Method for recycling waste concrete

A technology of waste concrete and concrete admixture, which is applied in the field of concrete, can solve the problems of high energy consumption and high recycling cost, and achieve the effects of low recycling cost, saving garbage disposal costs, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for recycling waste concrete, comprising the steps of:

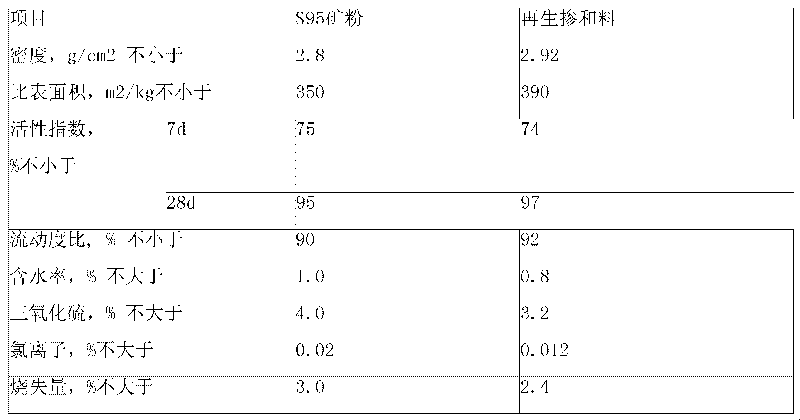

[0021] (1) Sorting out the metal, wood, plastic, etc. in the waste concrete, and then crushing it into a hammer crusher until the particle size is less than or equal to 20mm, and then removing the impurities in it: metal, wood, plastic, etc. Pick it up, then put it into a ball mill, add concrete activator by 4% of its weight, and grind to a specific surface area greater than or equal to 390 square meters per kilogram; waste concrete contains 20% waste mortar in this embodiment .

[0022] (2) The particle size specific surface area that step (1) obtains is greater than or equal to the regenerated admixture of 390 square meters per kilogram, and cement, medium coarse sand, 5-25mm crushed stone, water, concrete admixture in the following parts by weight Proportioning and mixing to prepare recycled concrete;

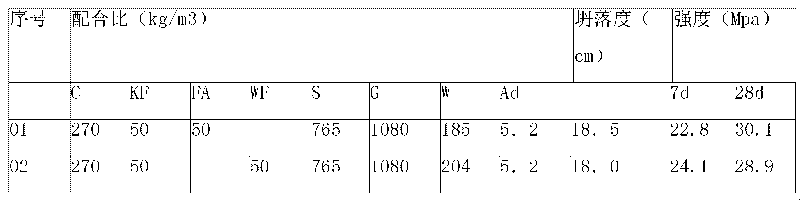

[0023] 90 parts of recycled admixture, 250 parts of cement, 730 parts of medium-coarse sand, 1000 ...

Embodiment 2

[0025] 100 parts of recycled admixture, 270 parts of cement, 765 parts of medium-coarse sand, 1080 parts of crushed stone, 185 parts of water, and 5.2 parts of concrete admixture.

[0026] All the other implementations are as in Example 1.

Embodiment 3

[0028] 110 parts of recycled admixture, 290 parts of cement, 790 parts of medium-coarse sand, 1150 parts of crushed stone, 195 parts of water, and 5.8 parts of concrete admixture.

[0029] All the other implementations are as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com