Waste concrete crushing and screening device

A technology for waste concrete and concrete blocks, which is applied in the direction of grain processing, etc., and can solve the problems of reducing the quality of output concrete blocks, insufficient screening capacity of crushing devices, and insufficient screening capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

[0026] The object of the present invention is to provide a device for crushing and screening waste concrete to solve the problem that in the process of crushing existing waste concrete, it is often necessary to crush waste concrete with a large size. The method makes it difficult to break into concrete blocks of the size we need. At the same time, because of the insufficient screening capacity of the crushing device, it is impossible to clean and eliminate the iron metals such as steel bars in the crushed products that affect the quality of concrete blocks. , not only reduces the utilization rate of waste concrete, but also reduces the quality of the output concrete block.

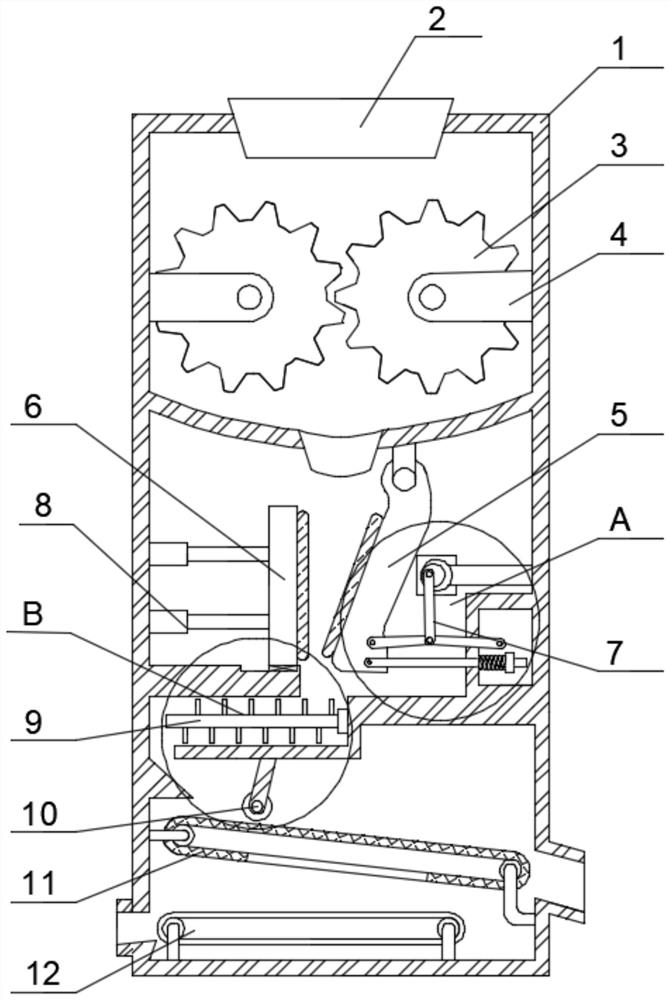

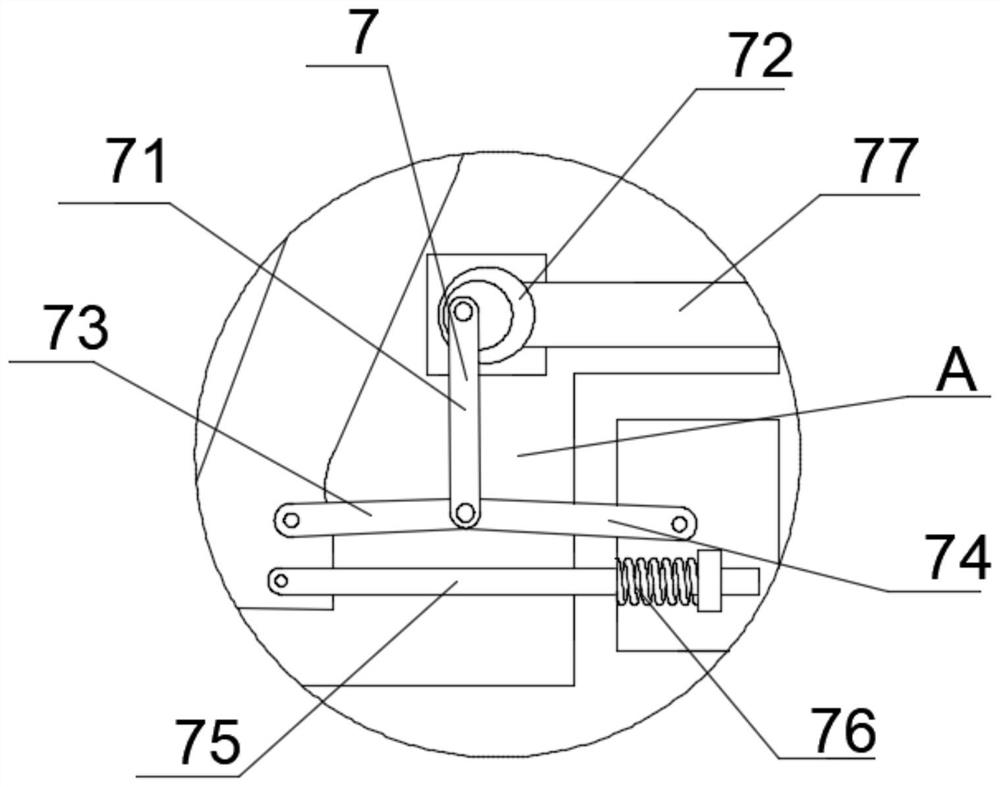

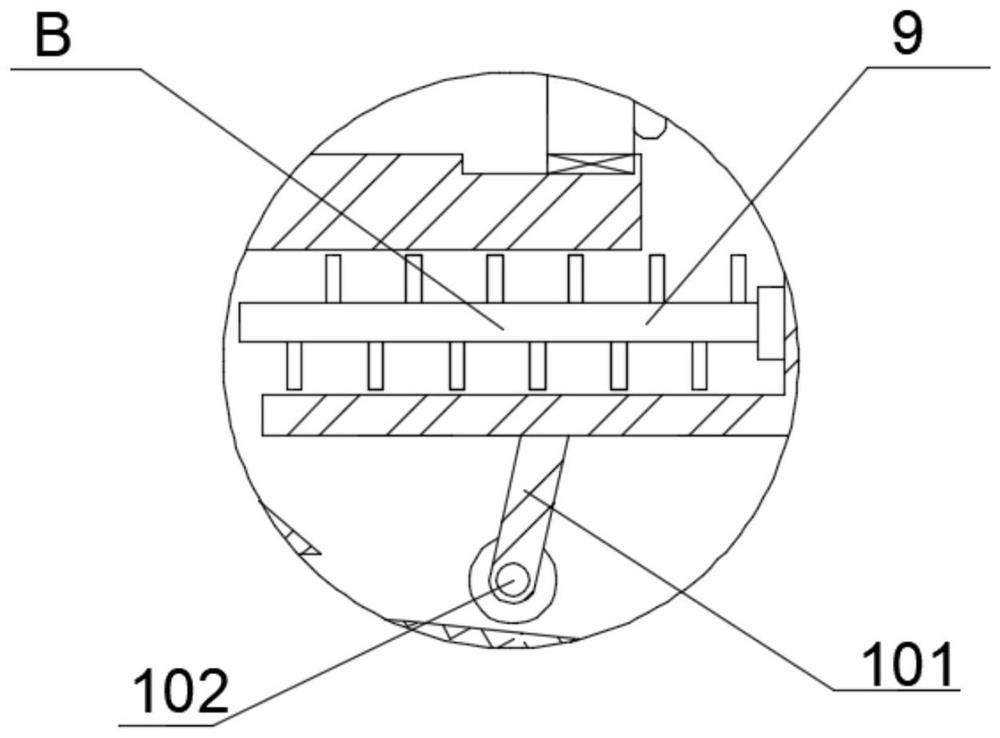

[0027] like figure 1As shown, in the embodiment of the present invention, a device for crushing and screening waste concrete includes a roller structure 3, a jaw cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com