Multi-cylinder hydraulic antifriction bearing taper crusher

A cone crusher and rolling bearing technology, applied in the field of mining machinery and equipment, can solve the problems of poor assembly process of iron passing and cavity cleaning devices, increased machine maintenance costs and downtime, increased machine use costs, etc., to improve crushing efficiency and output , simple structure, and the effect of reducing the cost of equipment use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

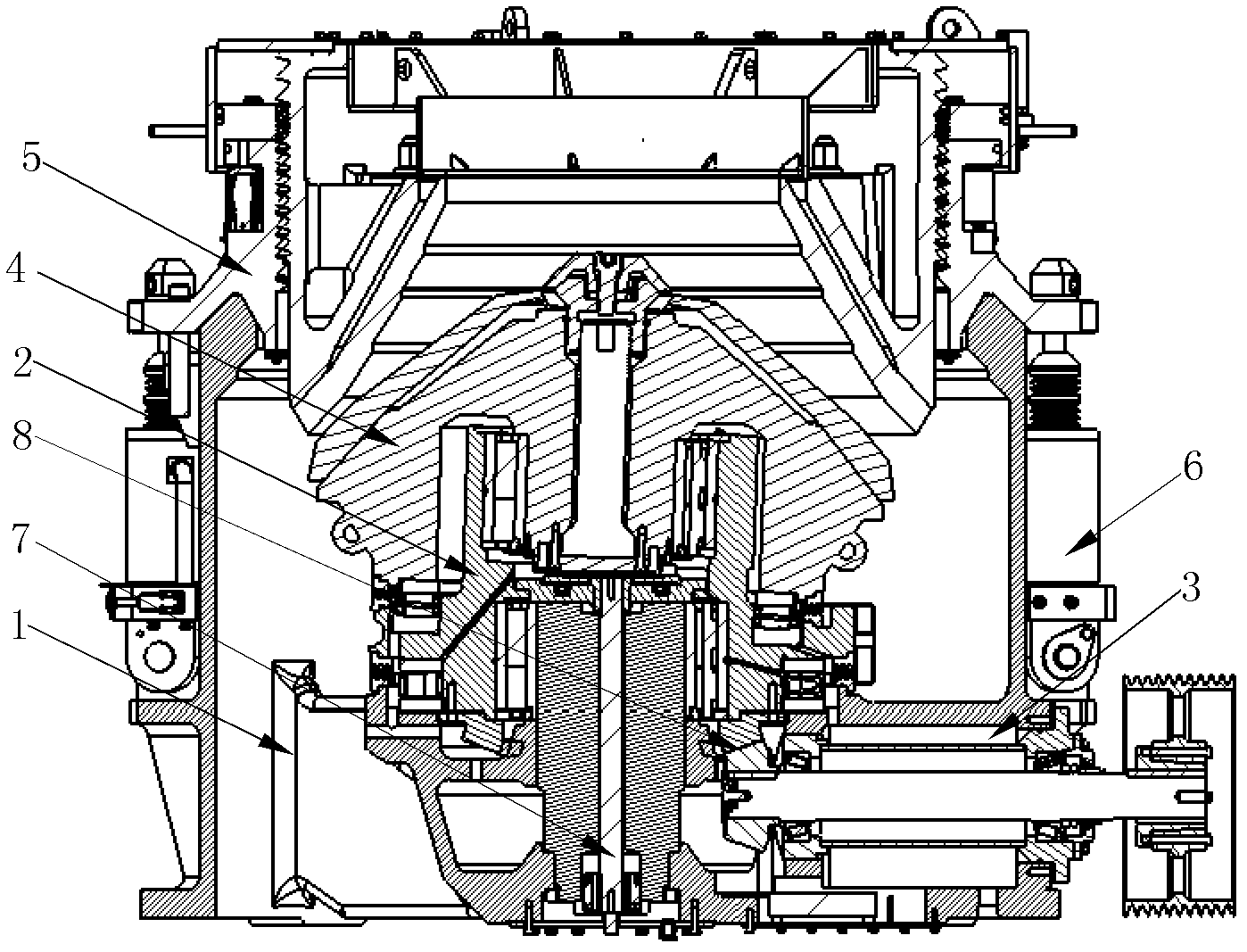

[0030] Such as figure 1 As shown, the multi-cylinder hydraulic rolling bearing cone crusher includes a lower frame 1, an eccentric shaft sleeve mechanism 2, a transmission group 3, a moving cone 4, an upper frame group 5, and an iron and cavity cleaning device 6. The upper frame Group 5 is set above the lower frame 1, the transmission group 3 and the eccentric bush mechanism 2 are installed on the lower frame 1, the transmission group 3 is connected with the eccentric bush mechanism 2, and the eccentric bush mechanism 2 is equipped with a moving cone 4. The lower frame 1 and the upper frame group 5 are directly equipped with an iron passing and cavity cleaning device 6, the eccentric bushing mechanism 2 adopts a rolling bearing type eccentric bushing mechanism 2, and the iron passing and cavity cleaning device 6 adopts an overflow The flow valve type iron passing and cavity clearing device 6, the bottom of the moving cone 4 is also connected with the moving cone anti-rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com