Movable concrete slump testing device

A testing device and concrete technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to guarantee the levelness of the platform, the testing tools need to be improved, and the sample height direction is elongated, etc. The effect of improving construction quality and improving accuracy

Active Publication Date: 2016-06-01

GUANDONG YIAN CITY CIVIL AIR DEFENSE ENG CO LTD

View PDF6 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0007] The operation is not standardized enough and is completely controlled by personnel. For example, the density of tamping varies according to the strength of the operator. During the process of unloading the bucket, the concrete will stick to the wall of the bucket, forming a negative pressure adsorption force, which makes the test The sample is elongated in the height direction, causing secondary damage to the sample and affecting the test effect

[0008] Whether the test platform is level has an important impact on the test results. The existing test process is basically tested on the ground, and the level of the platform cannot be guaranteed.

[0009] Combining the above factors, the existing testing tools need to be improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

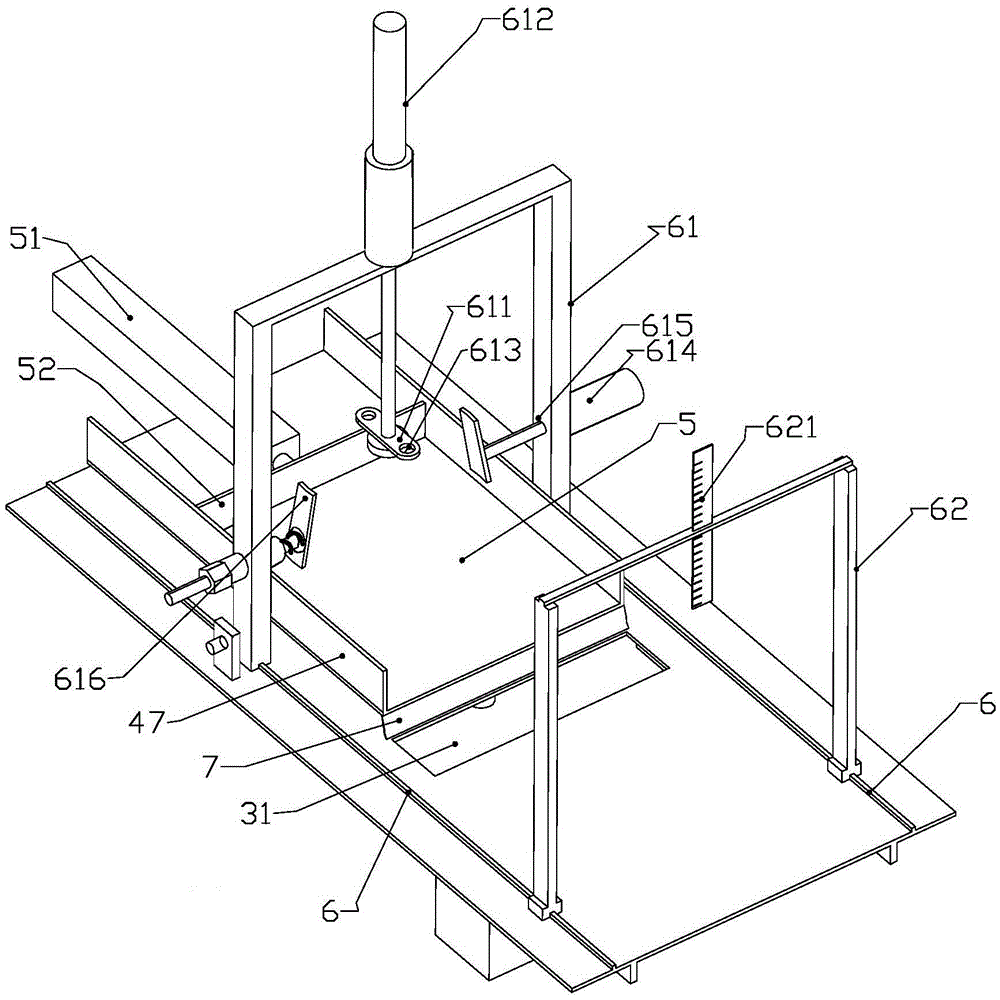

[0076] Embodiment 2, the above-mentioned elastic buffer mechanism and the second cylinder can be formed by Figure 13 Replace the ejector rod in the middle, wherein the ejector rod is locked on the side column through a nut, and the arc-shaped pressing plate 616 is directly clamped to the test cylinder.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

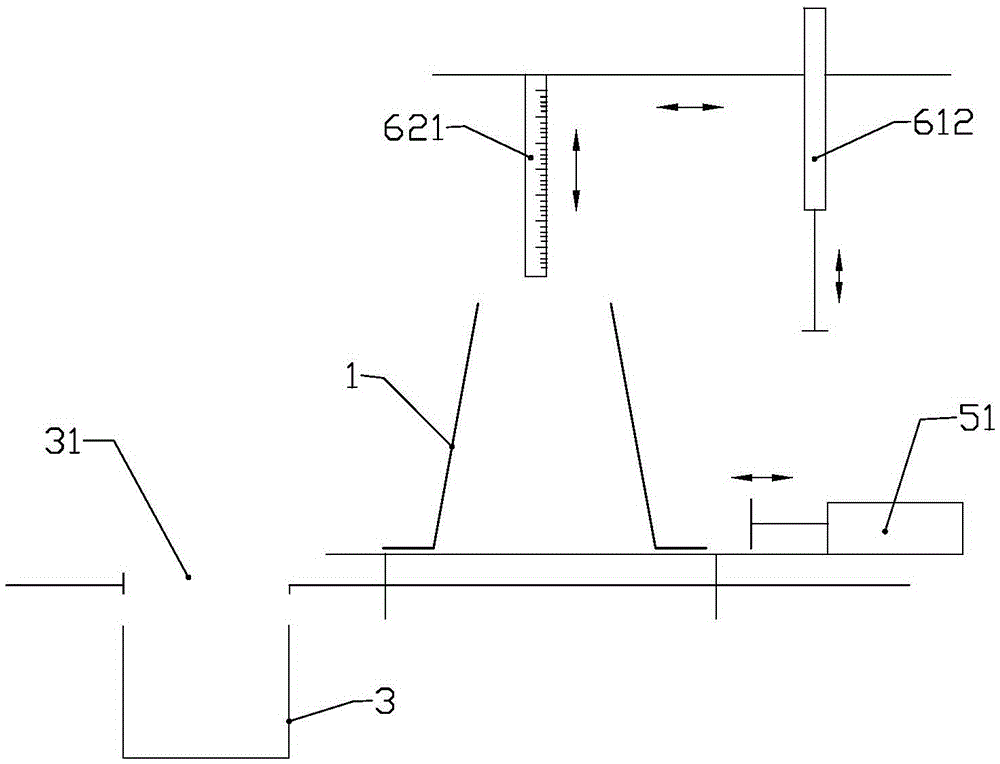

The invention discloses a movable concrete slump testing device. The movable concrete slump testing device comprises a testing tube, a cart, a tamping mechanism, a measuring mechanism and a clearing mechanism, wherein a panel adjustable in height and angle is arranged on the table surface of the cart, has a three-dimensional adjusting capability, and is convenient to level; on the table surface, a first portal frame and a second portal frame are arranged on linear sliding rails; the tamping mechanism is arranged on the first portal frame; the measuring mechanism is arranged on the second portal frame; the clearing mechanism is arranged on the panel, and is matched with a discharge opening in the table surface for use; and a concrete recycling barrel is fixed below the discharge opening. The concrete slump testing cart is applicable for on-site concrete slump test, can adjust the levelness of a test platform according to site adjustment to ensure accuracy of a measurement result as well as a tamping force and a demoulding force, has a more standardized process and provides a support for accurate determination of the concrete slump.

Description

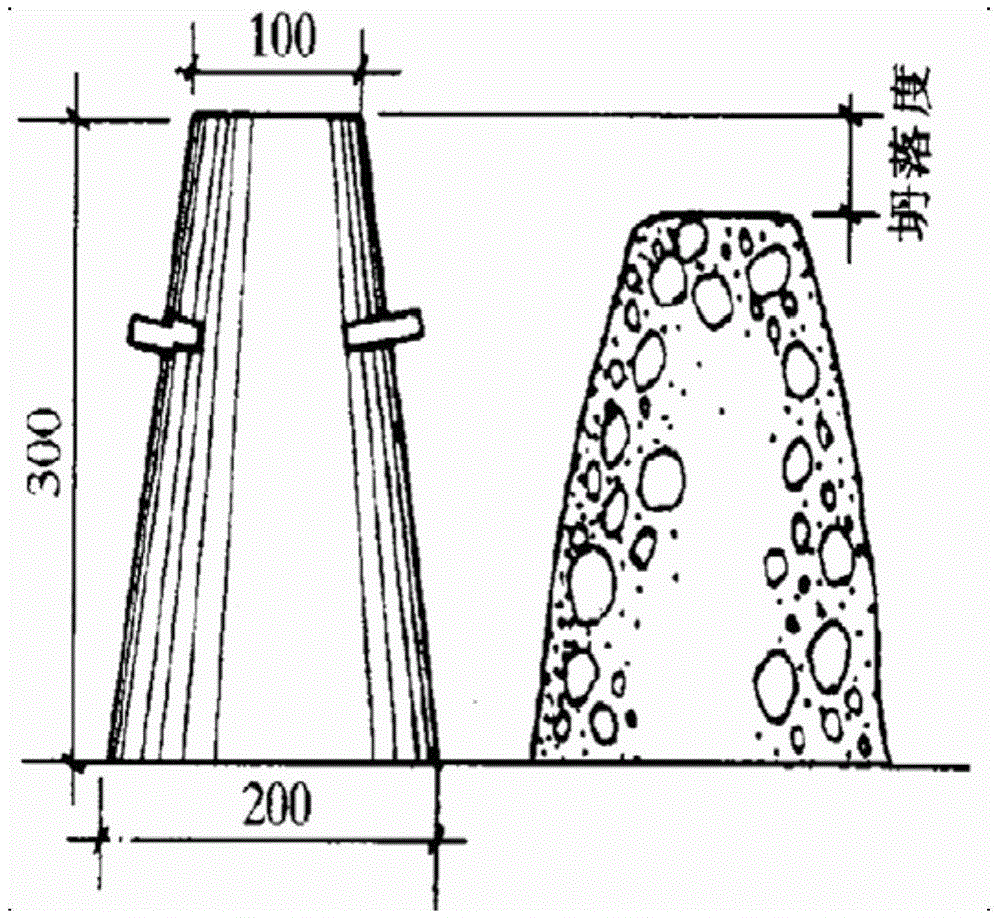

technical field [0001] The invention relates to the technical field of concrete slump test tools, in particular to a portable concrete slump test device that can realize standardized measurement. Background technique [0002] Concrete slump mainly reflects the plasticizing performance and pumpability of concrete. The main factors affecting concrete slump include raw materials, mixing time, transportation machinery, pouring speed, pouring time, etc. In addition, the amount of additives and easily overlooked cement Temperature also affects metrics. [0003] Concrete slump refers to the workability of concrete, specifically to ensure the normal progress of construction, including water retention, fluidity and cohesion of concrete. [0004] Existing conventional test method for slump: Use a trumpet-shaped slump bucket with an upper mouth of 100mm, a lower mouth of 200mm, and a height of 300mm, pour concrete into it and compact it, then pull out the bucket, and the concrete will...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N33/38

CPCG01N33/383

Inventor 陈华锋

Owner GUANDONG YIAN CITY CIVIL AIR DEFENSE ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com