Preparation and application of copper-molybdenum separation inhibitor

An inhibitor, copper-molybdenum technology, applied in solid separation, flotation and other directions, can solve the problems of polluting the environment, easy to hydrolyze and volatilize, easy to hydrolyze and volatilize, etc., and achieve simple preparation method, no irritating odor, and inhibiting effect. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

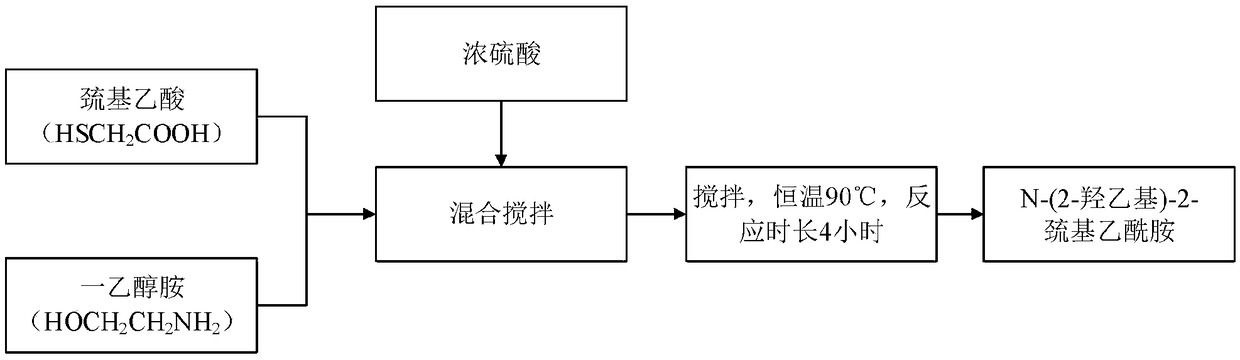

[0024] The preparation and application thereof of a kind of copper-molybdenum separation inhibitor can further be:

[0025] The mass ratio of thioglycolic acid to monoethanolamine is 1.5:1.

[0026] The catalyst is concentrated sulfuric acid, and the added amount of the concentrated sulfuric acid is 1-1.5% of monoethanolamine.

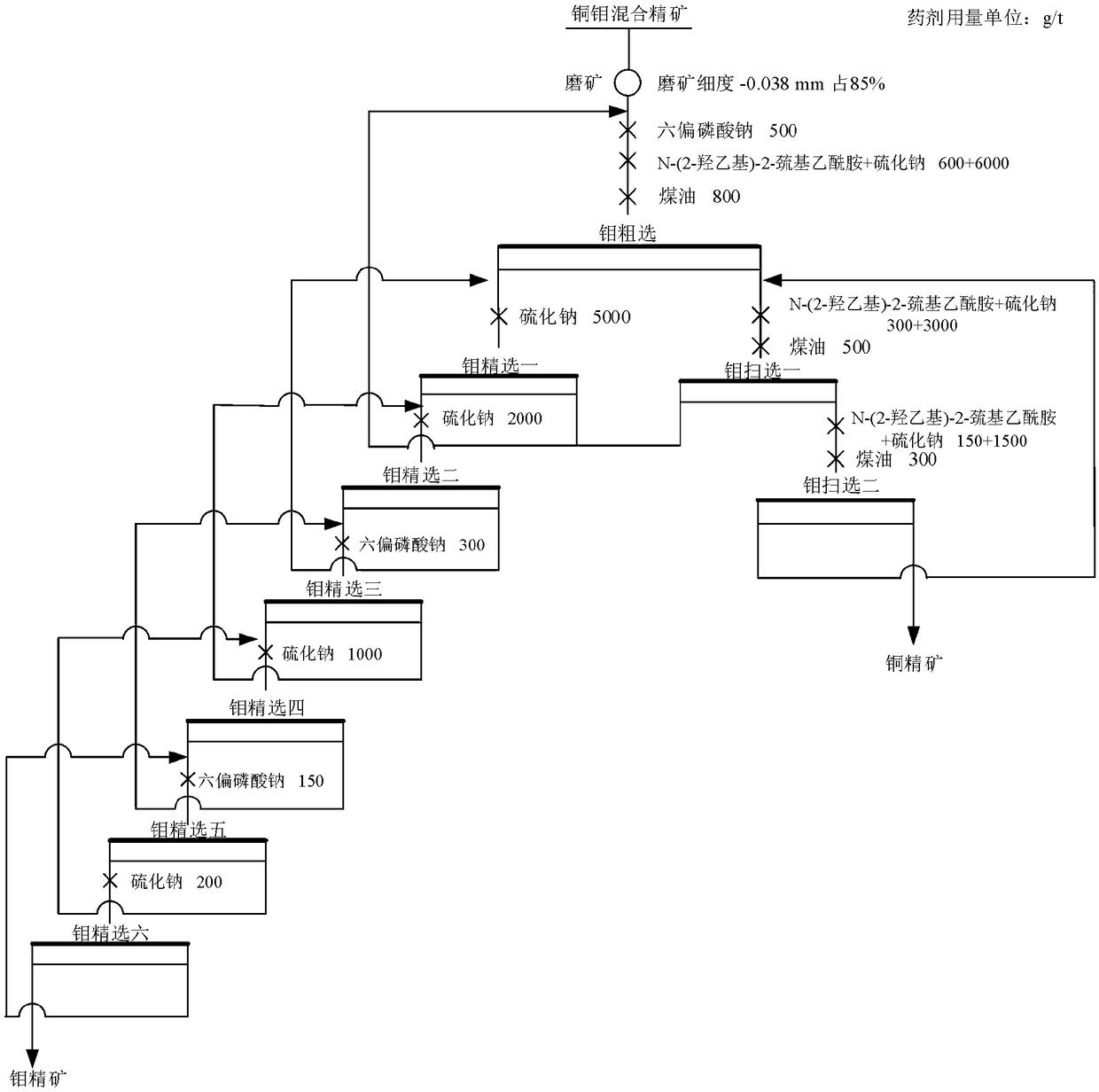

[0027] As a copper-molybdenum separation inhibitor, it is used in the flotation separation of copper-molybdenum concentrate for primary roughing, secondary sweeping, and six-stage beneficiation.

[0028] The flotation separation is carried out in turn according to the following process steps and conditions:

[0029] (1) Chemical removal of mixed concentrate: based on the dry weight of each ton of raw ore, add water to the copper-molybdenum mixed concentrate at a liquid-solid ratio of 2:3 for grinding until the grinding fineness is -0.038mm, accounting for 85% .

[0030] (2) Rough separation of molybdenum: the amount of regulator sodium hexametaphosp...

Embodiment 1

[0037] For the copper-molybdenum mixed concentrate produced by Duobaoshan copper (molybdenum) mine in Nenjiang County, Heilongjiang, its chemical composition (wt%) is as follows: 19.06% copper and 0.794% molybdenum, and the copper minerals are mainly chalcopyrite, porphyrite Copper ore; molybdenum minerals are mainly molybdenite.

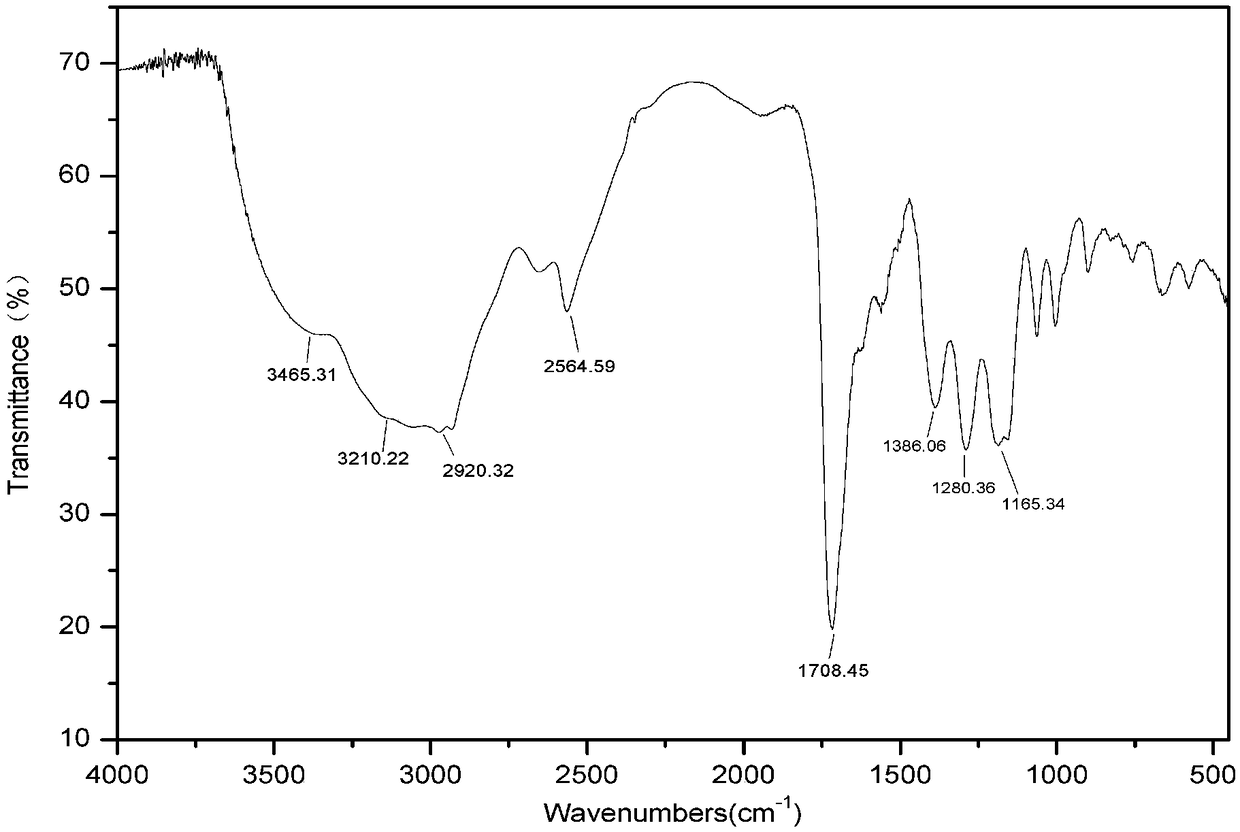

[0038] First weigh 150g of thioglycolic acid (HSCH 2 COOH) and 100g of monoethanolamine (HOCH 2 CH 2 NH 2 ) into the reaction vessel, stir and mix evenly, slowly add 1g of concentrated sulfuric acid into the mixing system, stir while adding, after stirring evenly, place it on a constant temperature magnetic stirrer, control the temperature at 90°C, stir and react for 4h, after the reaction is completed That is, a colorless liquid: N-(2-hydroxyethyl)-2-mercaptoacetamide.

[0039] According to the dry weight of each ton of raw ore, add water to the copper-molybdenum mixed concentrate according to the liquid-solid ratio of 2:3 for grinding, and aft...

Embodiment 2

[0041] For the copper-molybdenum mixed concentrate produced by Gutian copper (molybdenum) mine in Liancheng County, Fujian Province, its chemical composition (wt%) is as follows: 24.63% copper and 0.967% molybdenum, wherein the copper minerals are mainly chalcopyrite; molybdenum The mineral is mainly molybdenite.

[0042] First weigh 150g of thioglycolic acid (HSCH 2 COOH) and 100g of monoethanolamine (HOCH 2 CH 2 NH 2 ) into the reaction vessel, stir and mix evenly, slowly add 1g of concentrated sulfuric acid into the mixing system, stir while adding, after stirring evenly, place it on a constant temperature magnetic stirrer, control the temperature at 90°C, stir and react for 4h, after the reaction is completed That is, a colorless liquid: N-(2-hydroxyethyl)-2-mercaptoacetamide.

[0043] According to the dry weight of each ton of raw ore, add water to the copper-molybdenum mixed concentrate according to the liquid-solid ratio of 2:3 for grinding, and after grinding until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com