Method and system for recycling utilization of mass fresh mixed waste concrete

A waste concrete, high-volume technology, used in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as increased costs, waste, and large fluctuations in solid content, saving resources and reducing energy consumption. , the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

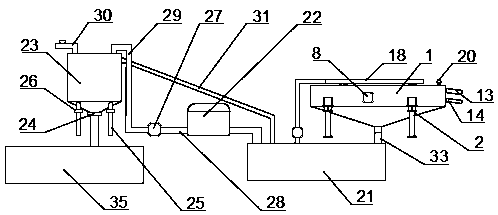

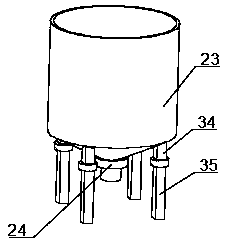

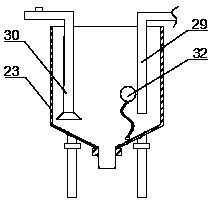

[0029] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0030] A method for recycling freshly mixed waste concrete in large quantities, comprising the following steps:

[0031] Step 1: Separating and recycling the sand and gravel in the waste concrete;

[0032] Use the loader to transport the waste concrete into the sand and stone separation device for separation, and recycle the separated sand and stone for the production of fresh concrete, and discharge the waste slurry into the waste slurry pool;

[0033] Step 2: recycle the waste pulp;

[0034] Use the cyclone to separate the fine sand from the waste slurry in the waste slurry pool to obtain fine sand and recycled slurry, then recycle the fine sand for the production of fresh concrete, and pump the recycled slurry into the solid with weighin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com