Building concrete recycling equipment,

A concrete and equipment technology, applied in the field of construction concrete recycling equipment, can solve the problems of poor crushing effect, inability to adjust the size of fragments, and inability to adjust the crushing bite range, etc., to achieve good crushing effect and easy discharging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

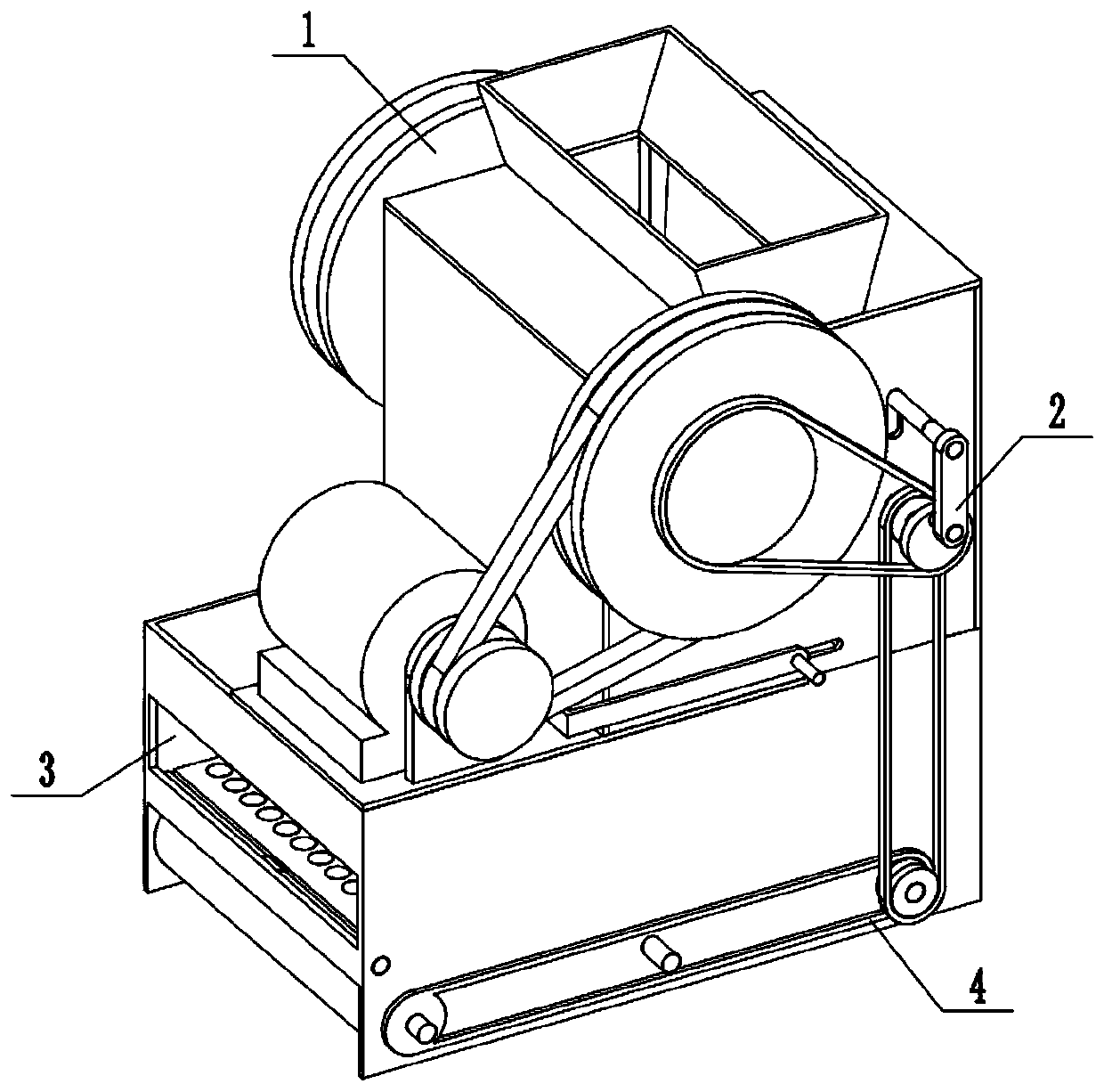

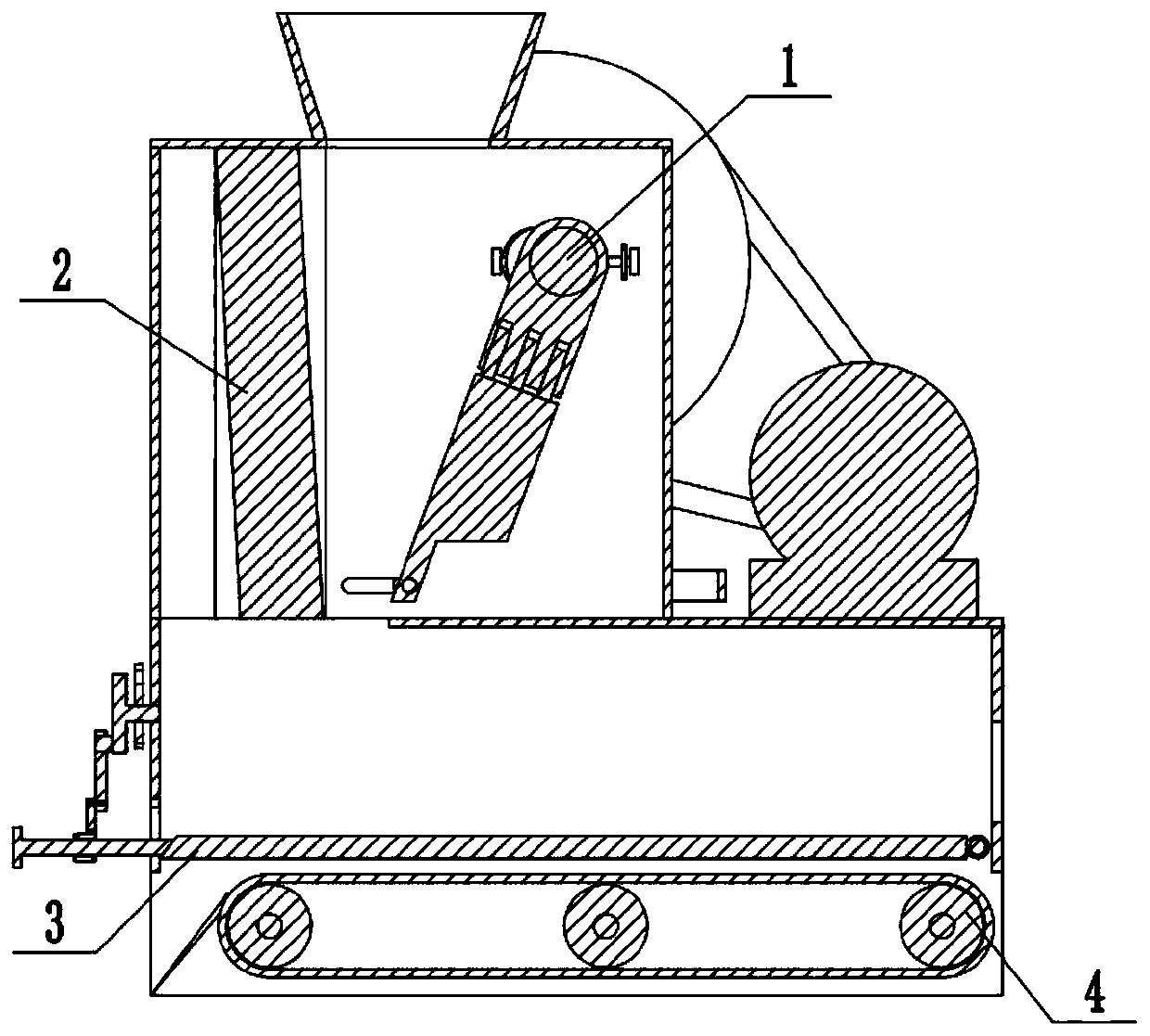

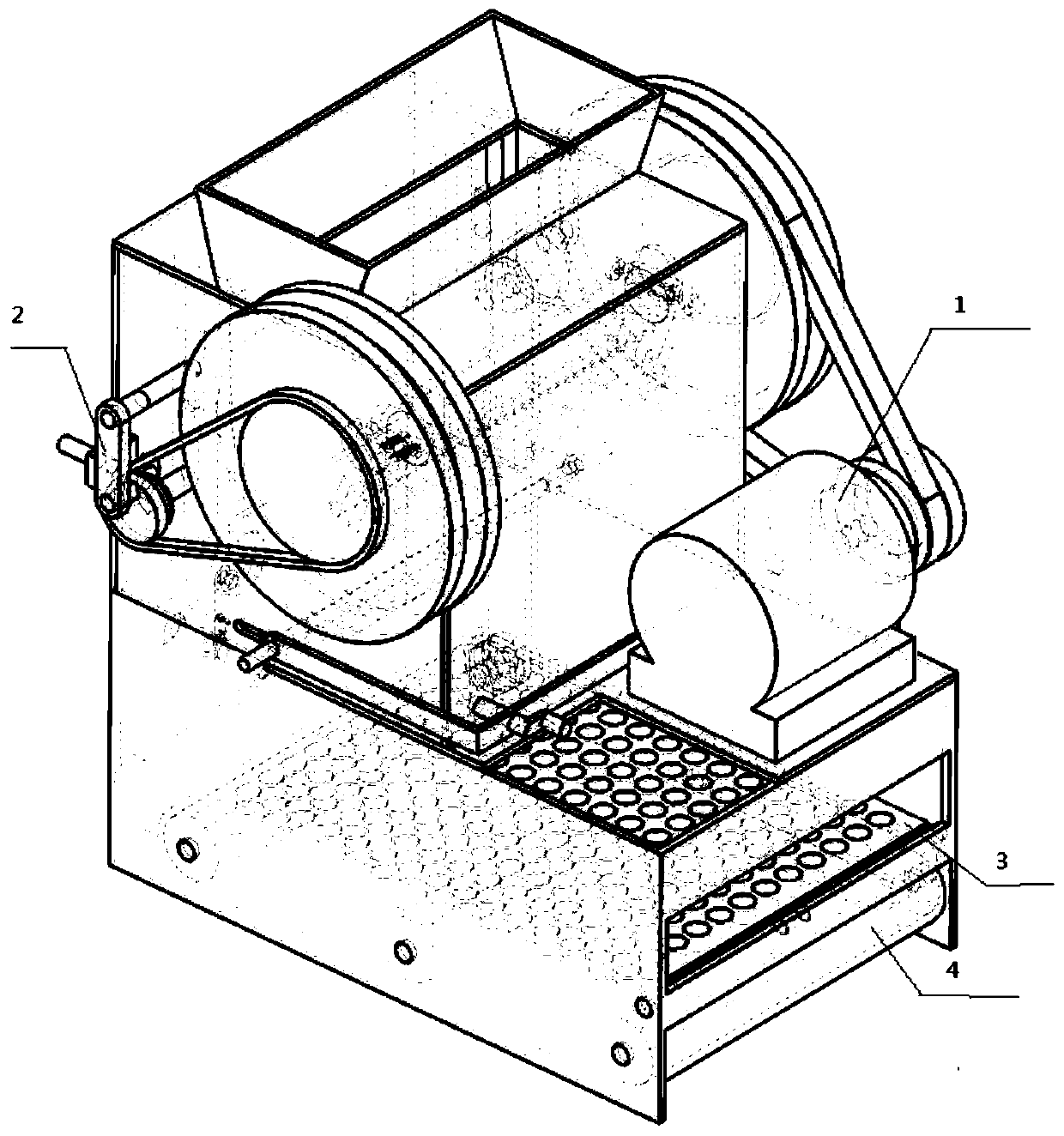

[0033] Combine below Figure 1-18 Embodiment, a kind of building concrete recycling equipment, including the upper jaw assembly 1, the lower jaw assembly 2, the separation assembly 3 and the conveying assembly 4, characterized in that: the upper jaw assembly 1 and the lower jaw assembly 2 are connected , the separation assembly 3 is connected to the upper jaw assembly 1, the separation assembly 3 is connected to the lower jaw assembly 2, the delivery assembly 4 is connected to the separation assembly 3, and the delivery assembly 4 is connected to the lower jaw assembly 2.

specific Embodiment approach 2

[0035] Combine below Figure 1-18 Embodiment, this embodiment will further explain Embodiment 1. The upper jaw assembly 1 includes a motor 1-1, a pulley I 1-2, a motor bracket 1-3, a V-belt 1-4, a pulley II 1-5, Bottom plate 1-6, side plate Ⅰ 1-7, side plate Ⅱ 1-8, upper plate 1-9, material inlet 1-10, counterweight wheel 1-11, shaft Ⅰ 1-12, shaft Ⅱ slide rail 1-13, Chute 1-14, shaft II 1-15, slider 1-16, adjustment handle 1-17, threaded shaft 1-18, slider limit block 1-19, ball 1-20, driven slider 1-21 , upper jaw plate Ⅰ1-22, upper jaw chute 1-23, upper jaw plate II 1-24, rotating shaft 1-25, rotating shaft chute 1-26, rotating shaft bracket 1-27, thread adjustment rod 1-28 and handle 1-29, Motor 1-1 is provided with motor shaft, and the motor shaft of motor 1-1 is connected with pulley Ⅰ1-2, and the motor shaft of motor 1-1 is connected with motor support 1-3 rotation, and motor support 1-3, motor 1- 1 are all connected with the bottom plate 1-6, the pulley Ⅰ1-2, the V-be...

specific Embodiment approach 3

[0037] Combine below Figure 1-18 Embodiment, this embodiment will further explain Embodiment 1. The lower jaw assembly 2 includes sprocket III 2-1, chain II 2-2, sprocket IV 2-3, sprocket IV shaft 2-4, dial shaft I2- 5. Connecting rod Ⅰ2-6, lifting shaft 2-7, lifting shaft chute 2-8, lower jaw slider 2-9, lower jaw slider slide rail 2-10 and lower jaw plate 2-11, two sprockets III 2- 1 respectively connected with belt pulley Ⅱ1-5, counterweight wheel 1-11, two sprockets Ⅲ2-1, two chains Ⅱ2-2, two sprockets Ⅳ2-3 sprocket chains, two sprockets Ⅳ2 -3 are respectively connected with the two sprocket IV shafts 2-4, the two sprocket IV shafts 2-4 are respectively connected with two side plates I1-7 in rotation, and the two sprocket IV2-3 are respectively connected with two dial shafts Ⅰ2-5 is rotatably connected, the two dial shafts Ⅰ2-5 are respectively rotatably connected with the two connecting rods Ⅰ2-6, and the two connecting rods Ⅰ2-6 are respectively rotatably connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com