Waste concrete recycling and crushing device

A waste concrete and crushing device technology, applied in magnetic separation, solid separation, grain processing, etc., can solve the problems of high site requirements, high transportation costs, and large space occupation, so as to improve quality, reduce impurity content, and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

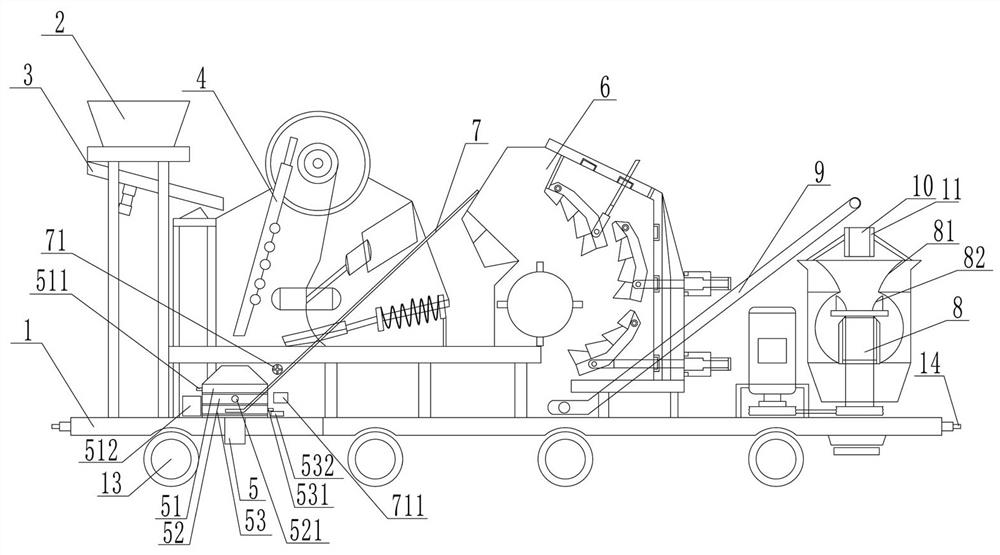

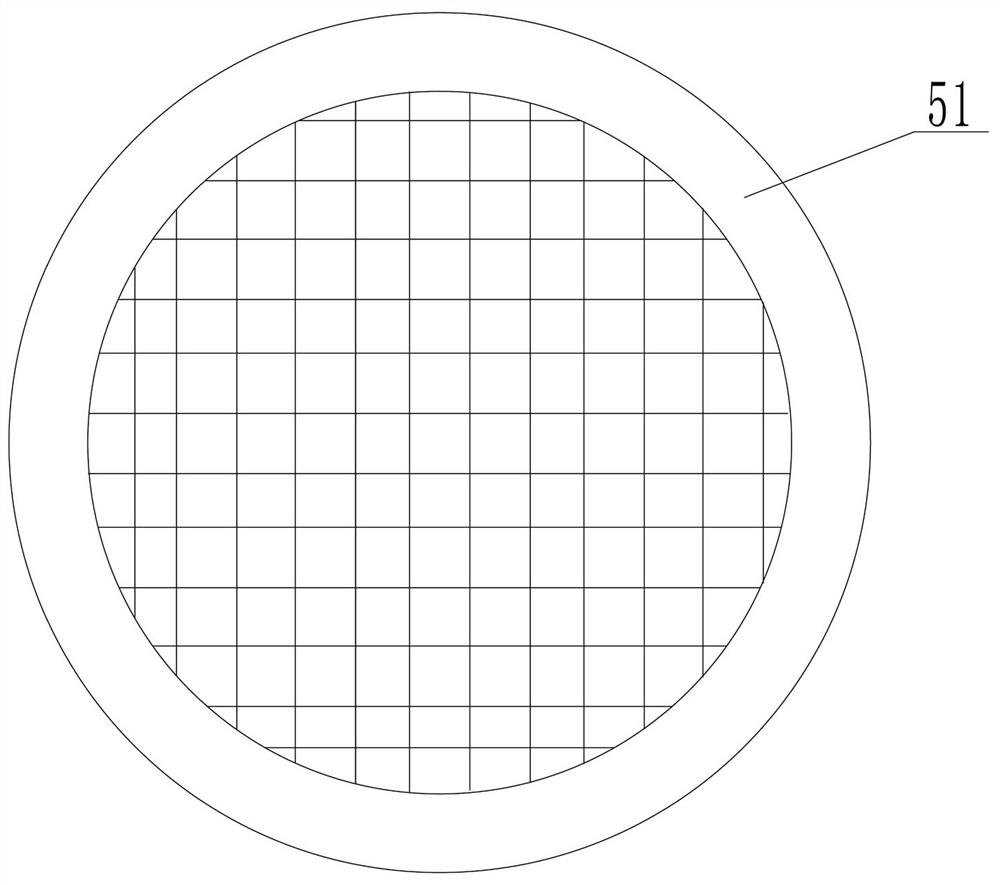

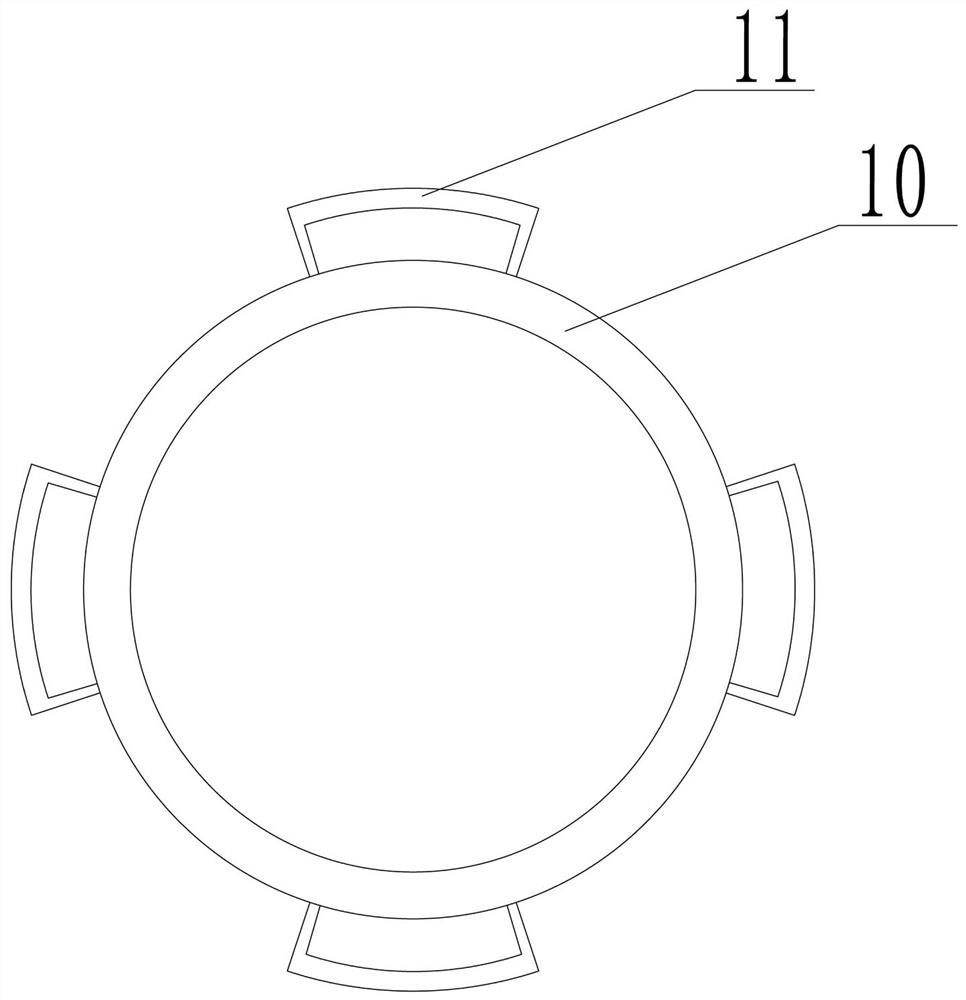

[0031] as attached Figure 1-4As shown, this embodiment provides a crushing device for recycling waste concrete, which includes a frame 1, a feeding device sequentially arranged on the frame 1, a primary crushing device, a sorting device, a secondary crushing device and a manufacturing Sand device; the feeding device includes a feeding hopper 2 arranged on the frame 1, a vibrating feeder 3 arranged on the lower side of the feeding hopper 2; the primary crushing device is a jaw crusher 4, and the The feed port of the jaw crusher 4 communicates with the discharge port of the vibrating feeder 3; The feed port is connected; the secondary crushing device is an impact crusher 6, and the first conveyor belt 7 is arranged between the feed inlet of the impact crusher 6 and the second discharge port 521 of the rotary vibrating screen 5, and the second A conveyor belt 7 transpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com