Patents

Literature

116 results about "Concrete recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

When structures made of concrete are demolished or renovated, concrete recycling is an increasingly common method of utilizing the rubble. Concrete was once routinely trucked to landfills for disposal, but recycling has a number of benefits that have made it a more attractive option in this age of greater environmental awareness, more environmental laws, and the desire to keep construction costs down.

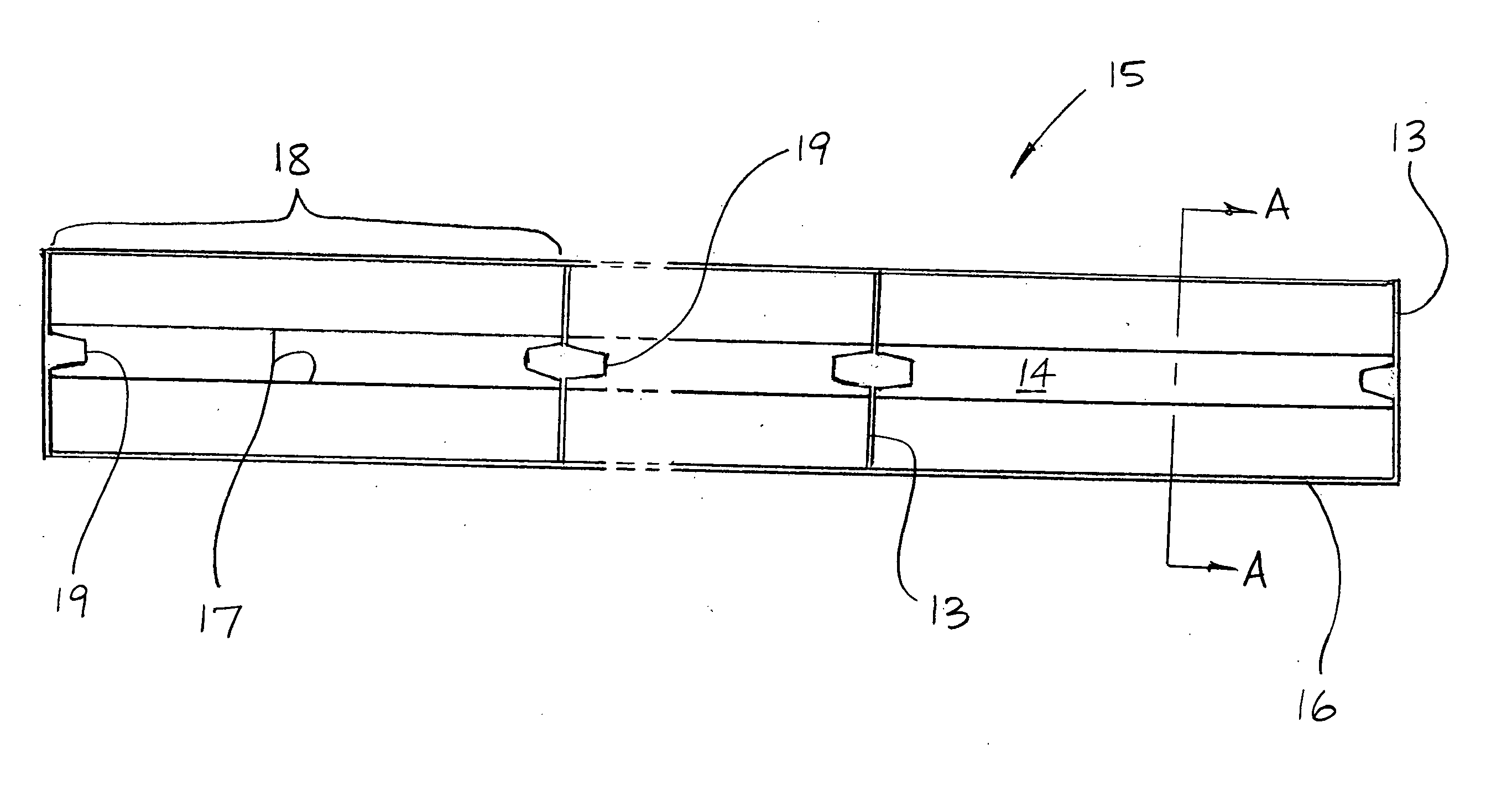

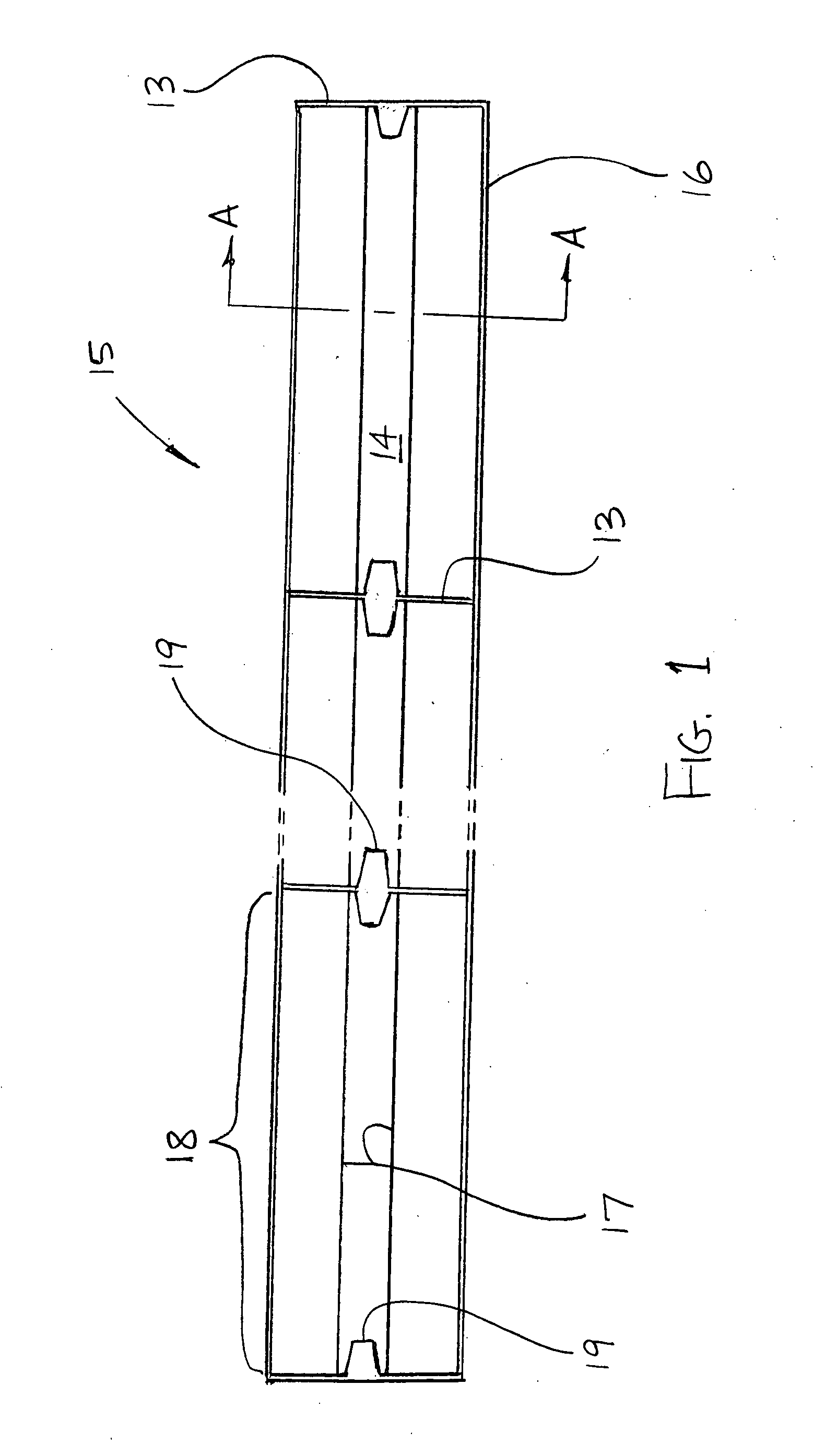

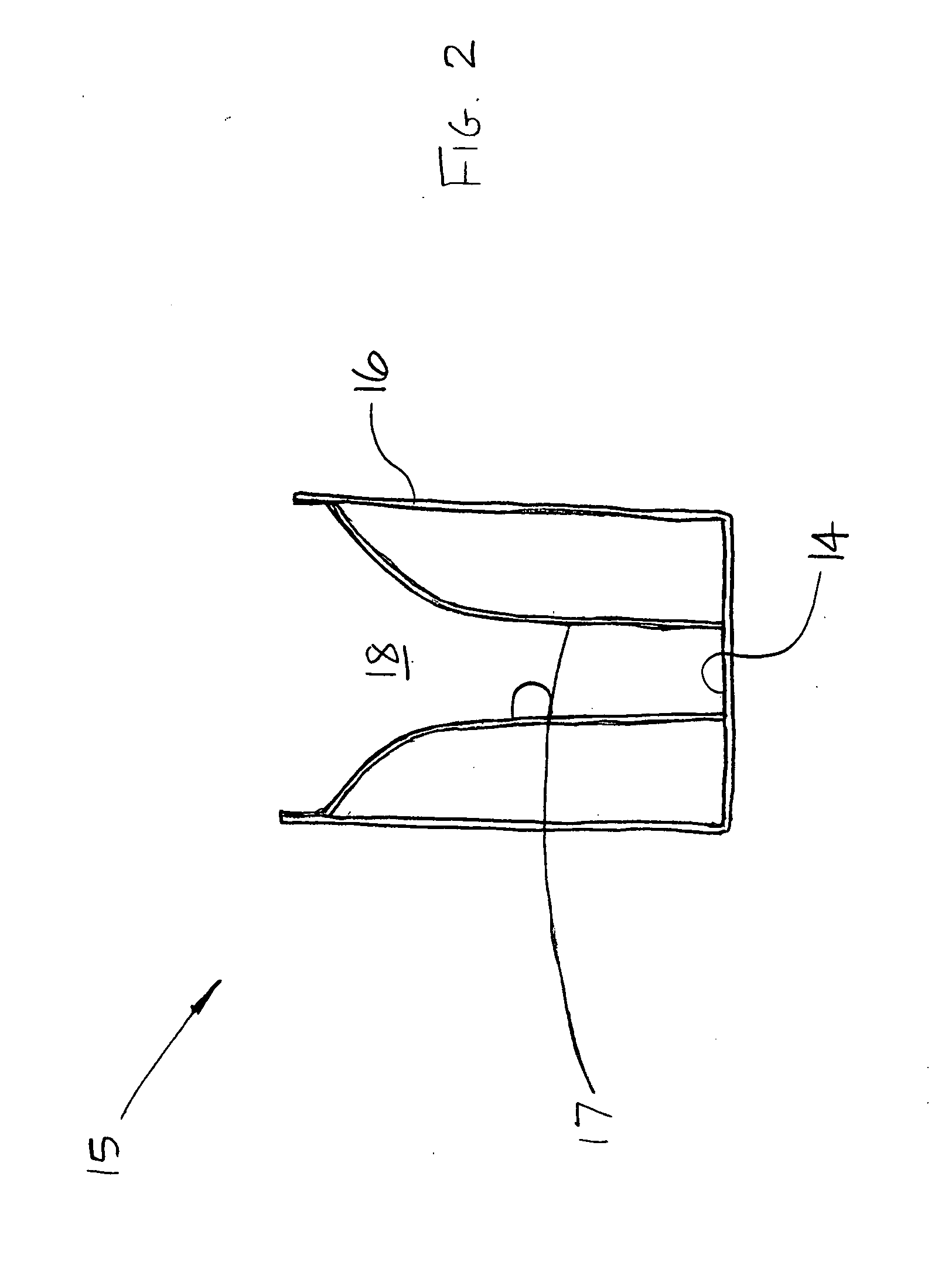

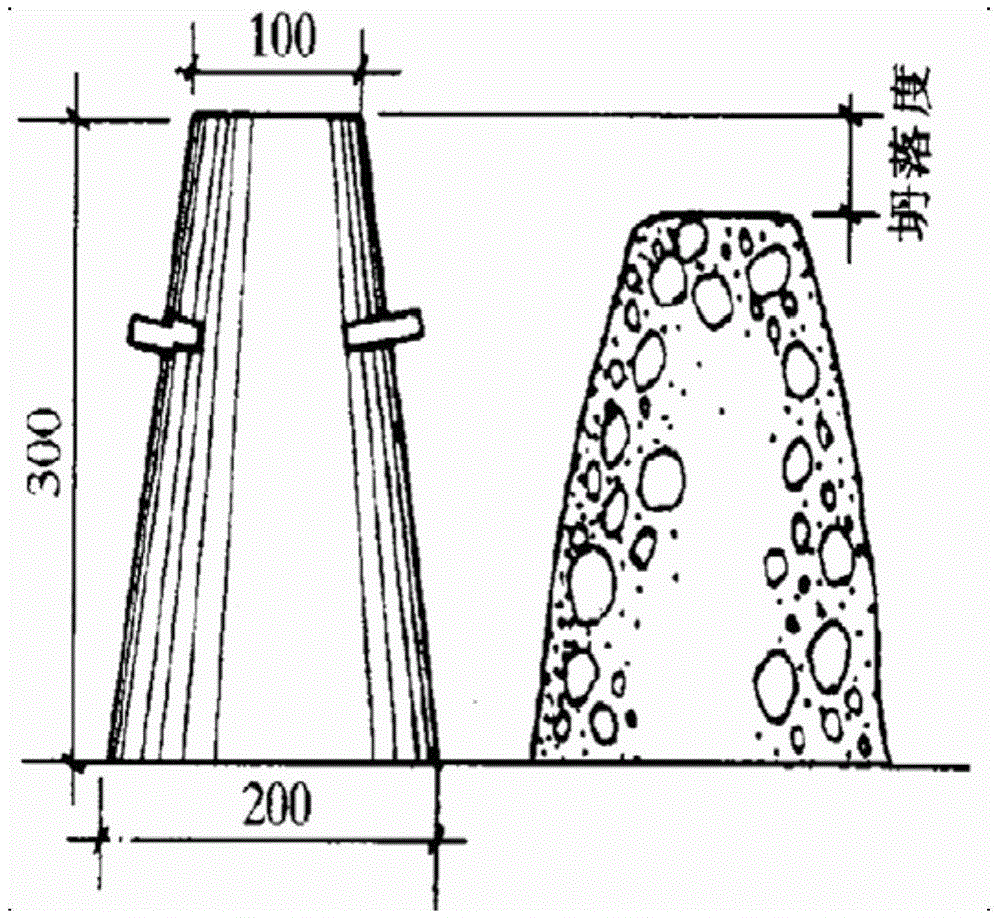

Roadway barrier components formed using a system for recycling wet concrete and means for assembling multiple components into a continuous safety barrier wall

A wet concrete recycling system for mixing trucks returning to the cement plant throughout the workday. “Residual-collection” molds, kept on-hand at the plant, are filled with any excess wet concrete present in the returning trucks. The molds are configured to form finished components such as roadway barrier sections (i.e. jersey walls), and the like. The finished components are low in cost due to the use of recycled wet concrete, inexpensive reinforcing materials, and handles / assembly elements fabricated from other recycled materials. The finished components may be sold or leased to customers, thereby converting costs typically associated with traditional residual concrete disposal techniques into supplemental income streams. The finished components may be assembled into continuous roadway safety barrier walls. All structures assembled from two or more of the finished components are inexpensive due to the low cost of the individual components, easily constructed, and may be permanent or temporary in nature.

Owner:STRAUB ERIK K

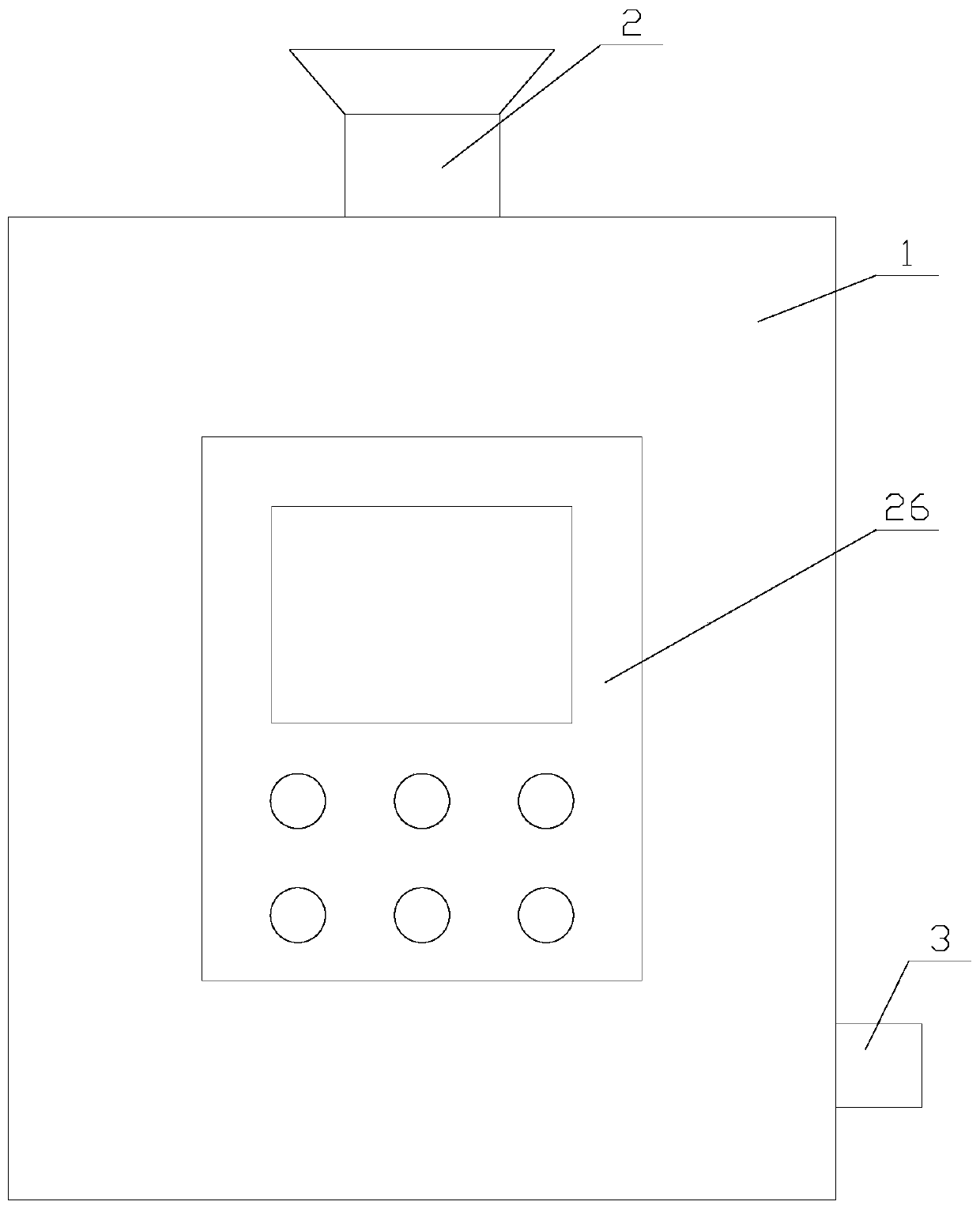

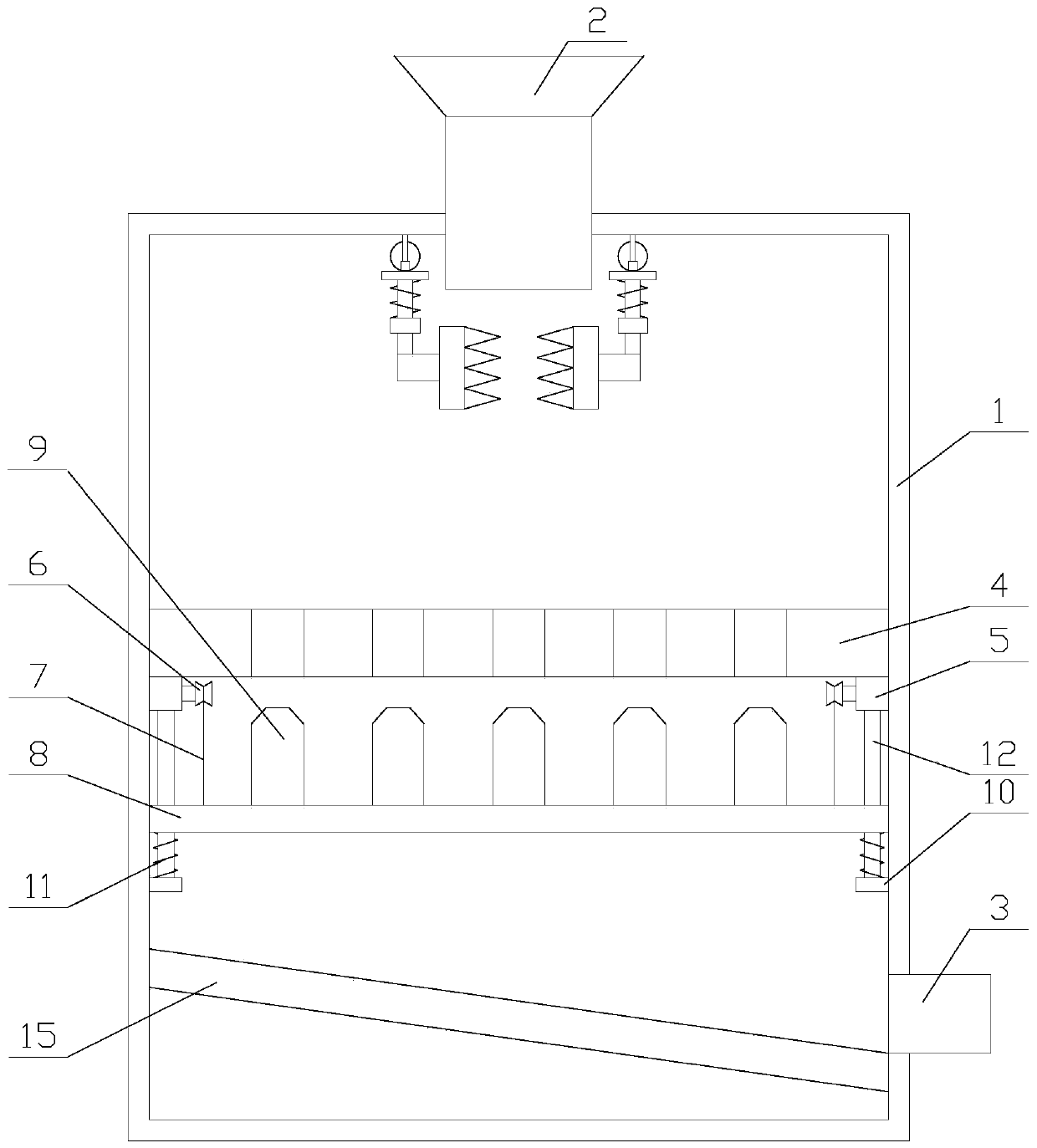

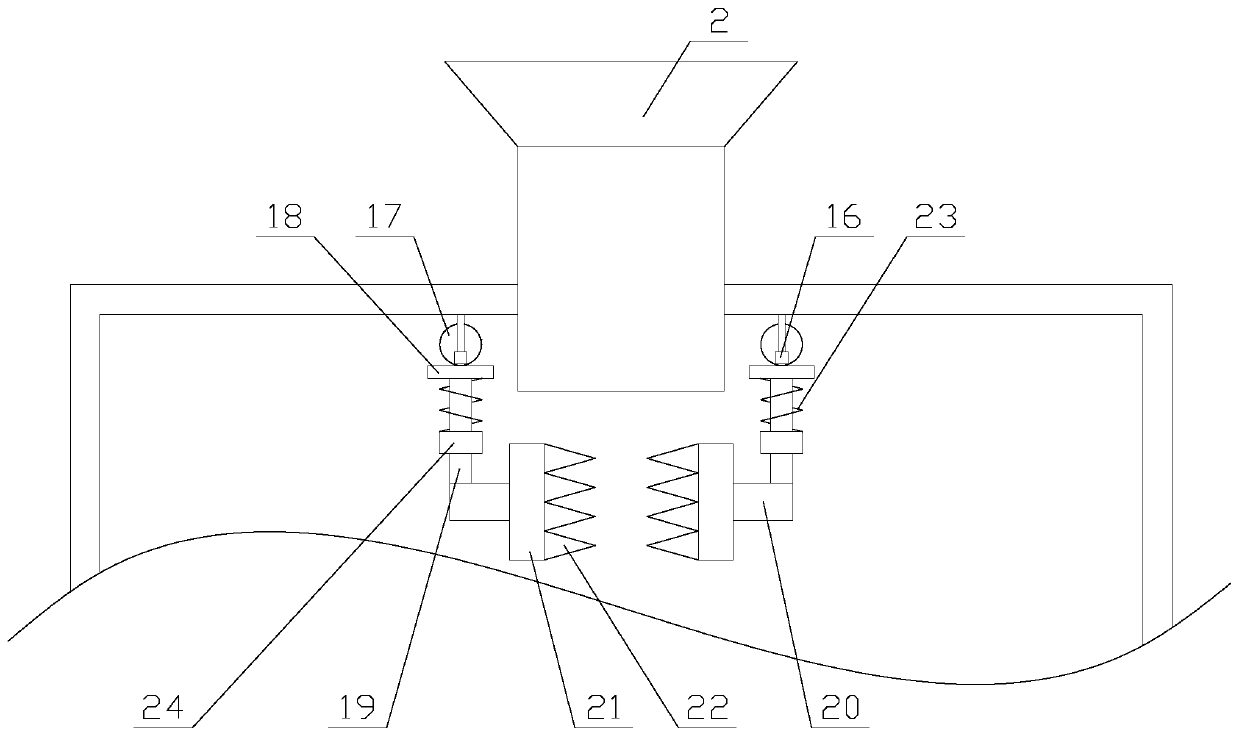

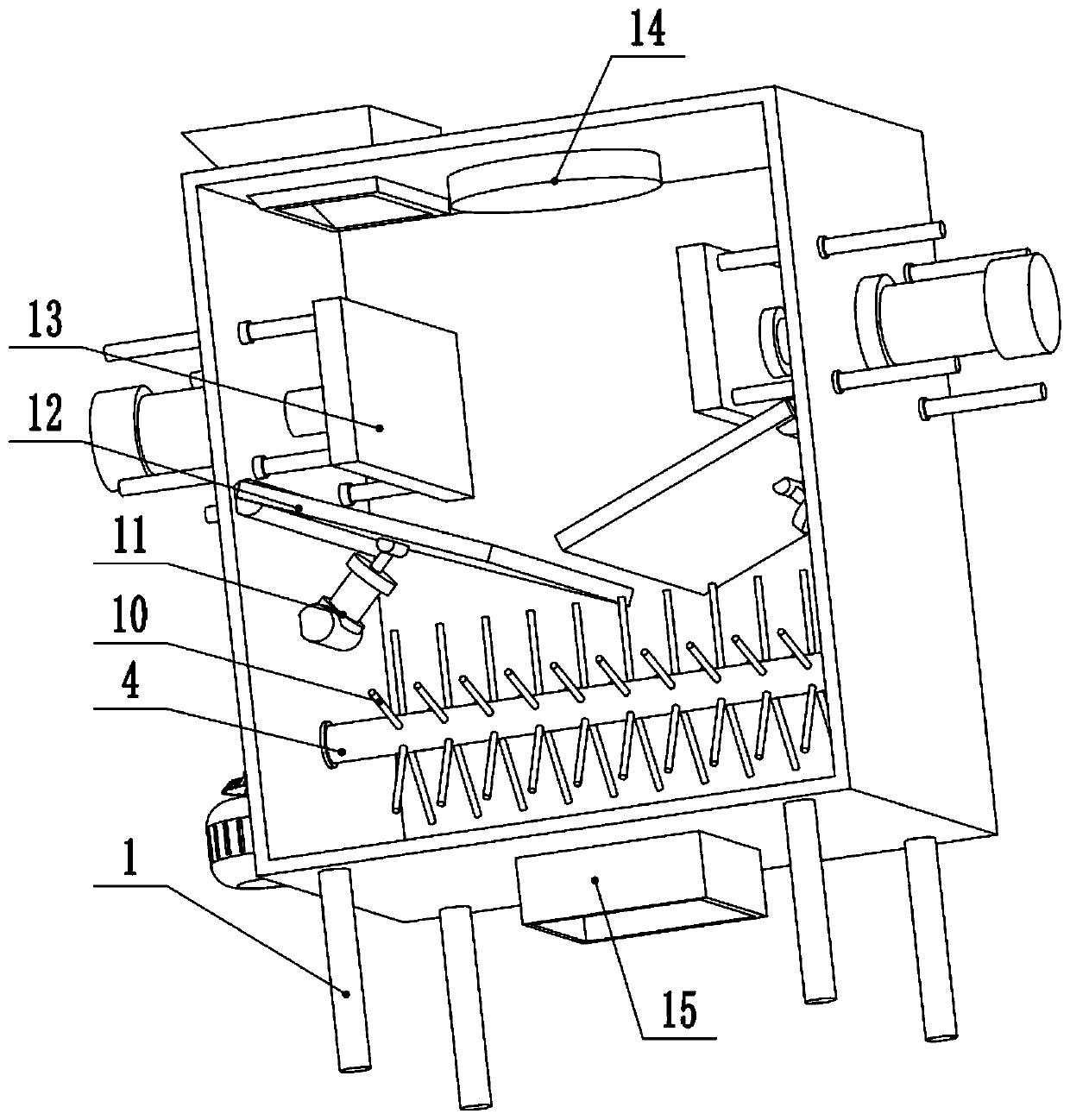

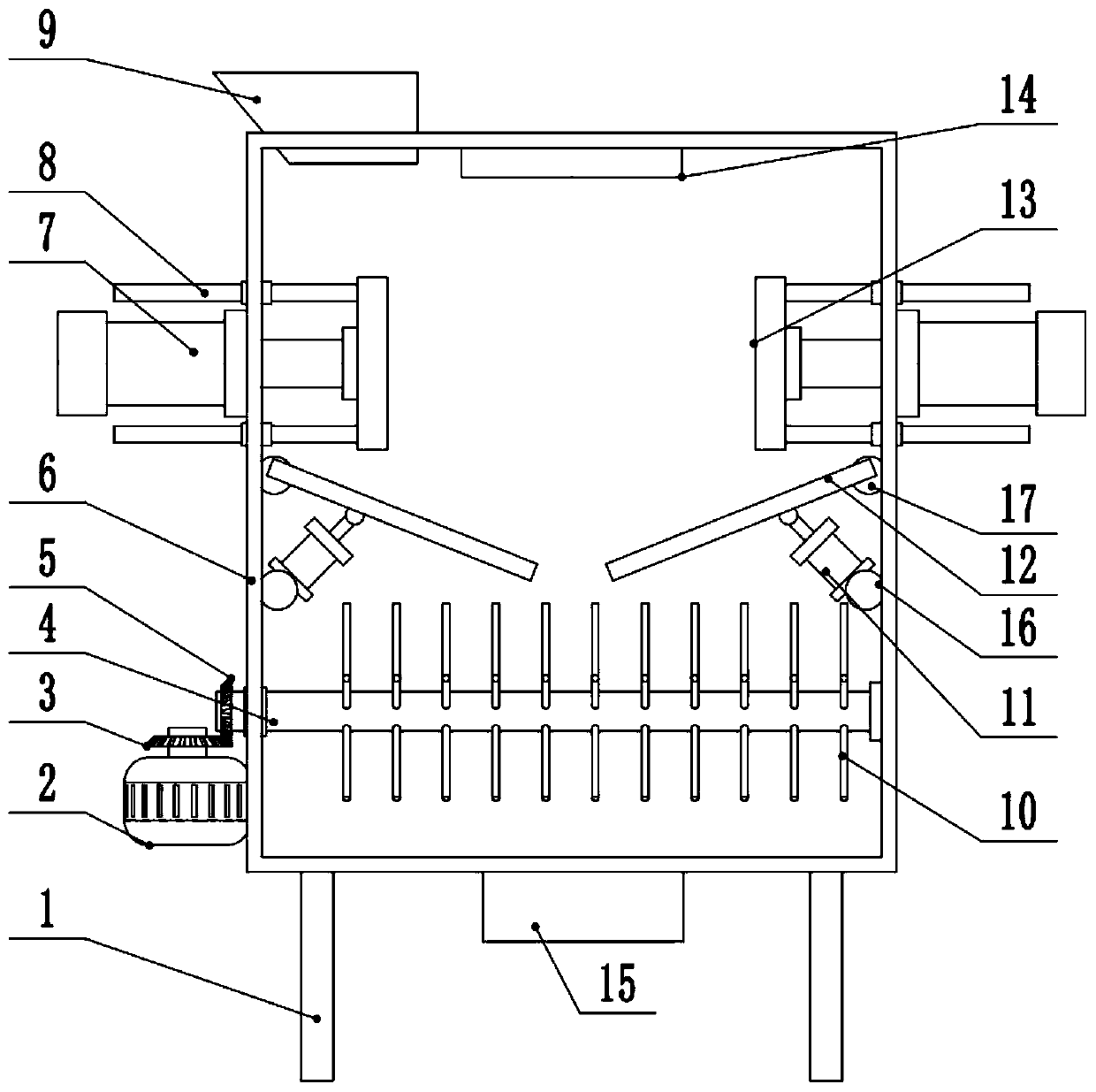

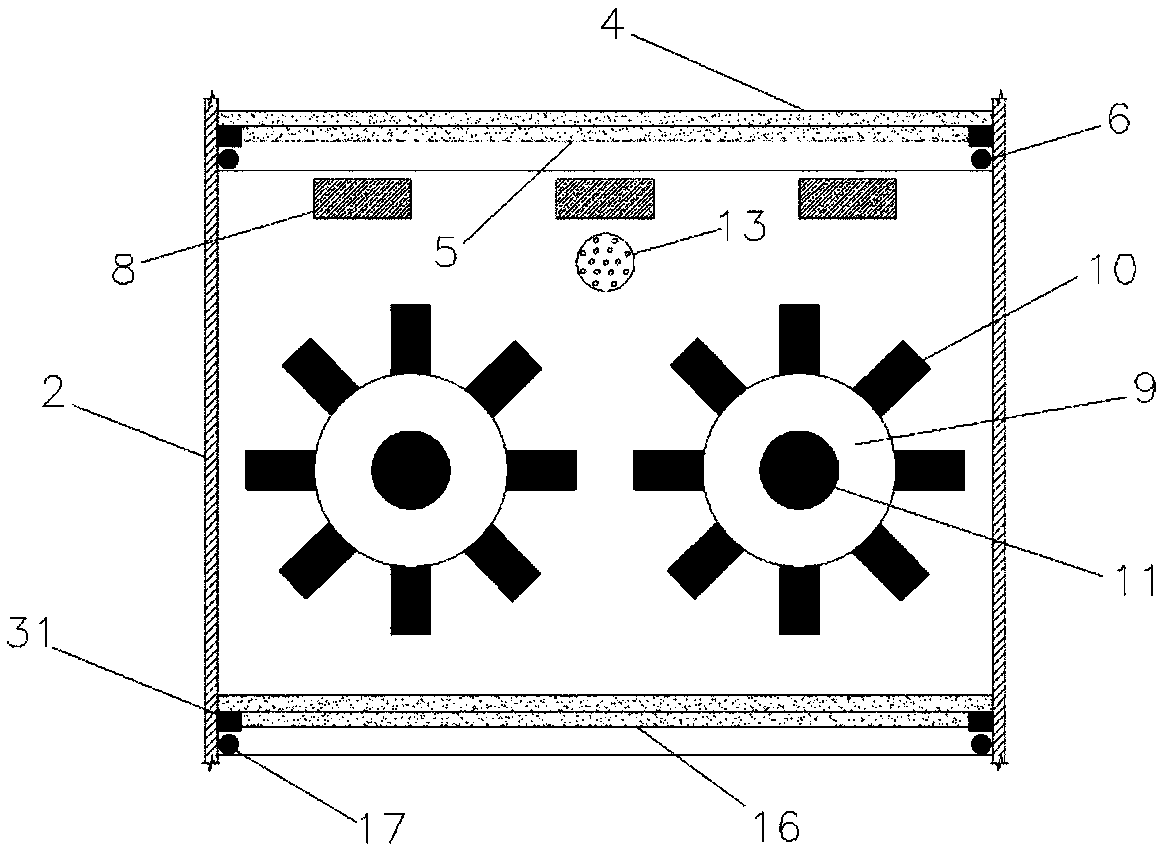

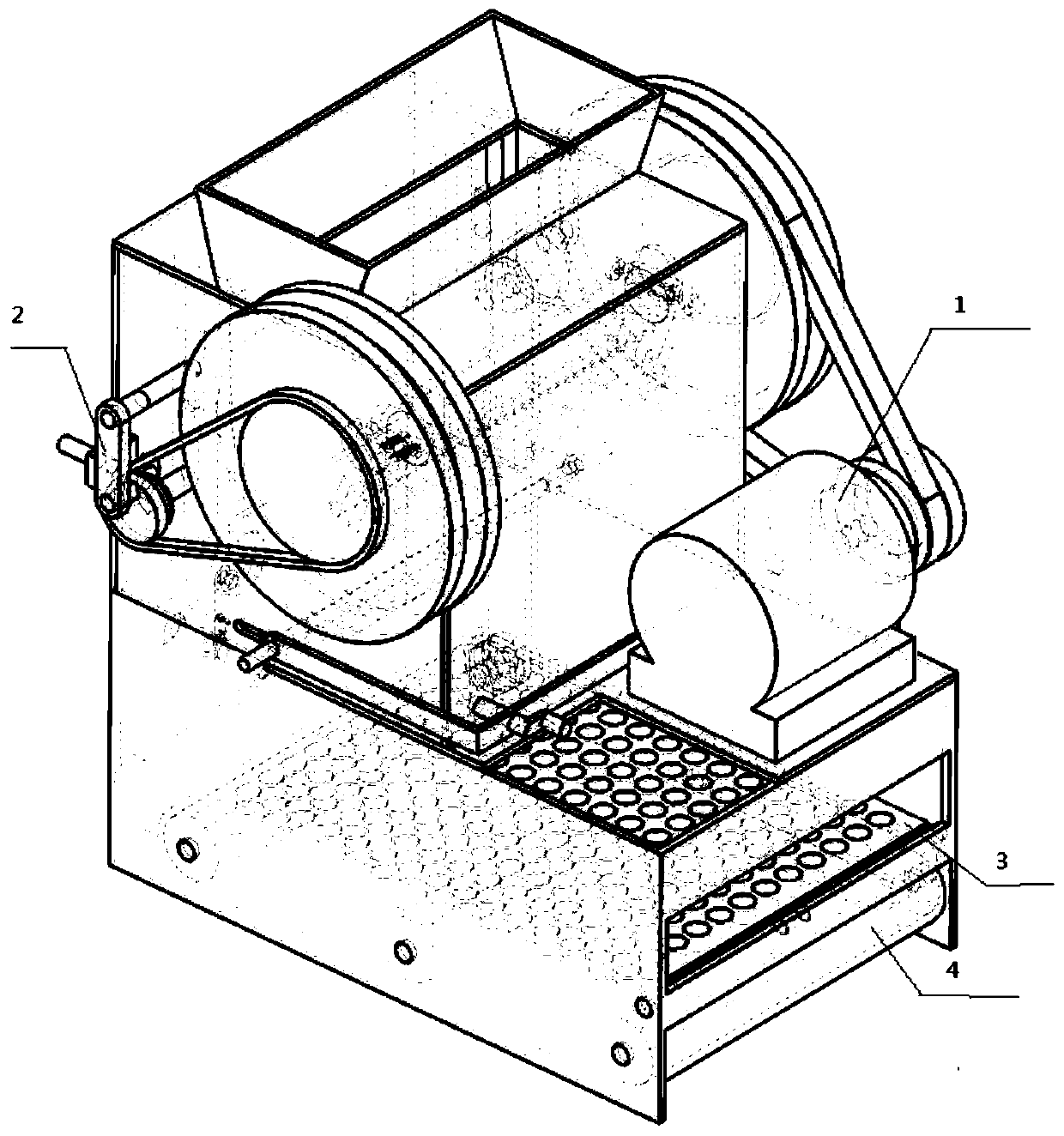

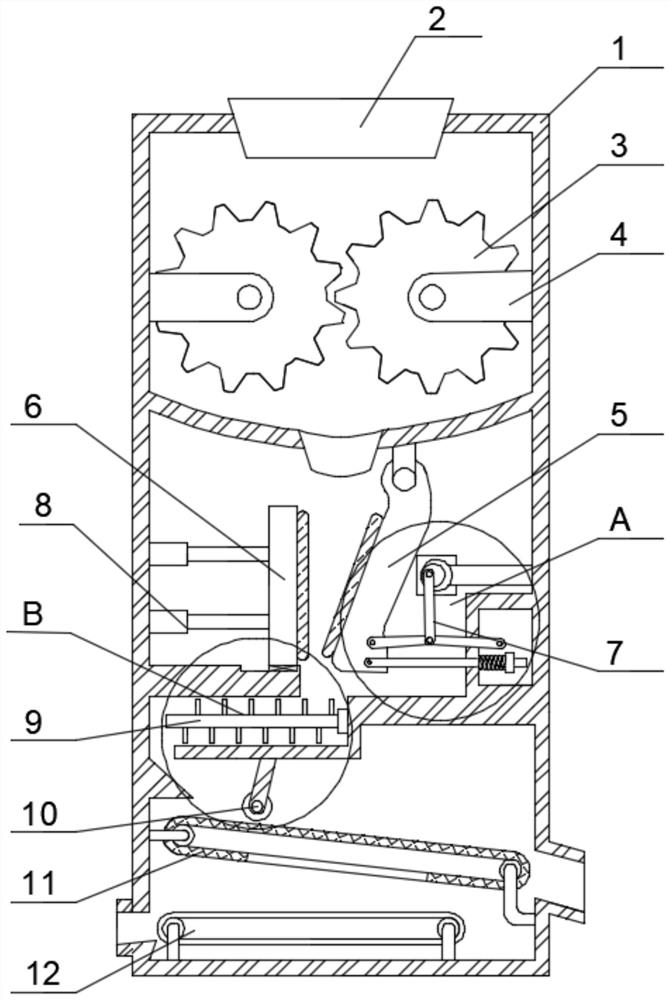

Anti-blocking waste concrete recycling screening device with good crushing effect

InactiveCN109772501AImprove crushing effectSimple structureSievingScreeningScreening effectElectric machinery

The invention relates to an anti-blocking waste concrete recycling screening device with the good crushing effect. The anti-blocking waste concrete recycling screening device with the good crushing effect comprises a main body, a feeding pipe, a discharging pipe and screen cloth, and further comprises an unchoking mechanism and two crushing mechanisms. The unchoking mechanism comprises a mobile plate, two mobile assemblies and a plurality of unchoking rods. Each mobile assembly comprises a first motor, a wire spool, a pull wire, a fixed plate and a first spring. Each crushing mechanism comprises a driving assembly and a crushing assembly. Each crushing assembly comprises a connecting block and a crushing plate. Each driving assembly comprises a second motor, an eccentric wheel, a supporting plate, a lifting rod, a second spring and a lantern ring. According to the anti-blocking waste concrete recycling screening device with the good crushing effect, because the unchoking mechanism canbe used for carrying out unchoking work on screen meshes on the screen cloth, it is avoided that the screening effect is affected because the screen meshes are blocked by concrete; and because the crushing mechanisms can be used for carrying out crushing work on concrete chunks, and it is avoided that the screening work cannot be carried out because concrete is large in size.

Owner:江苏昆腾新材料科技有限公司

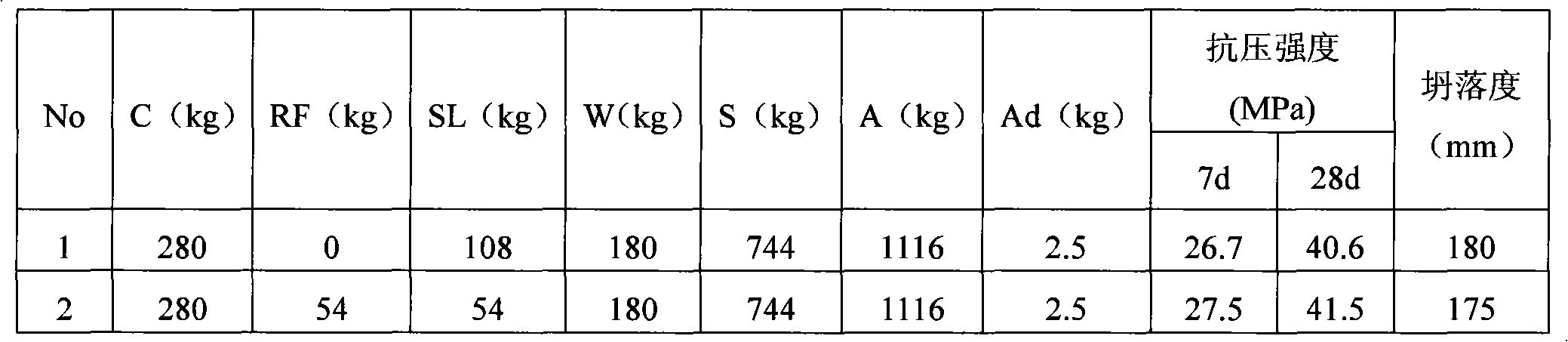

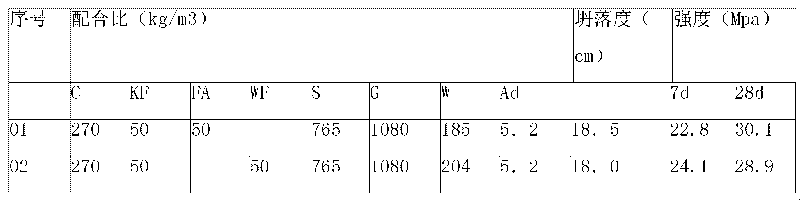

Pumpable high-strength recycled concrete and preparation technology thereof

InactiveCN106007556AHigh strengthIncrease slumpSolid waste managementSuperplasticizerPulverized fuel ash

The invention discloses pumpable high-strength recycled concrete and a preparation technology thereof. Waste concrete is utilized to make recycled coarse and fine aggregates. In the crushing process of the waste concrete, the recycled coarse aggregates and the recycled fine aggregates are produced, and good grading is formed. A proper amount of natural stones, cement, pulverized fuel ash, silicon powder, a high-efficiency water reducing agent and water are added according to the proportion, and C40-C60 graded high-strength recycled concrete can be obtained after mixing. The waste concrete in construction waste is fully utilized, and waste concrete recycling is achieved on the premise that the strength and performance are not affected.

Owner:GUANGZHOU UNIVERSITY

Waste concrete recycling and screening device

InactiveCN103071624AAvoid pollutionAvoid wastingSievingGas current separationMixed materialsEngineering

The invention discloses a waste concrete recycling and screening device, which mainly comprises a first screening device, a second screening device and vibration devices, wherein the first screening device has a multi-layer rotary screen structure; the second screening device has a single-layer rotary screen structure; the first screening device and the second screening device are connected through conveying equipment; lower parts of the first and second screening devices are provided with the vibration devices; and the first and second screening devices can move vertically along the vibration devices to vibrate. A problem that meshes of the screening devices are blocked is solved and the screening efficiency is improved. A mixture of coarse aggregate (stones), fine aggregate (sand) and hardened mortar recycled from waste concrete is effectively screened, and the separated and screened stones and sand have performance similar to natural stones and sand and can be reutilized in newly mixed concrete; and sand in small grain size (less than 1.25mm) of the hardened mortar and powder in grain size of less than 0.16mm of the hardened mortar can be screened out totally to serve as a cement mixed material or an admixture of premixed concrete, so that waste resources are recycled.

Owner:XUCHANG HENGRUI BUILDING MATERIALS CO LTD

Recycling method of waste concrete

InactiveCN101538132AImprove mechanical propertiesPromote ecological balanceSolid waste managementConcrete recyclingFineness

The invention discloses a recycling method of waste concrete, comprising the following steps of: (1) carrying out crushing processing to the waste concrete, carrying out drying processing to the crushed waste concrete with the drying temperature of less than 80 DEG C; (2) carrying out screening to the crushed waste concrete with meshes of the screen being less than or equal to 2.36mm; (3) carrying out ball milling to the crushed fine waste concrete obtained by the step (2) and with the particle size of not more than 2.36mm, obtaining the powder with the specific surface area of fineness being larger than or equal to 300m<2> / kg after ball milling; and (4) adopting the waste concrete particles obtained by the step (2) and with the particle size of larger than 2.36mm as recycled concrete aggregate. Compared with the similar product in the prior art, the recycling method can completely recycle the waste concrete, is beneficial to ecological balance of the ambient environment, can achieve use requirements without calcination, does not need extra resource for consumption and has low production cost.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

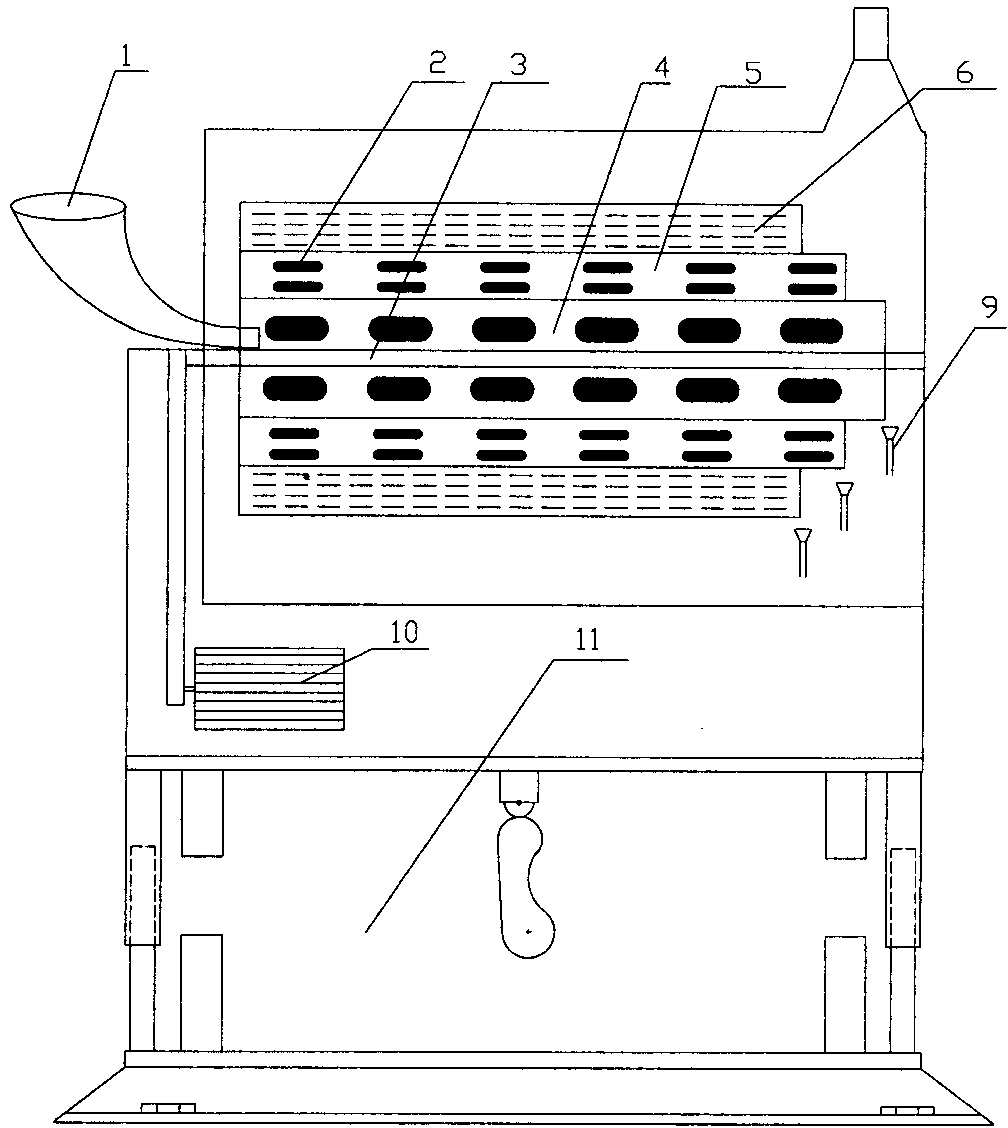

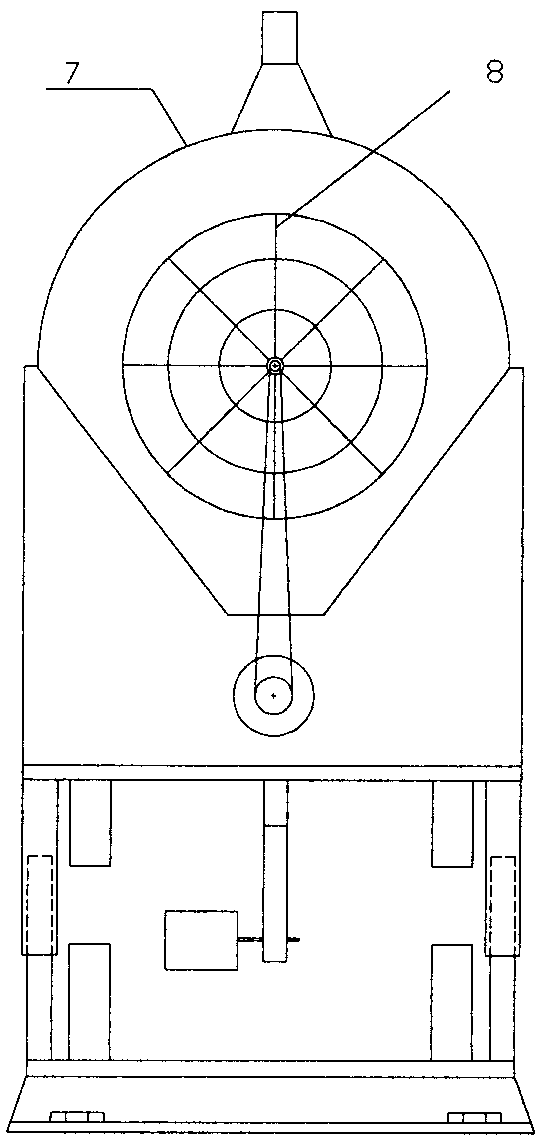

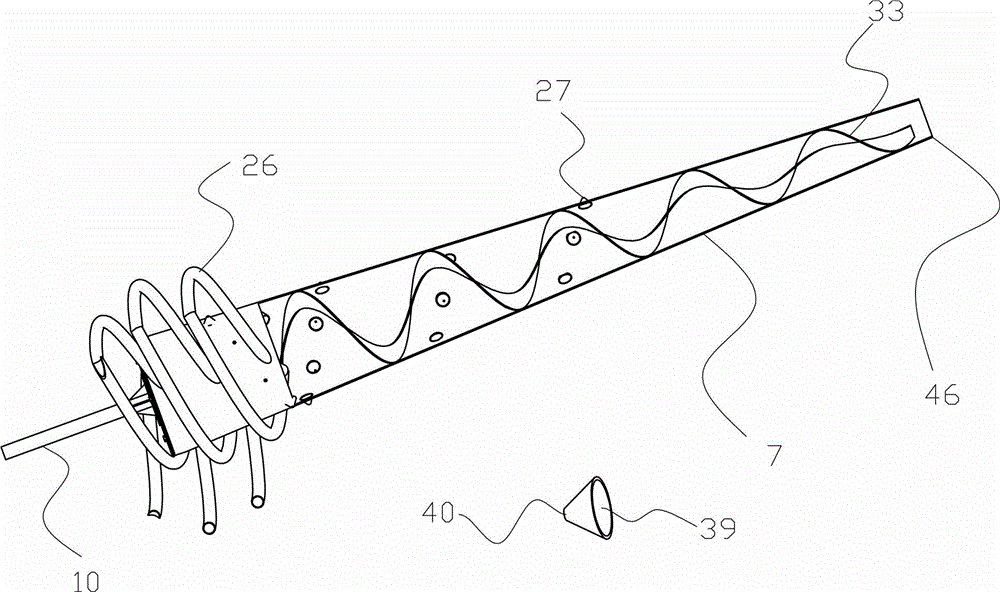

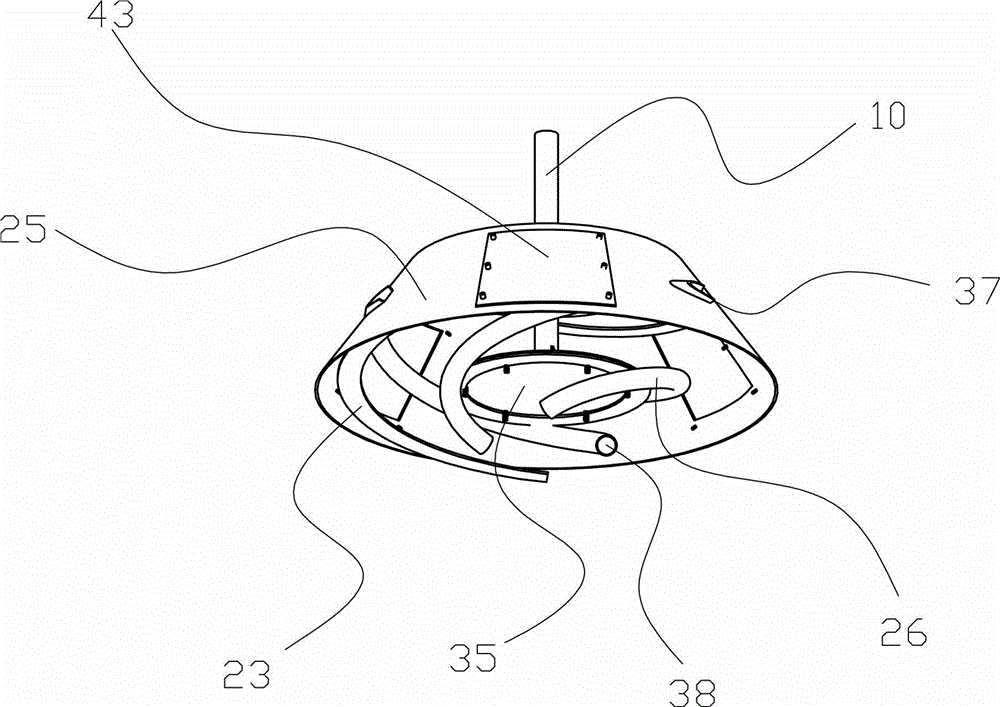

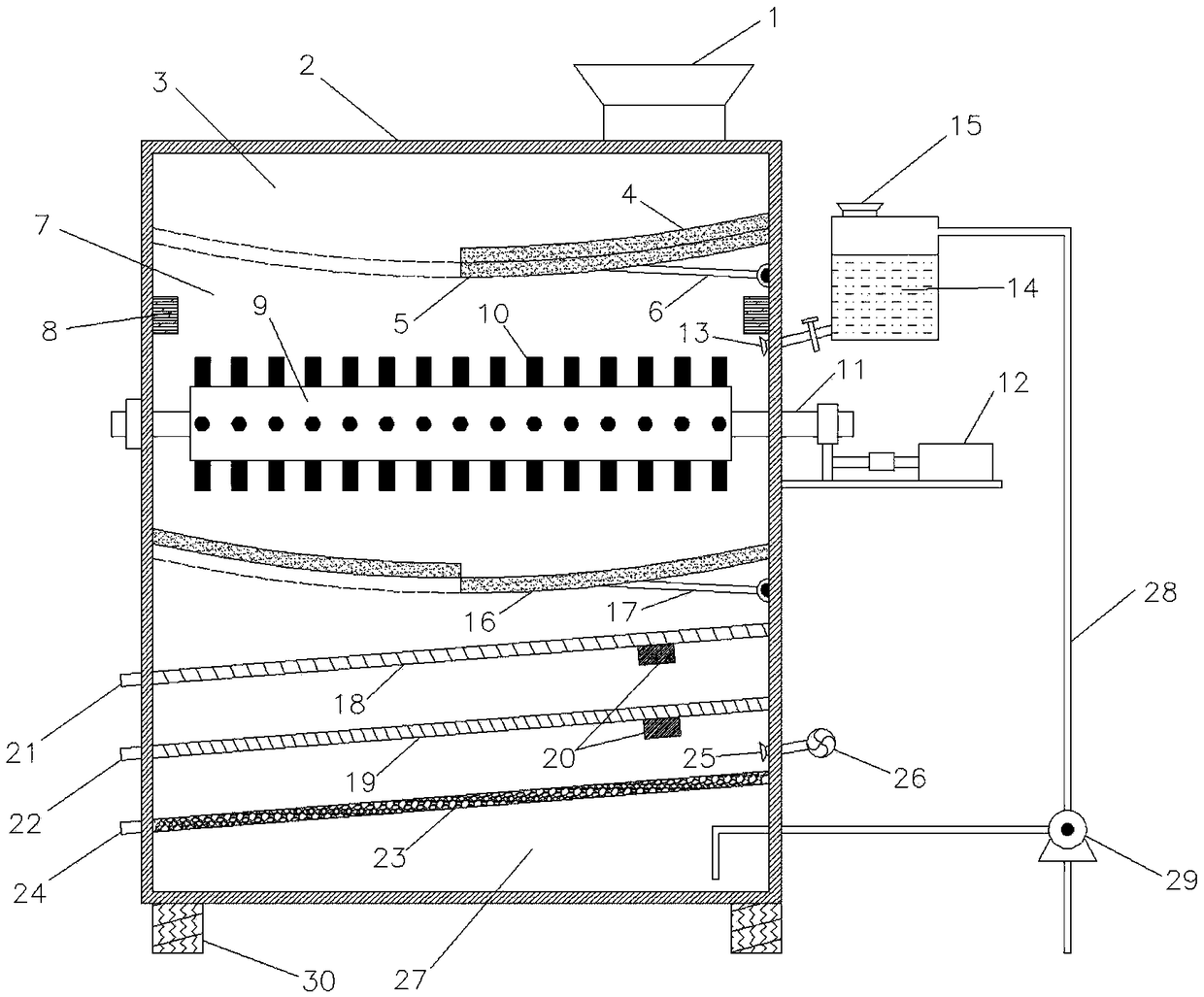

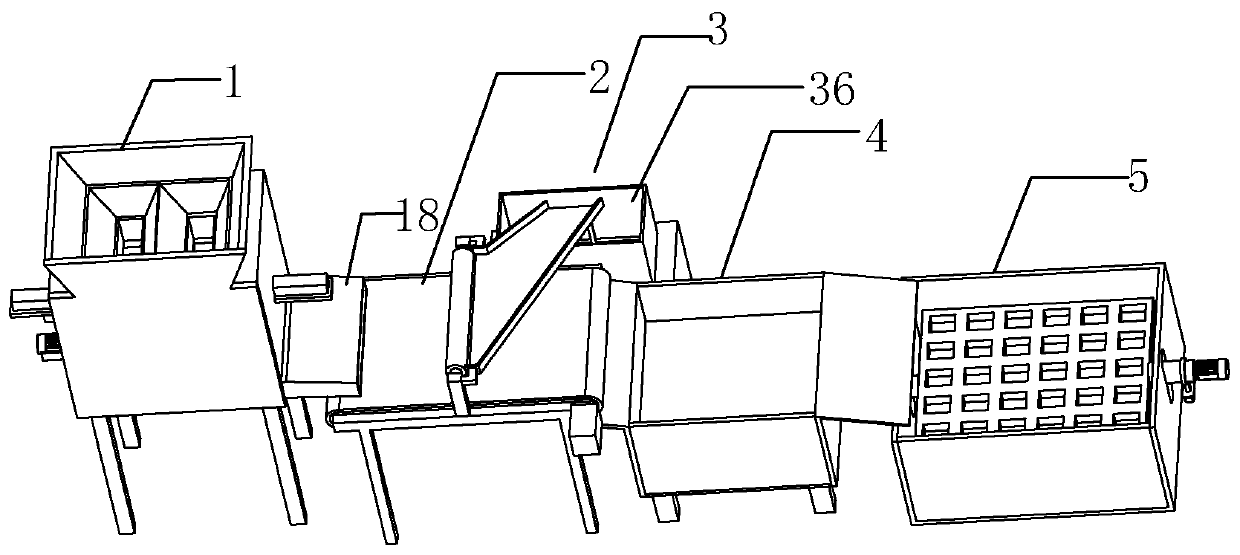

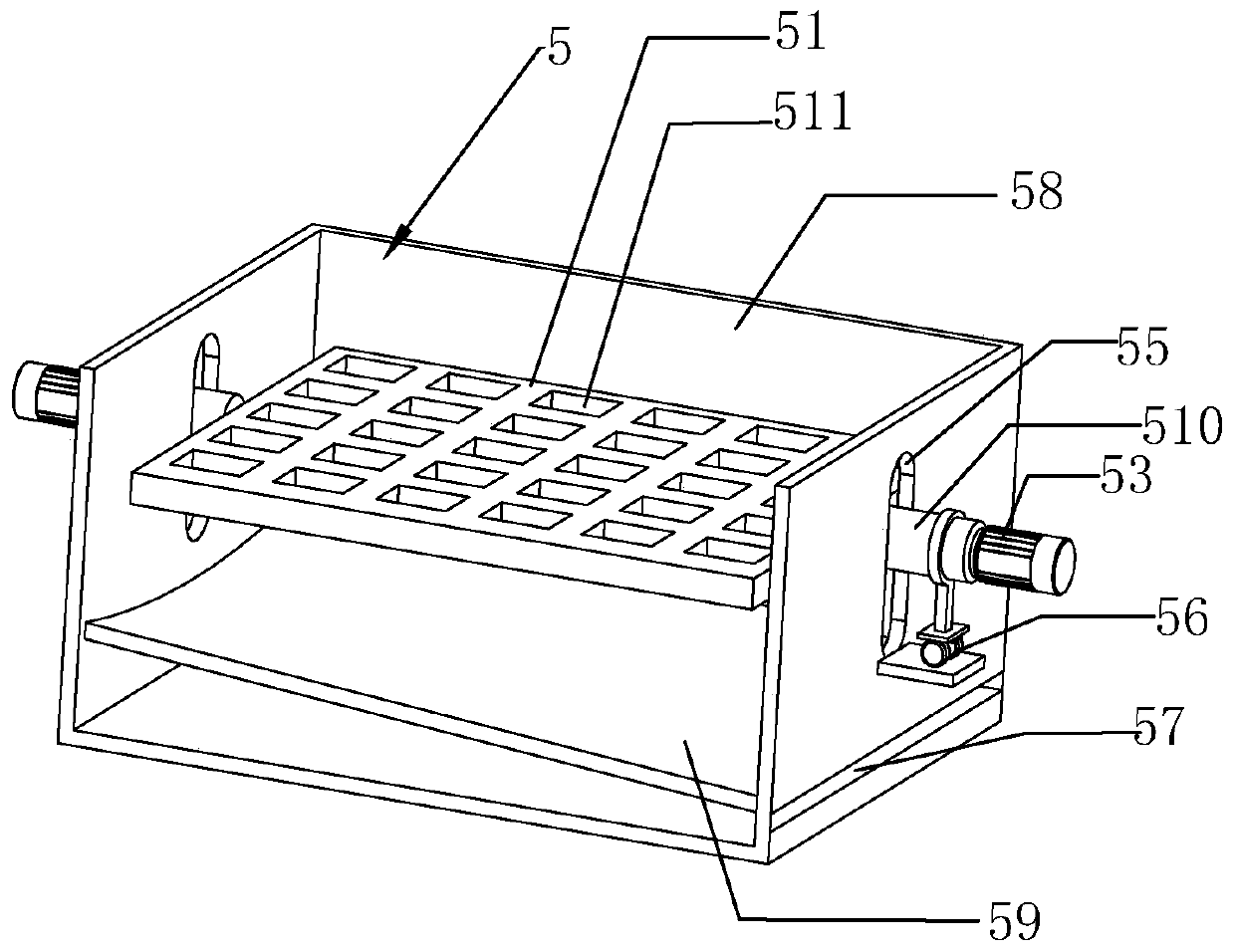

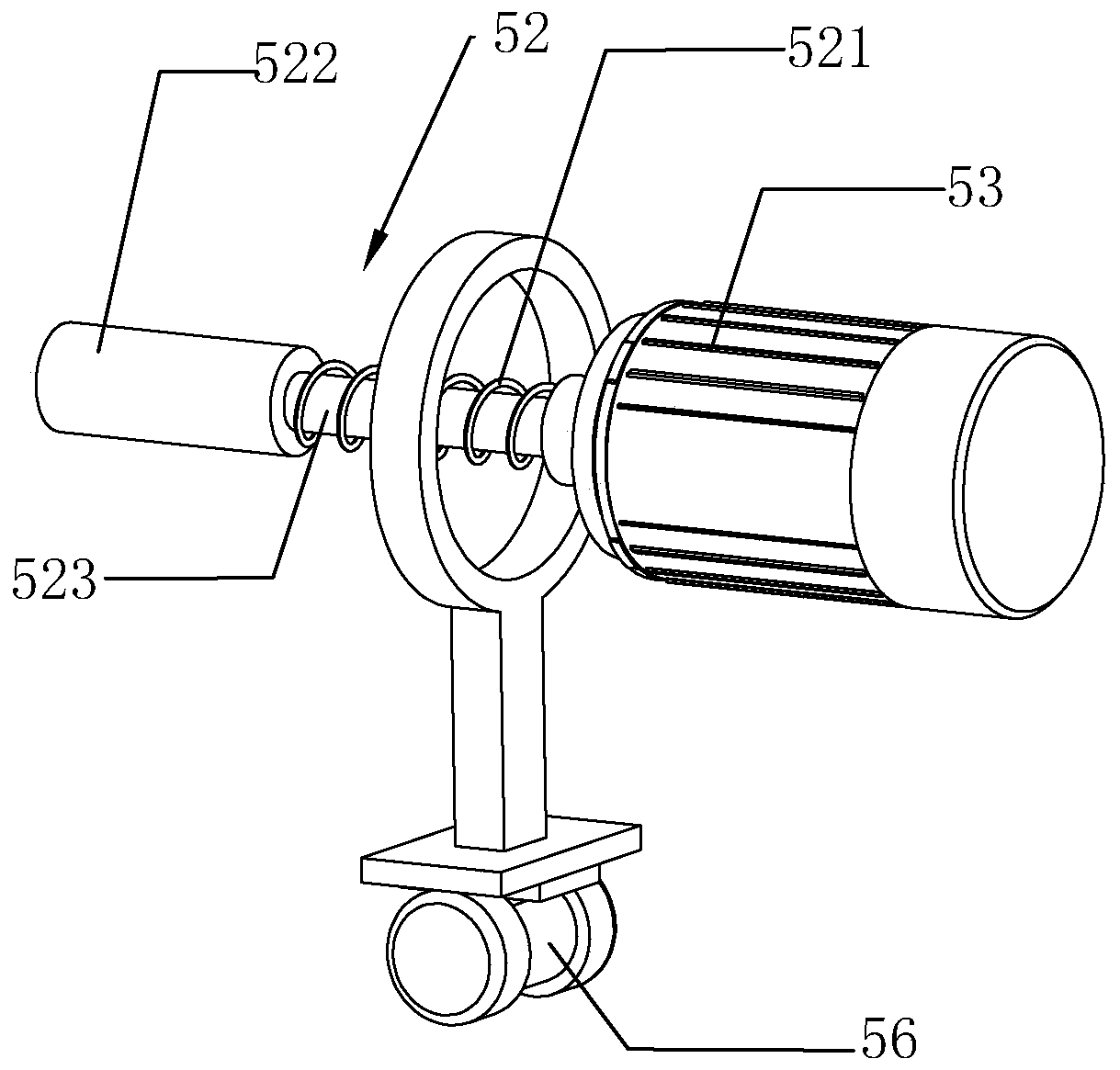

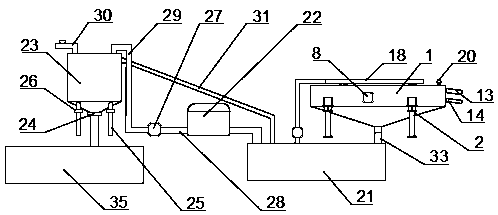

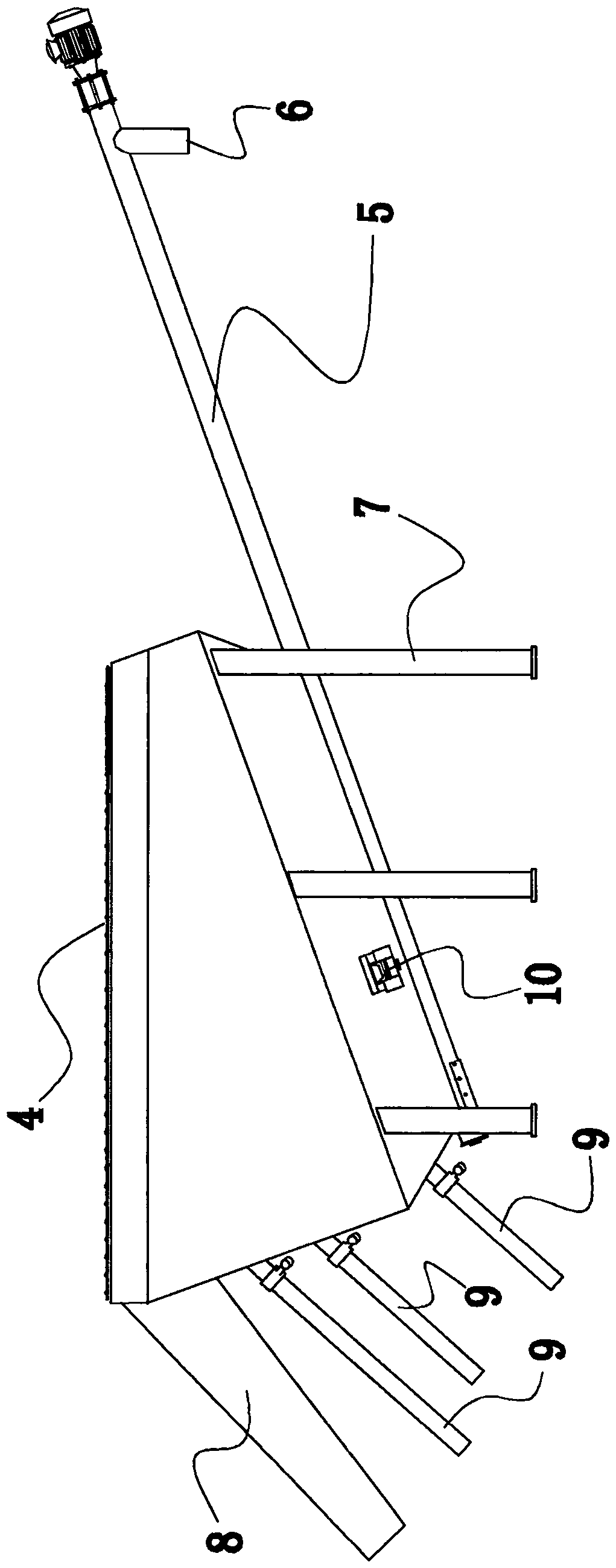

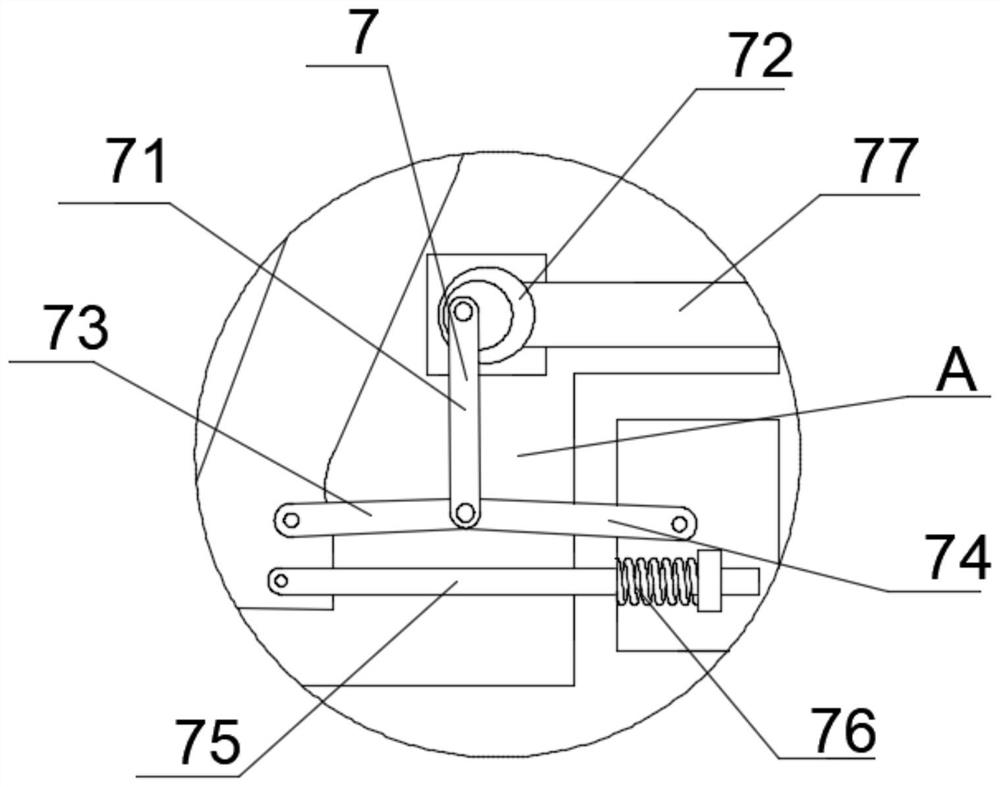

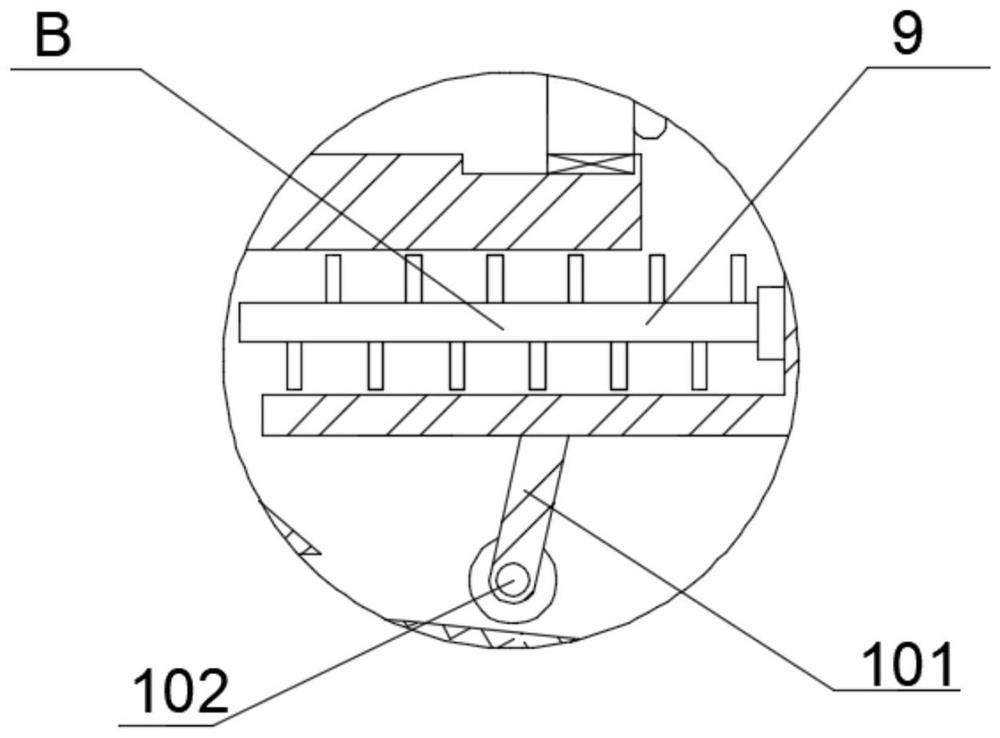

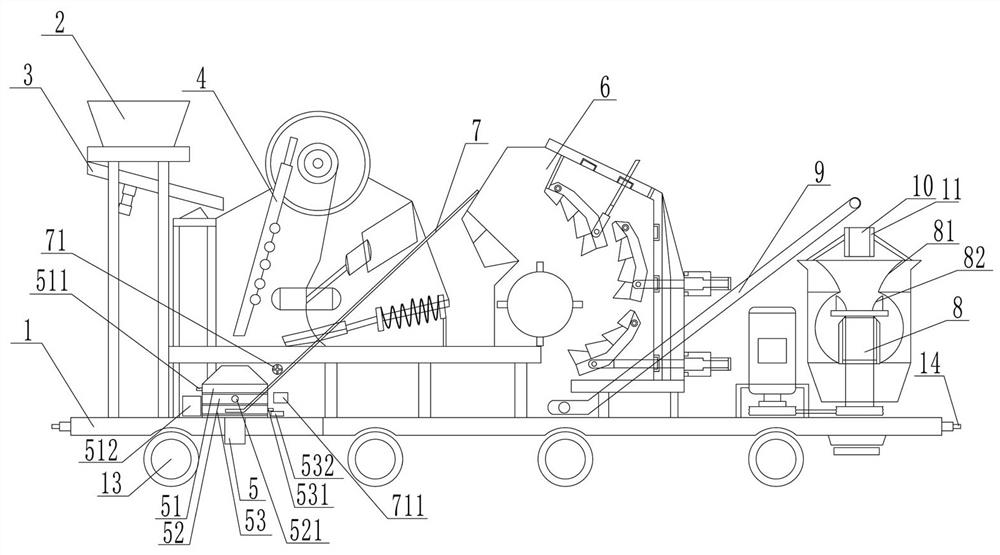

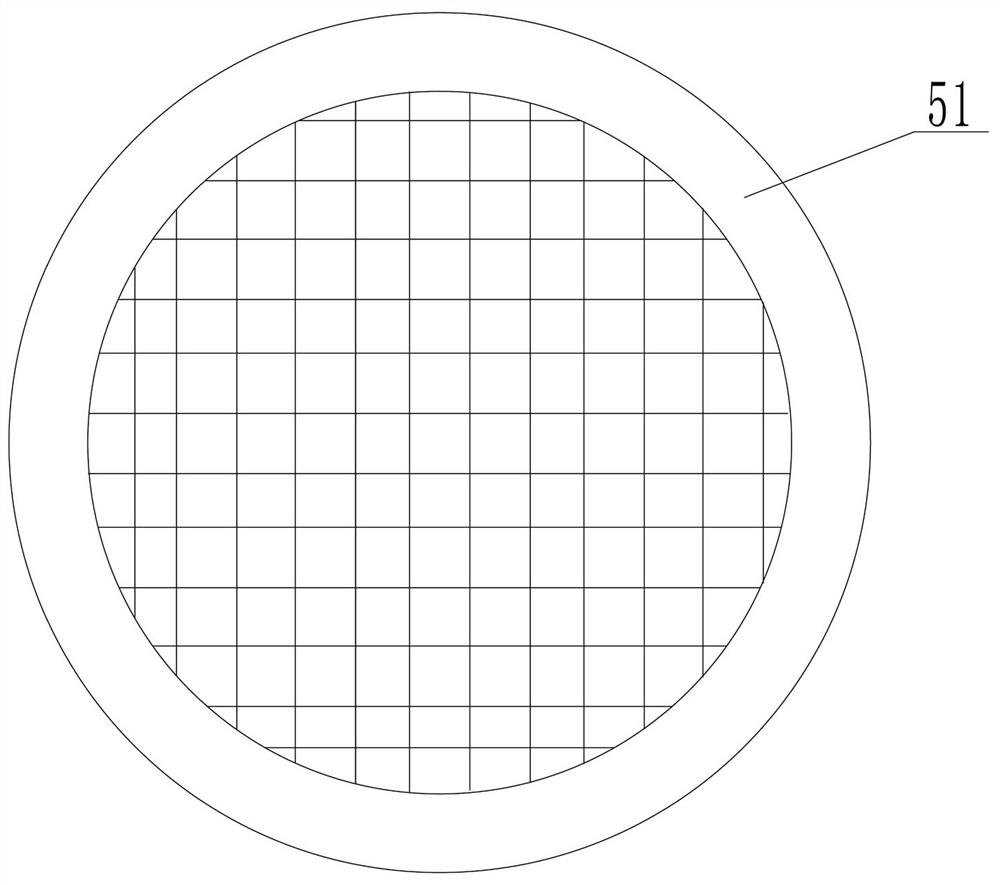

Wet concrete recycling and screening machine with automatic sewage pumping and transporting function and application method thereof

The invention belongs to the technical field of wet concrete recycling, and relates to a wet concrete recycling and screening machine and an application method thereof. The machine has an automatic sewage pumping and transporting function and an automatic fine sand filtration function. The provided screening machine has the advantages of small material transportation resistant force, controllable sewage flow, easy separation between fine sand from sewage, and reduction on energy and water. The screening machine comprises screening and transporting devices for sewage, stones, and sand materials. The application method comprises steps of pre-mixing, transportation, screening on stones and sand materials, and transportation of stones and sand materials. The recycling and screening machine has the following advantages: (1) the material is fed in a higher place and discharged in a lower position, and thus the transportation resistant force is greatly reduced; (2) the sewage in the recycling and screening machine is pumped and transported, and changed is the conventional sewage recycling method through a sewage overflowing opening; (3) the filtration of sewage containing fine sand and automatic screen net cleaning are realized; (4) the vehicle washing tank is clean without washing, the fine sand in sewage can be completely filtered and removed without a swirl separation system, and the screen net can be maintained a clean state without washing during vehicle cleaning.

Owner:铜陵亚摩管业有限公司

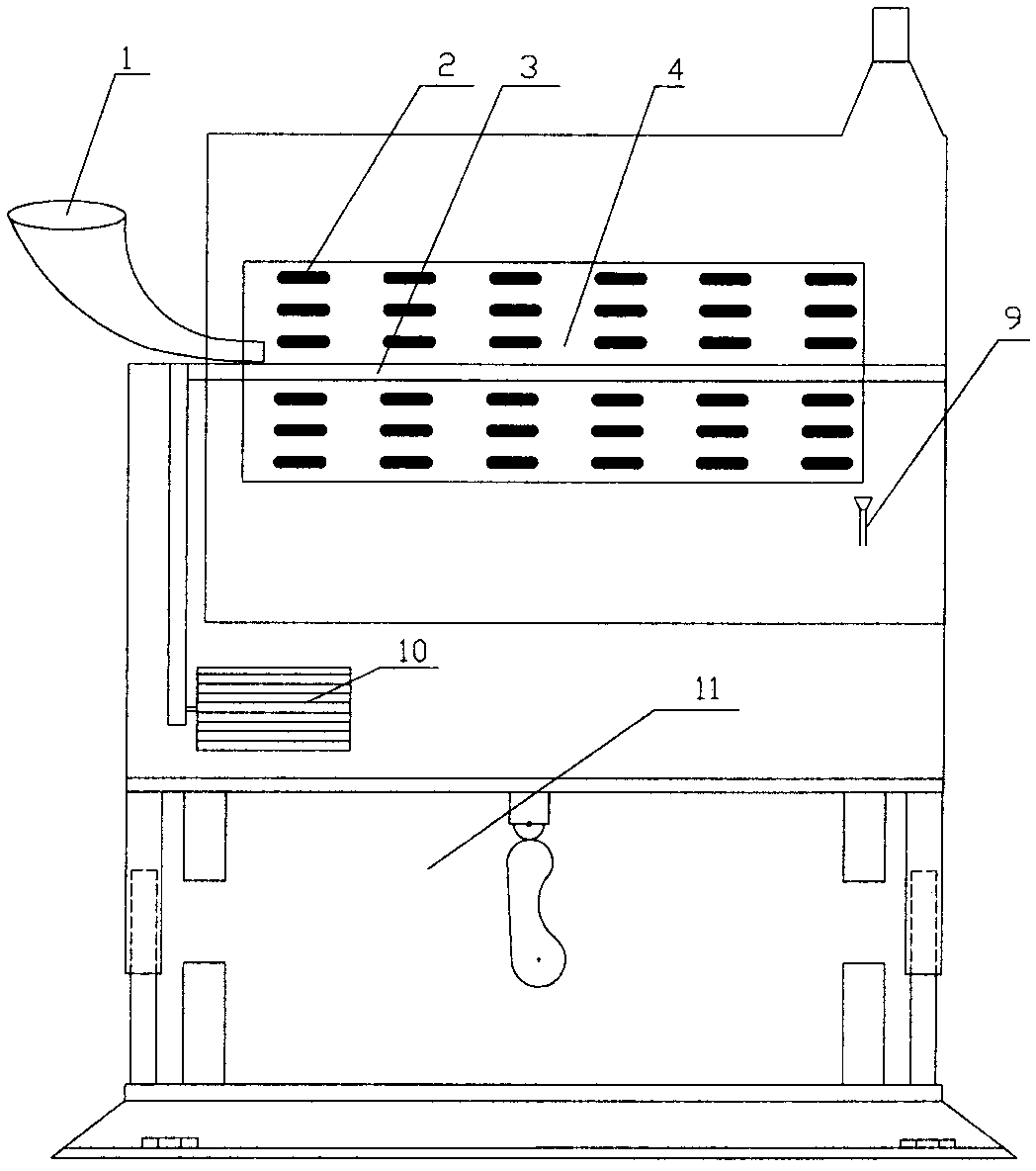

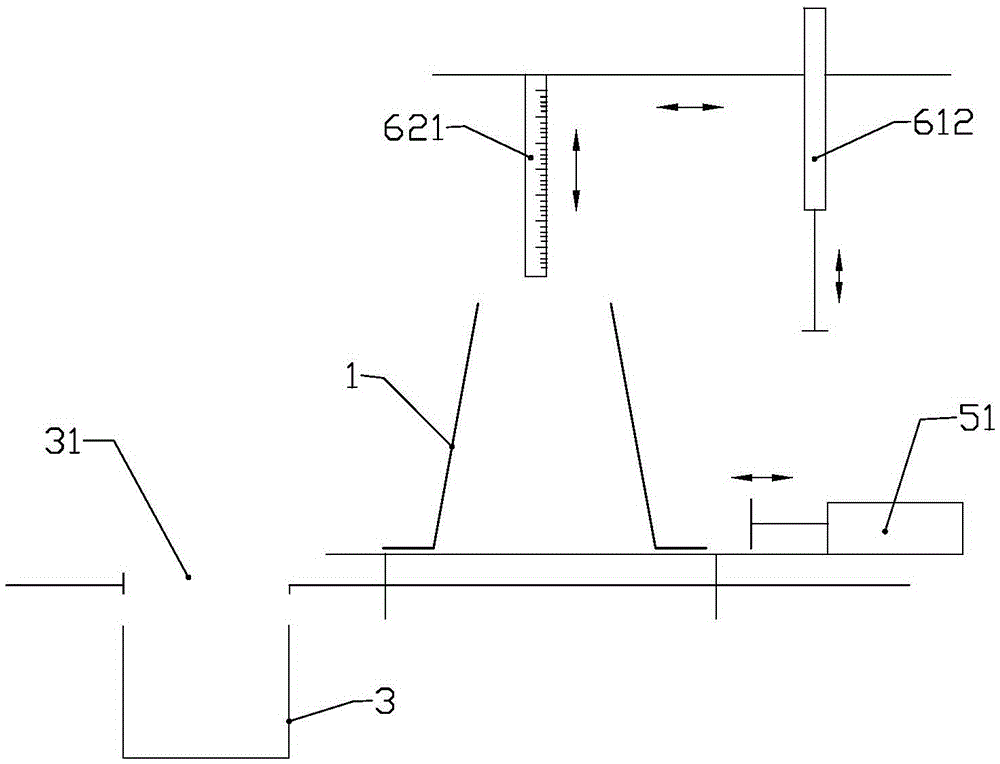

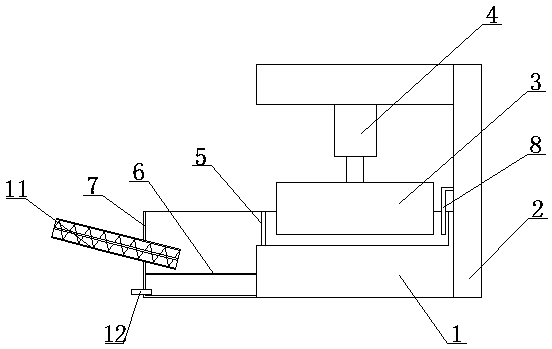

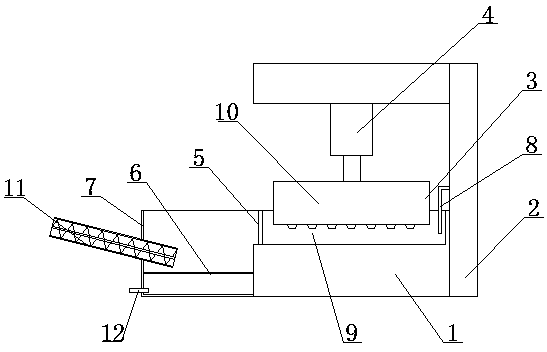

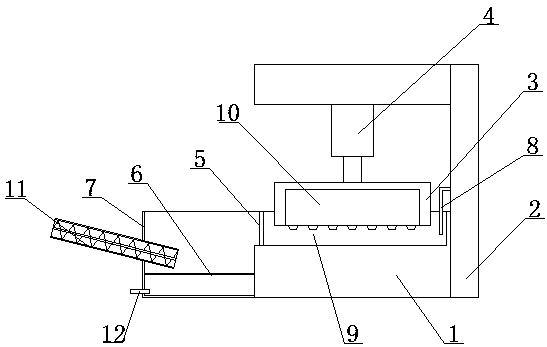

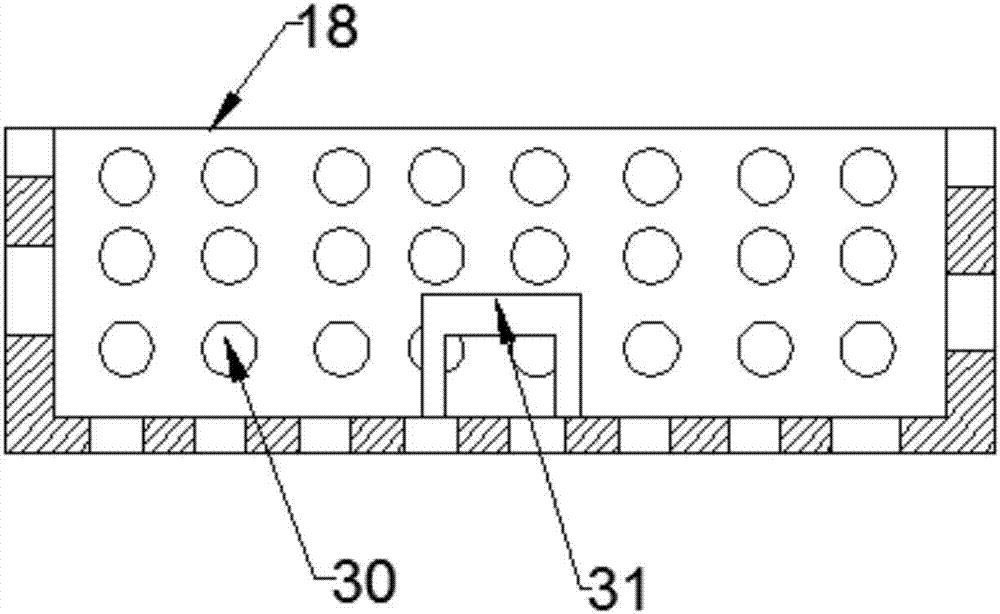

Movable concrete slump testing device

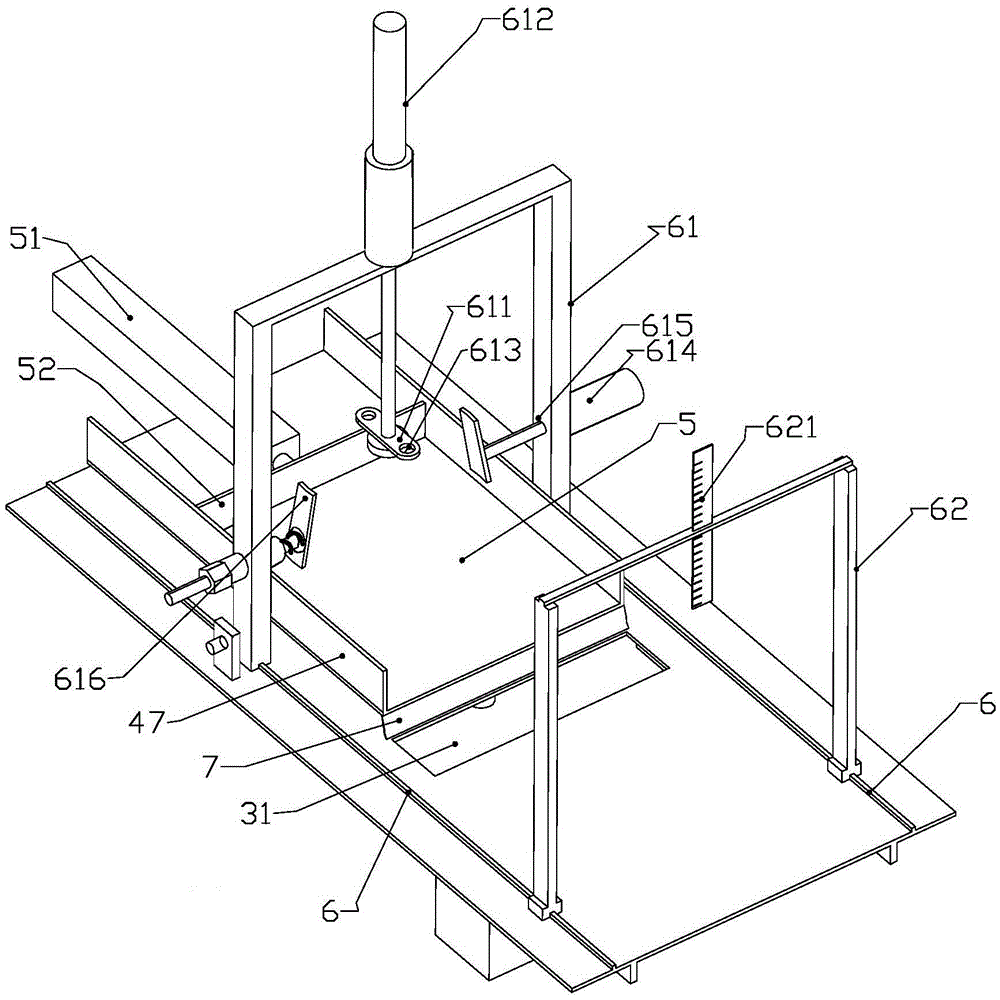

ActiveCN105628903AGuarantee authenticityGuaranteed validityMaterial testing goodsTest platformPortal frame

The invention discloses a movable concrete slump testing device. The movable concrete slump testing device comprises a testing tube, a cart, a tamping mechanism, a measuring mechanism and a clearing mechanism, wherein a panel adjustable in height and angle is arranged on the table surface of the cart, has a three-dimensional adjusting capability, and is convenient to level; on the table surface, a first portal frame and a second portal frame are arranged on linear sliding rails; the tamping mechanism is arranged on the first portal frame; the measuring mechanism is arranged on the second portal frame; the clearing mechanism is arranged on the panel, and is matched with a discharge opening in the table surface for use; and a concrete recycling barrel is fixed below the discharge opening. The concrete slump testing cart is applicable for on-site concrete slump test, can adjust the levelness of a test platform according to site adjustment to ensure accuracy of a measurement result as well as a tamping force and a demoulding force, has a more standardized process and provides a support for accurate determination of the concrete slump.

Owner:GUANDONG YIAN CITY CIVIL AIR DEFENSE ENG CO LTD

Concrete recycling device used for building energy saving and environment protecting

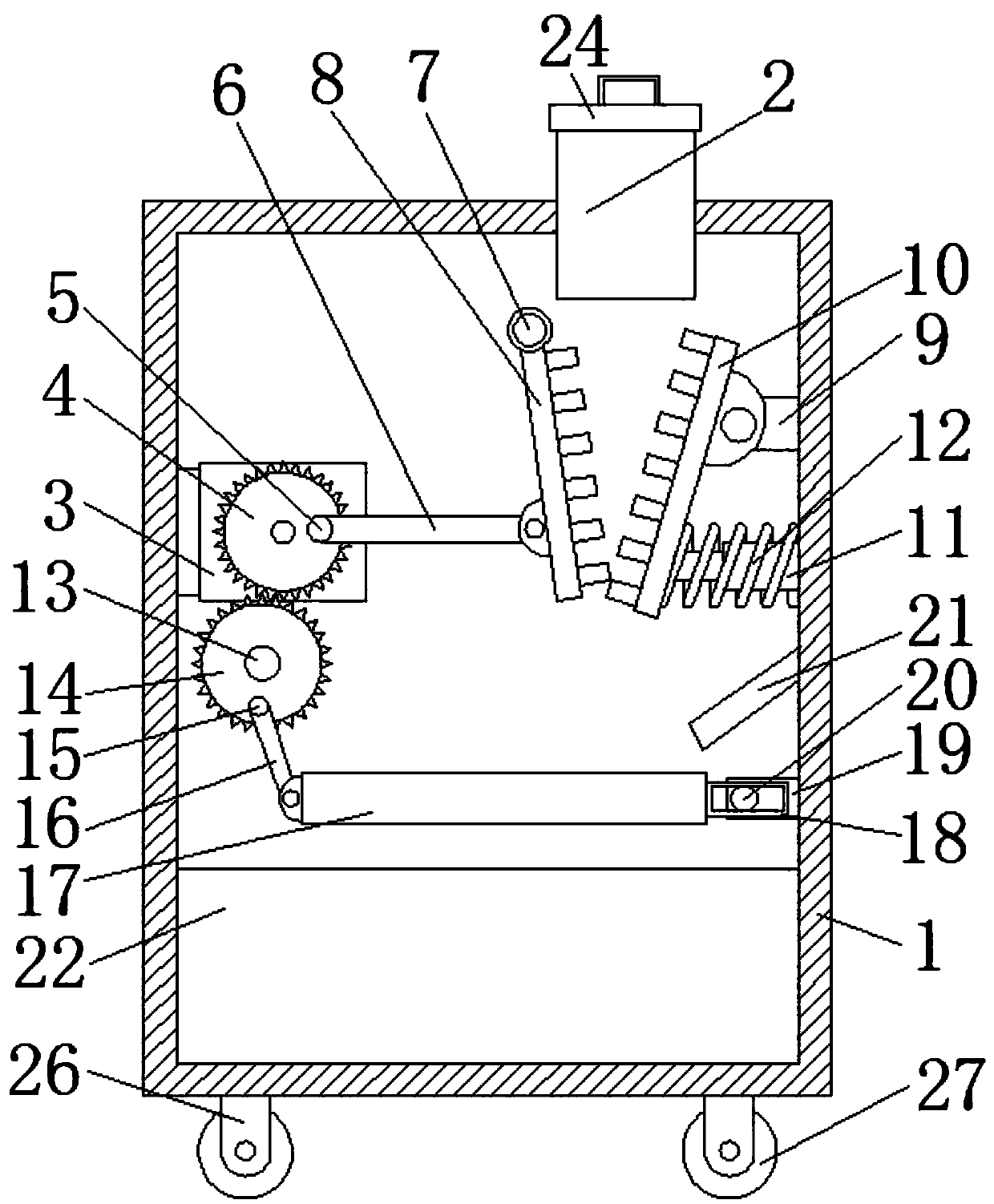

InactiveCN109513471AImprove recycling efficiencyAvoid distributingSievingScreeningGear wheelBuilding energy

The invention discloses a concrete recycling device used for building energy saving and environment protecting. The concrete recycling device comprises a box. The right side of the top of the box communicates with a feed pipe. The left side of an inner cavity of the box is fixedly connected with a motor through a motor base. An output shaft of the motor is fixedly connected with a first gear. Thefront face of the first gear is fixedly connected with a first rotary block. The surface of the first rotary block is sleeved with a first connecting rod. The inner cavity of the box is fixedly connected with a fixing rod. According to the concrete recycling device, through cooperative using of the motor, the first gear, the first rotary block, the first connecting rod, a left crushing block, thefixing rod, a limit block, a telescopic rod, a spring, a second gear, a second rotary block, a second connecting rod and a screening box, the problem that a traditional concrete recycling device is low in recycling efficiency is solved, the concrete recycling device used for building energy saving and environment protecting has the advantage of high recycling efficiency, the concrete recycling efficiency is improved, and the device deserves application and popularization.

Owner:孝感申泽机械科技有限公司

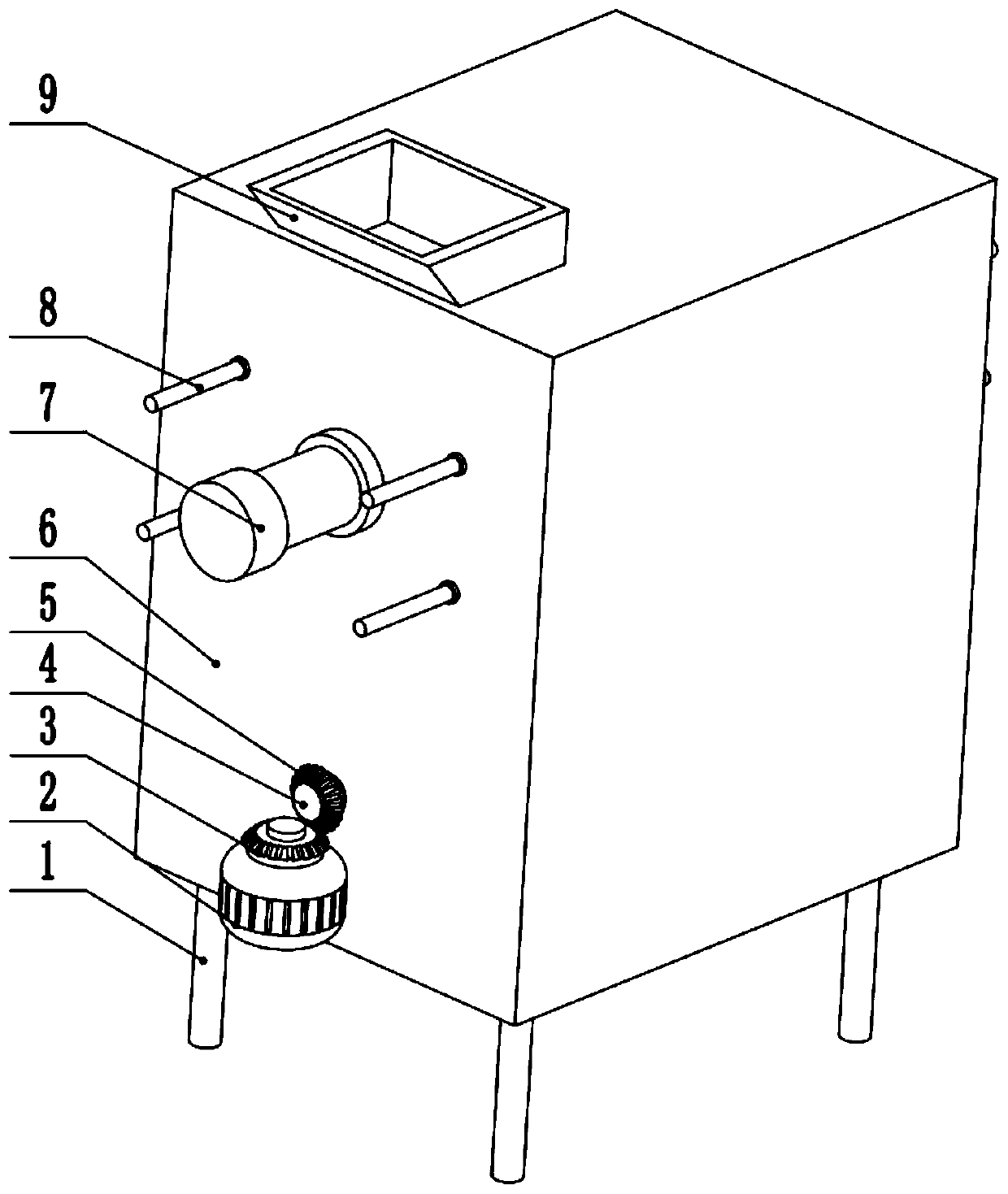

Cement concrete recycling method

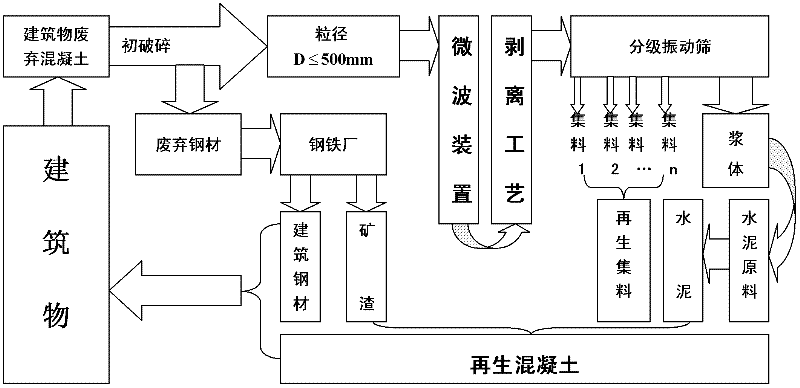

InactiveCN102503197AReduce energy consumptionSolid waste managementCement productionChemical compositionCement slurry

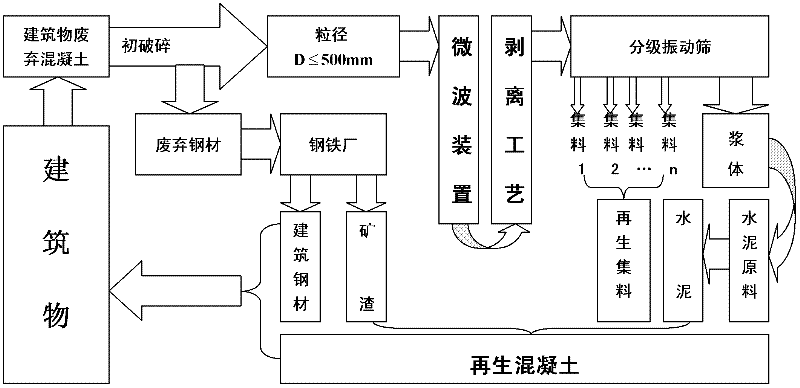

A cement concrete recycling method is disclosed, which comprises three parts of stripping aggregates and slurries in waste concrete, regenerating the aggregates and regenerating the slurries. A microwave heat treatment method is adopted for stripping the aggregates and slurries in the waste concrete, and mainly comprises the following steps: utilizing the difference between the microwave absorbing capability of the slurries and the microwave absorbing capability of the aggregates, putting the waste concrete into a sealed device provided with a microwave generator, subjecting the waste concrete to microwave irradiation so as to increase the temperature until the concrete is made brittle by irradiation, rotating the brittle concrete in a cylinder with a gridding lining, and utilizing the mutual collision to thoroughly strip the slurries and the aggregates. The aggregate regeneration comprises the following steps: for the aggregates stripped from the concrete, screening the residual part after a powder concentrator collects a part of the dehydrated phase powders of cement slurries, and preparing into regenerated aggregates of different sizes. The slurry regeneration comprises the following steps: according to different chemical compositions of the dehydrated phases of the cement slurries, blending and correcting raw materials specifically, enabling the rate of the raw material to meet the requirements of silicate cement raw material, and then adopting a traditional kiln or microwave to sinter and prepare silicate cement.

Owner:WUHAN UNIV OF TECH

Multi-stage environmentally friendly crushing device for concrete waste

InactiveCN111468272ACompletely brokenGood effectGrain treatmentsHydraulic cylinderArchitectural engineering

The invention relates to the technical field of concrete recycling, and discloses a multi-stage environmentally friendly crushing device for concrete waste. The multi-stage environmentally friendly crushing device comprises a crushing box, wherein the upper surface of the crushing box is provided with a feed inlet on the left side, the top of the crushing box is provided with an electromagnet, theupper parts of the left and right side walls of the crushing box are provided with hydraulic cylinders, piston rods of the hydraulic cylinders are fixedly connected to extrusion plates, the middle parts of the left and right side walls of the crushing box are provided with second rotating seats that are rotatably connected to the upper parts of support plates, the middle parts of the lower surfaces of the support plates are rotatably connected to the piston rods of the cylinders, the lower ends of the cylinders are provided with first rotating seats that are rotatably connected to the lower part of the crushing box, the lower part of the left side wall of the crushing box is provided with a drive motor, and the output shaft of the drive motor is fixedly connected to a first bevel gear. The invention is suitable for a multi-stage environmentally-friendly crushing device for concrete waste. The extrusion plates are arranged on the upper part of the device to first crush large pieces ofconcrete and separate steel bars in the concrete.

Owner:新沂新硕混凝土有限公司

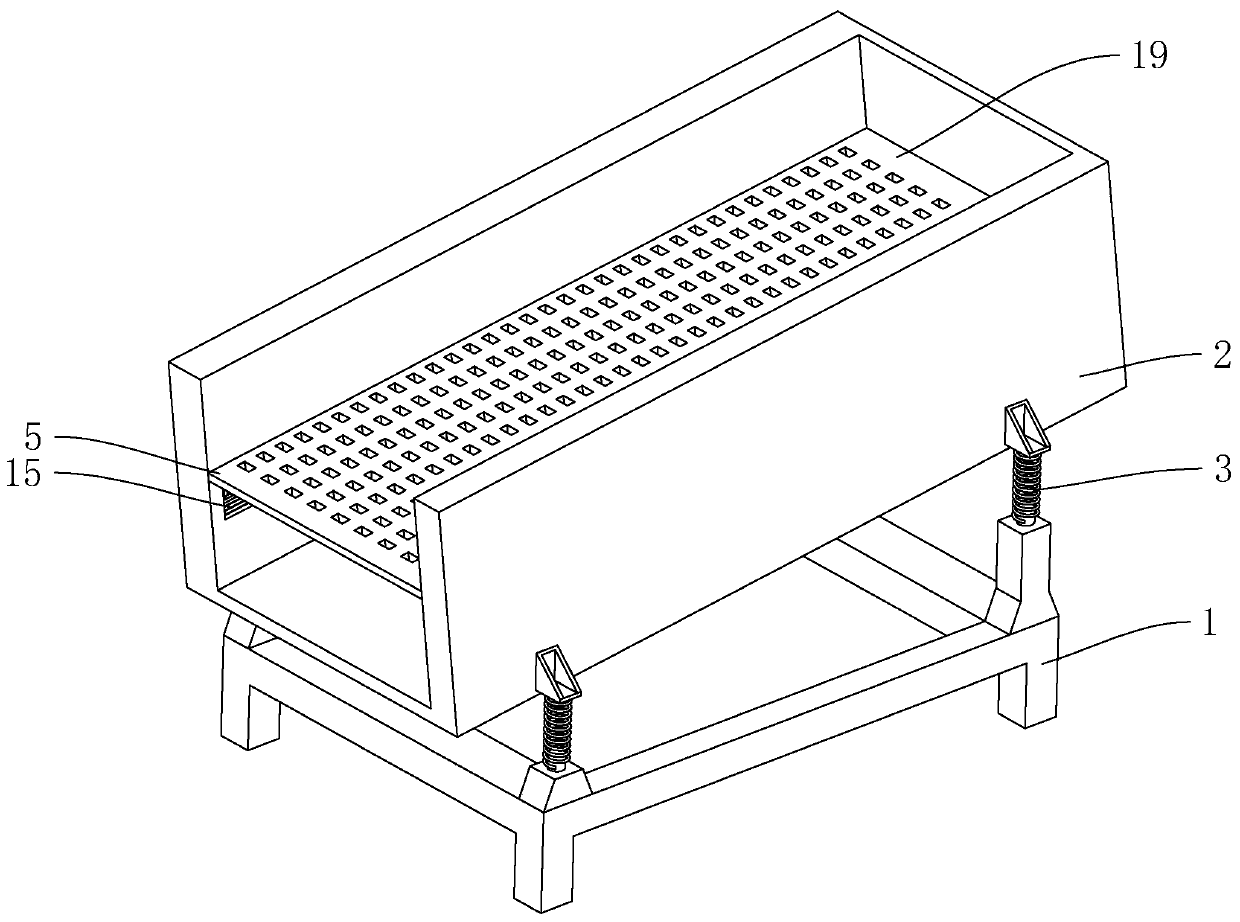

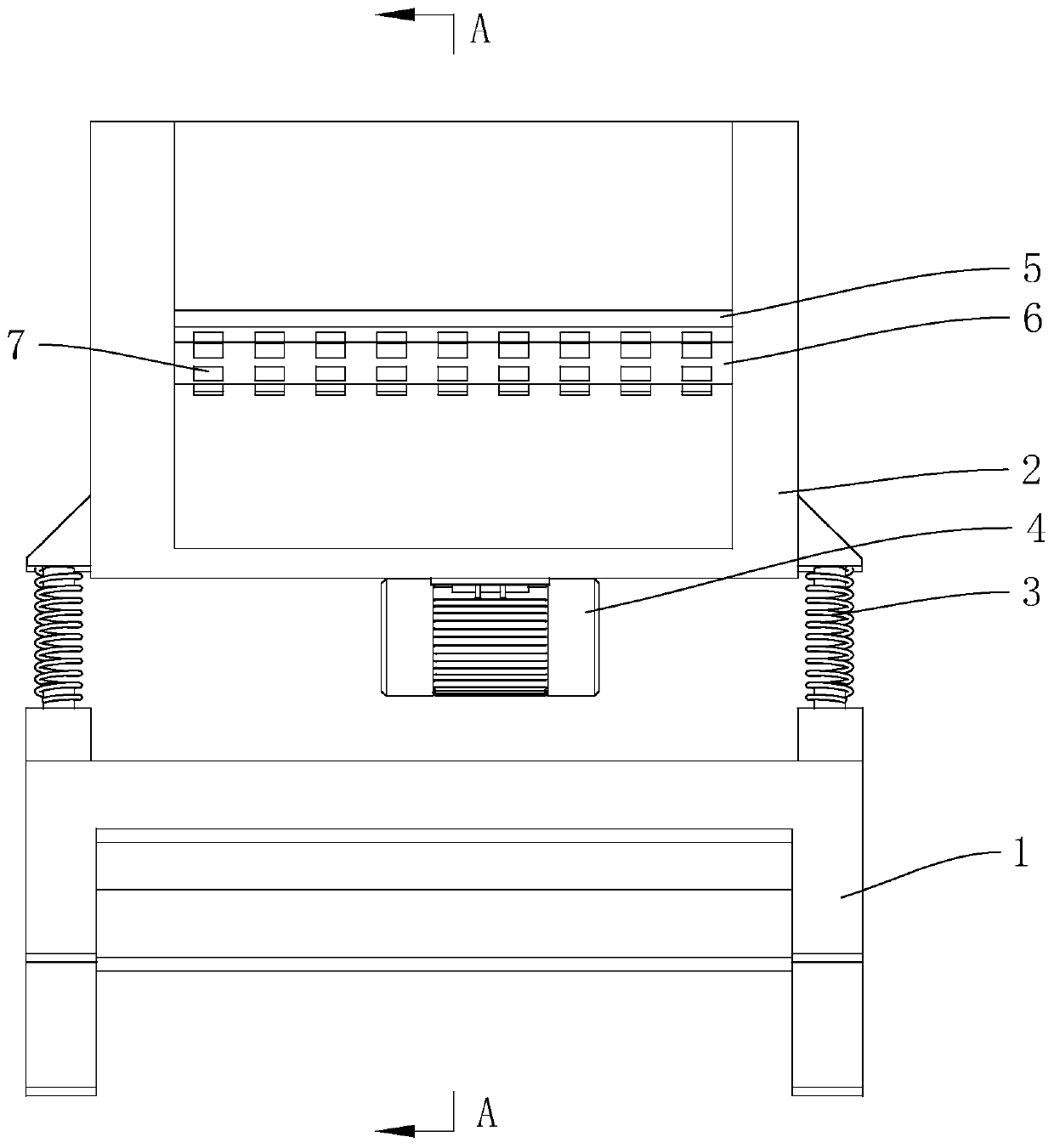

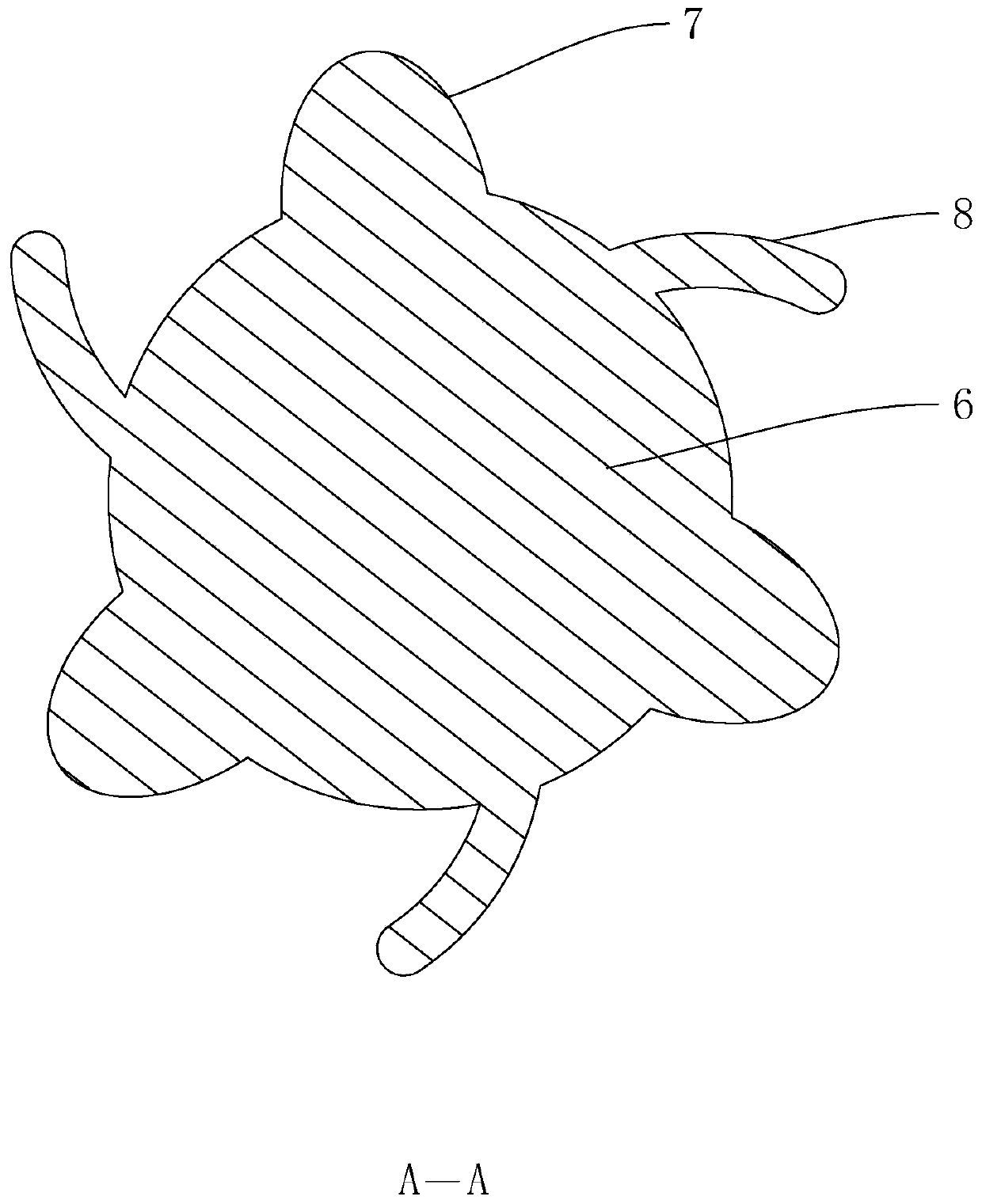

Recycled concrete aggregate screening device

ActiveCN111195596AImprove screening efficiencyPromote sportsSievingScreeningElectric machineryStructural engineering

The invention discloses a recycled concrete aggregate screening device, and relates to the field of concrete recycling equipment. The recycled concrete aggregate screening device is technically characterized by comprising a rack and a vibration hopper located on the rack, wherein damping springs are connected between the side wall of the vibration hopper and the rack, a vibration motor is arrangedon the side, facing the rack, of the vibration hopper, a screen plate with screen holes is arranged on the side, away from the rack, of the vibration hopper, the vibration hopper is obliquely arranged, a cleaning roller is arranged below the screen plate, a plurality of convex teeth meshing with the screen holes are arranged on the peripheral side of the cleaning roller, the axis of the cleaningroller is perpendicular to the inclination direction of the screen plate, a rotating assembly for driving the cleaning roller to rotate is arranged on the inner walls of the vibration hopper, and a driving assembly for driving the vibration hopper and the rotating assembly to move in the inclination direction of the screen plate is further arranged on the inner walls of the vibration hopper. The screening device has the advantage of being high in screening efficiency.

Owner:西安顺通建材有限责任公司

Method for recycling waste concrete

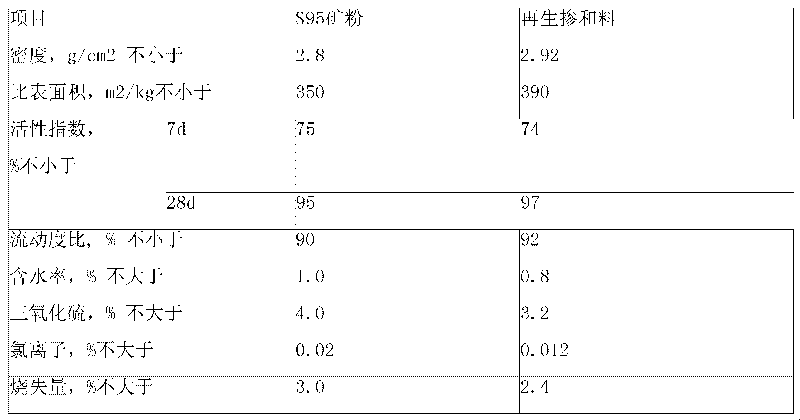

InactiveCN101734892AEmission reductionReduce pollutionSolid waste managementCrushed stoneSquare meter

The invention discloses a method for recycling waste concrete, which comprises the following steps: (1) crushing the waste concrete (which can contain mortar) in a crusher into a grain diameter of less than or equal to 20 mm, removing impurities, such as metal, wood and plastic, putting the waste concrete into a ball mill, simultaneously adding a concrete excitant accounting for 3 to 5 percent of the weight of the waste concrete, and milling the waste concrete into a specific surface area of more than or equal to 390 square meters per kilogram; and (2) mixing the recycled admixture with the specific surface area of more than or equal to 390 square meters per kilogram obtained from the step (1) and cement, medium-coarse sand, macadam with 5 to 25 mm, water and a concrete admixture in part by weight: 80 to 120 parts of the recycled admixture, 230 to 300 parts of the cement, 710 to 800 parts of the medium-coarse sand, 900 to 1,200 parts of the macadam, 160 to 200 parts of the water, and 4 to 6 parts of the concrete admixture to prepare the recycled concrete.

Owner:HUAIAN JIEDA CONCRETE

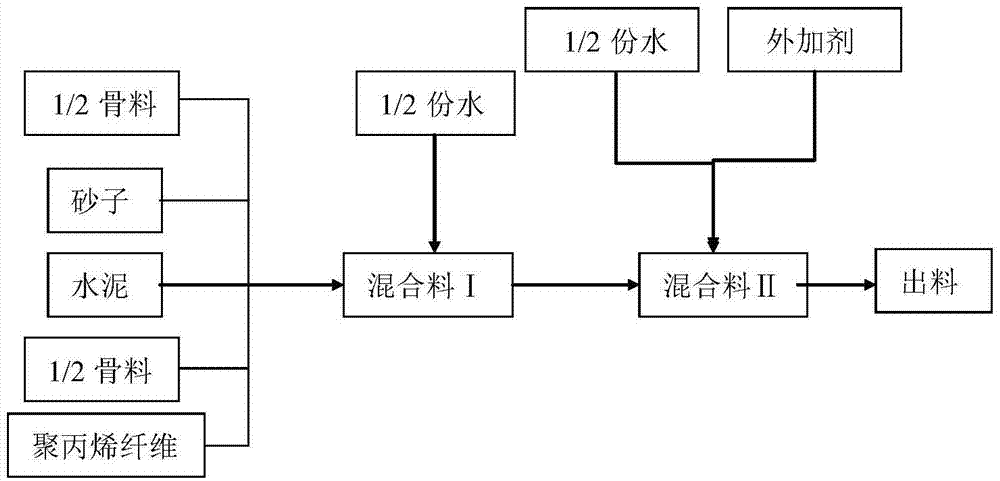

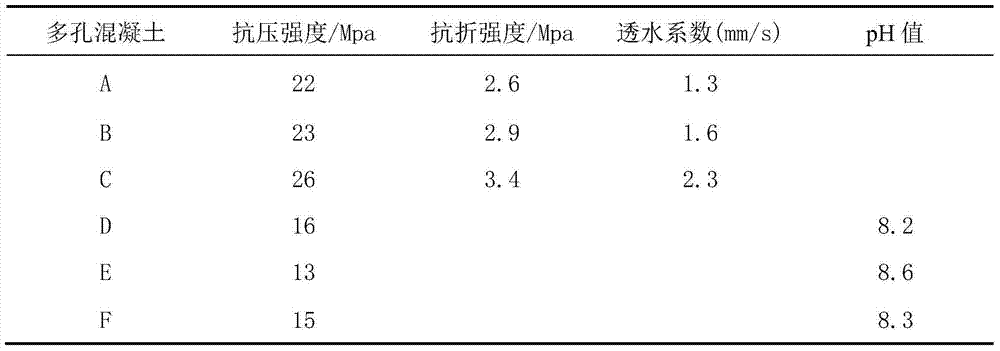

Porous concrete prepared from waste concrete aggregate and preparation method thereof

InactiveCN103771782ASolving Recycling ProblemsImprove tensile propertiesSolid waste managementSulfateSuperplasticizer

The invention discloses porous concrete prepared from waste concrete aggregate and a preparation method thereof. The porous concrete comprises 1-4 parts of polypropylene fiber, 250-300 parts of cement, 1200-1500 parts of recycled aggregate, 130-160 parts of sand, 90-110 parts of water, and 3-6 parts of admixture, wherein the admixture comprises 20-25 parts of a polycarboxylate superplasticizer, 10-15 parts of ferric sulfate, 10-15 parts of limestone powder and 50-60 parts of active silica solid particles. The preparation method comprises the following steps: firstly preparing the recycled aggregate of waste concrete, then mixing and stirring the polypropylene fiber, the cement, the recycled aggregate, the water and the admixture according to a mixture ratio, and uniformly stirring the mixture within corresponding time, thus obtaining the porous concrete. The waste concrete can be recycled and serves as the aggregate for preparing the porous concrete; meanwhile, the strength of the prepared porous concrete is improved, and the pH value is reduced, so that the normal use of the porous concrete in architectural engineering is ensured.

Owner:XUZHOU UNIV OF TECH

High quality recycled aggregate recycling equipment for waste building concrete

The invention discloses high quality recycled aggregate recycling equipment for waste building concrete. The equipment comprises an equipment box body; a storage chamber, a heating and stirring chamber, a filtering separation chamber and a water filter tank are sequentially arranged in the equipment box body from top to bottom; a feeding inlet is formed in the top of the equipment box body; the box body is communicated with a water circulation system; the waste concrete entering the storage chamber of the equipment box body in batches is stirred, crushed and heated by means of a stirring roller and microwave heating equipment at the same time in the heating and stirring chamber, is then cooled by means of the water circulation system, is separated into coarse aggregate and the fine aggregate in the filtering separation chamber by means of a two-stage vibrating screen, and is collected at an outlet; the sieve residue is filtered in the filtering separation chamber and is then dischargedoutside when becoming fine powder. The equipment provided by the invention can avoid the damage, caused by the extrusion grinding and crushing, on the aggregate in a waste concrete recycling process;by adopting a processing way of simultaneously using microwave heating and the mechanical stirring, the production efficiency is greatly increased, the production process is efficient, environmentally-friendly, the control is simple, the energy is saved, and the cost is lowered; the high quality recycled aggregate recycling equipment is beneficial to popularization.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Equipment system for recycled concrete production

InactiveCN111215180AImprove recycling efficiencyEasy to sieveSievingScreeningArchitectural engineeringElectric machinery

The invention discloses an equipment system for recycled concrete production, and relates to the technical filed of concrete recycling. According to the technical points, the equipment system comprises a tearing unit and a screening unit, a conveyor belt is arranged at a first discharging outlet of the tearing unit, the input end of the conveyor belt is located at the lower end of the first discharging outlet, the output end of the conveyor belt is connected to the screening unit, the screening unit comprises a metal removing device, a wood chip removing chamber and a vibrating screen chamberwhich are sequentially connected, the vibrating screen chamber comprises a vibrating screen box, first screens are arranged in the vibrating screen box, the first screens are fixedly connected to thevibrating screen box, first vibrating motors are connected to the side walls of one of pairs of the first screens through connecting pieces, the connecting pieces penetrate through the side wall of the vibrating screen chamber, and the first vibrating motors are arranged on the outer side of the vibrating screen box. The first screens in the vibrating screen box are screened through the first vibrating motor arranged on one side in the vibrating screen chamber, the screening effect is improved, the screening of different components in the recycled concrete is facilitated, and the recycling efficiency of the recycled concrete is improved.

Owner:西安百固源混凝土有限公司

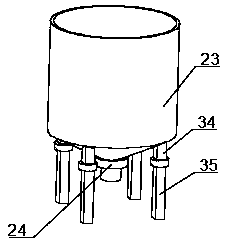

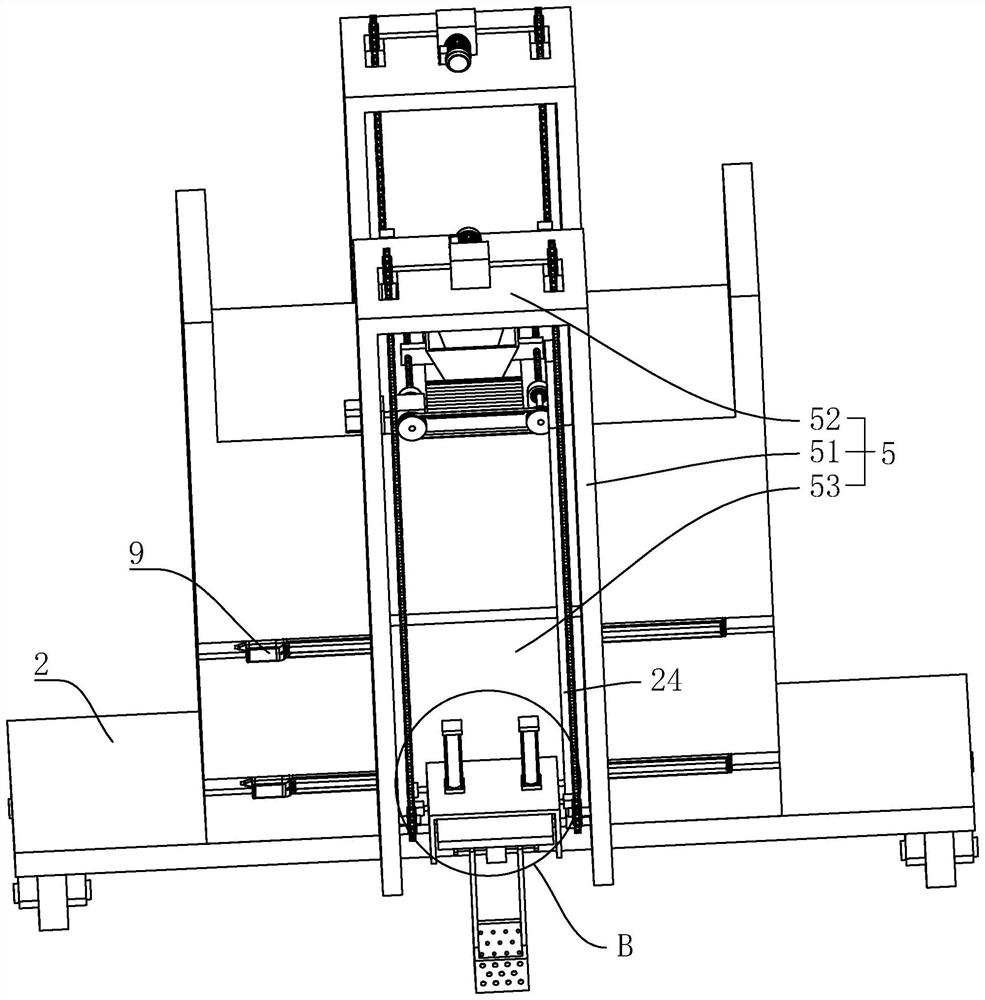

Method and system for recycling utilization of mass fresh mixed waste concrete

The invention belongs to the technical field of recycling utilization of waste concrete, and specifically provides a method and a system for recycling utilization of mass fresh mixed waste concrete. The method comprises the following steps: step 1, separating and recovering sand gravels from the waste concrete; step 2, recovering a waste slurry; and step 3, blending the recovered slurry into a fresh slurry for production of fresh mixed concrete. The system comprises a sand gravel separator, a waste slurry pool, a cyclone, a solid-content adjusting tank and a slurry recovery pump, wherein a plurality of supporting columns are arranged on the outer wall of the solid-content adjusting tank; each supporting column is provided with a weighing device; the slurry inlet of the cyclone extends intothe waste slurry pool; the slurry outlet of the cyclone is connected with the feed inlet of the slurry recovery pump; the discharge outlet of the slurry recovery pump is connected with the slurry inlet end of a slurry recovery pipe; and the slurry outlet end of the slurry recovery pipe extends into the solid-content adjusting tank. The method and the system provided by the invention can treat mass waste concrete, realize recycling utilization of a generated waste slurry for production of the fresh mixed concrete, and save resources.

Owner:CHONGQING CONSTR ENG NEW BUILDING MATERIALS +1

Concrete recycling device

The invention discloses a concrete recycling device. The concrete recycling device comprises a base used for containing waste, a support arranged on the base, a grinding plate located above the base and a drive mechanism arranged on the support and used for driving the grinding plate to move in the vertical direction. The base is connected with a settling pond, and the settling pond communicates with a spiral lifting mechanism. The concrete recycling device has the beneficial effects that concrete, building plates and other solid waste can be treated, the concrete, the plates and other structures are crushed and separated from metal materials, and therefore metal, the concrete, wood, plastic and other materials are classified and recycled respectively, and concrete recycling can be achieved; and the concrete recycling device has the advantages of being convenient to use and low in use cost and can effectively separate various different kinds of waste.

Owner:成都尊华荣域科技有限公司

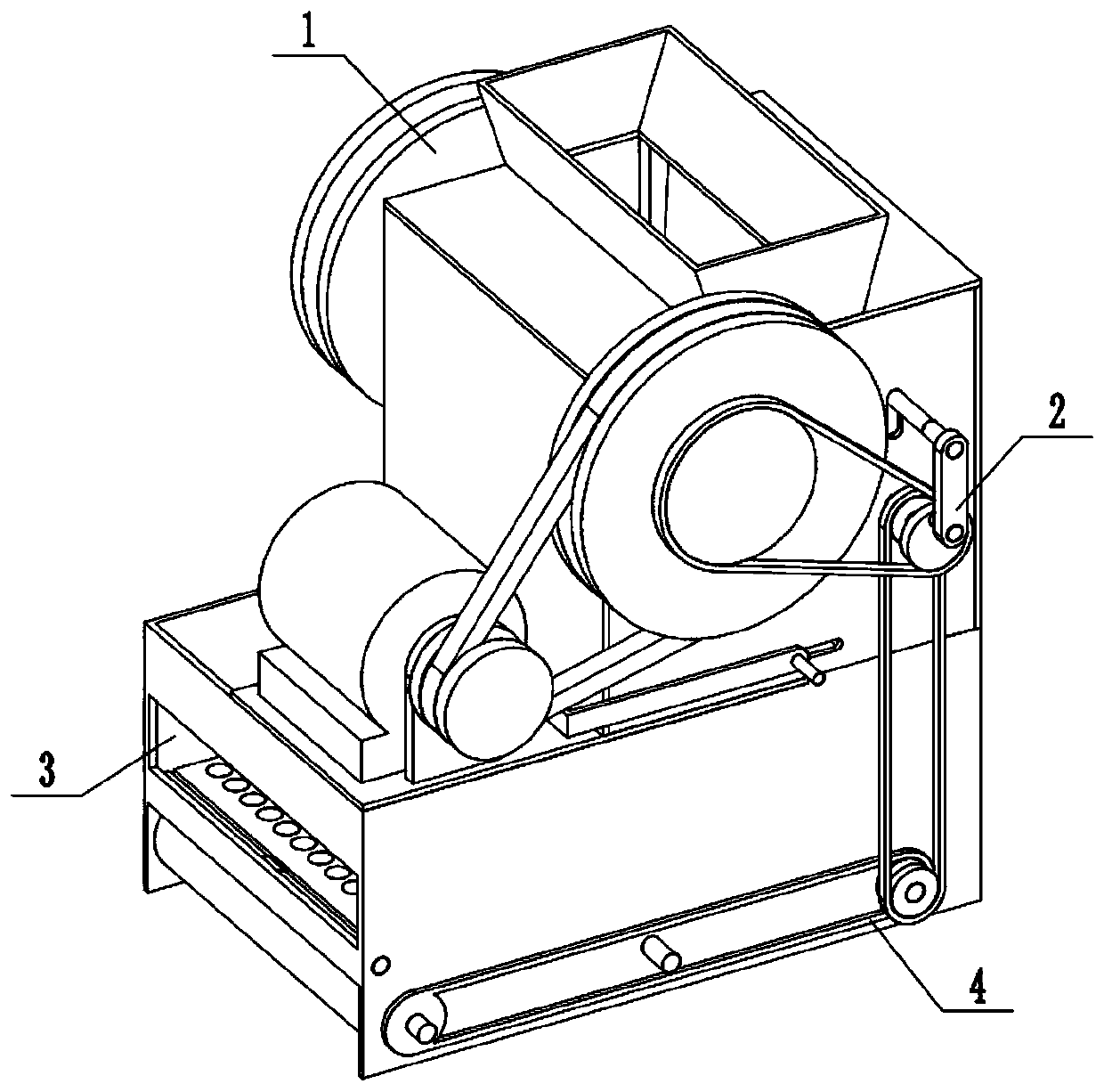

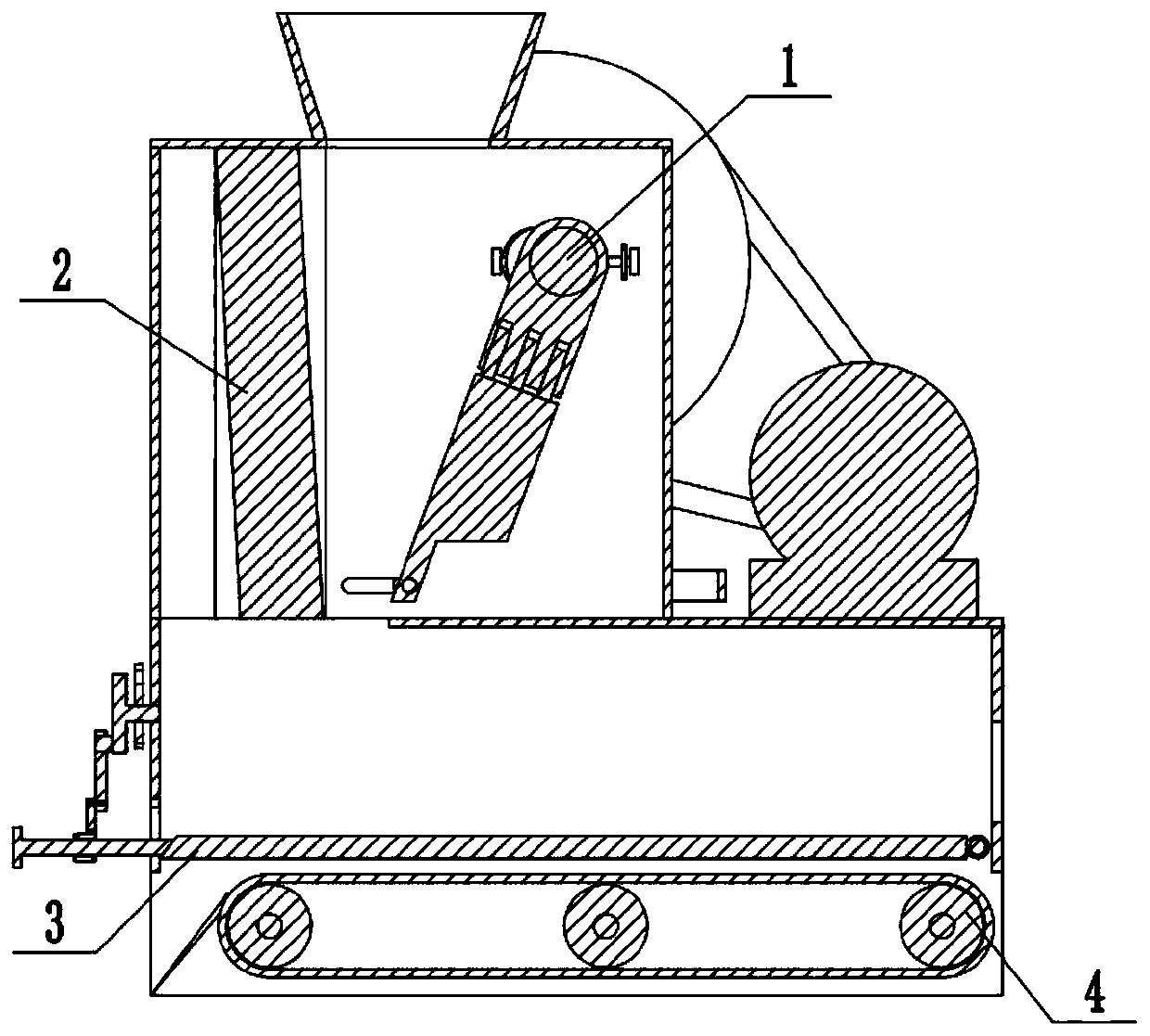

Building concrete recycling equipment,

ActiveCN110860326AImprove crushing effectEasy dischargeSievingScreeningReinforced concreteArchitectural engineering

The invention relates to the field of buildings, in particular to building concrete recycling equipment. Reinforced concrete rubbish occupies a large proportion in the building rubbish and needs to becrushed and decomposed, traditional jaw crushing equipment cannot adjust the crushing occlusion amplitude, cannot adjust the size of crushed blocks after crushing is completed, a lower jaw plate is fixed, and the crushing effect is poor. The problems are solved by the equipment, the reinforced concrete rubbish is poured into the equipment, the rubbish between the upper jaw plate and the lower jawplate is smashed by reciprocating occlusion of the upper jaw plate, the occlusion amplitude of the upper jaw plate is adjustable so as to adapt to building rubbish with different sizes, the size of smashed residues is adjustable, residues with different powder particle sizes can be obtained, the lower jaw plate moves up and down to obtain a better smashing effect and facilitate discharging at thesame time, and a mixture of reinforcing steel bars and residues is discharged from different discharging ports after being obliquely vibrated and separated by a sieve plate, and separation of the reinforcinsteel bars and residues is completed.

Owner:王朝晖

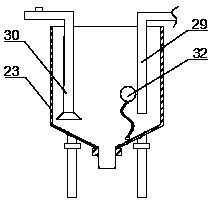

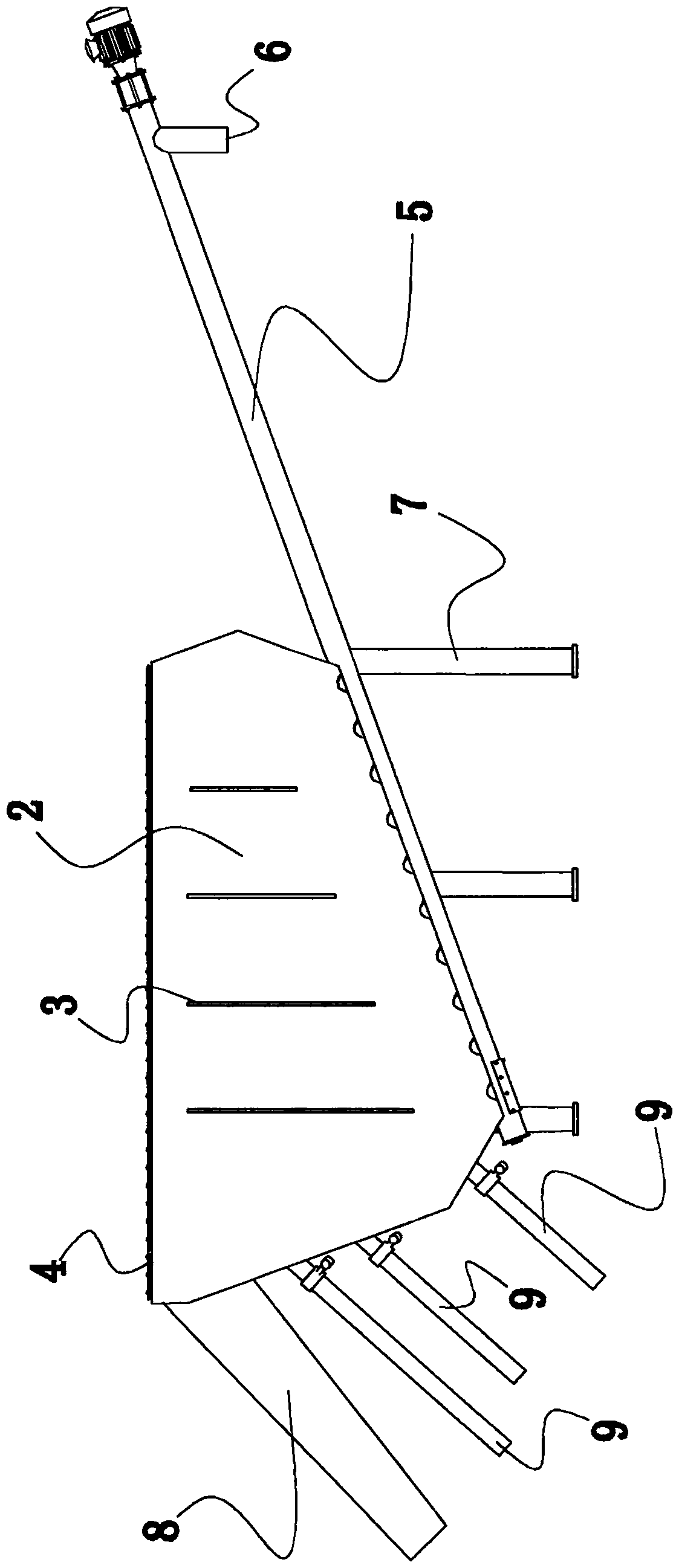

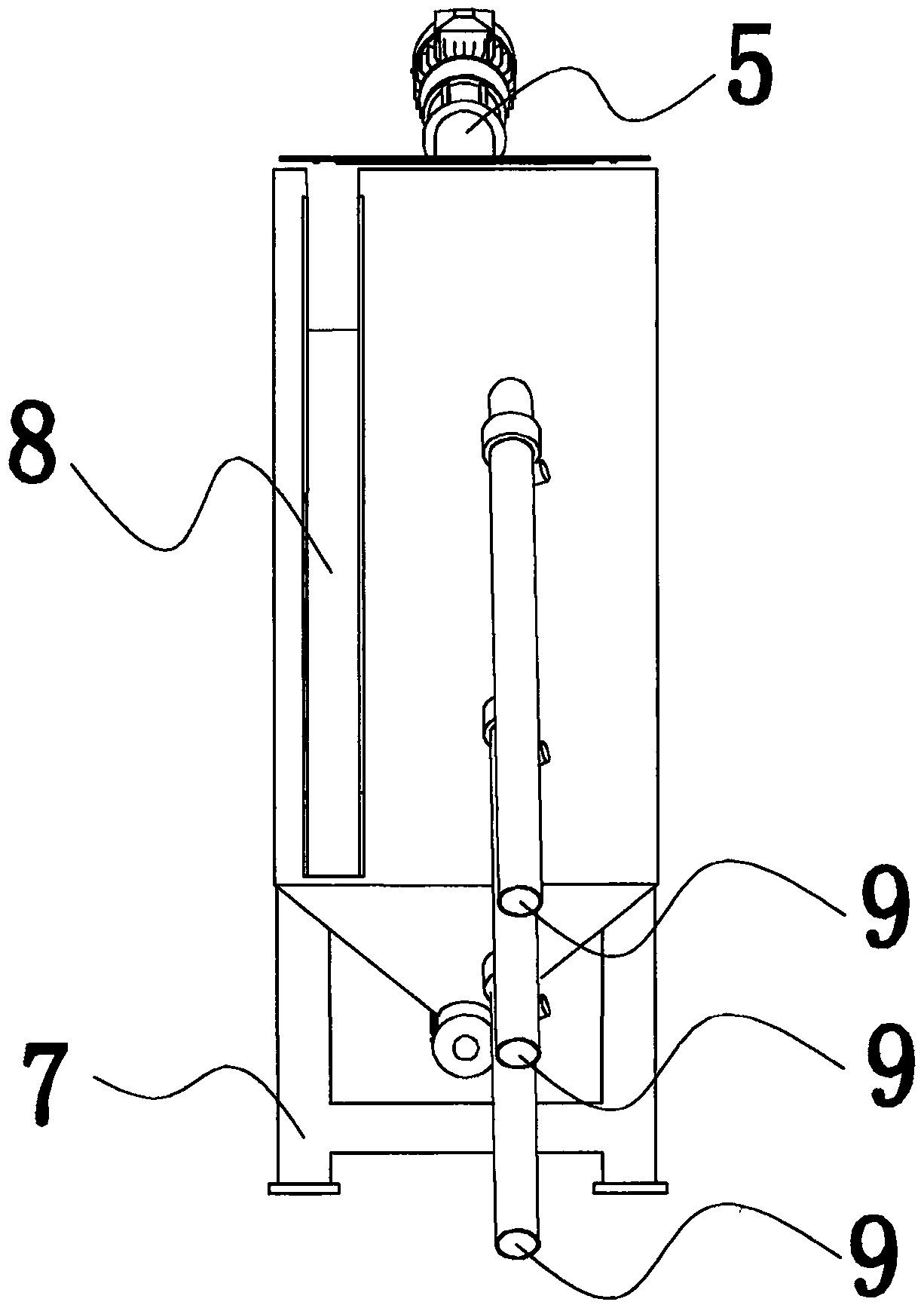

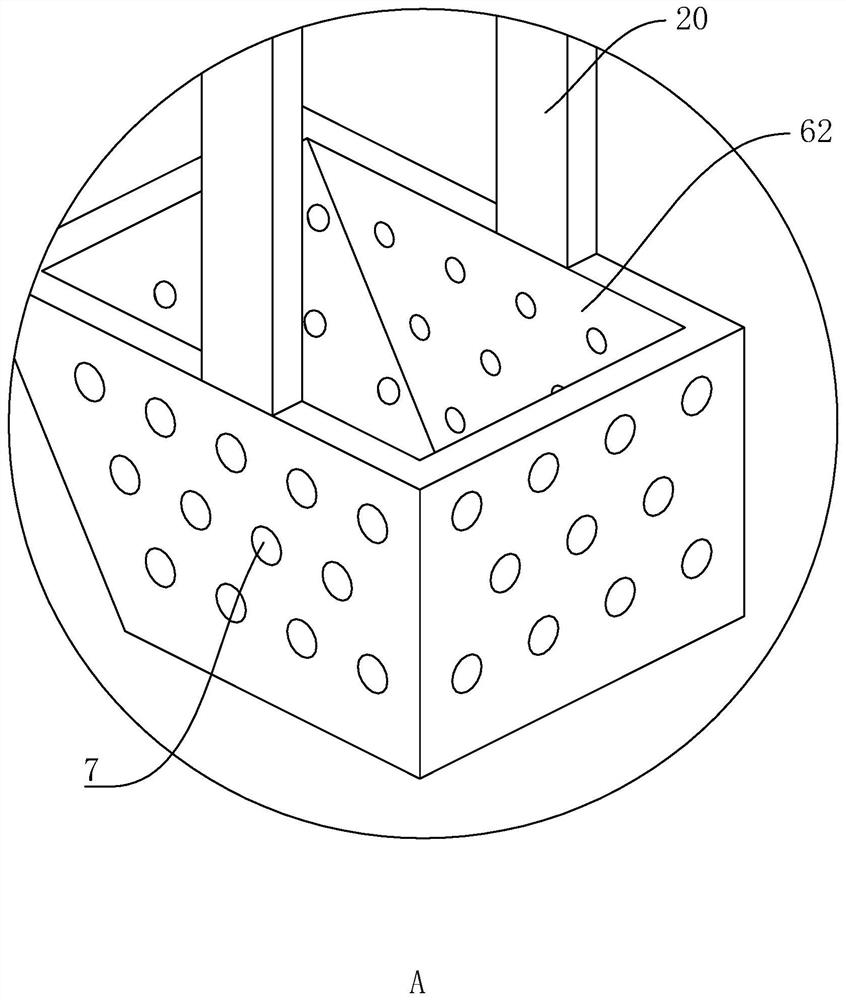

Mud-water separator for wet concrete recycling system and mud-water separating method of mud-water separator

InactiveCN108854170AAchieve the effect of separationSettling tanks feed/dischargeSedimentation settling tanksMultiple bufferingSludge

The invention belongs to the field of mechanical technology of mud-water separator for a wet concrete recycling system, and specifically relates to a mud-water separator for wet concrete recycling system and mud-water separating method of the mud-water separator; in order to solve the above technical problem, the invention provides a mud-water separator for the wet concrete recycling system and mud-water separating method, which is characterized in that: a sediment bin is divided into upper and lower parts, the upper part of the sediment bin is a box, the lower part is a cone, multiple buffering walls are arranged in the sediment bin, with each buffering wall arranged with buffering overflow port, a pedal net is arranged on the top of the sediment bin, a spiral conveyor is mounted on the bottom of the cone of the lower part of the sediment, the spiral conveyor is provided with a mud discharge outlet, landing legs 7 are mounted at both sides of the sediment bin, vibrators are mounted onboth sides of the bottom cone of the sediment bin, a sewage overflow hopper and multiple sets of blow-off pipes are mounted on the rear of the sediment bin. The mud-water separator for the wet concrete recycling system and mud-water separating method implement the effect of separation of mud and water from sewage for the wet concrete recycling system. In addition, the mud-water separator can extract and clean out the mud before the sewage enters the sewage pool.

Owner:张云轩

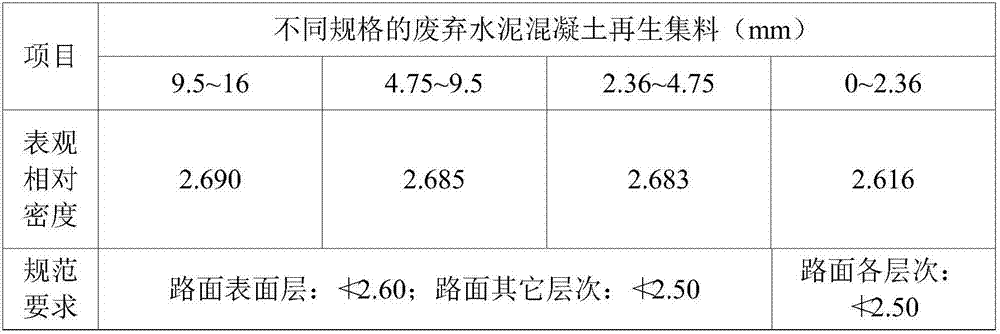

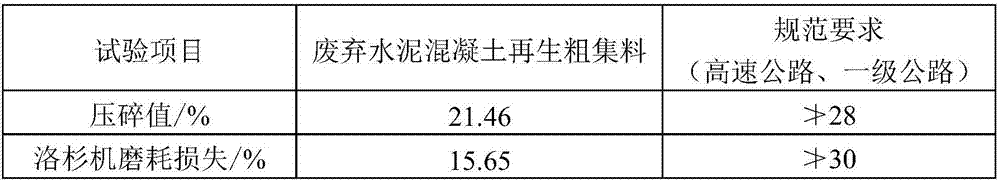

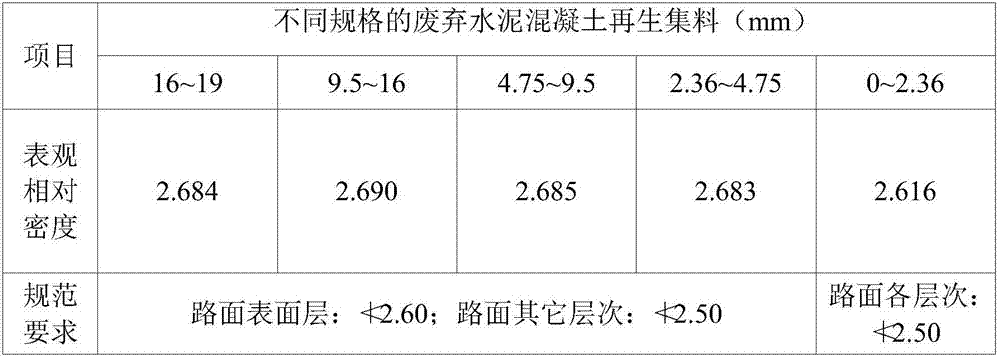

Waste cement concrete recycled aggregate warm mixed asphalt mixture and making method thereof

ActiveCN106946501ALow costIncrease profitSolid waste managementClimate change adaptationPerformance indexRoad surface

The invention provides a waste cement concrete recycled aggregate warm mixed asphalt mixture. The waste cement concrete recycled aggregate asphalt mixture is made from waste cement concrete recycled aggregate, limestone ore powder, asphalt and an asphalt warm mix agent. Two road environmental-protection technologies of waste cement concrete recycling aggregation and foam asphalt warm mixing are combined to make up for the shortcoming of possible reduction of the pavement performance of an asphalt mixture, caused by simple use of an asphalt warm mixing technology, in order to make the pavement performance index of the warm mixed asphalt mixture not lower than that of a hot mixed asphalt mixture, so building waste pollution is reduced, natural aggregate resources are saved, the energy consumption and the exhaust gas discharge during the production and the pavement of the hot mixed asphalt mixture are reduced, and construction waste resource recycling and dual environmental protection purposes of energy saving and discharge reduction are achieved. The waste cement concrete recycled aggregate asphalt mixture can be used for paving the upper layer, the middle layer and the lower layer of the asphalt pavement.

Owner:TAIZHOU POLYTECHNIC COLLEGE

Waste concrete crushing and screening device

InactiveCN112246398AReduce qualityAvoid easy separationGrain treatmentsArchitectural engineeringMetallic materials

The invention relates to the field of concrete recycling, in particular to a waste concrete crushing and screening device. The waste concrete crushing and screening device comprises a roller structure, a jaw type crushing structure and a screening structure, and in the using process, the roller structure crushes large-size concrete blocks into small-size concrete blocks through rotation of rollers; the concrete blocks subjected to primary crushing need to be extruded and crushed through the jaw type crushing structure to separate metal materials in the concrete blocks, the metal materials in crushed products are separated through an electromagnetic structure on the screening structure, crushing and screening of the waste concrete are completed, and the problems that in the existing waste concrete crushing process, due to the fact that an existing concrete crushing device adopts a one-time crushing mode, concrete blocks with required sizes are difficult to crush, and meanwhile due to the fact that the screening capacity of the crushing device is insufficient, ferrous metals such as reinforcing steel bars and the like which influence the quality of the concrete blocks in crushed products cannot be screened and removed are avoided.

Owner:李淑敏

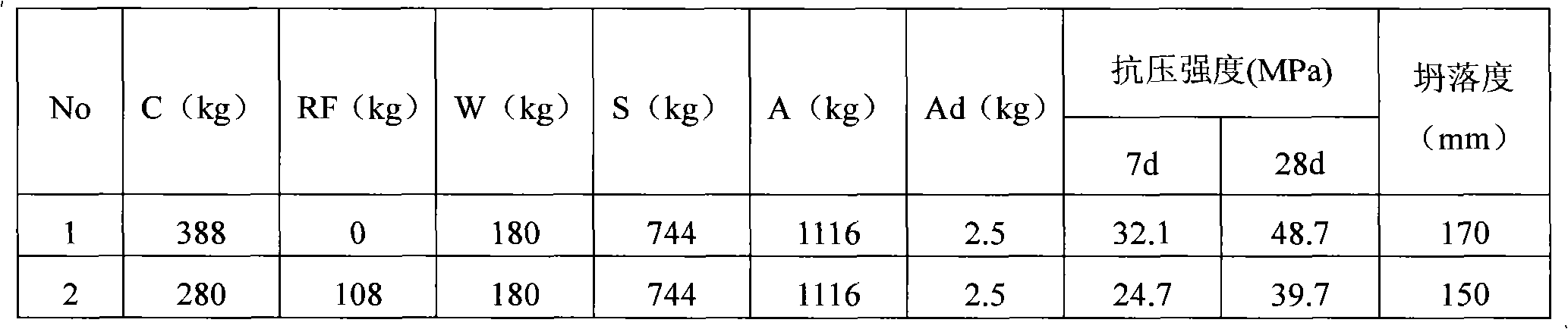

Waste concrete recycling and crushing device

The invention provides a waste concrete recycling and crushing device. The waste concrete recycling and crushing device comprises a rack as well as a feeding device, a primary crushing device, a sorting device, a secondary crushing device and a sand making device which are sequentially arranged on the rack, wherein the feeding device comprises a feeding hopper arranged on the rack and a vibrating feeder arranged on the lower side of the feeding hopper; the primary crushing device is a jaw crusher, and a feeding hole of the jaw crusher communicates with a discharge hole of the vibrating feeder; the sorting device is a rotary vibration screen, and a feeding hole of the rotary vibration screen communicates with a discharge hole of the jaw crusher; a first conveying belt is arranged between a feeding hole of the secondary crushing device and a second discharging hole of the rotary vibration sieve; and a second conveying belt is arranged between the feeding hole of the sand making device and a discharge hole of an impact crusher. The device has the characteristics that production is carried out on a collection site, the particle shape of the recycled aggregate is improved, impurities in the recycled aggregate are reduced, transportation and production are convenient, and the quality of the recycled concrete can be stably improved.

Owner:韩保勤

Waste concrete recycling method with low processing cost

InactiveCN111848006ASoft natureNot easy to changeSolid waste managementGel preparationEnvironmental engineeringSorptivity

The invention discloses a waste concrete recycling method with a low processing cost. The invention belongs to the technical field of concrete processing. The method comprises: arranging hydrogel powder, drying the prepared hydrogel, preparing the hydrogel into a solidified block, crushing the waste concrete into powder with the same size as the waste concrete granular material, at the moment, adding the waste concrete granular material and the hydrogel powder into stirring equipment, and mixing. When adding waste concrete granular materials and hydrogel powder into stirring equipment, stirring equipment needs to be set, stirring directions are the same, the hydrogel is soft in property, the shape is kept, a large amount of water can be absorbed, the mixed modified concrete has certain water absorption performance, the shape of the modified concrete is not easy to change after the modified concrete absorbs water, the internal adhesiveness of the modified concrete is improved, the interior of the modified concrete is not easy to be too dry due to the fact that the hydrogel has certain water absorption performance, and cracks of the modified concrete due to the fact that the interiorof the modified concrete is too dry are reduced.

Owner:汉江城建集团有限公司

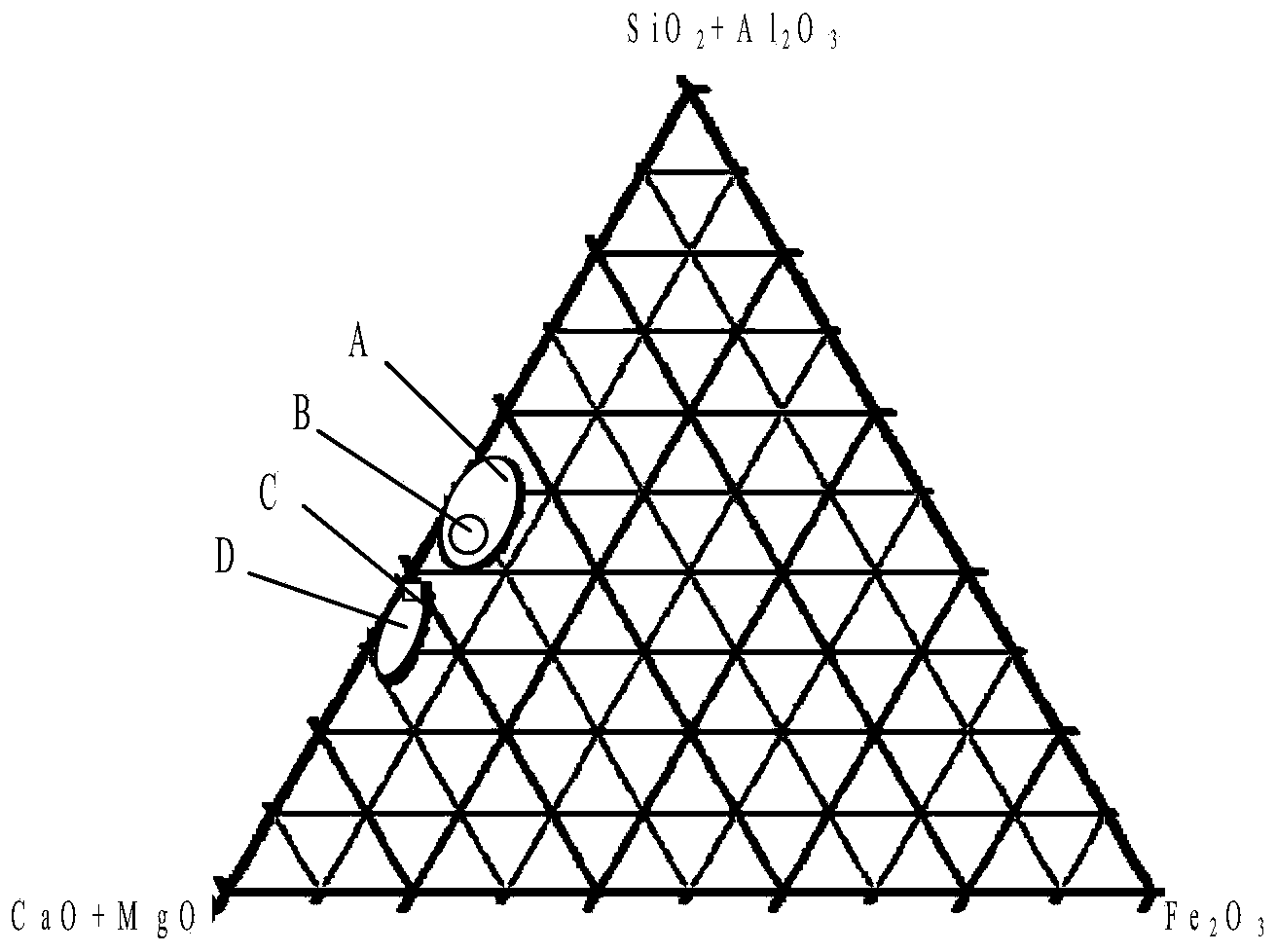

Sodium silicate alkali activated slag concrete recycling method

The invention discloses a sodium silicate alkali activated slag concrete recycling method comprising the steps of firstly, carrying out proportioning calculation to obtain the ratio of coarse aggregates to fine aggregates, wherein the coarse aggregates and the fine aggregates have the similar chemical components with that of slag chemical components except ignition loss and water content; then, uniformly mixing the aggregates with the ratio and sodium silicate serving as an alkali activator to prepare an alkali activated cementing material, namely concrete; and after the service of the concrete is ended, calcining the concrete at the temperature of 1450-1500 DEG C, and carrying out water quenching to obtain an activated cementing material again so as to realize the recycle of a sodium silicate alkali activated cementing material. By using the sodium silicate alkali activated slag concrete recycling method, the recycle of alkali activated concrete is realized, and the limestone resource can be saved; and the sodium silicate alkali activated slag concrete recycling method has remarkable economical efficiency and operability.

Owner:安康盛美宝新型环保建材有限公司

Recycling system for concrete waste

InactiveCN110694326AGuaranteed pureEasy to recycleFiltration circuitsStationary filtering element filtersSewageSlurry

The invention discloses a recycling system for concrete waste, and relates to the technical field of concrete recycling. The system includes a sand gravel separation unit, a sand mud separation unit and a sewage tank which communicate in sequence; the sand gravel separation unit is arranged above the sand mud separation unit, the sand gravel separation unit includes a sand gravel separation barrel, and the sand gravel separation barrel is provided with a material inlet, a material outlet door, sand flowing holes and a blocking mechanism for intermittently blocking the sand flowing holes; the sand mud separation unit includes a sand mud separation box arranged below the sand gravel separation barrel, the top of the sand mud separation box is provided with a sand inlet, an inclined screen plate is arranged in the sand mud separation box, the lower end of the screen plate is provided with a sand discharge opening, and a spraying device and a cleaning device are arranged above the screen plate; and the bottom of the sand mud separation tank is connected to a slurry outlet pipe, and the slurry outlet pipe is connected to the sewage tank. The system has the beneficial effects of thoroughly separating sand, stone, cement and water in the concrete waste, ensuring the purity of the components, and facilitating the recycling.

Owner:西安建工建科混凝土有限公司

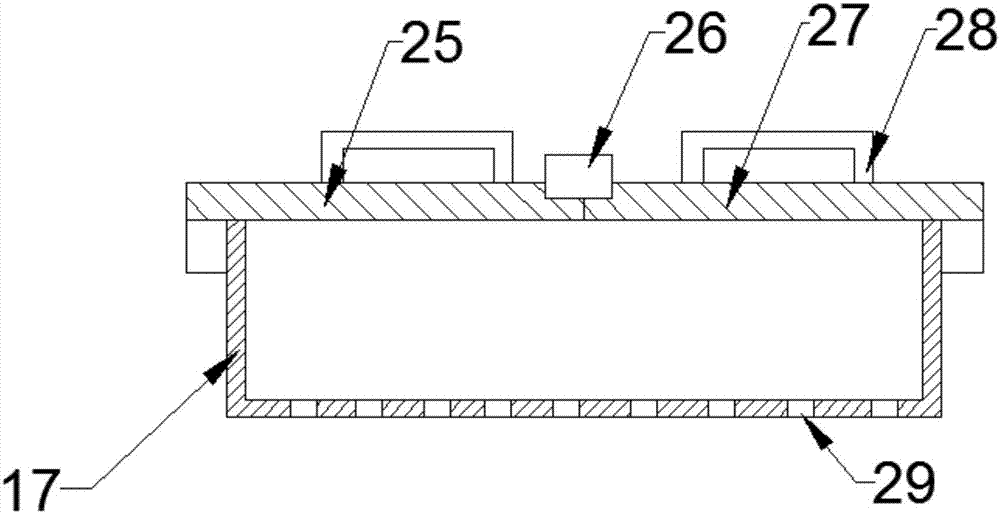

Sewage recycling equipment for cleaning concrete tank truck

InactiveCN107998727AEasy to throw outEasy dischargeMoving filtering element filtersWastewaterTank truck

The invention provides sewage recycling equipment for cleaning a concrete tank truck, and belongs to the technical field of building concrete recycling. The equipment comprises a supporting device anda recycling device; connecting struts are fixedly welded on a transverse plate; the periphery of each connecting strut is provided with a damping spring; a vibrating plate is fixedly arranged on theupper surfaces of the connecting struts; vibrating motors are fixedly arranged on two sides of the upper surface of the vibrating plate; a sand screening tank is arranged on the upper end of a motor through a sand sieve tank fixing frame; the sand screening tank is arranged in the inner cavity of a separation box; and a drain valve is arranged at the left end of a drain pipe. According to the equipment provided by the invention, a vibrating screen is arranged on the vibrating plate through supporting blocks each of which two ends are fixedly arranged, so that the function of preliminarily filtering and recycling concrete waste materials in waste water is achieved; and uniform screen meshes are arranged in the surface of the sand screen tank, so that the waste water is thrown out, and the function of collecting and recycling fine sand is realized. The equipment has the characteristics of simple structure, strong practicability and good recycling effect.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

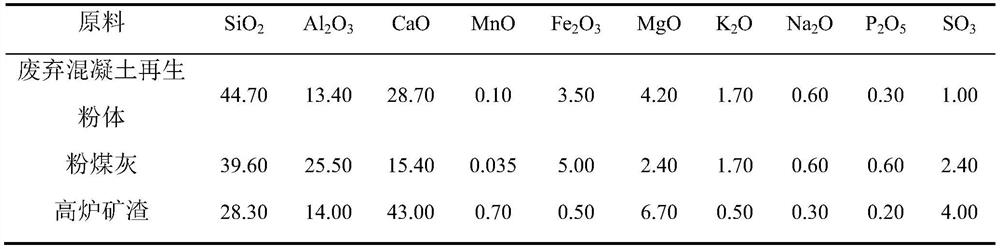

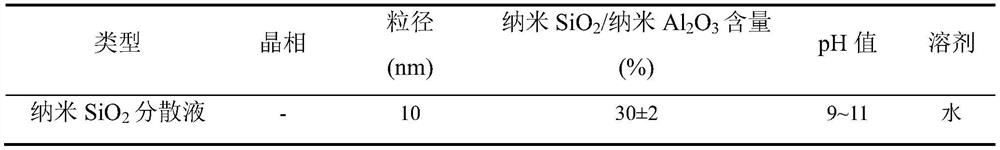

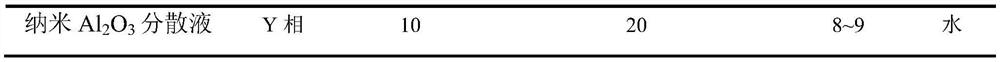

Modified high-strength geopolymer cementing material and preparation method thereof

The invention relates to a modified high-strength geopolymer cementing material and a preparation method thereof. The geopolymer cementing material is prepared by using waste concrete regenerated powder, blast furnace slag and fly ash as precursors, using a nano SiO2 aqueous dispersion or a nano Al2O3 aqueous dispersion for modification, and using a mixed solution of a sodium silicate solution and sodium hydroxide as an alkali activator. The waste powder generated in the waste concrete recycling process is consumed to prepare the geopolymer cementing material with high strength under the normal-temperature curing condition. The geopolymer cementing material is a green building material, and has the advantages of being high in early strength, excellent in durability and the like. High-added-value utilization of the waste concrete powder is achieved. The preparation method is also simple and easy to operate and has a wide application prospect.

Owner:SOUTHEAST UNIV

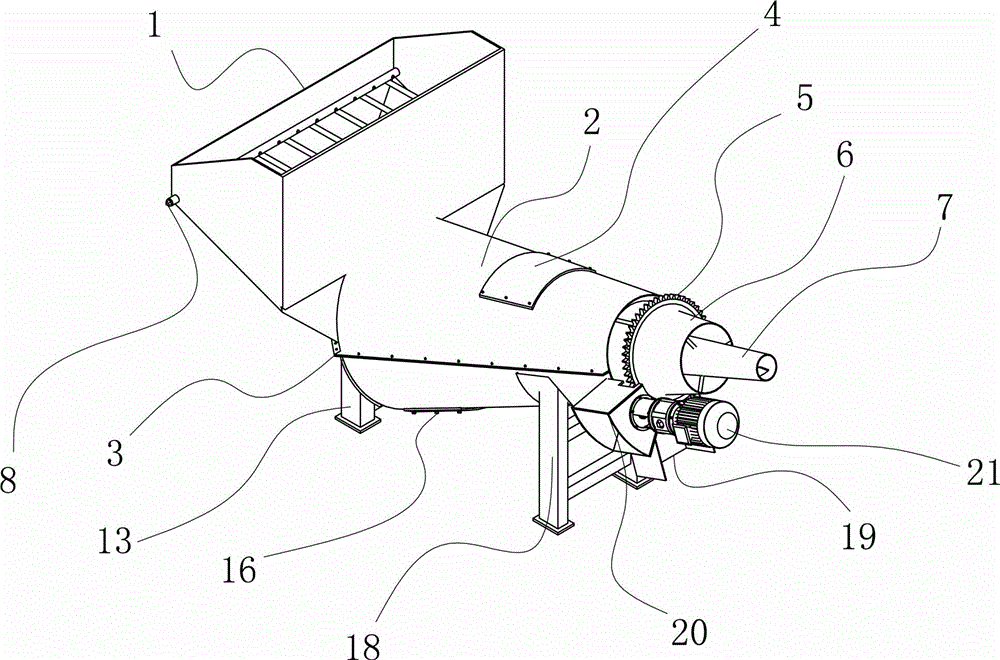

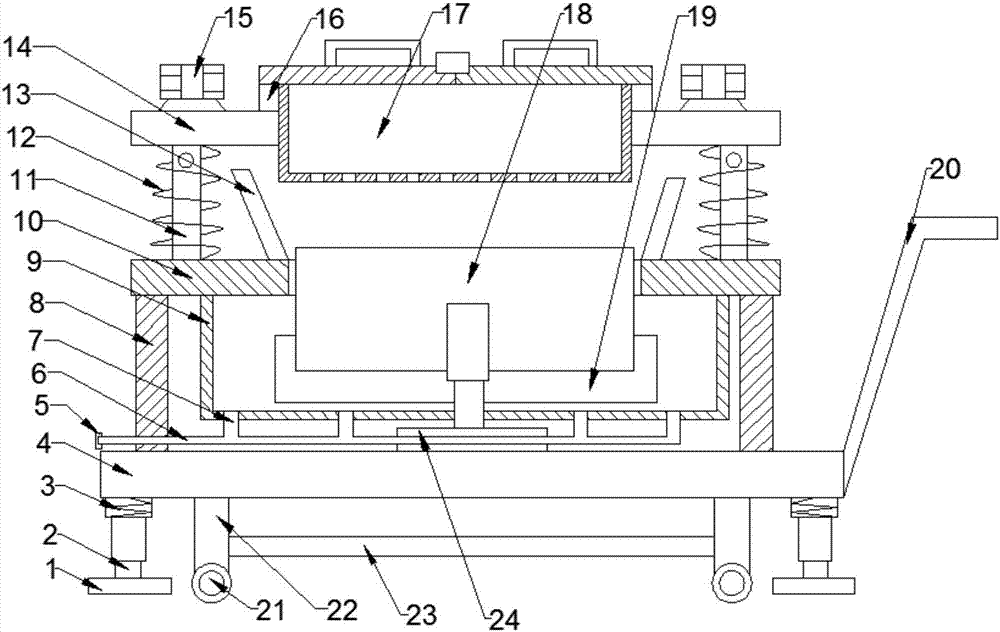

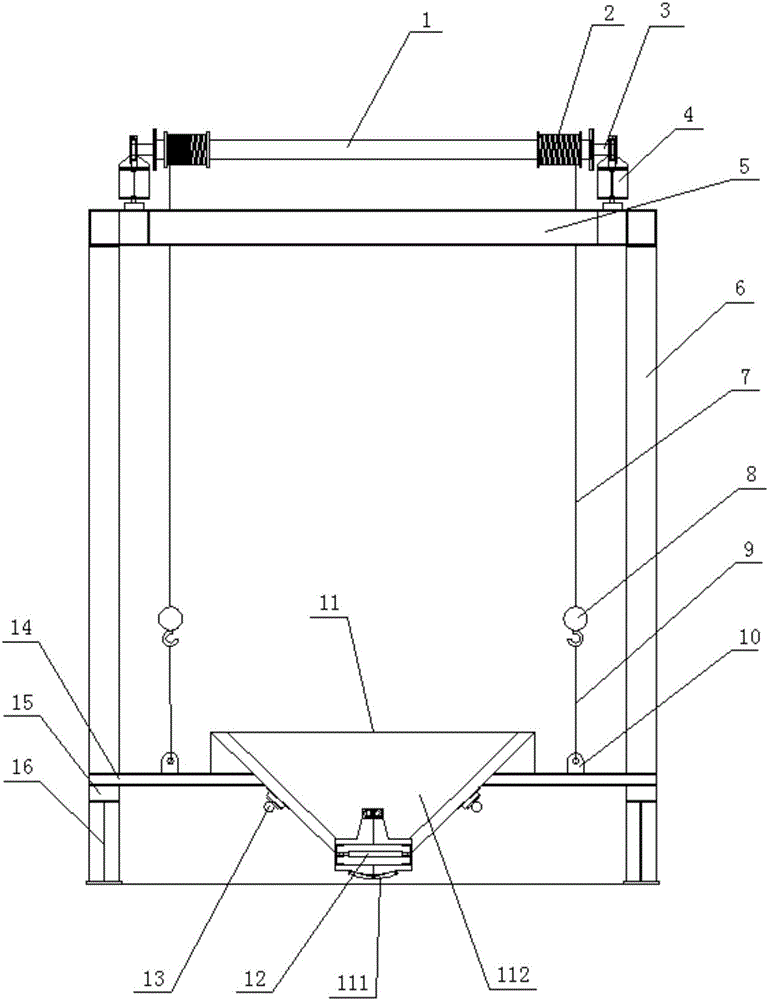

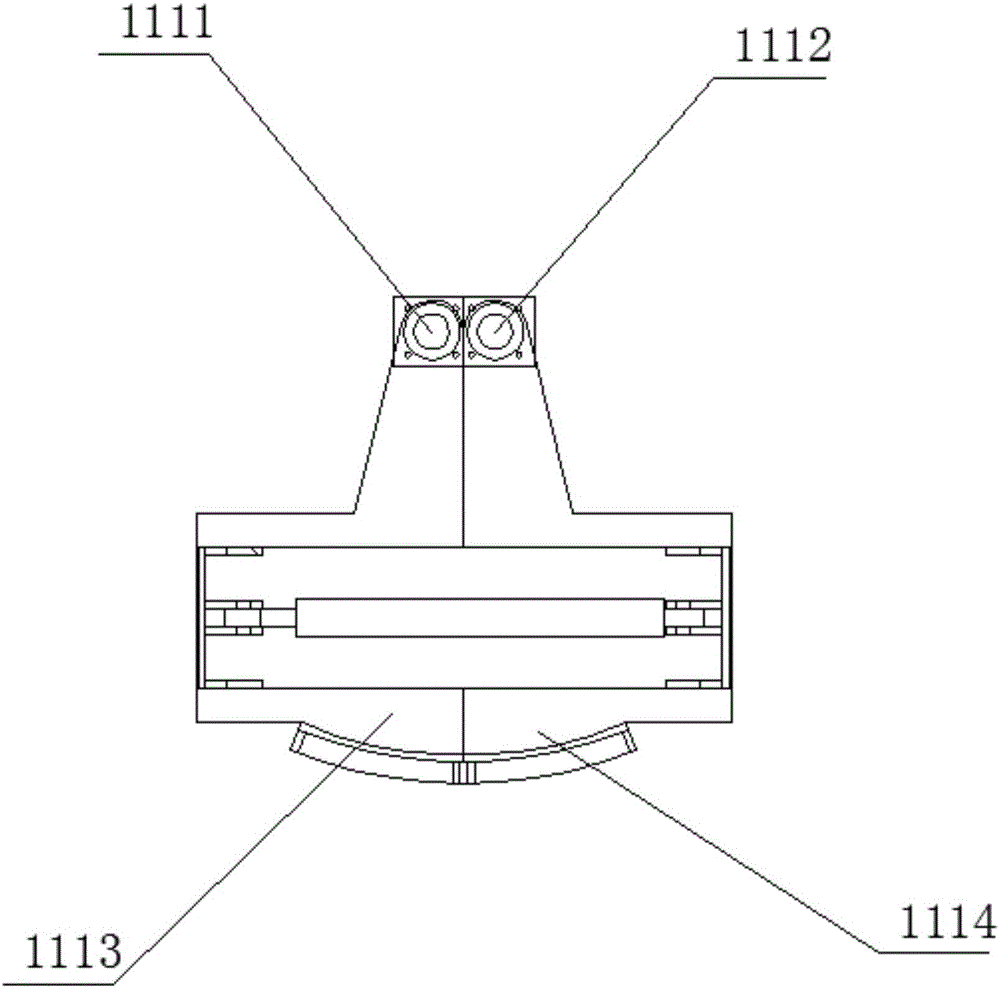

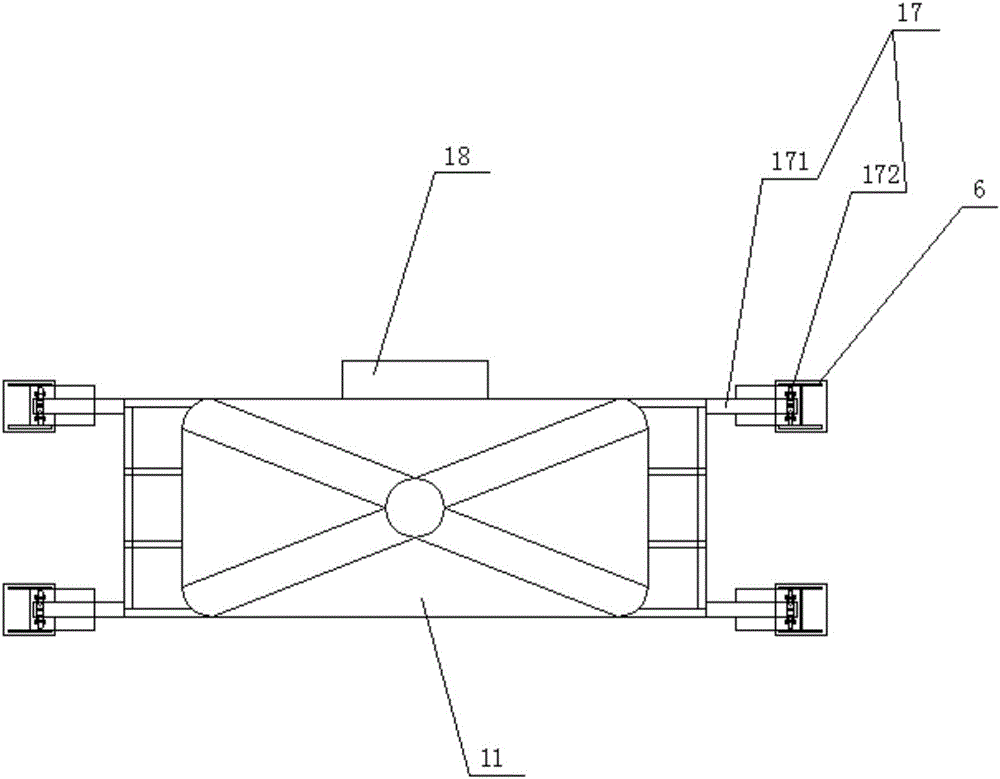

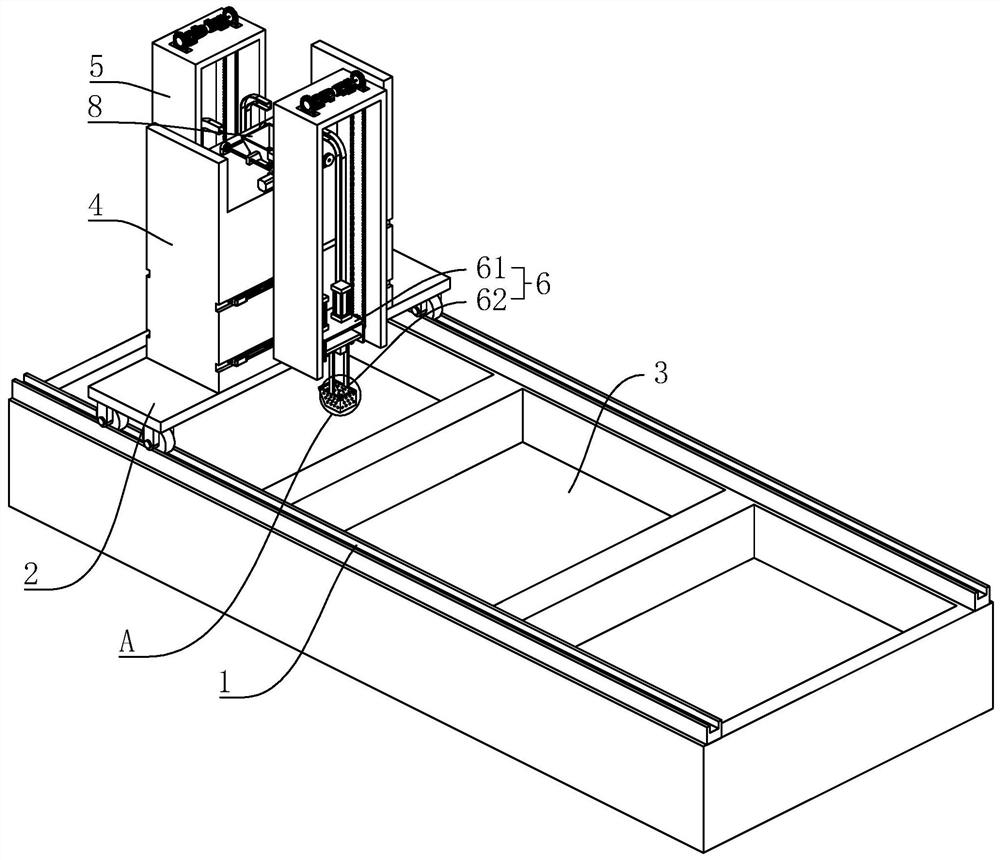

Solid waste recycling device for concrete

InactiveCN106079098AReduce wasteReduce consumptionSold ingredients supply apparatusEconomic benefitsLoad cell

The invention relates to concrete recycling equipment, and discloses a solid waste recycling device for concrete. The solid waste recycling device comprises vertical columns (6), wherein an upper frame (5) is arranged on the vertical columns (6); weighing sensors (4) are arranged on the upper frame (5); a winding drum (1) is arranged on the weighing sensors (4); wiring troughs (2) are arranged on the winding drum (1); first pull ropes (7) are arranged on the wiring troughs (2); lifting hooks (8) are arranged on the first pull ropes (7); a lower frame (14) is connected with the lifting hooks (8); a hopper (11) is arranged on the lower frame (14); vibration motors (13) are arranged on the hopper (11); baffle plates (15) are arranged on the lower frame (14); buffer springs (16) are arranged on the baffle plates (15); one end of each buffer spring (16) is connected with the corresponding baffle plate (15); and the other end of each buffer spring (16) is connected with the corresponding vertical column (6). The solid waste recycling device provided by the invention has the effects of turning waste into treasure, reducing the material loss, improving the economic benefit and protecting the environment.

Owner:浙江广天重工设备有限公司

Waste commodity concrete recovery and recycling technology

The invention relates to a waste commodity concrete recovery and recycling technology. The technology comprises a, cleaning commodity concrete through water, b, dividing a waste slag-waste water mixture obtained by the step a into sand and waste slurry, c, recovering the sand obtained by the step b and feeding the waste slurry into a primary sedimentation basin, d, after the waste slag in the primary sedimentation basin is deposited, making the supernatant freely flow to a secondary sedimentation basin through an overflow mouth at the upper part of the primary sedimentation basin and taking out the waste slag, e, after solid particle content and pH measurement, taking out one part of the slurry for recovery and recycle from the secondary sedimentation basin, and feeding the other part of the slurry into a primary reclaimed water tank through an overflow mouth at the upper part of the secondary sedimentation basin, and f, feeding the supernatant in the primary reclaimed water tank into a secondary reclaimed water tank through an overflow mouth at the upper part, wherein reclaimed water in the secondary reclaimed water tank can be recovered and recycled so that waste commodity concrete recovery and recycling are realized. The technology saves a cost and is safe and environmentally friendly.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD

Concrete gravel recycling and separating device

InactiveCN111841090AEasy to salvageAchieve transferConveyorsSettling tanks feed/dischargeEngineeringMaterial resources

The invention relates to the technical field of concrete recycling equipment, in particular to a concrete gravel recycling and separating device. The concrete gravel recycling and separating device comprises moving rails arranged on the two sides of a plurality of sedimentation tanks in the length direction, the multiple sedimentation tanks are sequentially arranged in the same horizontal direction, a supporting plate is slidably clamped to the moving rail in a matched manner, a machine body is fixedly connected to the supporting plate, a lifting mechanism used for fishing concrete is vertically connected to one side of the machine body in a sliding mode, a feeding hopper is arranged on the machine body, and a concrete separation mechanism is arranged in the machine body. The lifting mechanism on the machine body can be used for fishing concrete in different sedimentation tanks, after fishing, concrete can be directly transferred into the feeding hopper and continues to enter the separation mechanism, the concrete can be fished conveniently, transfer of the concrete can be synchronously achieved, manpower and material resources can be greatly saved, and great convenience is broughtto separation and recovery work of the concrete.

Owner:苏州一统混凝土有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com