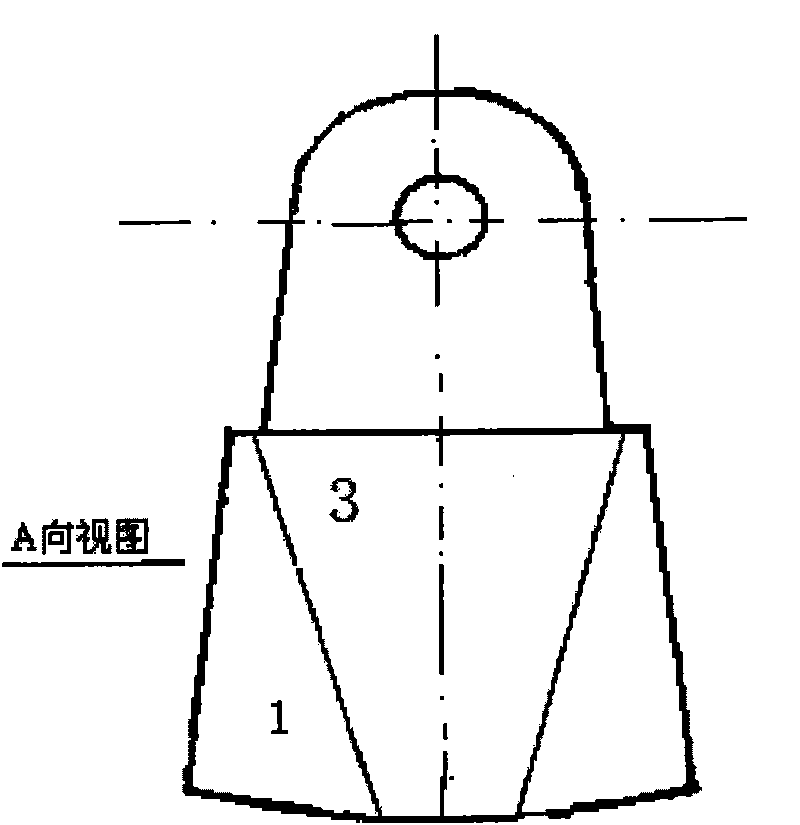

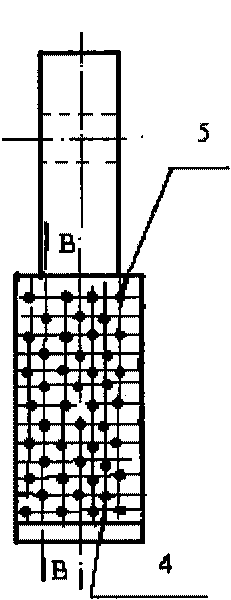

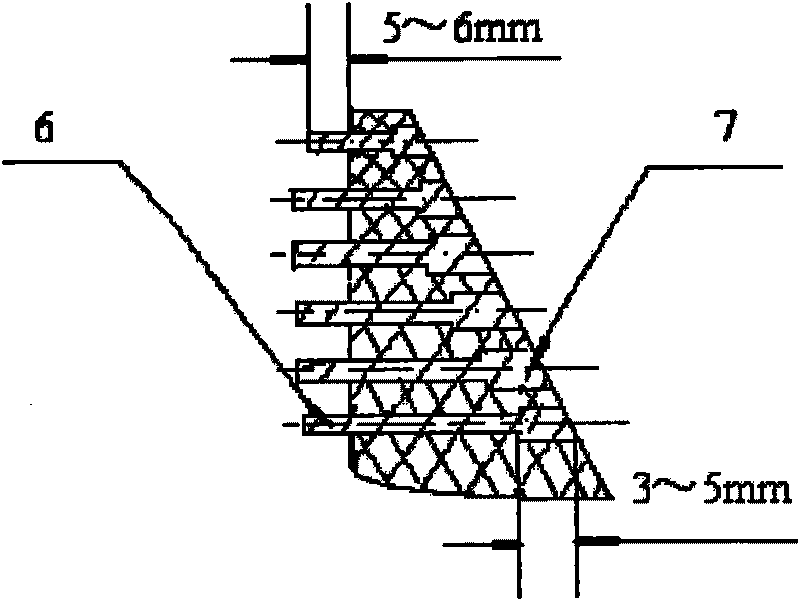

Crusher hammerhead cast of steel bond hard alloy bar and casting method of vanishing mould thereof

A technology of steel-bonded cemented carbide and cemented carbide rods, which is applied in casting molding equipment, casting molds, casting mold components, etc., to achieve the effects of low cost, not easy to fall off, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: produce the tup that unit weight is 800N, and this tup adopts low-alloy steel casting to form, inserts and casts steel bonded carbide rod in casting process; Wherein, the mass fraction of the chemical composition of low-alloy steel is: C 0.24%, Si 1.32%, S0.028%, P 0.032%, Mn 0.82%, Cr 1.67%, Mo 0.42%, V 0.05%, Ti 0.05%, RE 0.08%, Fe 95.29%; The casting material is GT35 steel-bonded hard alloy rod, which is a purchased part with a diameter of 2.5mm. The mass fraction of its chemical composition is: TiC 31%, Cr 3%, Mo 3%, C 0.9%, Fe 62.10%, The performance is: density / t.m -3 6.4~6.6, bending strength / Mpa 1380~1760, impact toughness / J.cm -2 39-78. Hardness (HRC): 36-45 in the annealed state and 66-69 in the quenched and tempered state.

[0016] The casting method of hammer head of the present invention, this casting method comprises the production process of low-alloy steel and lost foam casting process and heat treatment process, wherein, the production...

Embodiment 2

[0017]Embodiment 2: the production unit weight is the tup of 500N, and this tup adopts low-alloy steel casting to form, and casts steel-bonded carbide rod in casting process; Wherein, the mass fraction of the chemical composition of low-alloy steel is: C 0.267%, Si 1.44%, S 0.032%, P 0.035%, Mn 1.02%, Cr 1.89%, Mo 0.46%, V 0.05%, Ti 0.065%, RE 0.115%, Fe 94.626%; The material is GT35 steel-bonded carbide rod, which is an outsourced part with a diameter of 2.5mm. The mass fraction of its chemical composition is: TiC 31%, Cr 3%, Mo 3%, C 0.9%, Fe 62.10%. For: density / t.m -3 6.4~6.6, bending strength / Mpa 1380~1760, impact toughness / J.cm -2 39-78. Hardness (HRC): 36-45 in the annealed state and 66-69 in the quenched and tempered state.

[0018] The casting method of hammer head of the present invention, this casting method comprises the production process of low-alloy steel and lost foam casting process and heat treatment process, wherein, the production process of low-alloy st...

Embodiment 3

[0019] Embodiment 3: produce the tup that single weight is 200N, this tup adopts low-alloy steel casting to form, inserts and casts steel bonded carbide rod in casting process; Wherein, the mass fraction of the chemical composition of low-alloy steel is: C 0.295%, Si 1.56%, S 0.035%, P 0.038%, Mn 1.22%, Cr 2.10%, Mo 0.51%, V 0.08%, Ti 0.07%, RE 0.15%, Fe 93.942%; The material is GT35 steel-bonded hard alloy rod, which is a purchased part with a diameter of 2mm. The mass fraction of its chemical composition is: TiC 31%, Cr 3%, Mo 3%, C 0.9%, Fe 62.10%, and its performance is : Density / t.m -3 6.4~6.6, bending strength / Mpa 1380~1760, impact toughness / J.cm -2 39-78. Hardness (HRC): 36-45 in the annealed state and 66-69 in the quenched and tempered state.

[0020] The casting method of hammer head of the present invention, this casting method comprises the production process of low-alloy steel and lost foam casting process and heat treatment process, wherein, the production pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com