Rice bran oil dewaxing process

A rice bran oil and process technology, which is applied in the field of advanced products, can solve the problems of high labor intensity and slow bag filtration rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

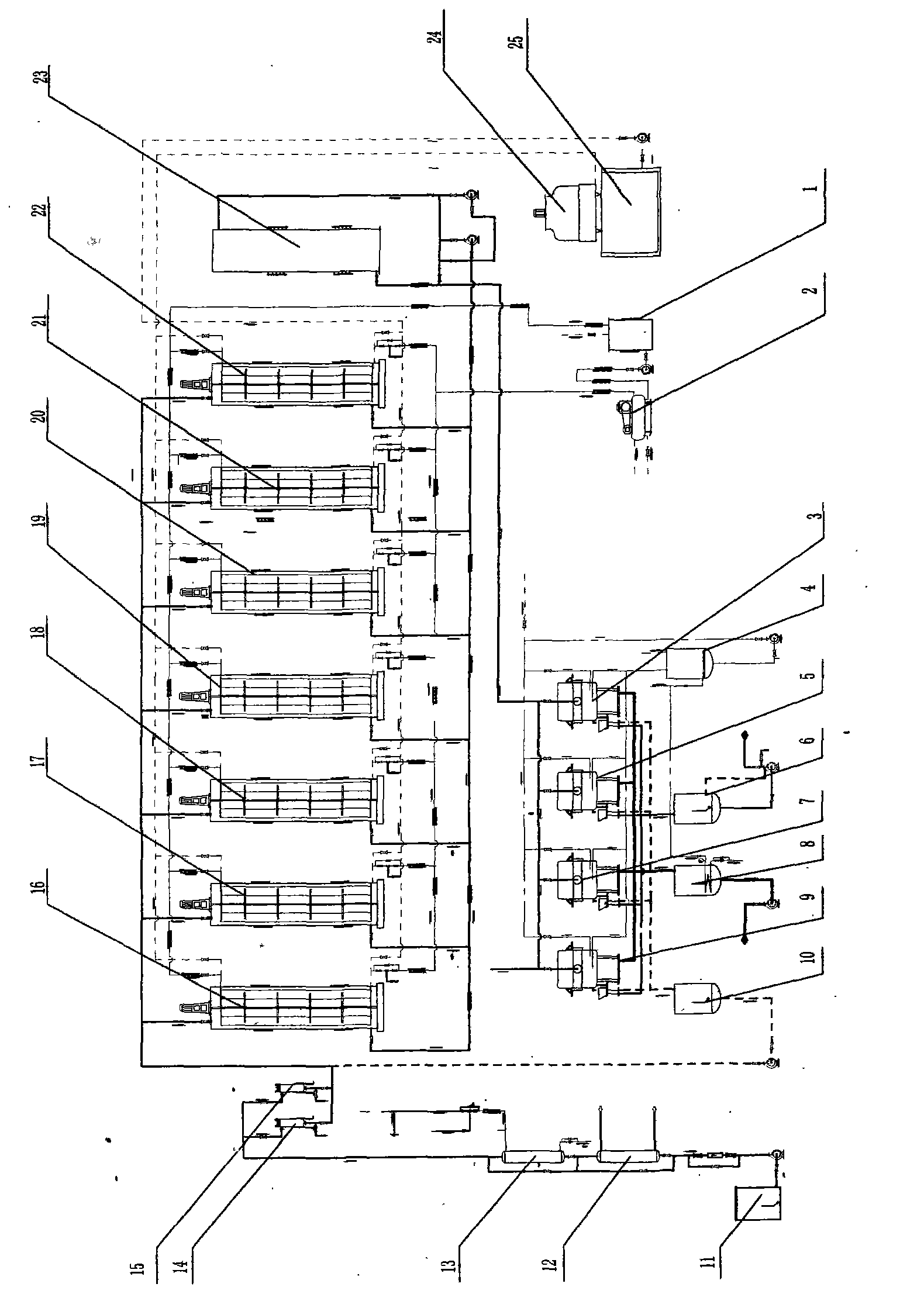

[0006] For the products involved in this project, the crude oil leached from the crude oil tank 11 is injected into the No. 1 tube heat exchanger 12 and the No. 2 tube heat exchanger 13 through the oil pump for heating; the bran wax in the crude oil is melted, and then Enter No. 1 fine filter 14 and No. 2 fine filter 15 to filter solid impurities. The filtered clear oil is injected into the junction and crystal growth tanks 16, 17, 18, 19, 20, 21, and 22 respectively, and the refrigerant liquid in the refrigerant tank 1 is poured into the crystallization tank through the refrigerator 2 to reduce the heat of the cooking oil in the crystallization tank. Replace it, so that the edible oil temperature in the crystallization tank is reduced to the temperature of crystallization. When the external temperature is low, the heat of the edible oil in the crystallization tank can be directly replaced by the cooling tower 24 and the clear water circulation pool 25, without starting the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com