Super-hydrophobic porous membrane as well as preparation method and application thereof

A porous membrane and super-hydrophobic technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of membrane distillation scaling and pollution, the inability to cope with membrane distillation scaling, and mass production difficulties, etc. problems, to achieve the effects of increased throughput, easy mass production, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

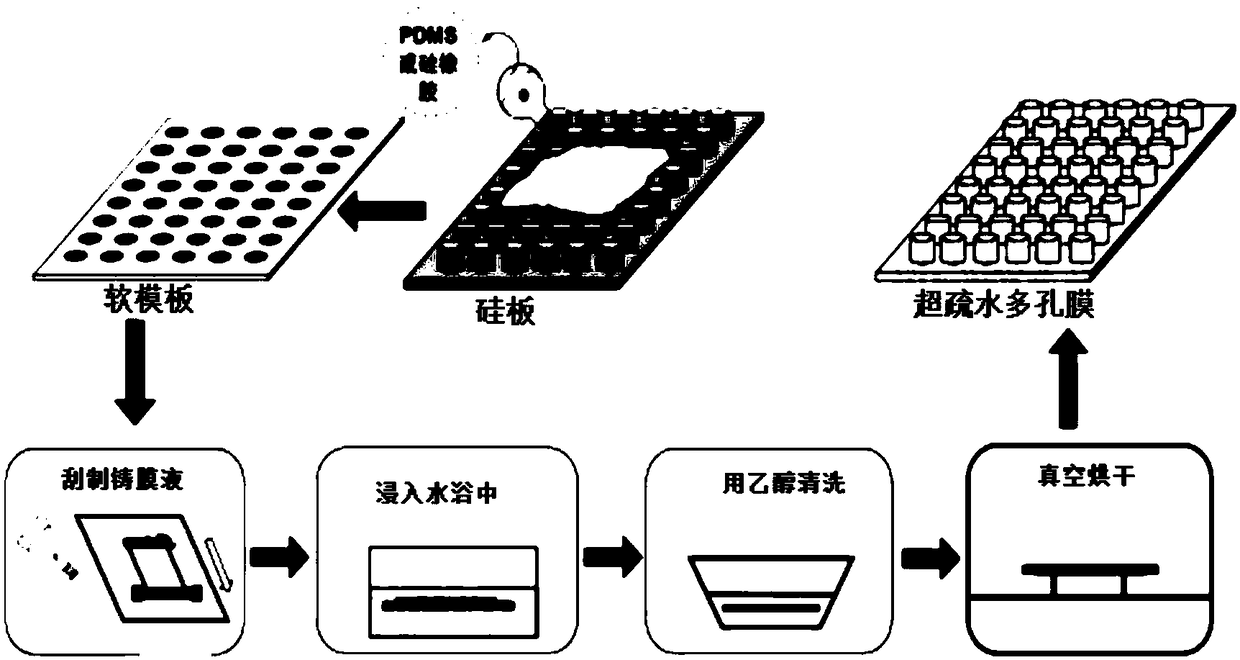

[0040] 4. Preparation of superhydrophobic porous membrane

[0041] Pour the prepared casting solution on the prepared soft template, and use a scraper of a specific size to scrape the film; put the scraped casting solution and soft template into a water bath at a specific temperature, and control the temperature of the environment. Temperature and humidity, through phase separation to form a film; then the formed film material is peeled off to obtain a porous film material with a super-hydrophobic surface; finally, ethanol is used as a cleaning agent for ultrasonic cleaning, and after drying, the surface with micro-columns / Superhydrophobic porous membrane materials with cone array structure.

[0042] In the above process, the specific size of the scraper refers to a scraper with a thickness of 50-500 μm. The water bath temperature is controlled to be 5-90°C; the ambient temperature is 10-40°C, and the humidity is 10-90%, preferably the water bath temperature is 20-75°C, the...

Embodiment 1

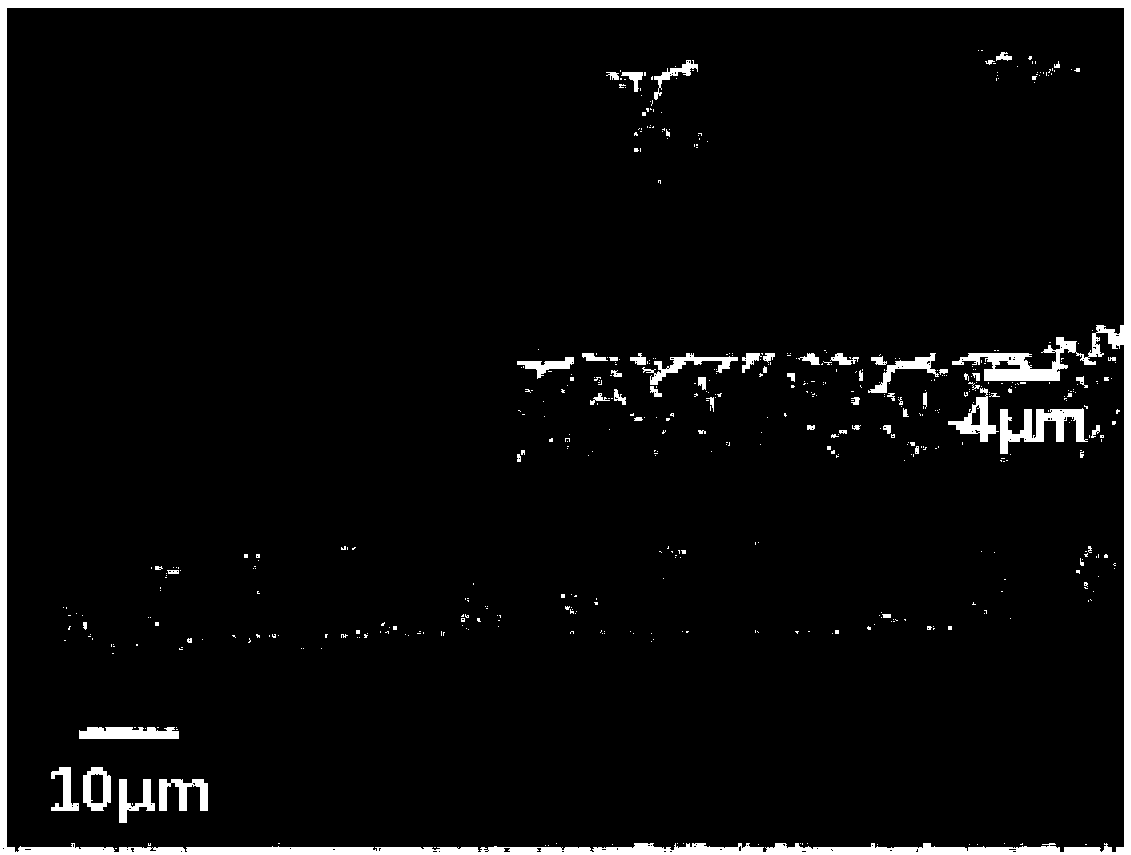

[0047] The micromolded polyvinylidene fluoride (PVDF) hydrophobic membrane of the present invention has a secondary structure such as figure 2 As shown, the polyvinylidene fluoride body is a primary structure with a three-dimensional pore-like structure, and the pores are uniform and interconnected. The secondary structure also has the same primary three-dimensional porous structure as the original primary structure, with an effective porosity of 0.7.

[0048] The preparation method of the micromolded polyvinylidene fluoride (PVDF) hydrophobic membrane is as follows:

[0049] (1) Select a smooth and flat silicon plate with a cylinder array with a height of 10 μm, an equivalent diameter of 5 μm, and a cylinder center distance of 10 μm on the surface.

[0050] (2) Mix polydimethylsiloxane (PDMS) and curing agent in a ratio of 10:1, let the mixed solution stand still for degassing for 10 minutes, slowly pour the degassed PDMS mixed solution on the silicon plate, and put the who...

Embodiment 2

[0055] The micromolded polyethersulfone (PES) hydrophobic membrane of the present invention has a secondary structure, wherein the polyethersulfone body is a primary structure with a three-dimensional porous structure, and the pores are uniform and interpenetrating. On the upper surface of sulfone, there is a secondary structure with uniform arrangement and uniform size. This secondary structure also has the same primary three-dimensional porous structure as the original primary structure, with an effective porosity of 0.65.

[0056] The preparation method of this micromolded polyethersulfone (PES) hydrophobic membrane is as follows:

[0057] (1) Select a smooth and flat silicon plate with a pyramid array with a height of 10 μm, an equivalent diameter of 5 μm, and a square pyramid center distance of 10 μm on the surface.

[0058](2) Use epoxy resin, mix the curing agent at a ratio of 10:1, let the mixture stand still for degassing for 10 minutes, slowly pour the degassed epoxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com