Waste concrete recycling and screening device

A waste concrete and screening device technology, which is applied in the direction of screening, solid separation, and separation of solids from solids with airflow, which can solve problems such as sieve blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

[0027] The waste concrete recovery and screening device described in this embodiment is an extension of the patented "waste concrete recovery device", which screens the separated coarse (stone) fine aggregate (sand) and hardened cement mortar mixture. So that the recovered stones and sand are similar to natural stones and sand, and can be effectively reused in newly mixed concrete, and the hardened cement paste powder (below 0.16mm) can be ultra-finely processed as cement mixture or Admixtures for ready-mixed concrete.

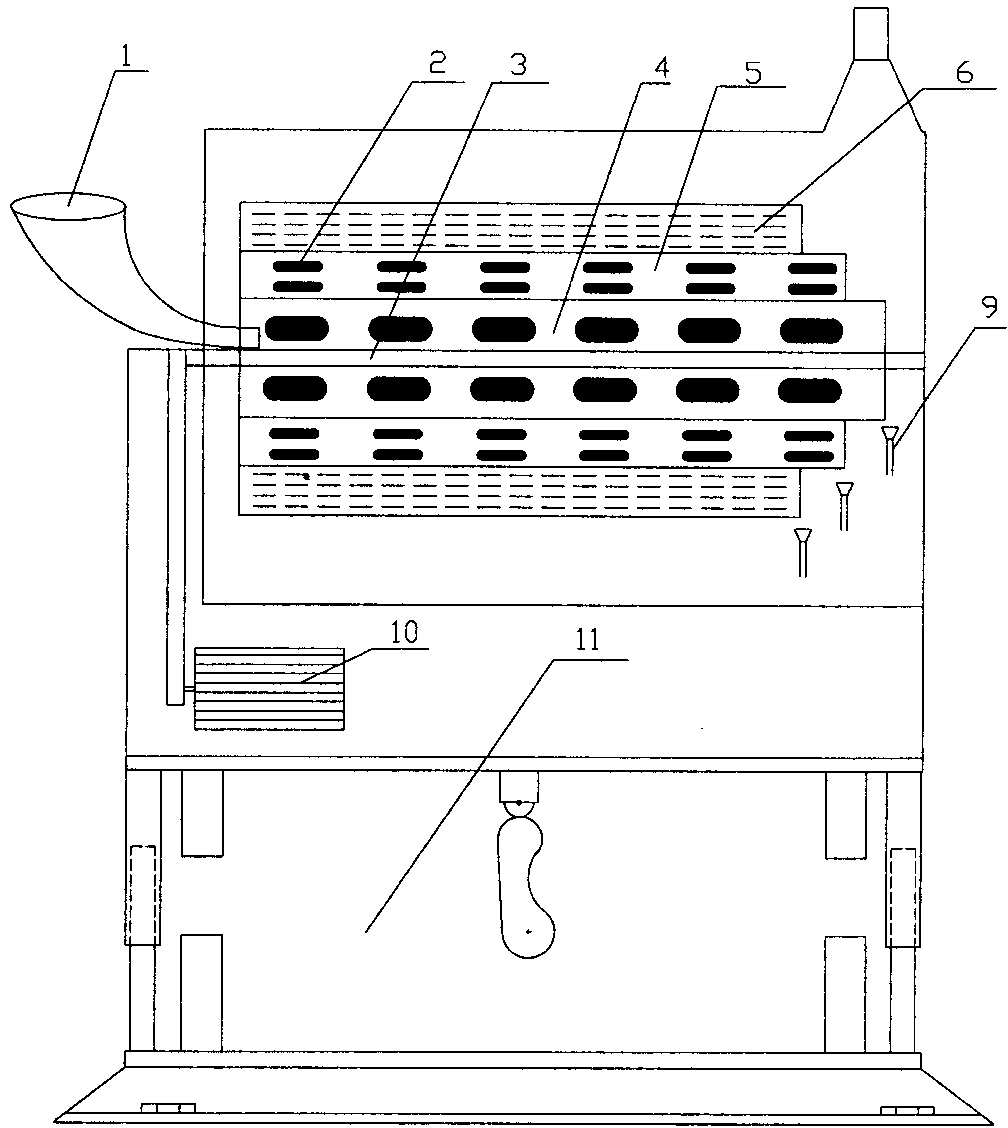

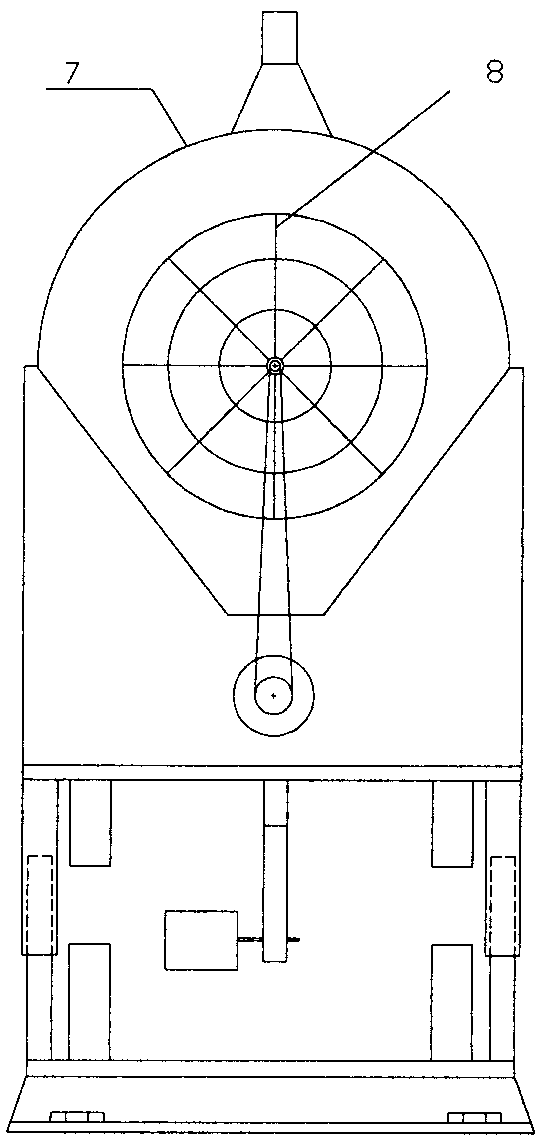

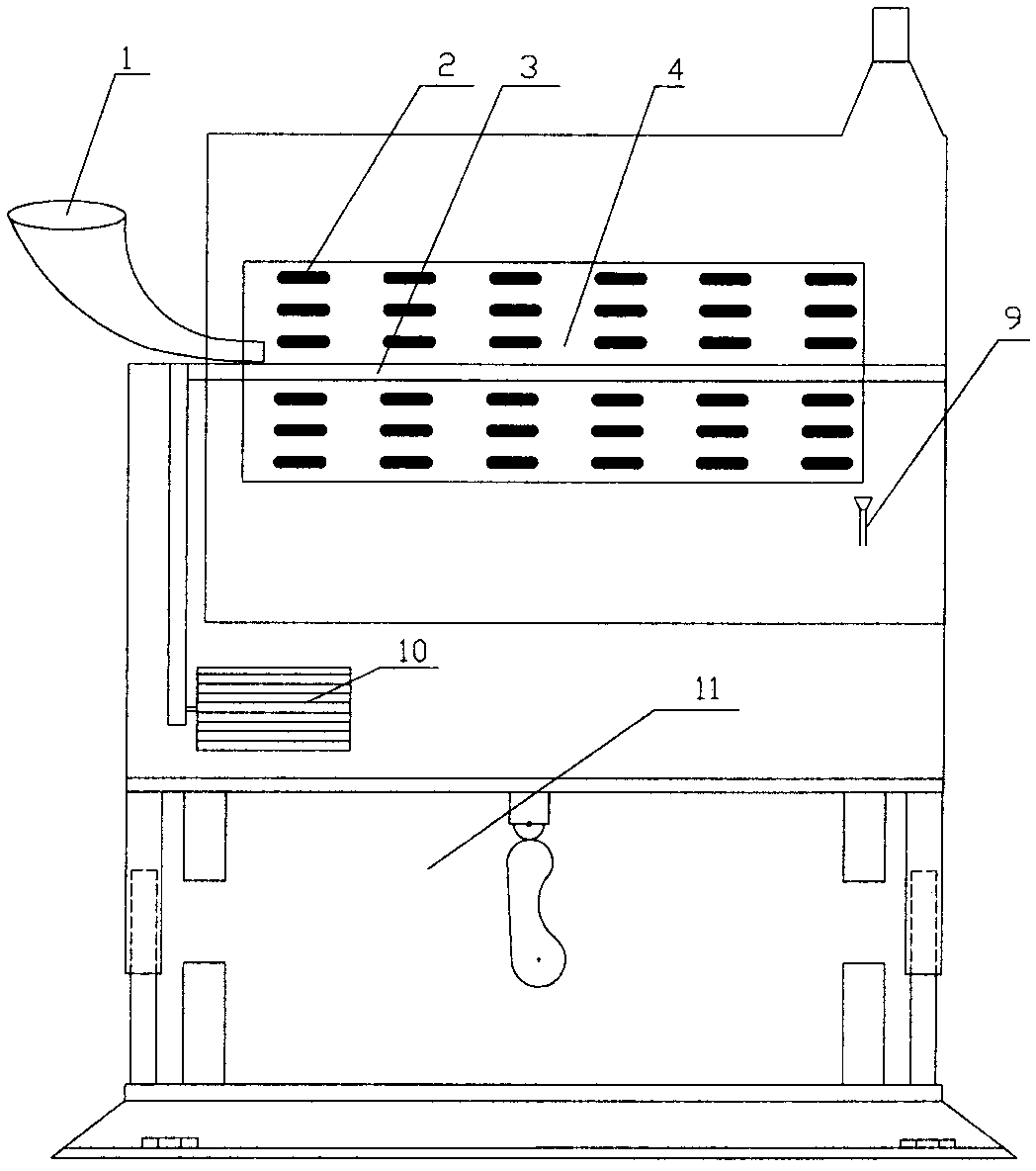

[0028] The waste concrete recycling and screening device described in this embodiment includes a first screening device and a second screening device

[0029] and vibrating device parts. The first screening device is a three-layer rotary sieve structure with sieve widths of 5.00mm, 1.25mm and 0.16mm respectively. It mainly screens out coarse aggrega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com