Device for real time online monitoring concentration of SO3 gas in flue gas

A gas concentration and flue gas technology, applied in the direction of measuring devices, color/spectral characteristic measurement, material analysis through optical means, etc., can solve problems such as difficulty in concentration detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

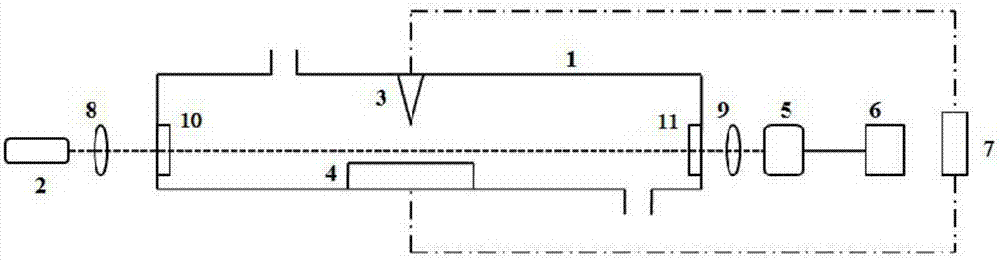

example 1

[0034] Using the above real-time online monitoring of SO in flue gas 3 The device and method of gas concentration are used to control SO at the outlet of a power plant 3 Concentrations were measured and unit load maintained at 300 MW. A 10 kV AC high voltage was applied to the absorption cell, and needle-plate electrodes were used. The optical analysis module uses a 7.16 μm quantum cascade laser and corresponding detectors. The signal of the photodetector is collected by the data acquisition card, and the signal is finally processed by the Labview program. Under this condition, SO 3 The average concentration is 21.57 mg / Nm 3 . Using the method in the national standard "Performance Test Method for Coal-fired Flue Gas Desulfurization Equipment—GB / T21508-2008" to obtain SO 3 The concentration is 21.35 mg / Nm 3 .

Embodiment 2

[0036] Using the above real-time online monitoring of SO in flue gas 3 The device and method of gas concentration are used to control SO at the outlet of a power plant 3 Concentrations were measured and unit load maintained at 200 MW. 100 kV AC high voltage was applied to the absorption pool, and needle-plate electrodes were used. The optical analysis module uses a 7.16 μm quantum cascade laser and corresponding detectors. The signal of the photodetector is collected by the data acquisition card, and the signal is finally processed by the Labview program. Under this condition, SO 3 The average concentration is 15.21mg / Nm 3 . Using the method in the national standard "Performance Test Method for Coal-fired Flue Gas Desulfurization Equipment—GB / T21508-2008" to obtain SO 3 The concentration is 15.02 mg / Nm 3 .

Embodiment 3

[0038] Using the above real-time online monitoring of SO in flue gas 3 The device and method of gas concentration are used to control SO at the outlet of a power plant 3 Concentrations were measured and unit load maintained at 300 MW. 10 kV AC high voltage is applied to the absorption cell, and column-plate electrodes are used. The optical analysis module uses a 7.16 μm quantum cascade laser and corresponding detectors. The signal of the photodetector is collected by the data acquisition card, and the signal is finally processed by the Labview program. Under this condition, SO 3 The average concentration is 21.65 mg / Nm 3 . Using the method in the national standard "Performance Test Method for Coal-fired Flue Gas Desulfurization Equipment—GB / T21508-2008" to obtain SO 3 The concentration is 21.34 mg / Nm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com