Same floor draining joint for building

A technology for same-layer drainage and drainage interface, which is applied in buildings, water supply installations, indoor sanitary pipeline installations, etc., and can solve the problems of unable to discharge ground water, accumulated water that cannot be safely drained, and floor drains that cannot be installed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

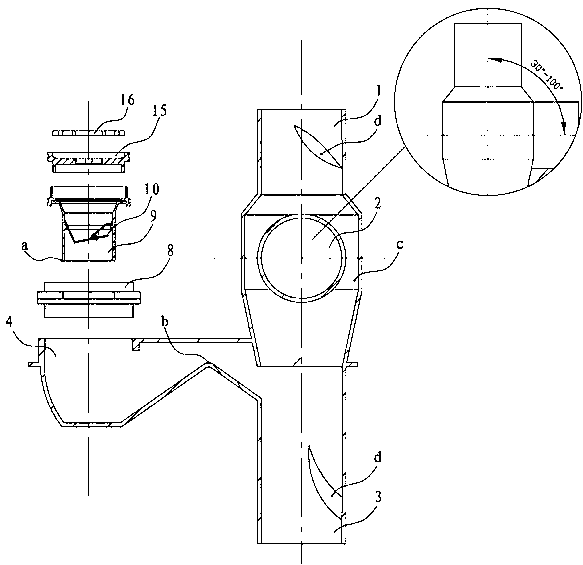

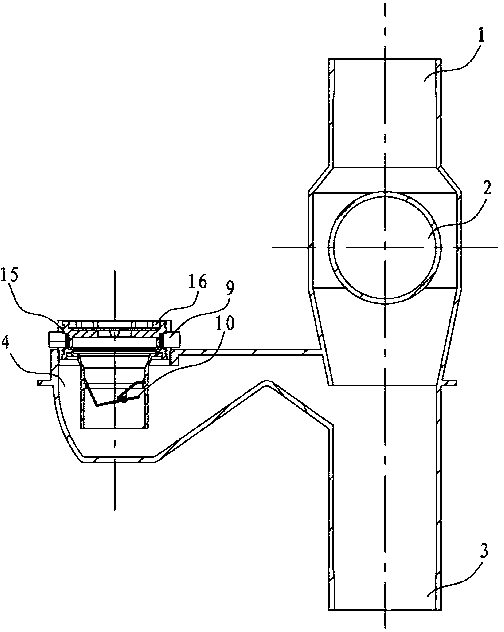

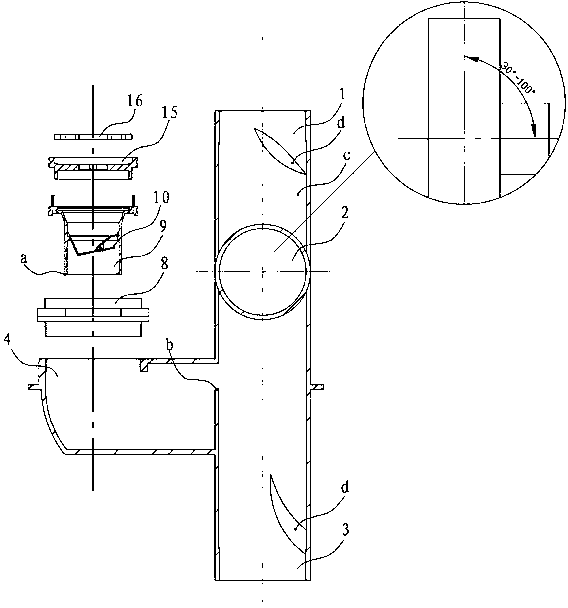

[0029] Such as Figure 1-4 The building drainage joint on the same floor as shown in the present invention is composed of an upper riser drainage interface 1, a lower riser drainage interface 3 and at least two horizontal pipe drainage interfaces 2, 4. The upper riser drainage interface 1 and the lower riser The upper and lower ends of the drainage interface 3 are connected, and the positions between at least two horizontal pipe drainage interfaces are staggered from each other and are located between the upper vertical pipe drainage interface 1 and the lower vertical pipe drainage interface. The direction of the drainage interface 1 of the upper riser is the same or nearly the same, and the angle between the direction of the inlet of at least one drainage interface 2 of the horizontal pipe and the direction of the drainage interface 1 of the upper riser is between 30° and 100°. The bottom of the horizontal pipe drainage interface 4 with the same or nearly the same orientation...

Embodiment 2

[0031] Such as Figure 5-10 As shown, in the building drainage joint on the same floor according to the present invention, there is a pipe section 8 under the cover plate 16, and the pipe section 8 is sealed and connected with the horizontal pipe drainage interface 4 facing the same direction as the upper riser drainage interface 1, and the water sealing device 9 In the pipe section 8, the water sealing device 9 and the pipe section 8 are separated from each other. The pipe section 8 is provided with one or more drainage inlets 5, 6. The cover plate 16 is detachable from the lower end pipe section. There is an inner sleeve 13, 14 in the pipe section 8 below the cover plate 16 and above the water sealing device 9, and the inner sleeve 13 is connected to the water sealing device 9. The inner sleeve 14 is located below the cover plate 16. There is a handle 15 between the inner sleeve 15 and the cover plate 16. The water seal device 9 is detachable from the horizontal pipe draina...

Embodiment 3

[0033] Such as Figure 5-10 As shown, in the building same-floor drainage joint according to the present invention, below the drainage inlets 5, 6 of the pipe section 8 and the inner sleeve drainage inlet 12, and above the drainage outlet of the water sealing device 9, a filter device 11 is provided; There is no inner sleeve drainage inlet on the inner sleeve corresponding to the drainage inlet 6, and the end of the pipe section drainage inlet 6 is provided with a filter head 7, and the filter head 7 is a joint provided with small holes, and a pipe section drainage outlet 6 is provided with one or one Above filter head 7. All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com