Successive separation method of aluminum-plastic composite packaging materials and device thereof

A packaging material, aluminum-plastic composite technology, applied in the direction of plastic recycling, recycling technology, process efficiency improvement, etc., can solve the problems of fuel energy consumption, low utilization value, gas emissions such as flue gas, etc. Cost saving and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below in conjunction with accompanying drawing and example describe in detail.

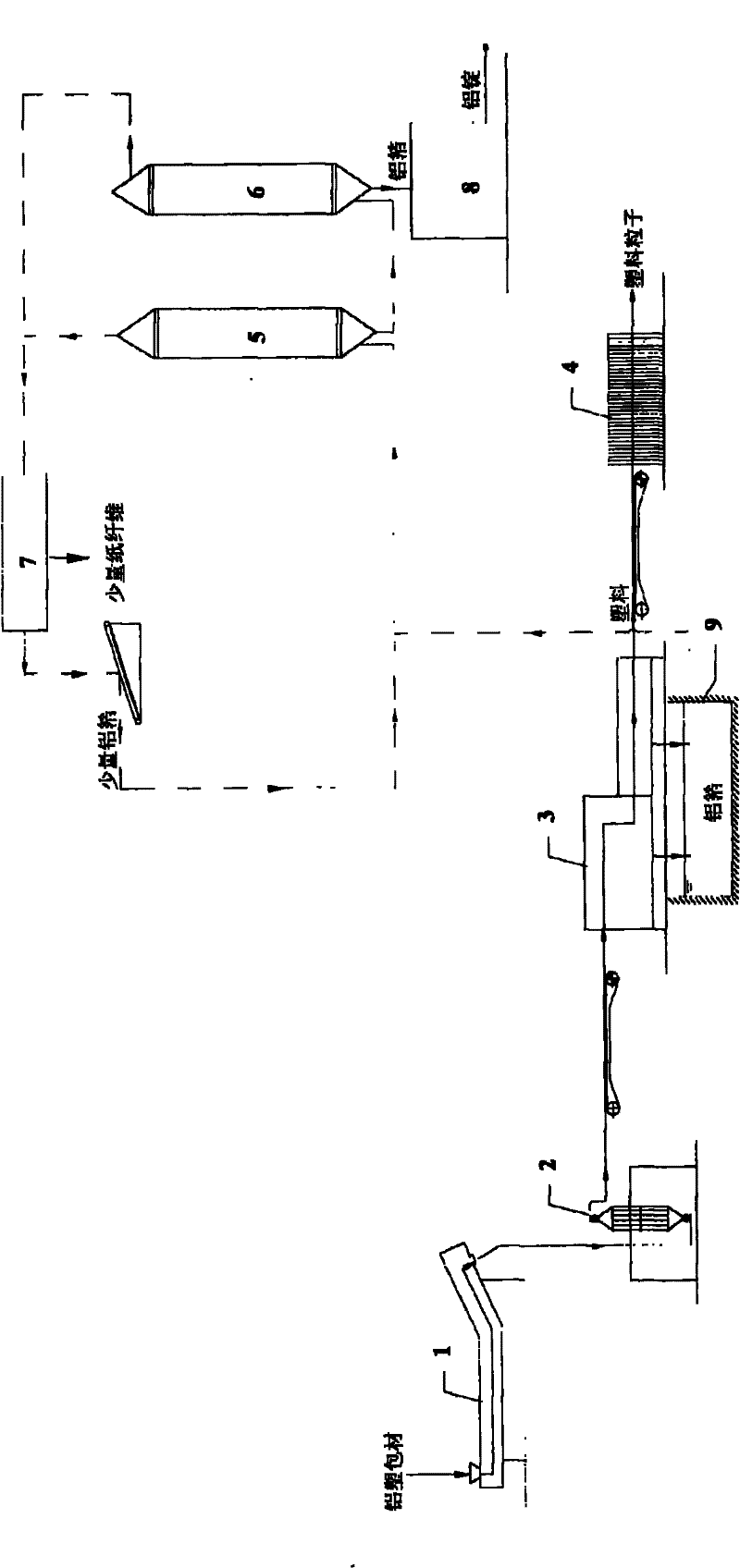

[0044] refer to figure 1 Shown, relevant specific implementation steps of the present invention are as follows:

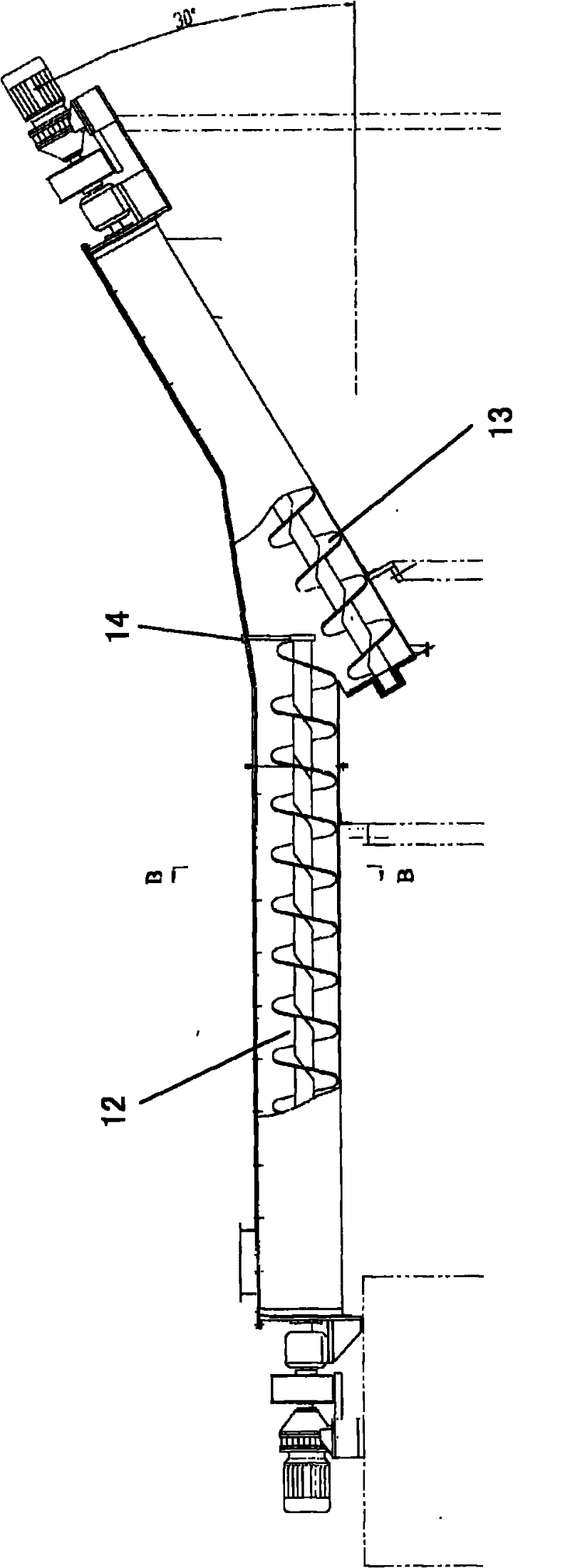

[0045] A) Soaking and stripping: the aluminum-plastic composite packaging material is continuously placed in the soaking separator 1, which contains a stripping agent prepared with formic acid, the concentration of which is 4mol / L, and can be adjusted by supplementing nitric acid The pH value was kept at 1-2 to ensure the reaction. The reaction temperature was maintained at 60° C. by the jacket of the immersion separator 1 to shorten the immersion separation time. The aluminum-plastic composite packaging material is soaked in the stripping agent while being stirred and advanced with the feeding screw device 12, and is continuously sent to the continuous centrifugal dryer 2 by the discharging screw device 13. To achieve continuous reaction. The residence time of the aluminum-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com