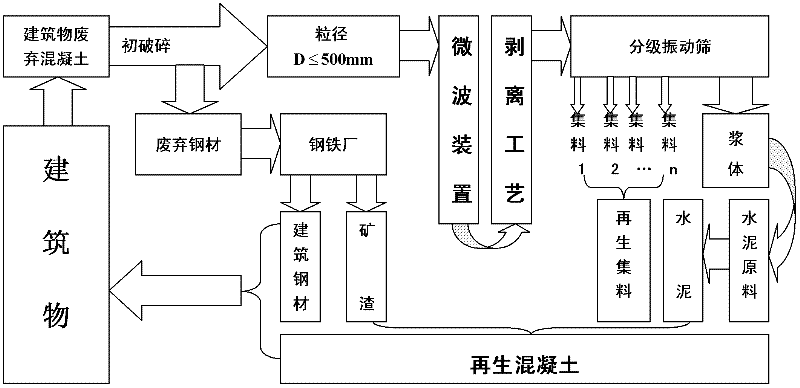

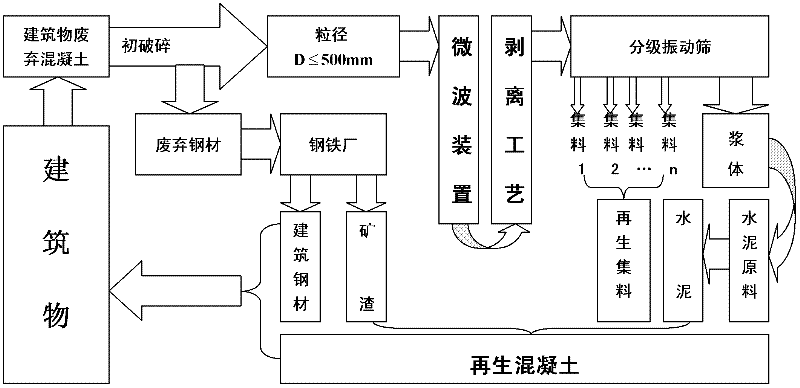

Cement concrete recycling method

A cement concrete, recycling technology, used in cement production, sustainable waste treatment, solid waste management, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] This method can already be implemented in the laboratory: the method is to use 100mm × 100mm × 100mm concrete, the coarse aggregate of the concrete is limestone crushed stone, the fine aggregate is limestone machine-made sand, and the test piece is directly placed in a 4kw microwave oven. After microwave irradiation, the temperature of the slurry part reaches about 750 °C, the surface temperature of the coarse aggregate is 482 °C, and the internal temperature is 96 °C. almost disappeared. The measured strength of the concrete test block is 0.46MPa, which can be easily peeled off. It only needs to be bumped several times on the aggregate screen and crushed with a little force to separate. The aggregate can become recycled aggregate after sorting. The composition of the dehydrated phase of the remaining cement slurry is similar to that of the Portland cement raw meal, except that the calcium oxide content is slightly higher. A small amount of clay and iron powder are add...

Embodiment 2

[0022] Take the waste concrete demolished from a construction site, use a metal detector to test that there is no rebar residue, and put it into a 4kw microwave oven. After microwave radiation, the temperature of the slurry part reaches about 850 °C, and the surface temperature of the tested coarse aggregate is 532 °C , the internal temperature is 187 ℃, there is basically no bonding strength between the slurry and the aggregate, and the gelatinity of the slurry is almost disappeared, which can be easily peeled off, just after several bumps and a little force on the aggregate screen Crush to separate. The aggregate can become recycled aggregate after sorting. The composition of the dehydrated phase of the remaining cement slurry is similar to that of Portland cement raw meal, except that the content of silica is slightly higher and the calcium oxide is slightly lower. A small amount of limestone and iron powder are added for correction, and silicon dioxide can be obtained by c...

Embodiment 3

[0024] Take the waste concrete demolished at a construction site, use a metal detector to test that there is no rebar residue, and put it into a 4kw microwave oven. After microwave radiation, the temperature of the slurry part can reach about 980 ℃, and the surface temperature of the tested coarse aggregate is 604 °C, the internal temperature is 246 °C, there is basically no bonding strength between the slurry and the aggregate, and the gelatinity of the slurry is almost disappeared, which can be easily peeled off. Crush hard to separate. The aggregate can become recycled aggregate after sorting. The composition of the dehydrated phase of the remaining cement slurry is similar to that of Portland cement raw meal, except that the content of silica and alumina is slightly higher, and the calcium oxide is slightly lower. Portland cement clinker can be obtained at 1400 ℃, and cement can be obtained by adding gypsum and grinding. These recovered aggregates and recycled cement can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com