Embedded machine wire box structure and method of prefabricated panel

A technology of prefabricated wall panels and wire boxes, which is applied in the direction of manufacturing tools, building structures, building components, etc., can solve the problems of high maintenance cost, complex construction, high cost, etc., improve component quality and production efficiency, and ensure structural safety , to ensure the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

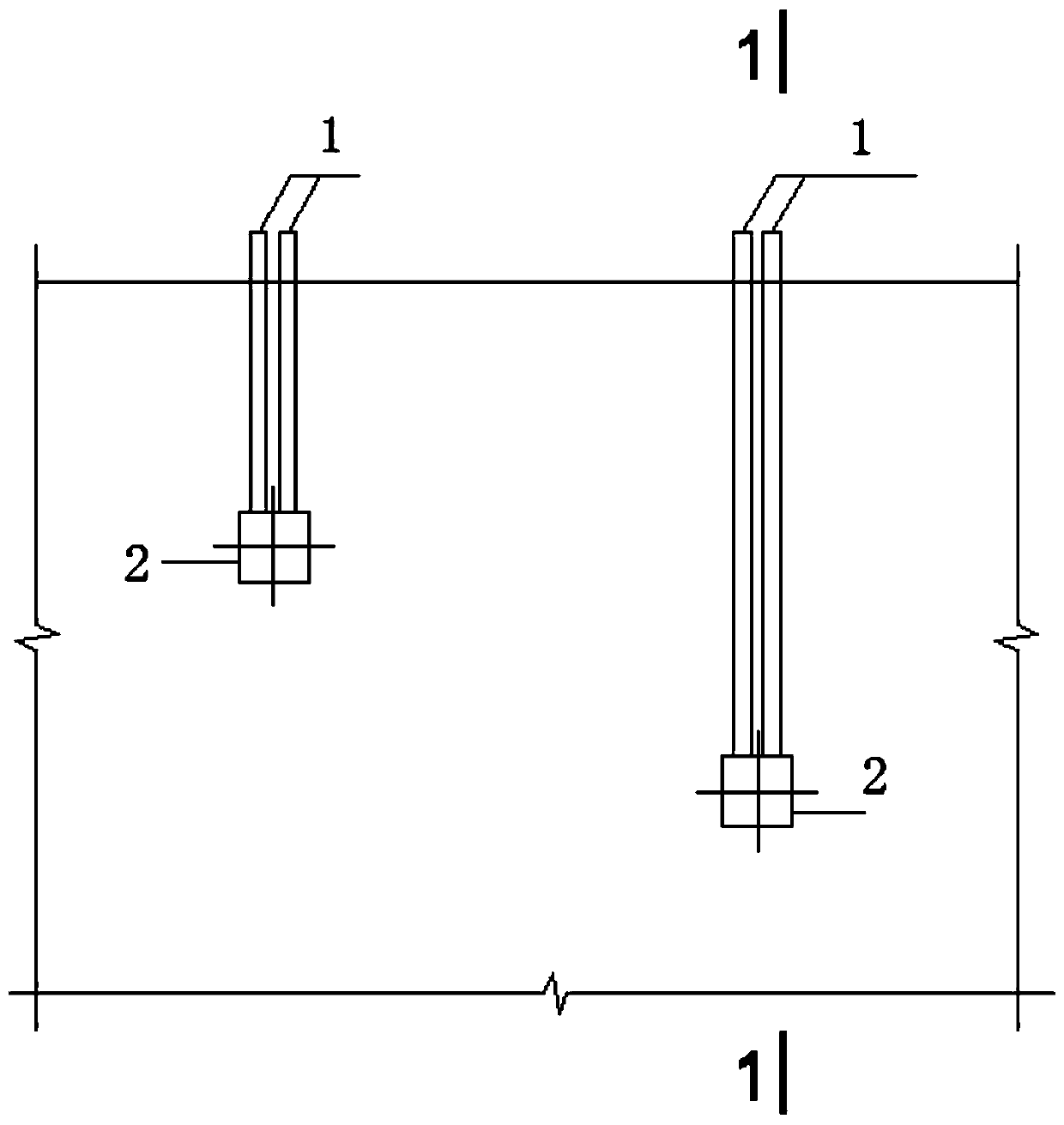

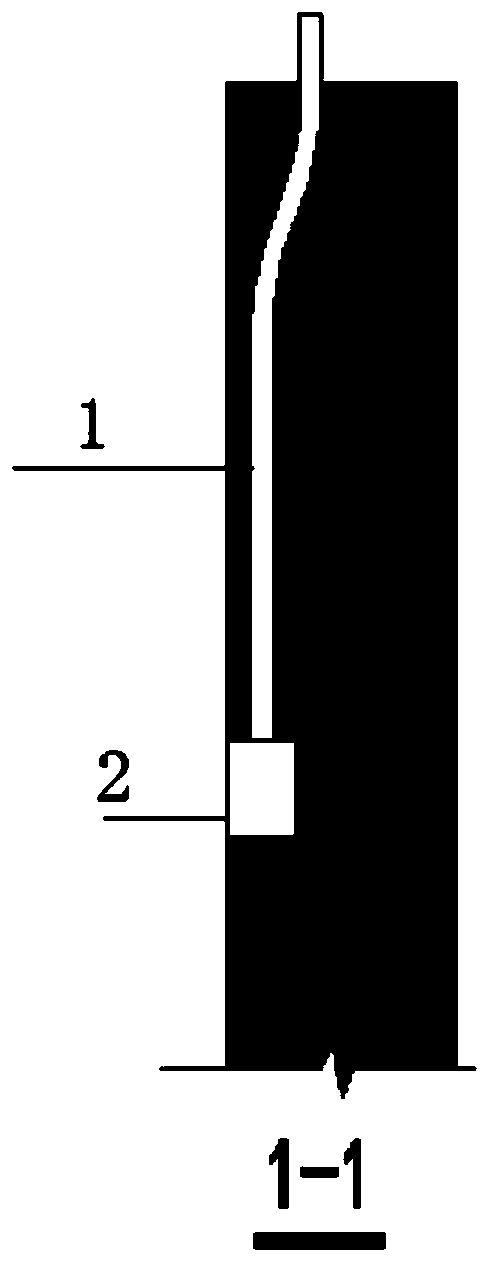

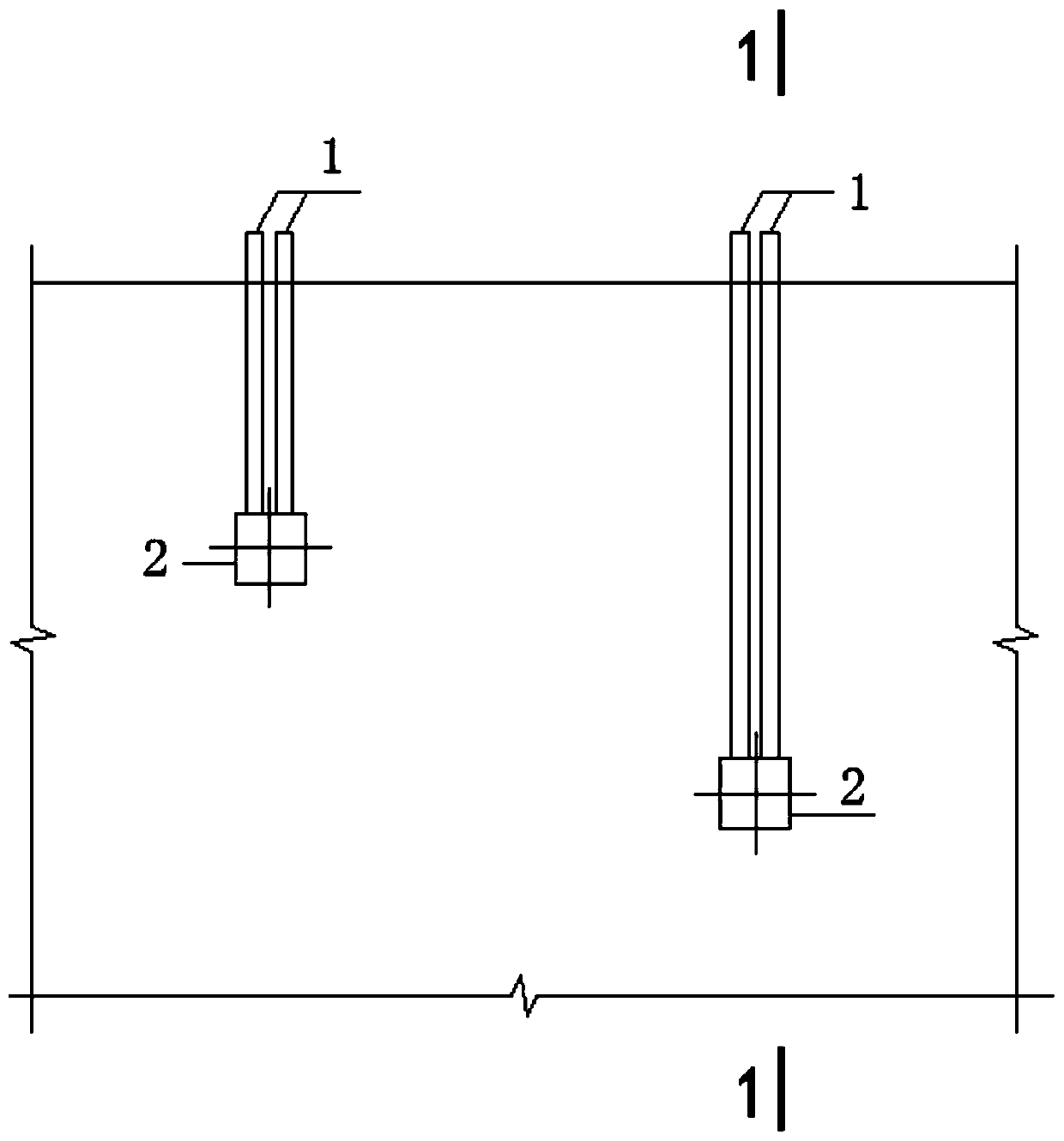

[0050] see Figure 5-8 and Figure 13-26 , a prefabricated wallboard pre-embedded machine wire box structure, including a sleeve 3, at least one pipeline 1; the pipeline passes through the side wall of the sleeve 3 and extends into the sleeve 3 to form a combined The combined embedded parts are pre-embedded in the prefabricated wallboard, and the casing 3 is arranged horizontally and the pipeline 1 is vertically arranged, and the casing 3 is connected with the inner side of the prefabricated wallboard; the inner diameter of the casing 3 is larger than that of the preparation and the pipeline 1 The outside diameter of the connected box.

[0051]In this embodiment, the inner diameter of the sleeve 3 is much larger than the outer diameter of the wire box to be connected to the pipeline 1 , and a cavity 301 is formed inside the sleeve 3 as an operating space.

[0052] In this embodiment, the combined embedded part includes a casing 3 and two pipelines 1, and the pipelines 1 have...

Embodiment 2

[0071] see Figure 9-12 , the difference from Embodiment 1 is that the prefabricated wall panels are fully prefabricated wall panels. All the other are the same as embodiment one.

Embodiment 3

[0073] see Figure 13-16 , The difference from Embodiment 1 is that the prefabricated wallboard is a double-sided laminated thermal insulation wallboard, and the inner end of the sleeve 3 is against the inner side of the outer leaf wall. All the other are the same as embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com