as attached figure 1 , 2 , 3, two coarse crushing wheels 3 are arranged parallel and horizontally in the coarse crushing chamber 2, and the wheel shaft 12 of the coarse crushing wheel 3 is installed on the two opposite side walls of the coarse crushing chamber 2 through bearings 220, and the fine grinding crushing chamber 14 is provided with a coarse crushing motor 21, which is installed on the upper side w...

Embodiment 2

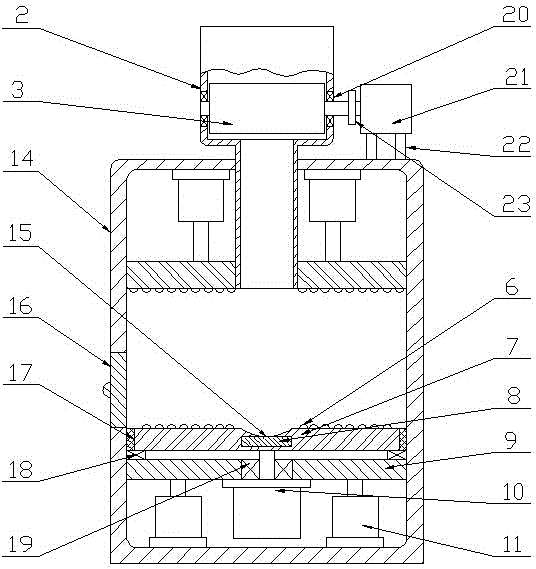

[0032] as attached figure 1 As shown, a coarse and fine integrated iron ore hydraulic pulverizer of the present invention has a structure including a coarse crushing chamber 2 and a fine grinding and crushing chamber 14, the coarse crushing chamber 2 is located at the upper part of the fine grinding and crushing chamber 14, and the top of the coarse grinding chamber 2 is set There are two feed ports 1 and 1, and the bottom discharge port of the coarse grinding chamber 2 communicates with the fine grinding and crushing chamber 14 through the discharge channel 13 .

[0033] as attached figure 1 , 4, 5, and 6, two coarse crushing wheels 3 are arranged in parallel and horizontally in the coarse crushing chamber 2, and the wheel shaft 12 of the coarse crushing wheel 3 is installed on two opposite side walls of the coarse crushing chamber 2 through the bearing two 20, and the coarse crushing The side wall of the chamber 2 is provided with an adjustment slideway 31 along the direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com