Patents

Literature

144results about How to "Reduce separation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene dispersion liquid and method for preparing graphene material power

The invention provides a graphene dispersion liquid which comprises an organic solvent and a graphene material dispersed in the organic solvent, wherein the graphene dispersion liquid is prepared by virtue of the following steps: S1, providing a graphene water-based slurry which comprises the graphene material and water; S2, adding the organic solvent once or multiple times into the graphene water-based slurry in an accumulated manner to obtain a mixed slurry, wherein the organic solvent and the water can form an azeotropic system; S3, heating the mixed slurry till all moistures in the mixed slurry are removed, so as to obtain the graphene dispersion liquid. The invention further provides a method for preparing graphene material power by using the graphene dispersion liquid.

Owner:NINGBO MORSH TECH +1

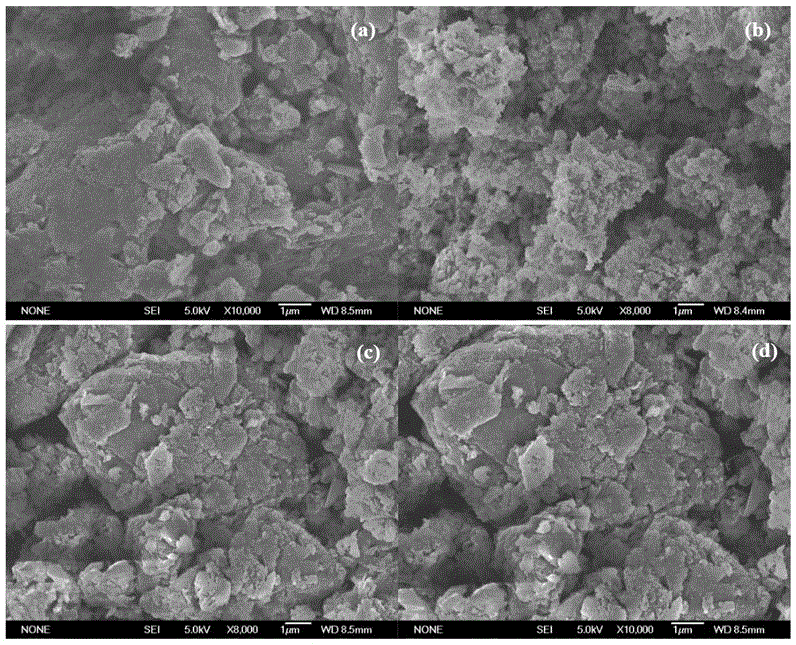

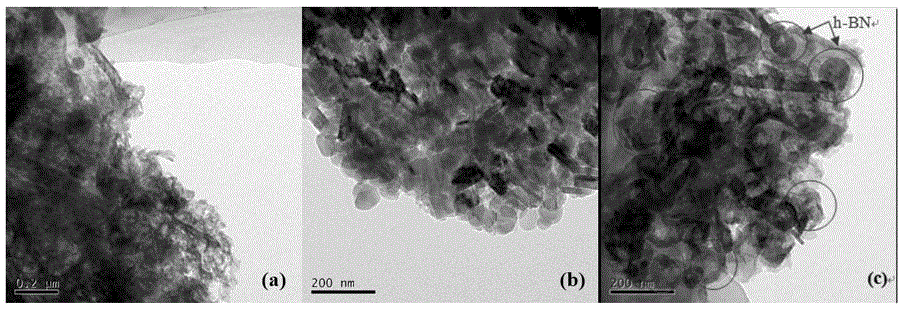

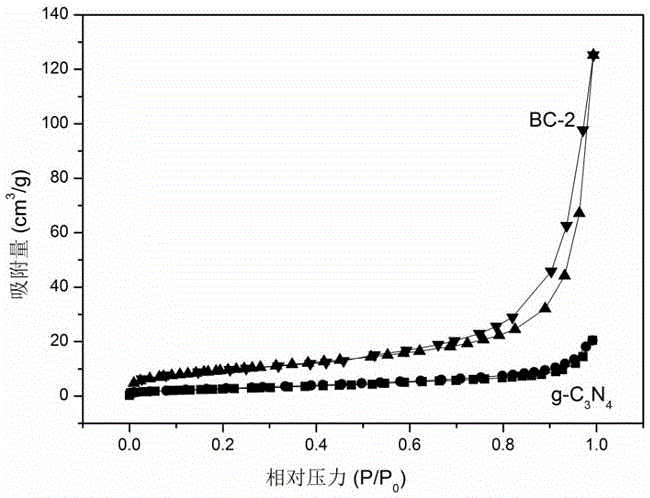

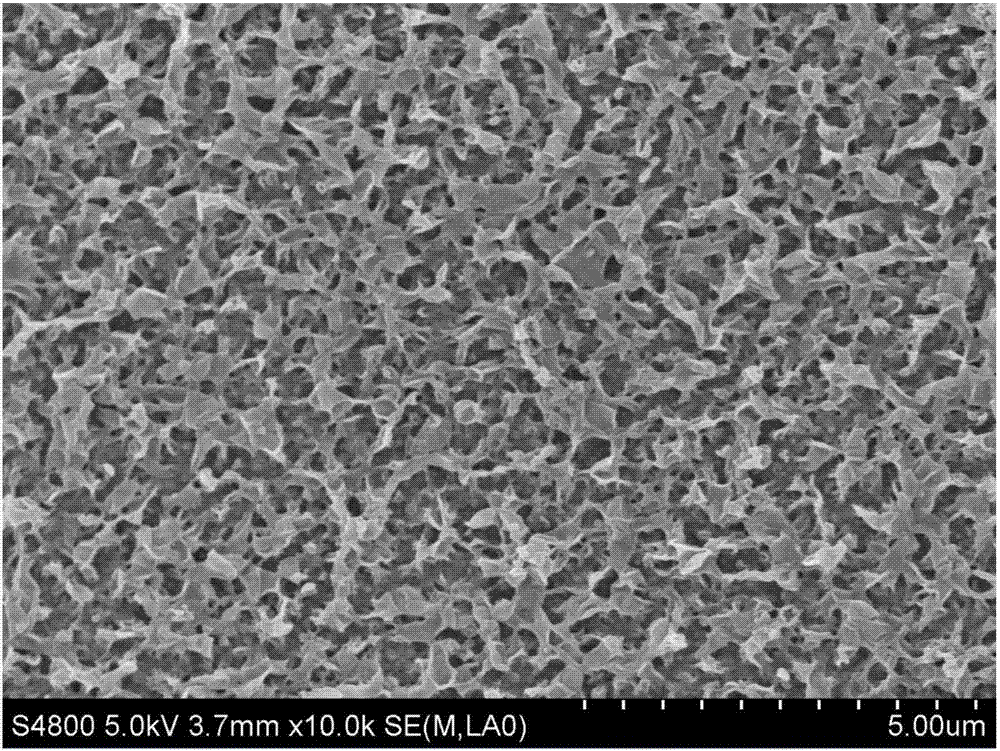

Hexagonal boron nitride modified graphitized carbon nitride composite optical catalyst as well as preparation method and application thereof

ActiveCN106732727AOptimized areaBoost ratePhysical/chemical process catalystsWater/sewage treatment by irradiationElectron holeHexagonal boron nitride

The invention discloses a hexagonal boron nitride modified graphitized carbon nitride composite optical catalyst as well as a preparation method and application thereof. According to the composite optical catalyst, by taking graphitized carbon nitride as a carrier, laminated hexagonal boron nitride modifies the graphitized carbon nitride carrier. The preparation method comprises the following steps: mixing the hexagonal boron nitride with a graphitized carbon nitride precursor; and calcining the mixed precursor to obtain the hexagonal boron nitride modified graphitized carbon nitride composite optical catalyst. The hexagonal boron nitride modified graphitized carbon nitride composite optical catalyst disclosed by the invention has the advantages of being environmentally friendly, fully free of metal doping, large in specific surface area, high in photoproduction electron-hole separating efficiency, high in optical catalytic activity, good in stability, corrosion-resistant and the like. The preparation method has the advantages of being simple, low in cost of raw materials, less in energy consumption, easy to control conditions and the like. The composite optical catalyst disclosed by the invention is used for degrading dye wastewater and has the advantages of being simple in application method, stable in optical catalytic performance, high in corrosion resistance, high in dye wastewater degrading efficiency.

Owner:HUNAN UNIV

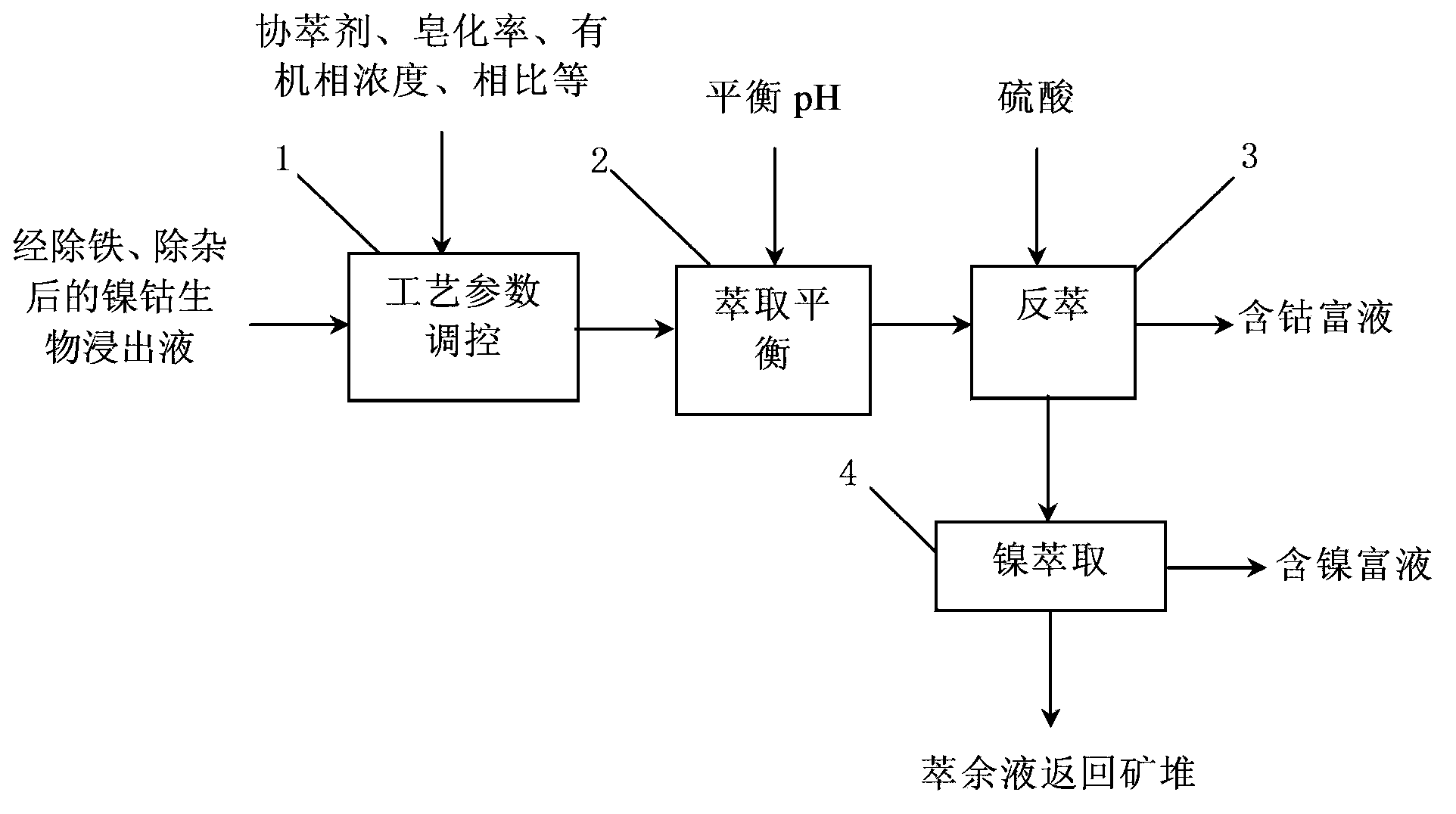

Method for improving extraction and separation efficiency of nickel and cobalt in biological leaching liquid

InactiveCN103898339AReduce separation efficiencyLow costProcess efficiency improvementKerosenePhase ratio

The invention relates to a method for improving extraction and separation efficiency of nickel and cobalt in biological leaching liquid. The method comprises the following steps: (1) respectively carrying out homogeneous saponification on a nickel-cobalt extraction agent P507 and a synergist Cynaex272 by adopting a NaOH solution, wherein the saponification time is 30 minutes, and the saponification rate is 60%; (2) mixing the saponified extraction agent P507 with the synergist Cynaex272 according to the volume ratio of 3:2 to form a combined extraction agent, and diluting the combined extraction agent of which the final concentration is 10% by using 260# sulfonated kerosene; (3) extracting under the conditions that the temperature is 25-28 DEG C and the initial pH value is 1.5-2.0, wherein the extraction phase ratio O / A is 1:4, the oscillation strength is 180rpm, and the extraction oscillation time is 3 minutes, controlling the extraction balance pH value to 4.0-4.5; stewing and splitting for 30 minutes, and separating an organic phase from a water phase; (4) adding sulfuric acid extraction cobalt to the separated organic phase, so as to achieve nickel-cobalt separation. By adopting the method, nickel-cobalt extraction and separation can be achieved under a low pH value, the extraction cost also can be reduced, the extraction grade is reduced, and the loss caused by nickel-cobalt is reduced, so as to improve the extraction and separation efficiency of nickel and cobalt.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

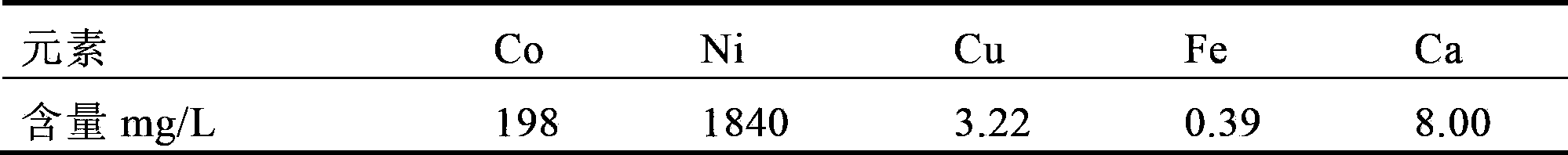

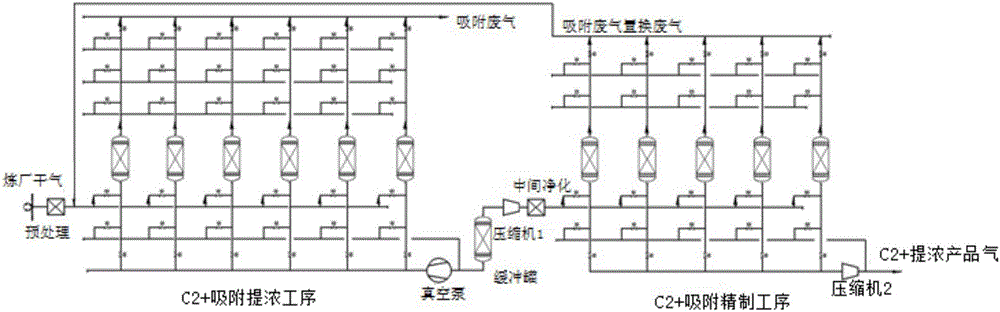

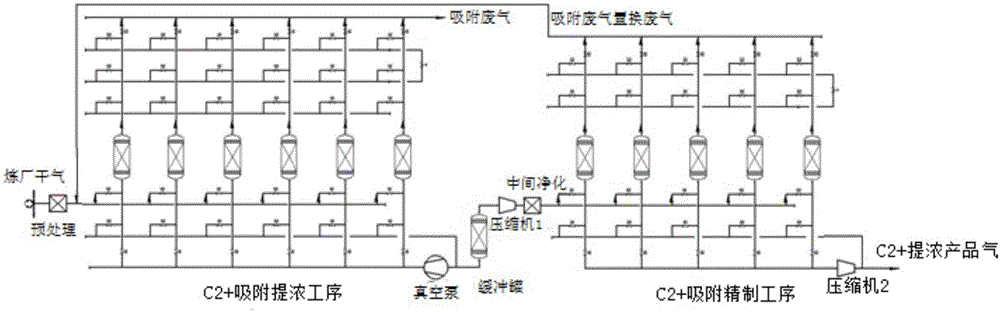

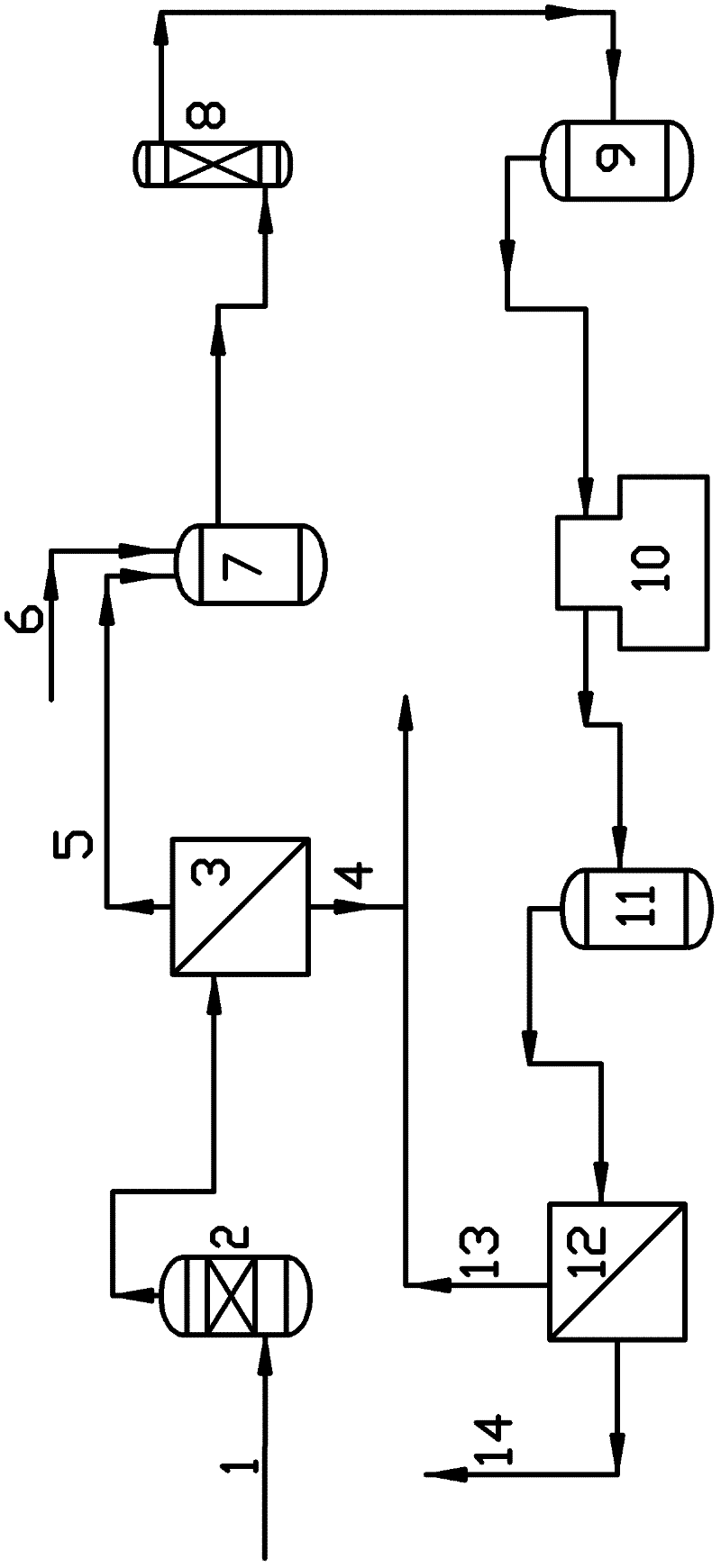

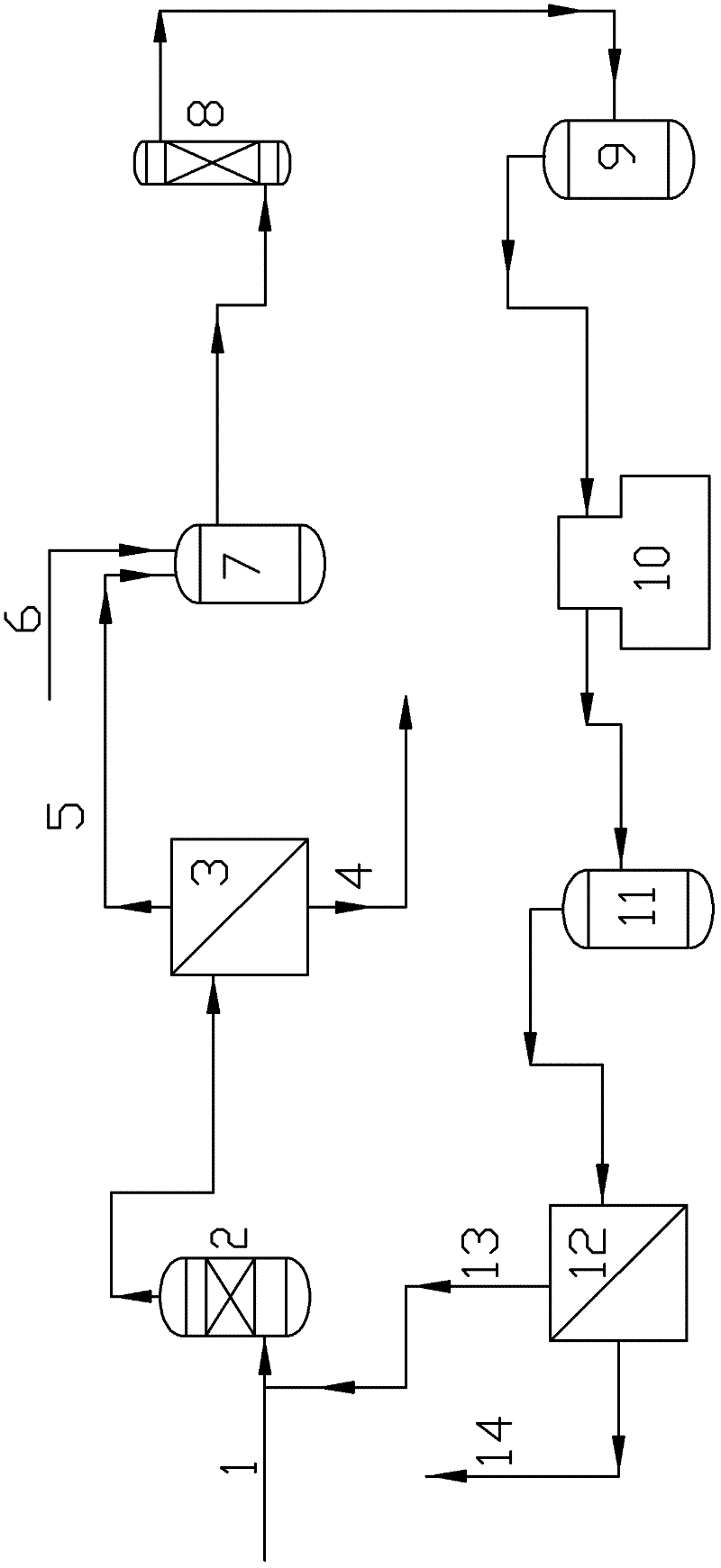

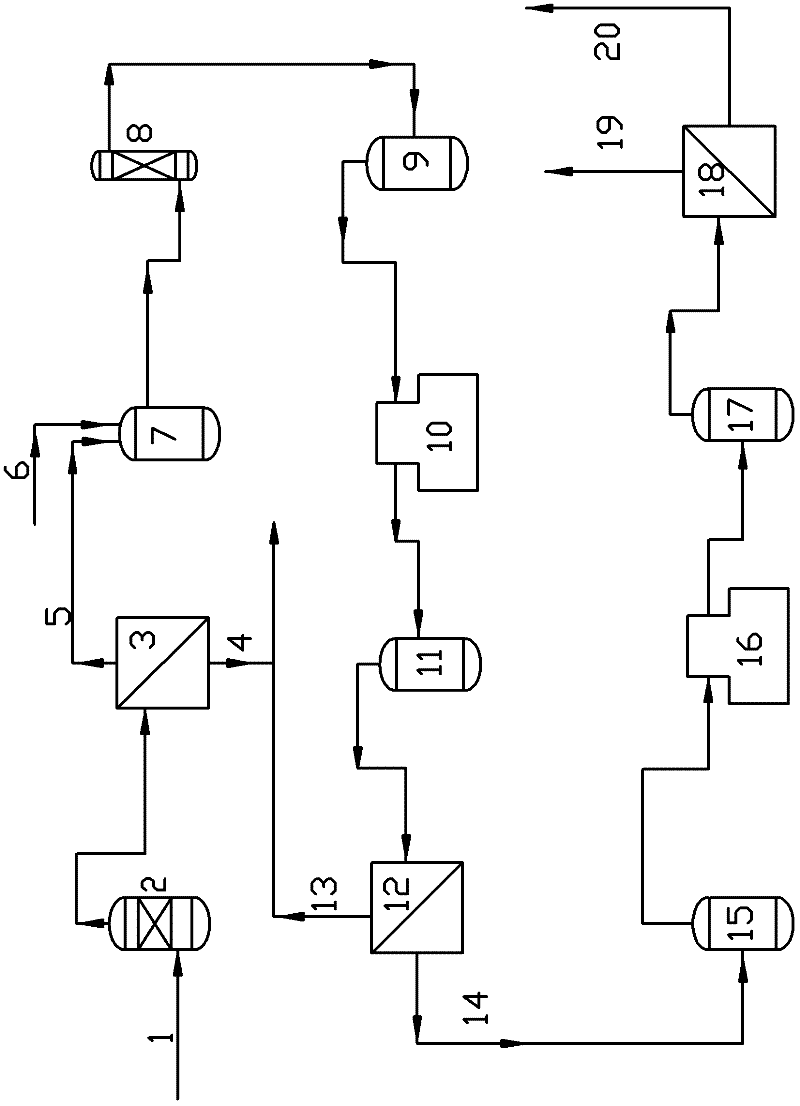

Two-stage PSA method for recovering C2+ from refinery dry gas according to concentration

ActiveCN107433107ABreak adsorption equilibriumReduce methane contentProductsGas treatmentHydrogenPetrochemical

The invention discloses a two-stage PSA method for recovering C2+ from refinery dry gas according to concentration, which relates to the technical field of separating and recovery of in valuable substances in petrochemical tail gas. The method comprises a pretreatment process, a C2+ adsorption concentration process, an intermediate purifying process, and a C2+ adsorption refining process, wherein, the pre-treated refinery mixed dry gas is introduced into the CO2+ adsorption concentration process, then flowed non-adsorption phase gas is the adsorption exhaust gas, or directly taken as hydrogen (H2) product gas, or taken as fuel gas, or taken as raw material gas for extraction of hydrogen for output; the flowed adsorption phase gas forms the intermediate gas through the intermediate purifying process, and then is introduced into the C2+ adsorption refining process for refining, the flowed non-adsorption phase gas is taken as the raw material gas for mixing with the refinery mixed dry gas, a mixture is returned to the C2+ adsorption concentration process; the flowed adsorption phase gas has the C2+ concentration being more than 90-95% (a volume ratio), wherein the methane impurity concentration is less than 4%, the flowed adsorption phase gas is taken as the C2+ concentrate product gas for output, and the yield of C2+ is more than 90-95%.

Owner:SICHUAN TECHAIRS

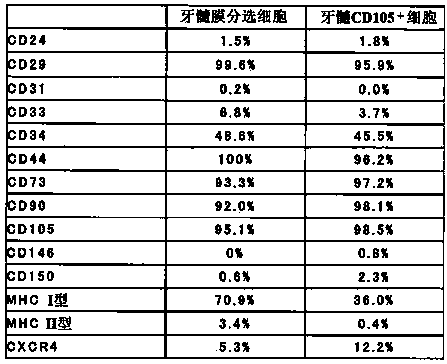

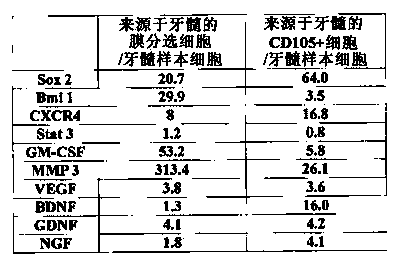

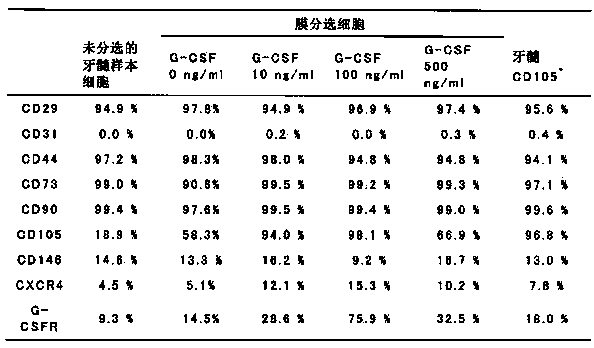

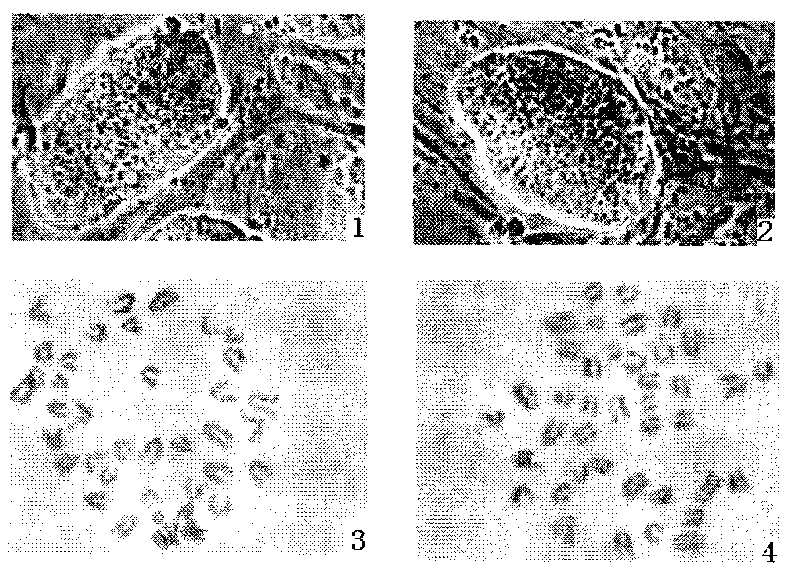

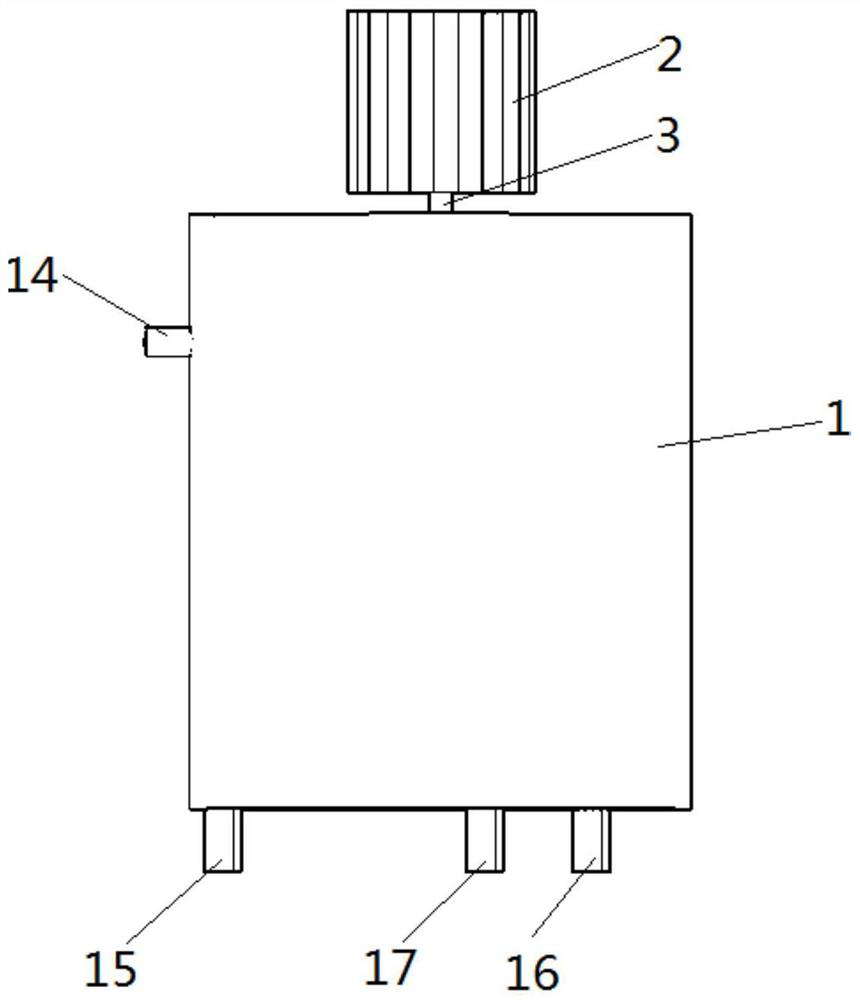

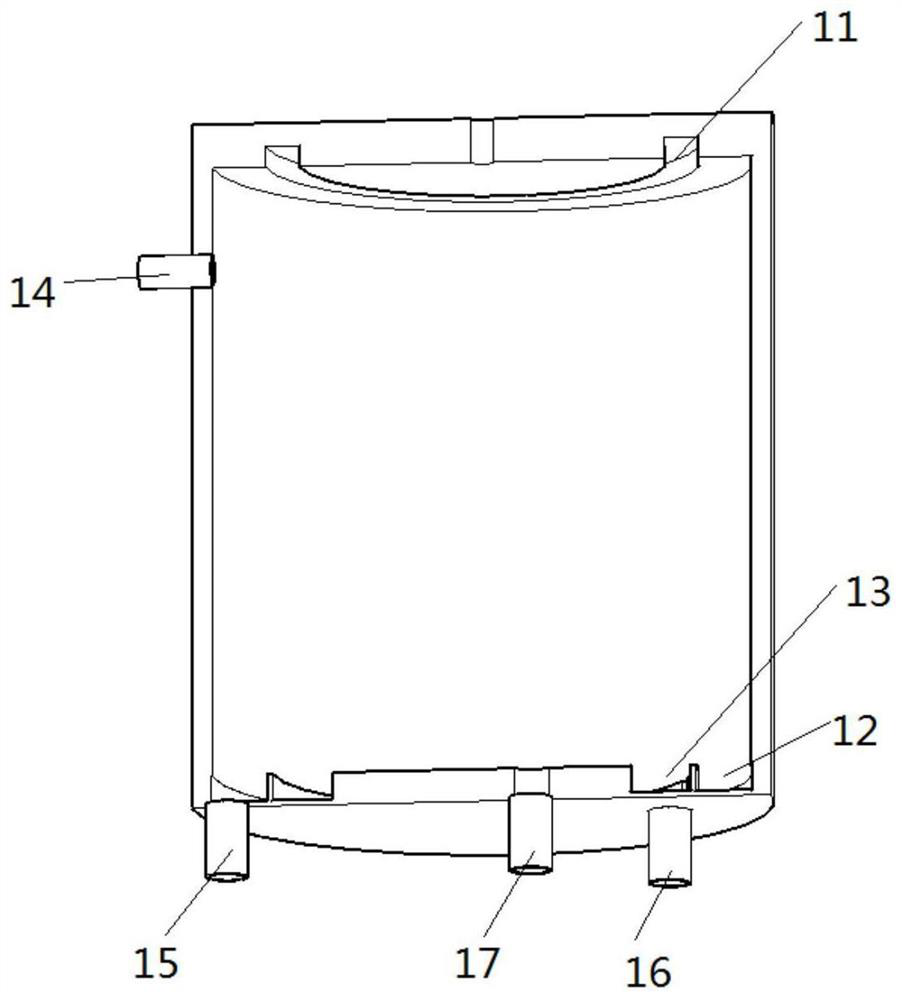

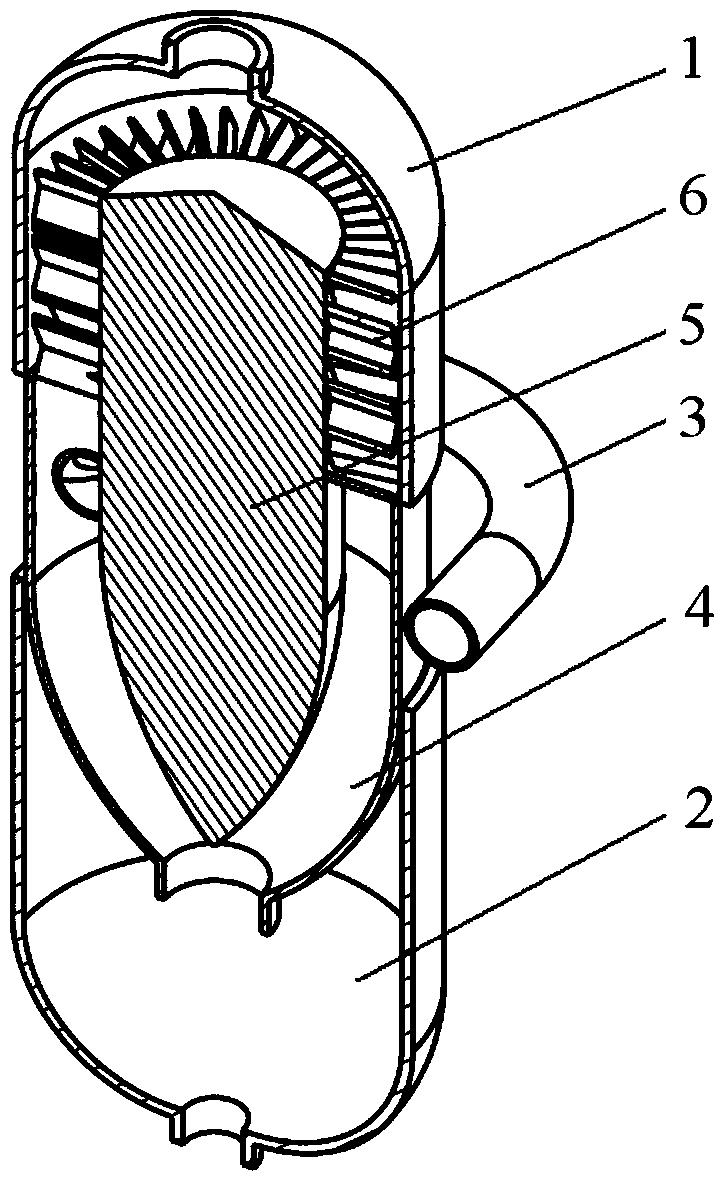

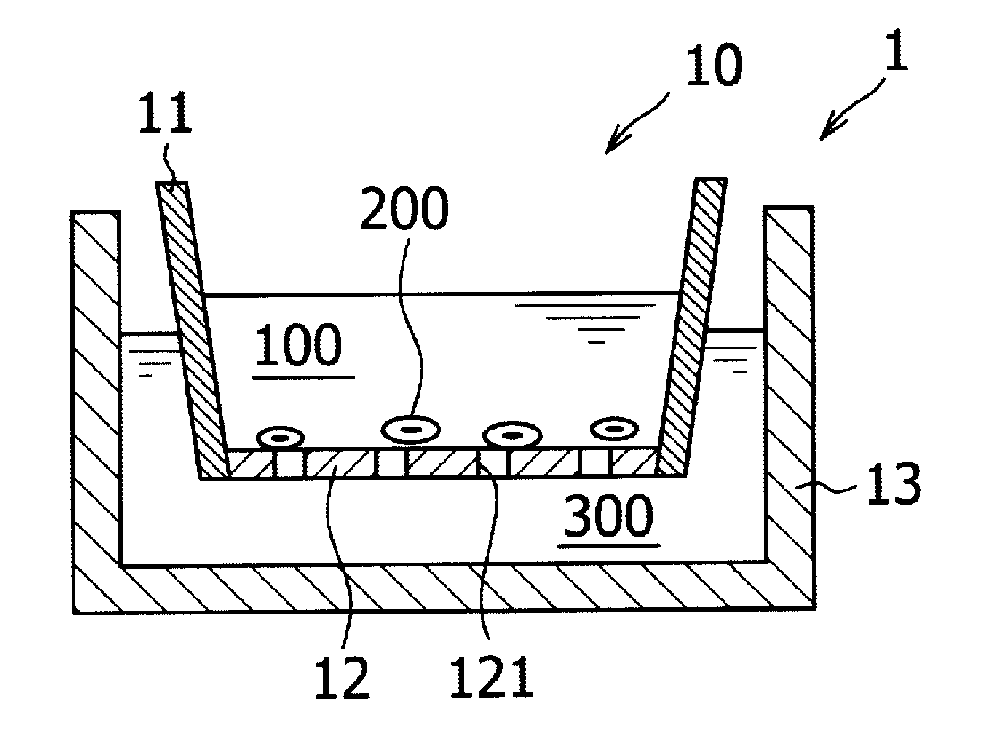

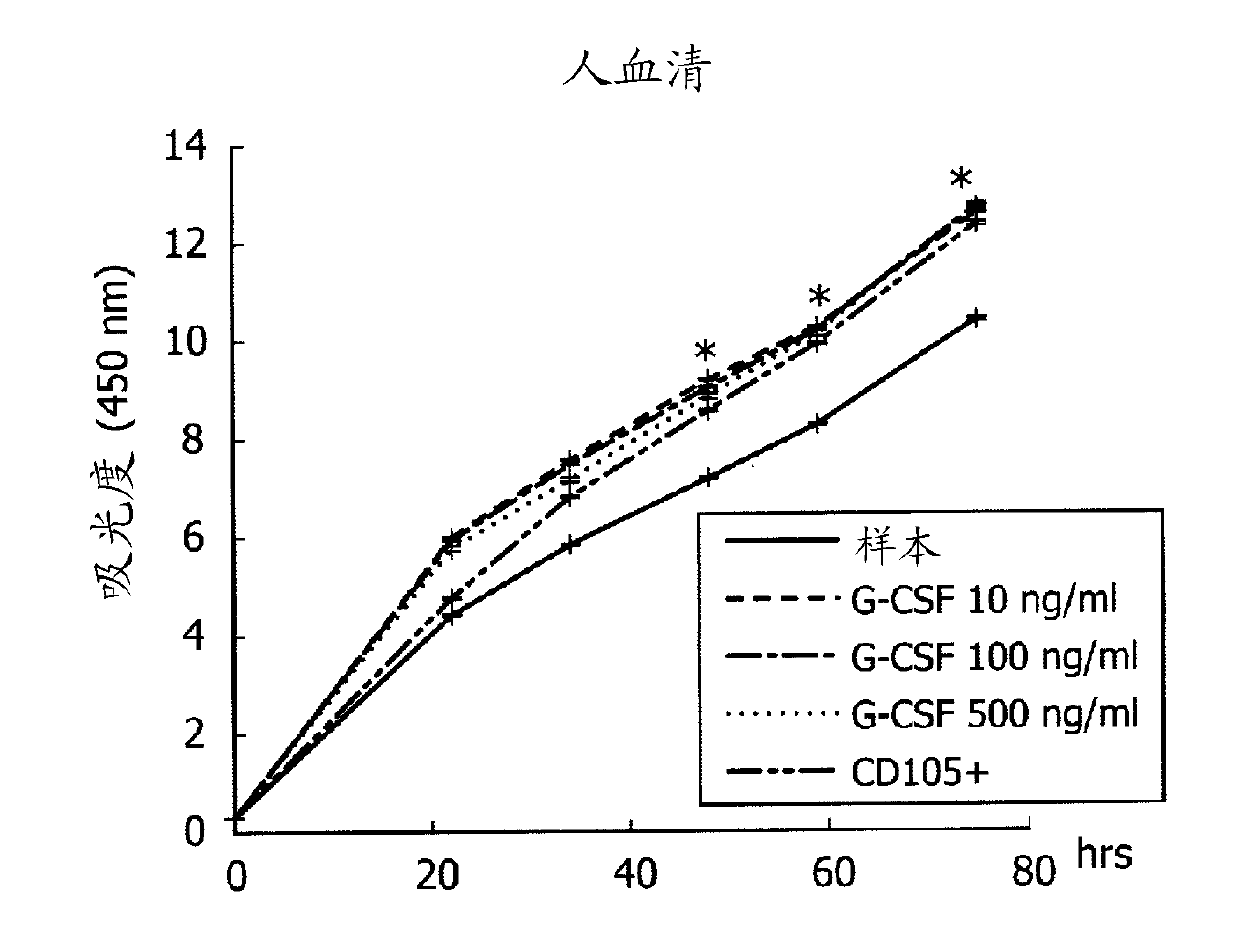

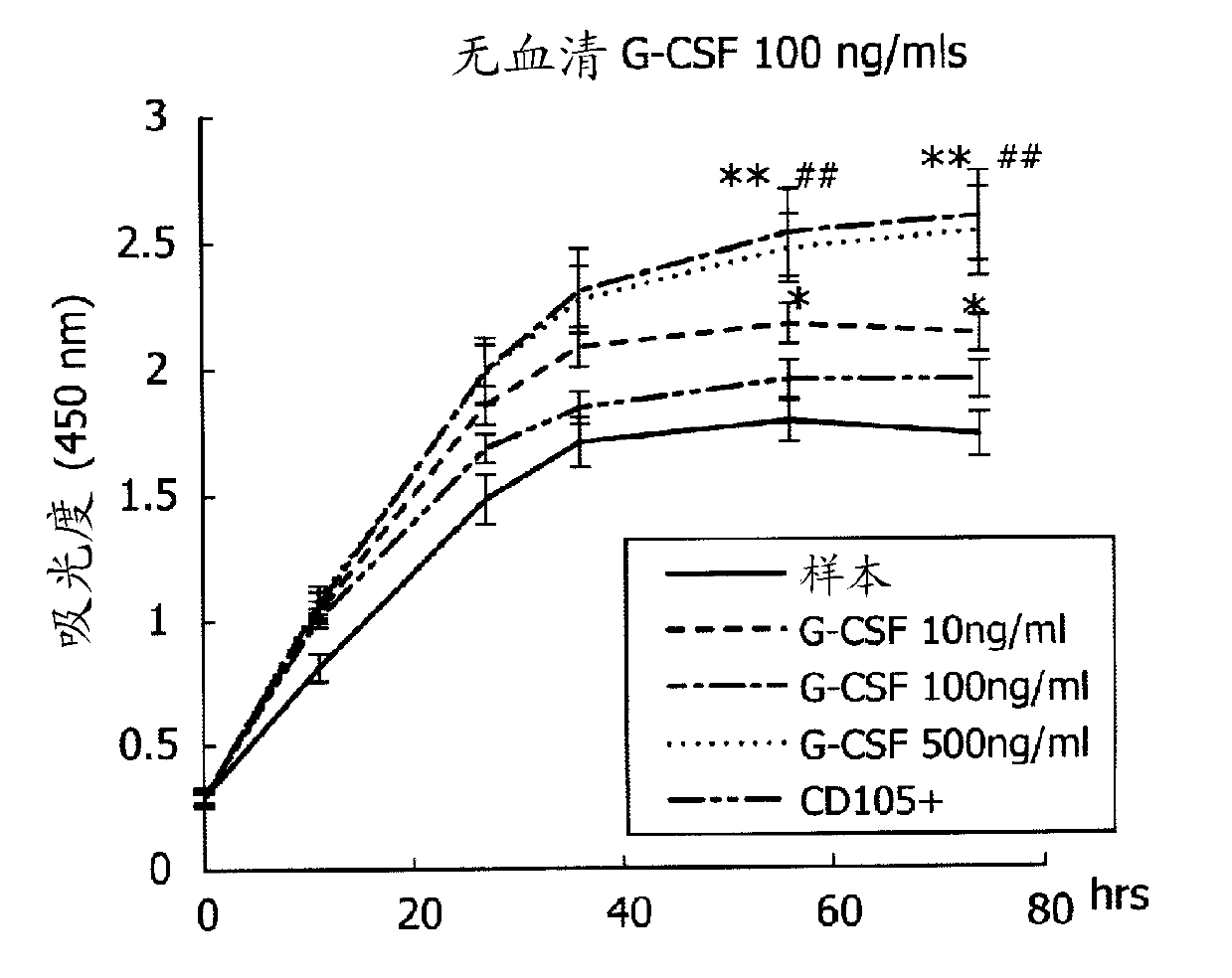

Membrane-separation-type culture device, membrane-separation-type culture kit, stem cell separation method using same, and separation membrane

InactiveCN103597068AEasy to useEfficient and cheap to useMembranesSemi-permeable membranesHydrophobic polymerPolyethylene glycol

A membrane-separation-type culture device (1) which comprises an upper structure (10) that comprises a vessel involving, at at least a part thereof, a membrane (12) having pores (121) for allowing stem cells to pass therethrough and a lower structure (13) that comprises a vessel for holding a fluid in such an amount that the membrane in the upper structure can be immersed in the fluid; a membrane-separation-type culture kit which comprises the membrane-separation-type culture device (1) and a cell migration factor; a stem cell separation method which comprises a step of seeding cells or tissues of interest on the membrane (12) in the upper structure (10), a step of filling a culture medium containing a cell migration factor in the lower structure (13), and a step of bringing the membrane (12) in the upper structure (10) into contact with the culture medium in the lower structure (13); and a separation membrane which comprises a base membrane comprising a hydrophobic polymer and a functional layer comprising at least one hydrophilic polymer selected from a vinyl-pyrrolidone-type polymer, a polyethylene-glycol-type polymer and a vinyl-alcohol-type polymer which is bound to the surface of the base membrane via a covalent bond, wherein the weight of the hydrophilic polymer that constitutes the functional layer is 1.5 to 35 wt% relative to the total weight of the separation membrane.

Owner:TORAY IND INC

In-vitro maturation culture method for oocyte of mouse and method for establishing parthenogenetic embryonic stem cell line

InactiveCN101735978ASimple ingredientsLow costMicroorganism based processesEmbryonic cellsStem cell lineBiological activation

The invention discloses an in-vitro maturation culture method for an oocyte mouse and a method for establishing a parthenogenetic embryonic stem cell line. In the in-vitro maturation culture method, an immature oocyte is cultured in a basic culture solution in which the HCG (human chorionic gonadotropin) and PMSG (pregnant mare serum gonadotropin) are added, and the maturation rate of the oocyte can reach more than 83 percent. In the method for establishing a parthenogenetic embryonic stem cell line, the parthenogenetic activation culture development is carried out on the mouse oocyte after in-vitro maturation culture to obtain the embryonic stem cell line; a hepatocyte obtained by the method has no immunogenicity, is simultaneously equivalent to a stem cell derived from a fertilized embryo on totipotency and has guiding significance for utilizing in-vitro maturation of the immature oocyte of a human and separating parthenogenetic embryonic stem cells. Aiming at the current conditionsof human ovum donation shortage, great discarding of clinical immature oocytes by an assisted reproductive technology, and the like, the two methods are combined to lay the foundation for developing and utilizing the in-vitro maturation culture of the immature oocyte of people and further researching the parthenogenetic embryo by utilizing an in-vitro mature ovum and separating the embryonic stemcells.

Owner:SUN YAT SEN UNIV

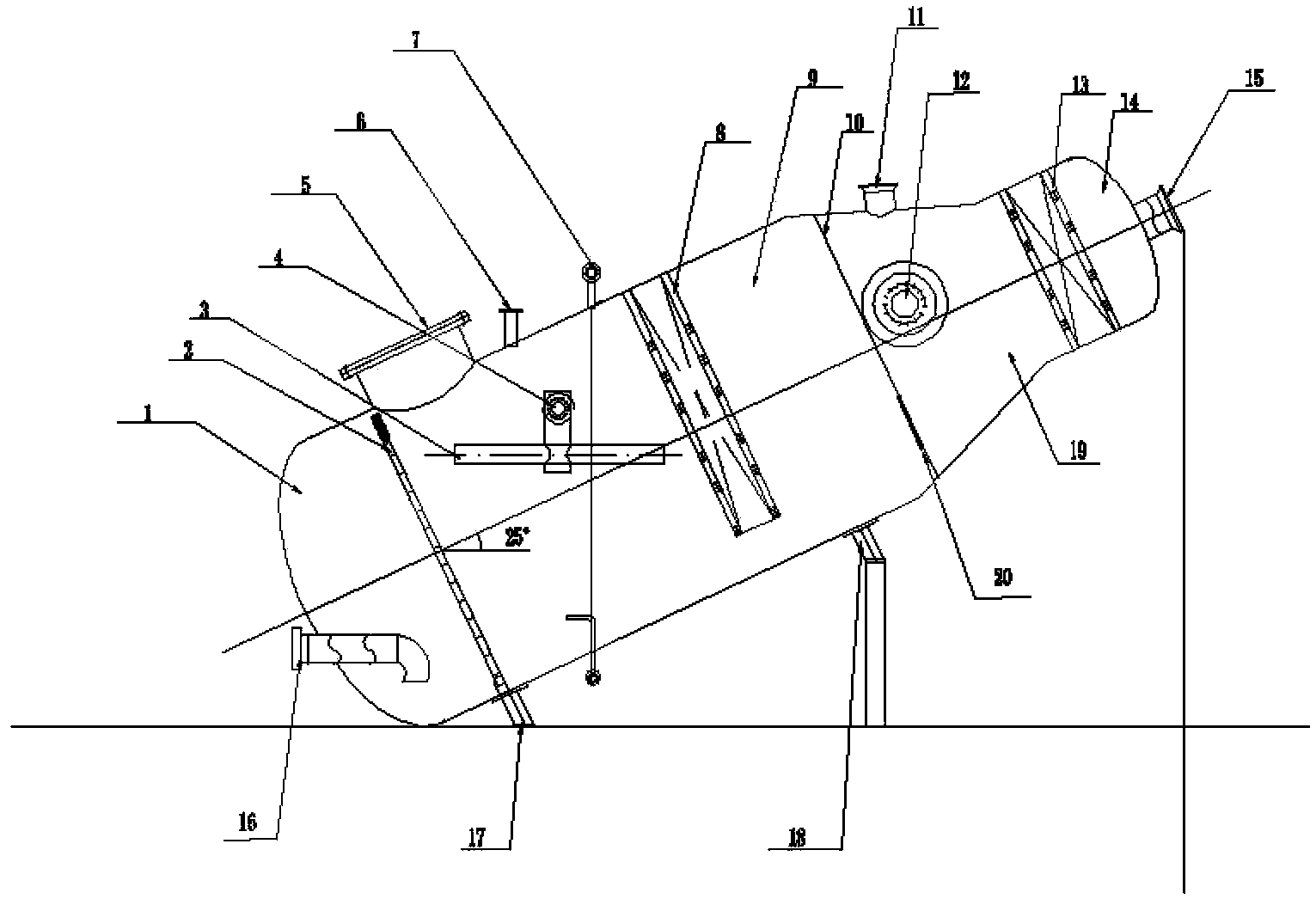

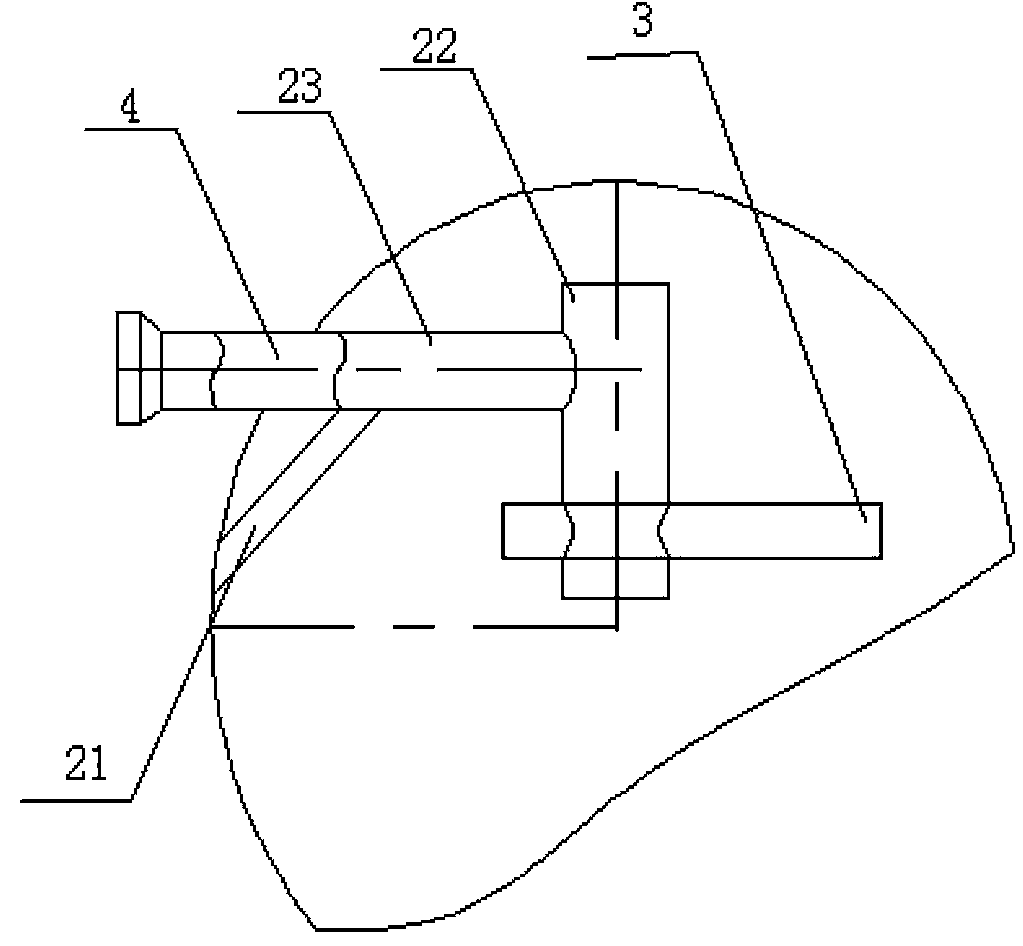

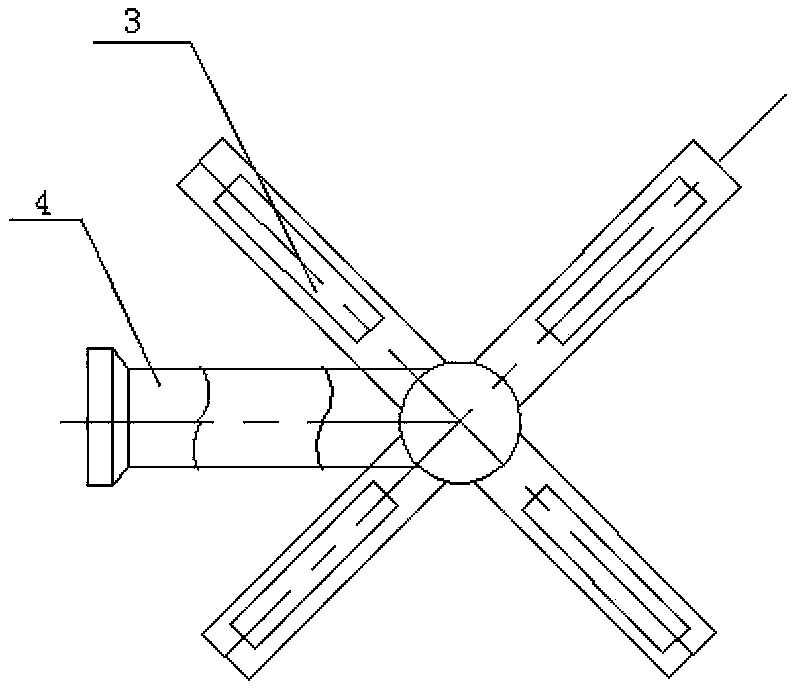

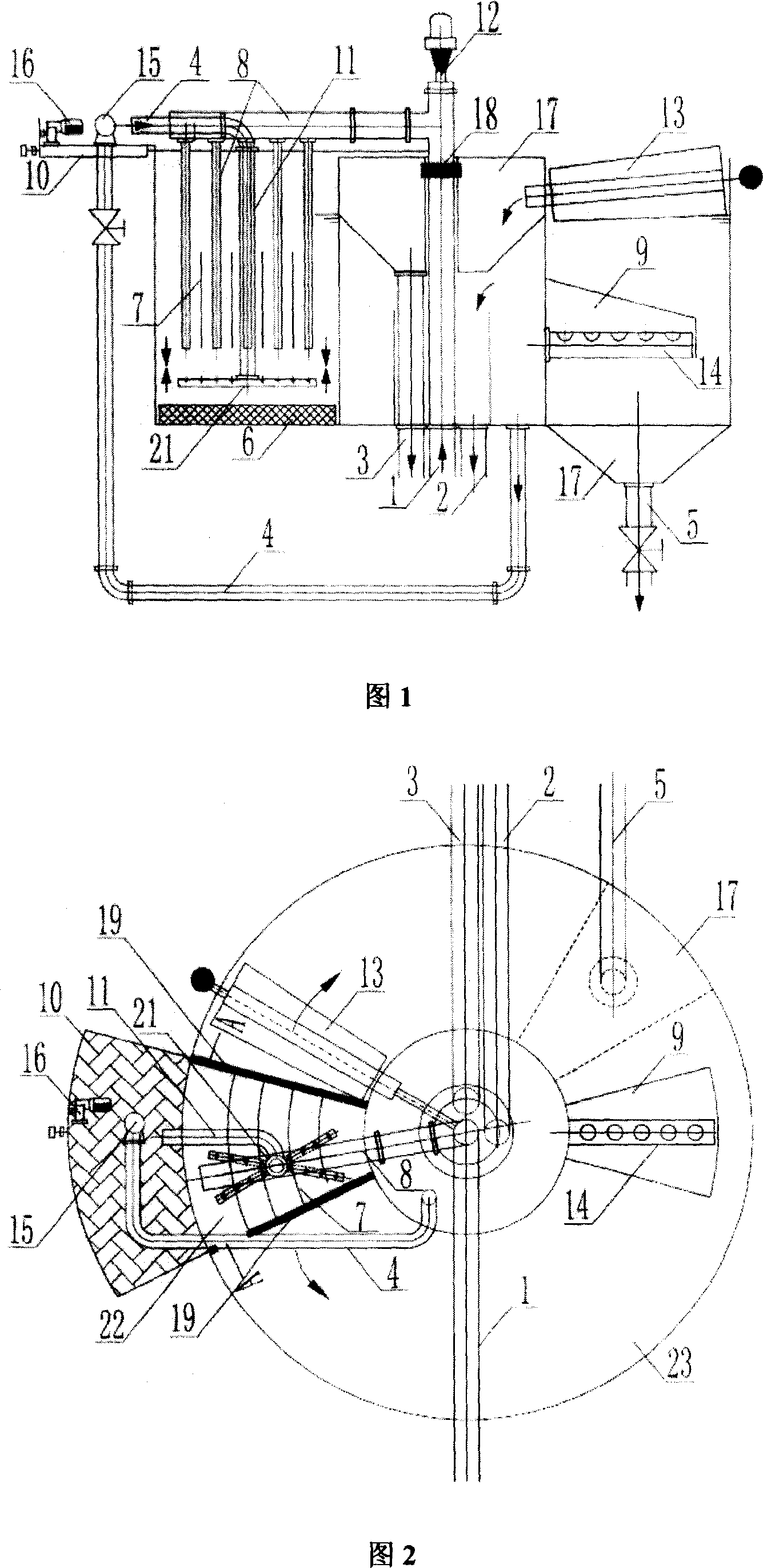

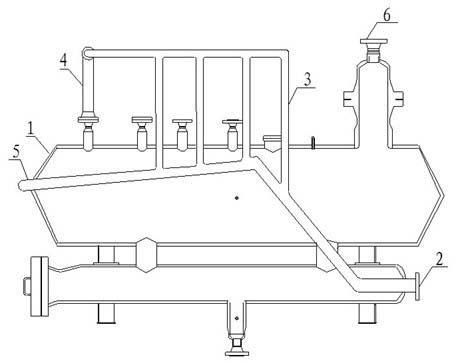

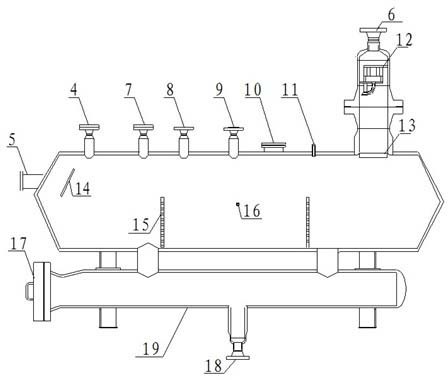

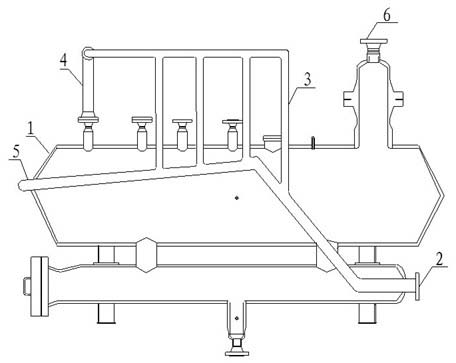

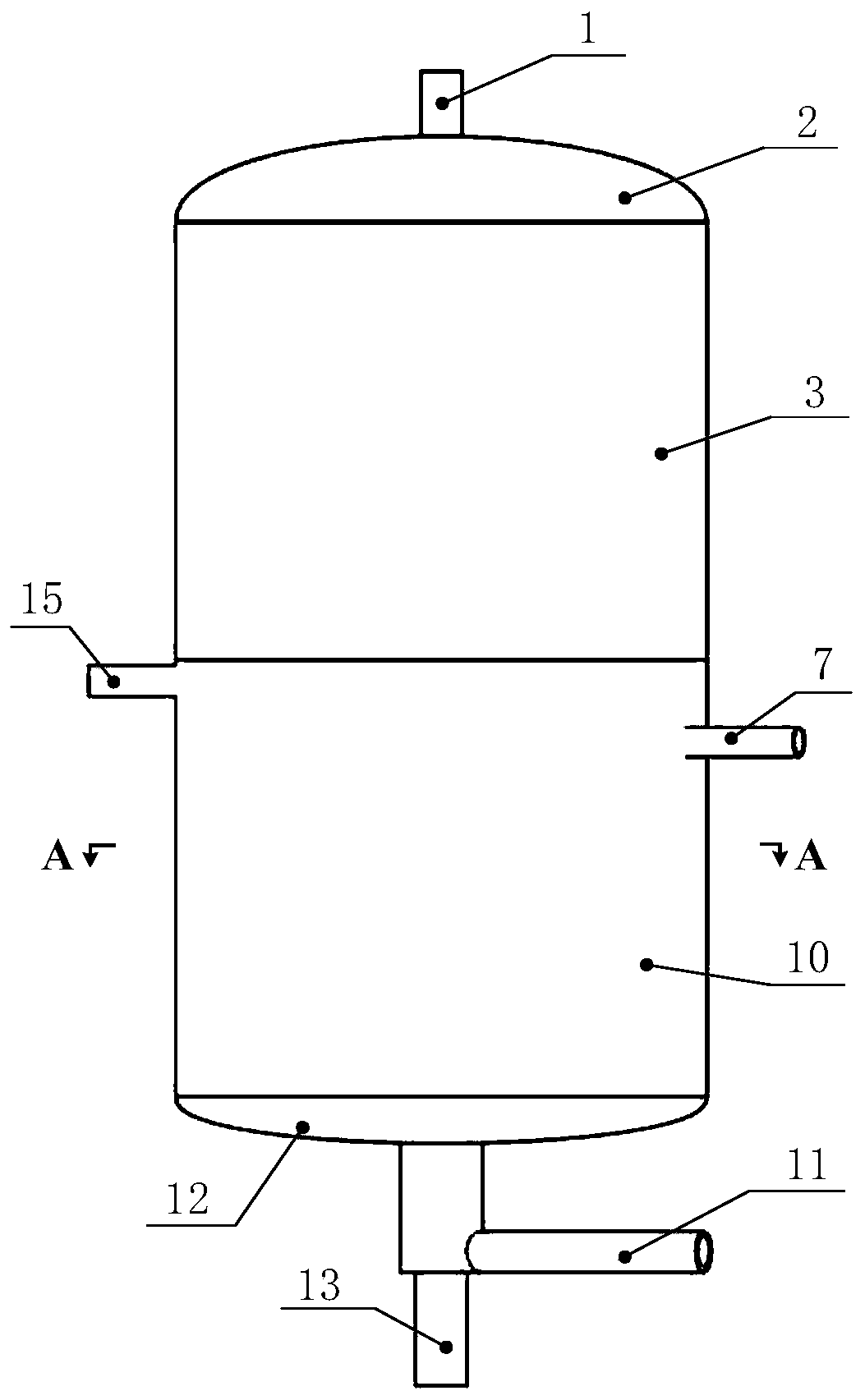

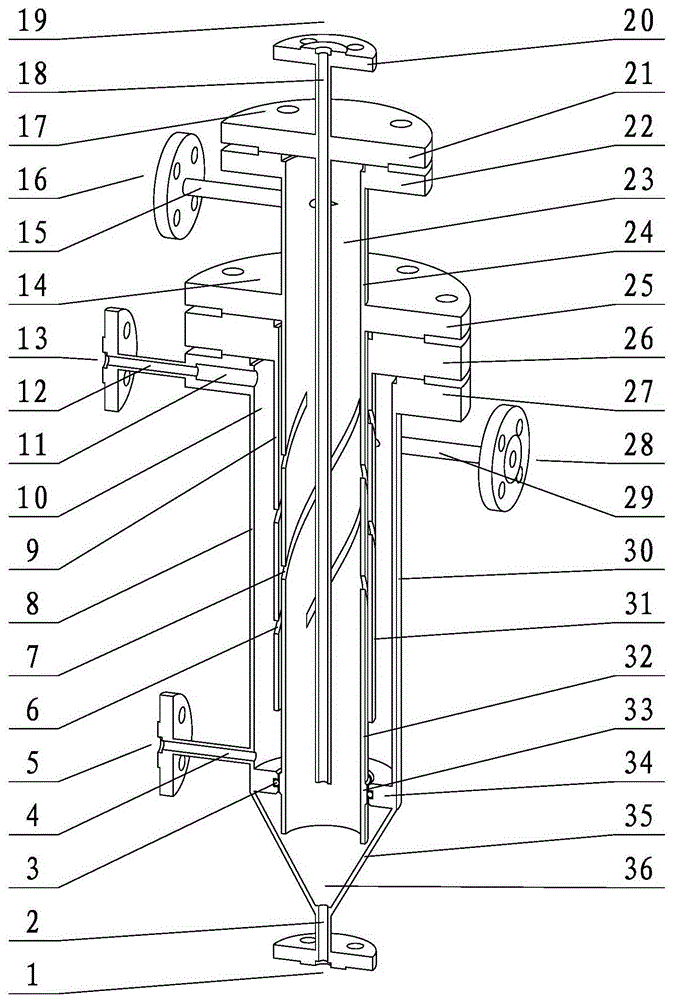

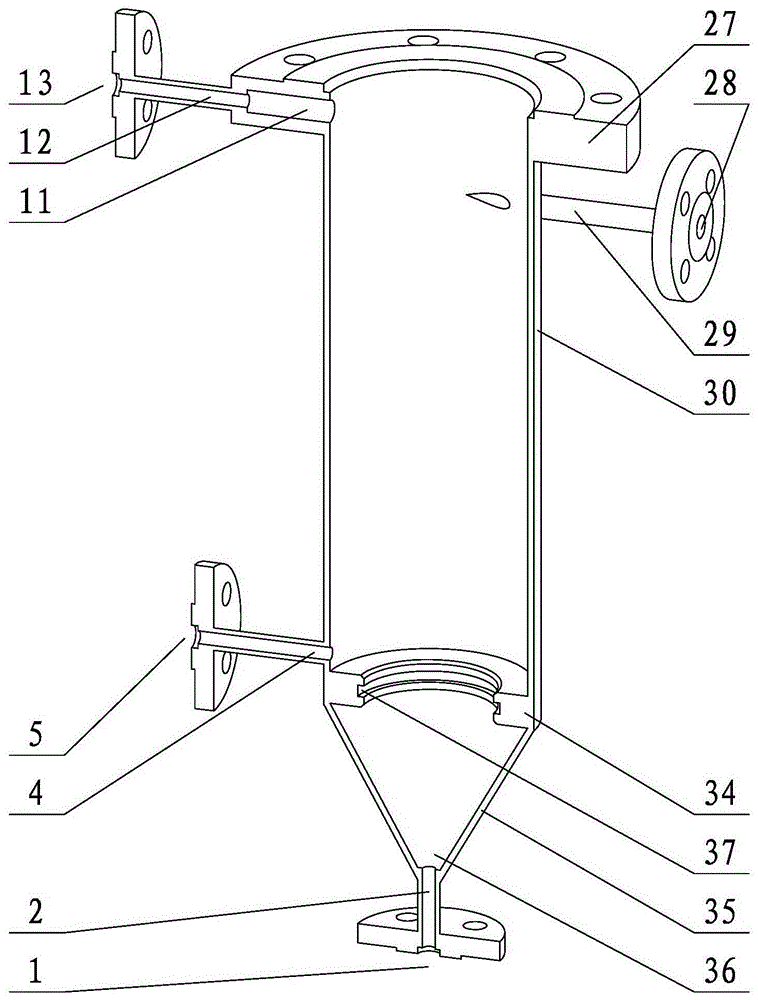

Elevation type three-phase separator

ActiveCN103657158APrevent \"dead oil\"Prevent \"dead water\"Combination devicesLiquid degasificationThree-phaseDensity difference

The invention relates to an elevation type three-phase separator which mainly comprises a tank body (1), wherein a certain included angle is formed between an axial line of the tank body (1) and a horizontal plane, a drain pipe (16) is arranged below the tank body (1), a second coalescer (8), a baffle plate (10) and a first coalescer (13) are sequentially arranged in the tank body (1) from bottom to top, two cross-intercommunicated oil collecting pipes (3) are arranged below the second coalescer (8) horizontally, a gas-liquid inlet (12) is arranged above the baffle plate (10), a safety valve (11) is arranged above the baffle plate (10), the first coalescer (13) is arranged in the tank body (1) above the gas-liquid inlet (12), and an exhaust hole (15) is formed in the top of the tank body (1). The elevation type three-phase separator is mainly applied to an oil well containing water and gas in the oilfield development industry, and oil, gas and water are separated by using a density difference of oil, gas and water and a forced separation facility of the elevation type three-phase separator.

Owner:PETROCHINA CO LTD

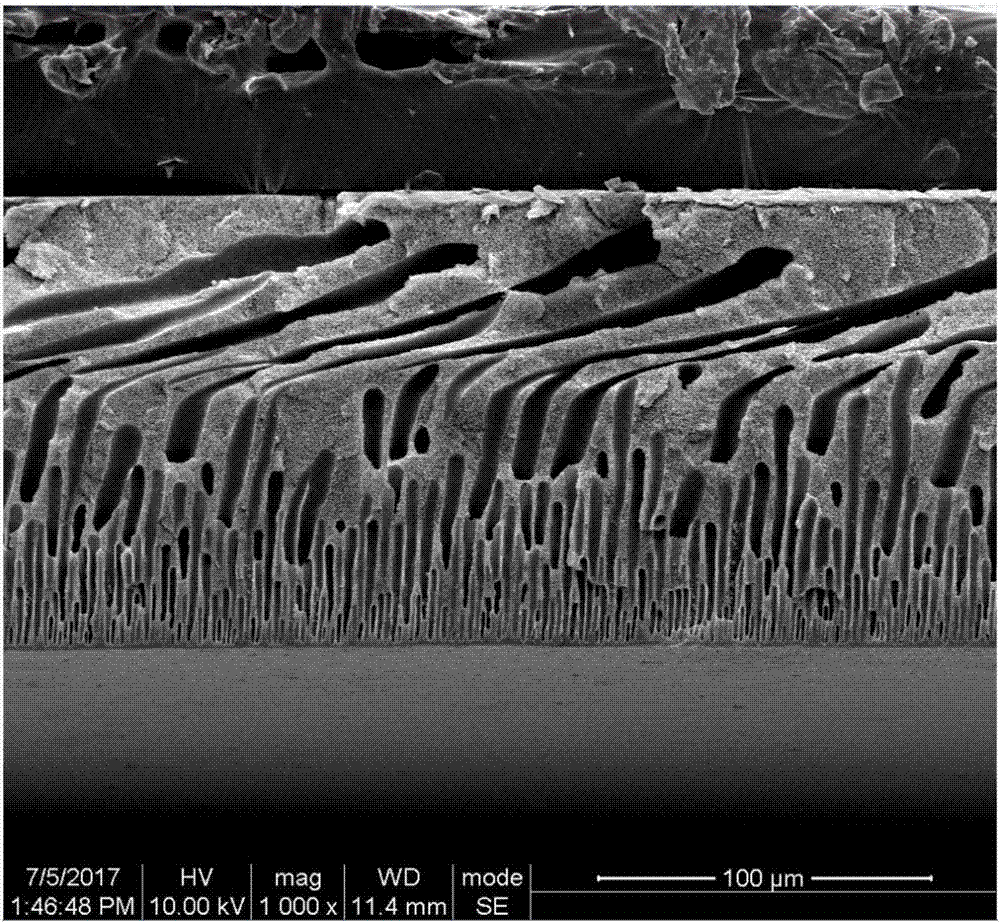

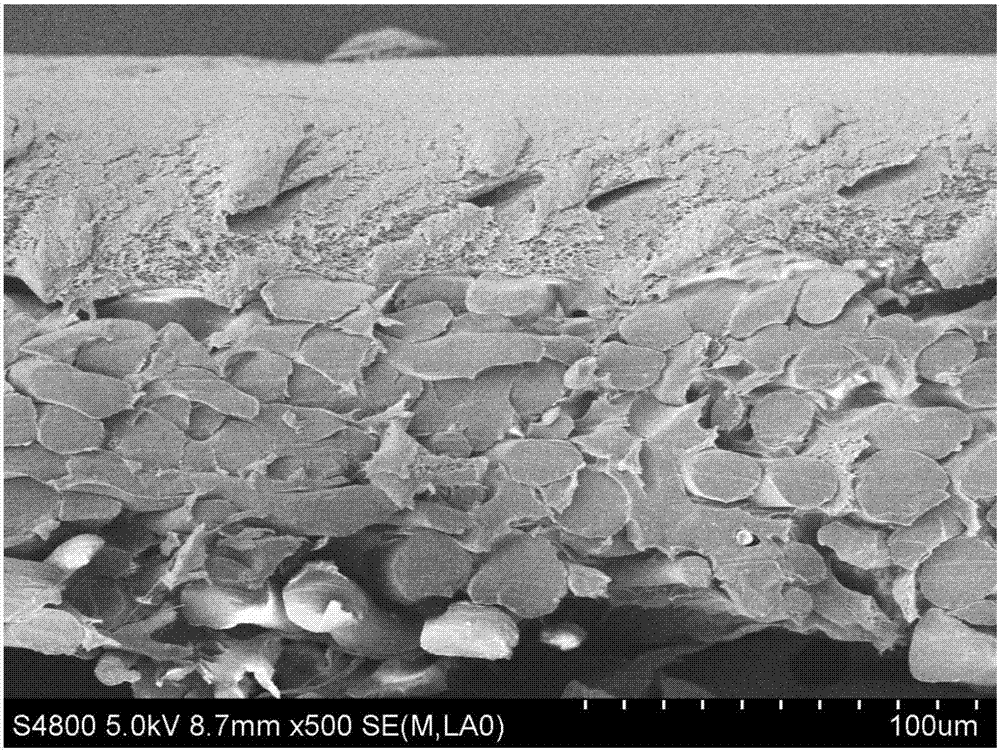

Polyarylene sulfide sulfone compound separating film and preparation method thereof

The invention discloses a polyarylene sulfide sulfone compound separating film and a preparation method thereof. The polyarylene sulfide sulfone compound separating film comprises a polyarylene sulfide sulfone base film and a selective separating functional layer, wherein the selective separating functional layer is prepared from any one of fatty polyamide, aromatic polyamide, methyl-silicone andcellulose acetate through a coating method or an interfacial polycondencation method. According to the invention, the selective separating functional layer is added to the polyarylene sulfide sulfonebase film and the defects on the surface of the polyarylene sulfide sulfone base film are covered by the compact selective separating functional layer, so that the surface of the polyarylene sulfide sulfone compound separating film has a uniformly distributed pore structure, the porosity is increased and the pore size distribution is uniform; the interception capacity thereof is obviously promotedafter the selective separating functional layer is added; when the selective separating functional layer with hydrophilic group is adopted, hydrophilic modification for the polyarylene sulfide sulfone is not required.

Owner:四川中科兴业高新材料有限公司

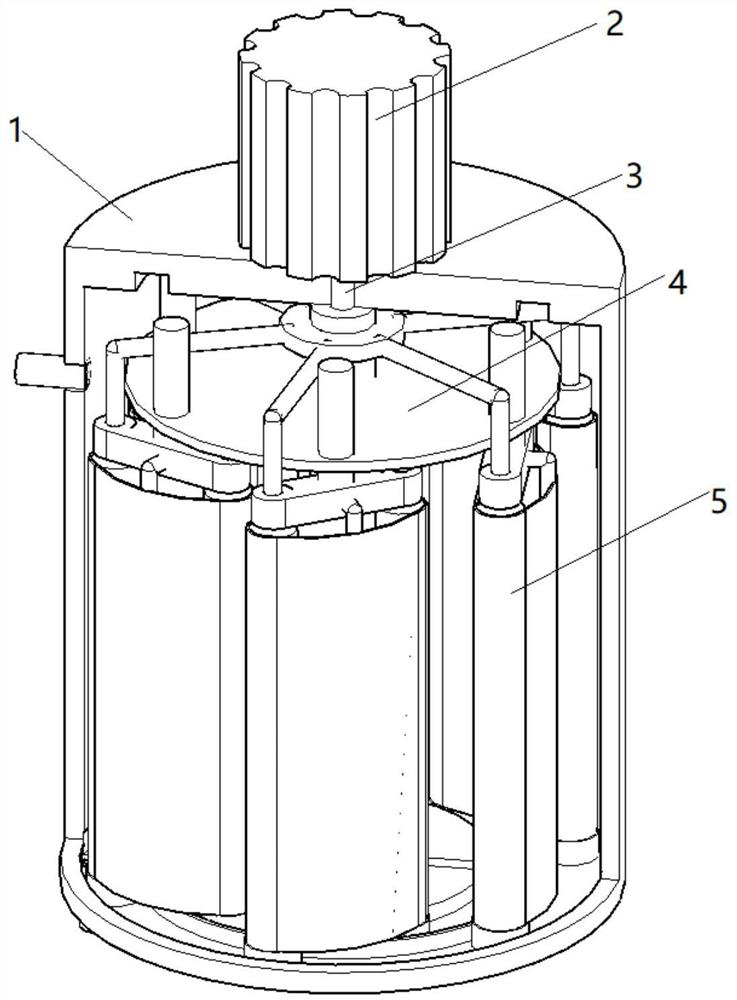

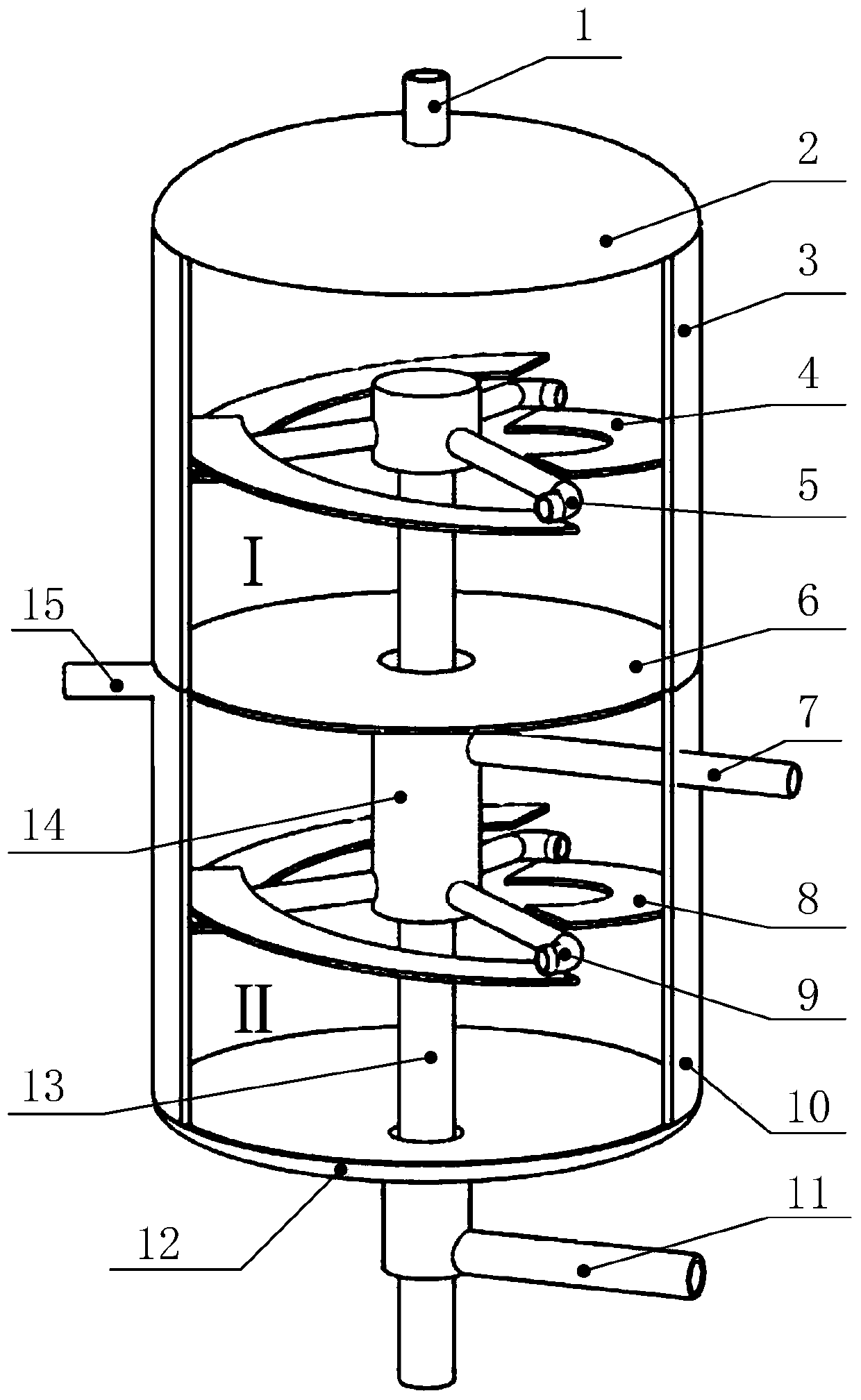

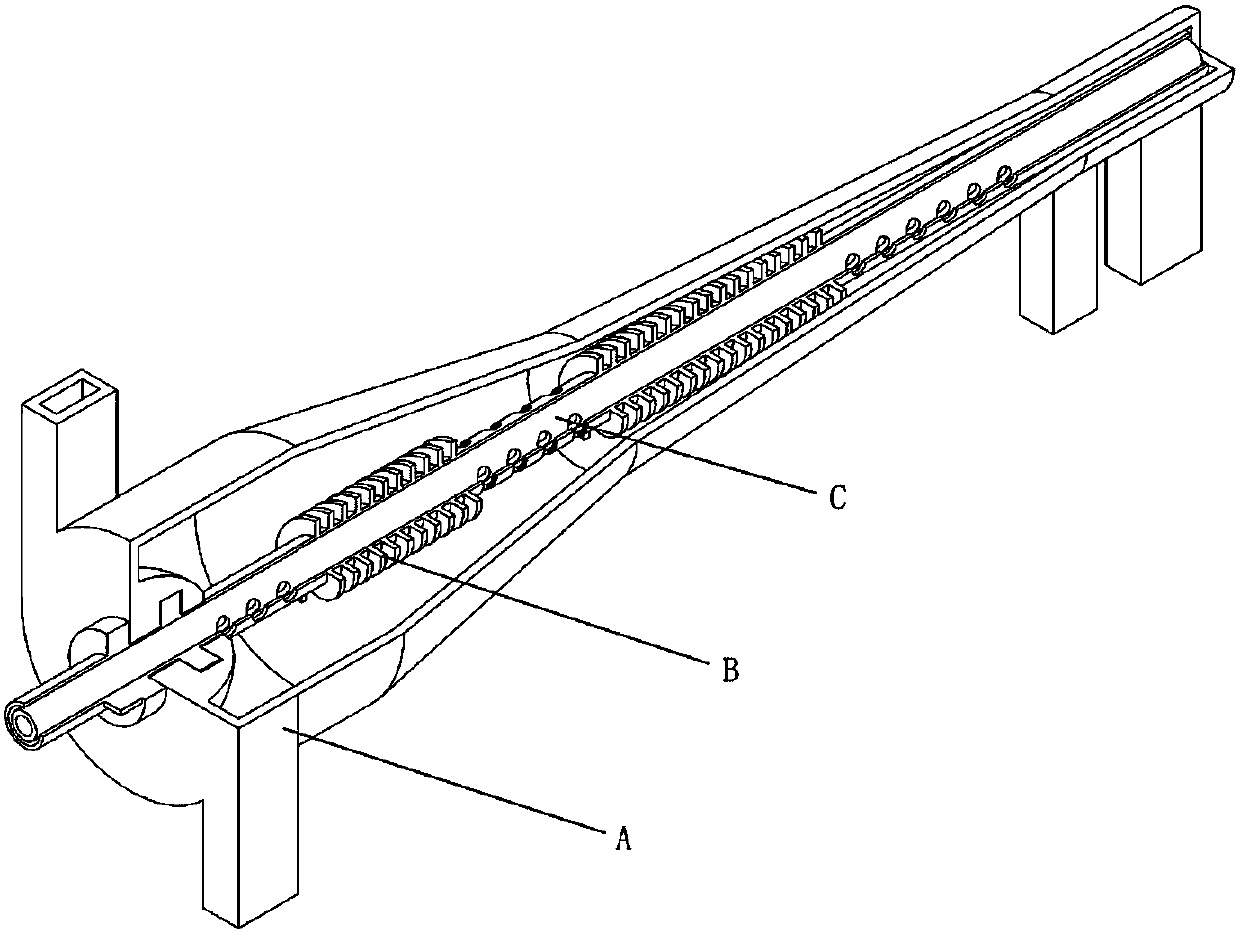

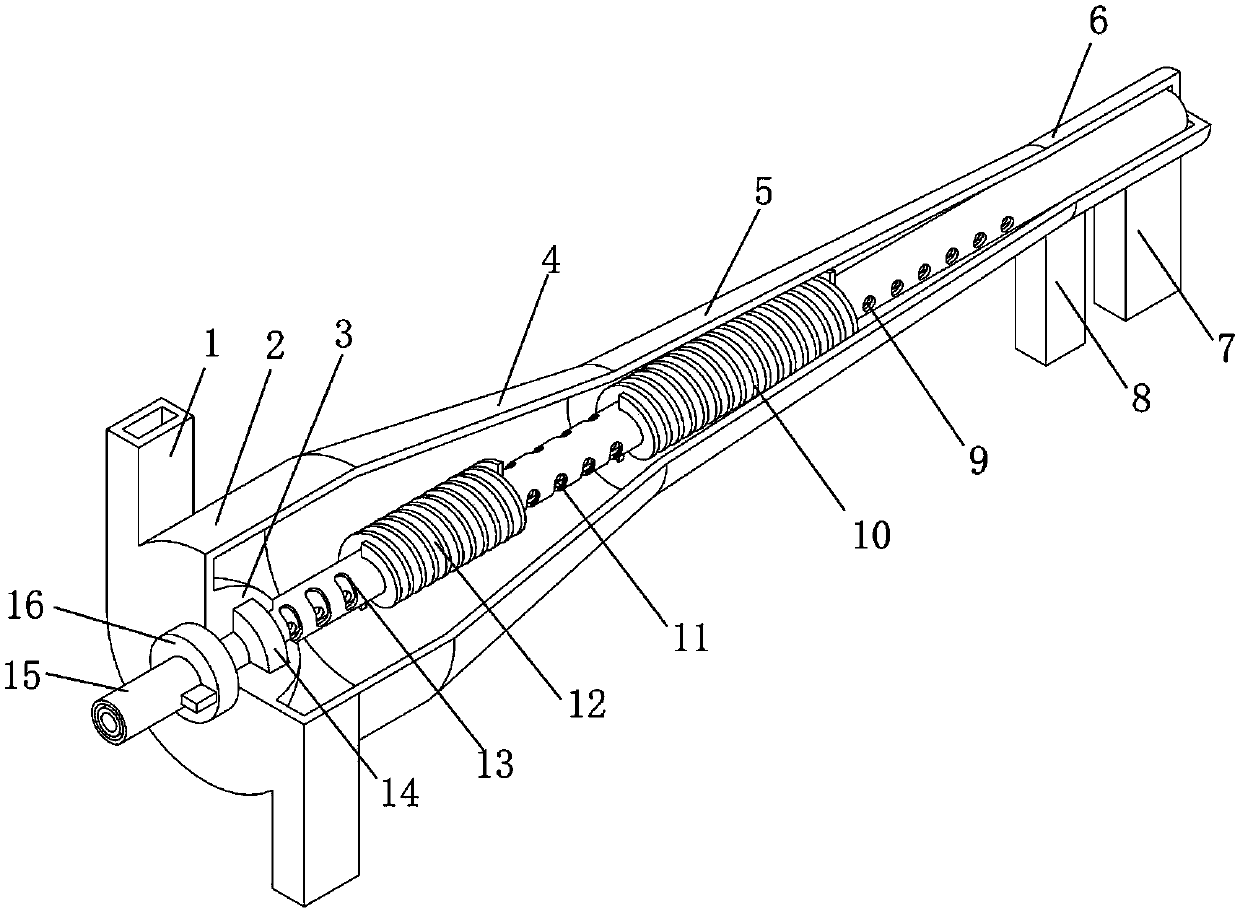

Rotary polymer distiller

ActiveCN112316466APrevent splashReduce separation efficiencyMolecular distillationDistillationThin membrane

The invention belongs to the field of molecular distillation equipment, and particularly relates to a rotary macromolecular distiller which comprises a distillation cylinder, a motor is mounted at thetop of the distillation cylinder, the output end of the motor is connected with a rotating rod rotationally connected to the interior of the distillation cylinder, and a transmission device is arranged on the outer side of the rotating rod. The transmission device comprises a horizontally-arranged rotating plate, the middle of the rotating plate is movably connected to the outer portion of the rotating rod in a sleeving mode through a first one-way bearing, cylindrical holes are formed in the periphery of the rotating plate, and movable rods are arranged in the cylindrical holes. The belts ina film scraping device are arranged at equal intervals along the center of the distillation cylinder, a uniform thin film is formed when the belts rotate, and when redundant liquid which is not subjected to film forming splashes towards the middle, the liquid is continuously brought to the other side of the inner wall of the distillation cylinder by the non-film-scraping ends of the belts to be subjected to the film forming process; and a plurality of belts form a redundant liquid to continuously participate in the film forming operation, so that the unseparated liquid is prevented from splashing onto the condensation plate.

Owner:ANHUI JINGHE IND

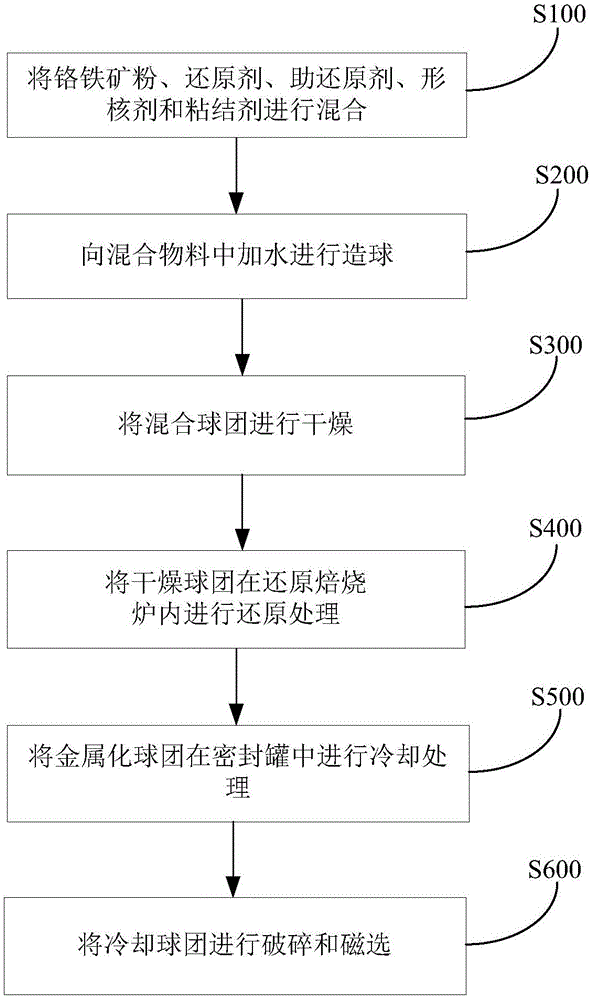

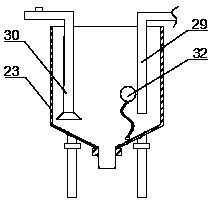

Community closed medium water landscape water system organism gas float BOAG treatment method and device

InactiveCN101104534AReduce pollutionSave waterTreatment using aerobic processesSustainable biological treatmentReclaimed waterWater quality

Provided is a BOAF treating method for purifying the water landscape, water system and water quality in the sealed small social region and the apparatus thereof. The method substitutes a drug feeding system necessary for all of the gas flotation apparatus by a biological reacting pool, mixes the original water in the water landscape and water system in the sealed small social region with the active bio-floculation from the BOAF pool. A mixed liquid flow formed by depositing in the biochemical reacting pool for a certain period is flowing into the BOAF pool for a treatment. The water output from the BOAF pool is returned to the water landscape and water system after sterilizing by the ultraviolet sterilizer. The mixing liquid flowing into the BOAF pool obtains a separation of the water output and the active bio-floculation by the means of gas flotation. The active bio-floculation returns to the front end of the biochemical reacting pool and continues to mix with the original water for a recycle reaction. A small part of water output forms the gas dissolving water and returns to the BOAF pool to provide slight bubbles for the bio-floculation separation. The system apparatus ensures a qualified landscape water and keeps a water environment balance in the water system in the sealed small social region.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

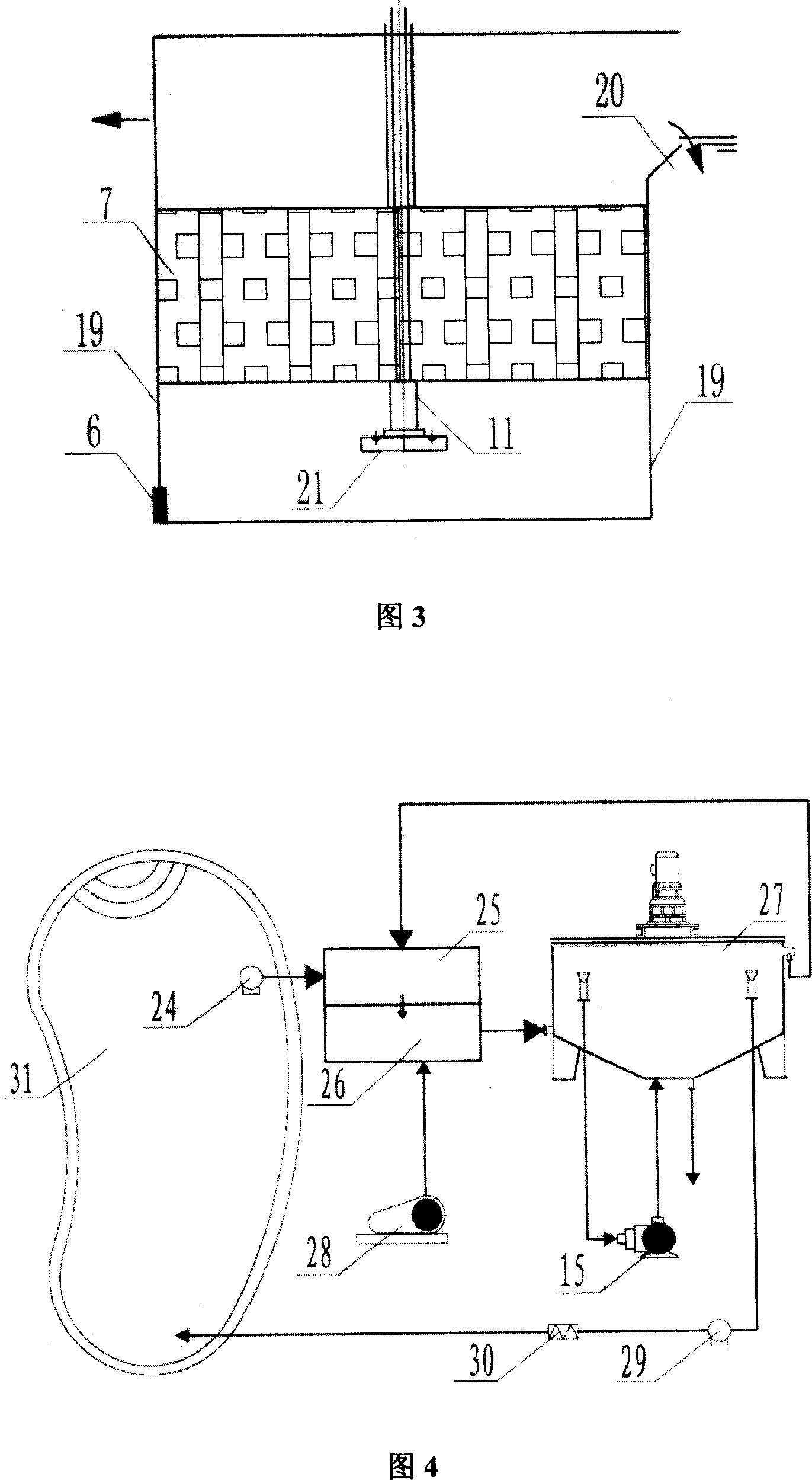

Ferrochrome preparation method

The invention discloses a ferrochrome preparation method. The ferrochrome preparation method comprises the following steps: (1) mixing chromite ore fine, a reducing agent, a reducing assistant, a nucleating agent and a binder to conveniently obtain a mixed material; (2) adding water into the mixed material for pelletizing to conveniently obtain mixed pellets; (3) drying the mixed pellets to conveniently obtain dry pellets; (4) performing reduction treatment of the dry pellets in a reduction roaster to conveniently obtain metallic pellets; (5) cooling down the metallic pellets in a seal pot to conveniently obtain cooled pellets; and (6) performing crushing and magnetic separation of the cooled pellets to conveniently obtain ferrochrome and tailings. The ferrochrome preparation method can effectively utilize chromite powder resource and is low in production cost and simple in process, and chromium in the obtained ferrochrome is high in grade.

Owner:SHENWU TECH GRP CO LTD

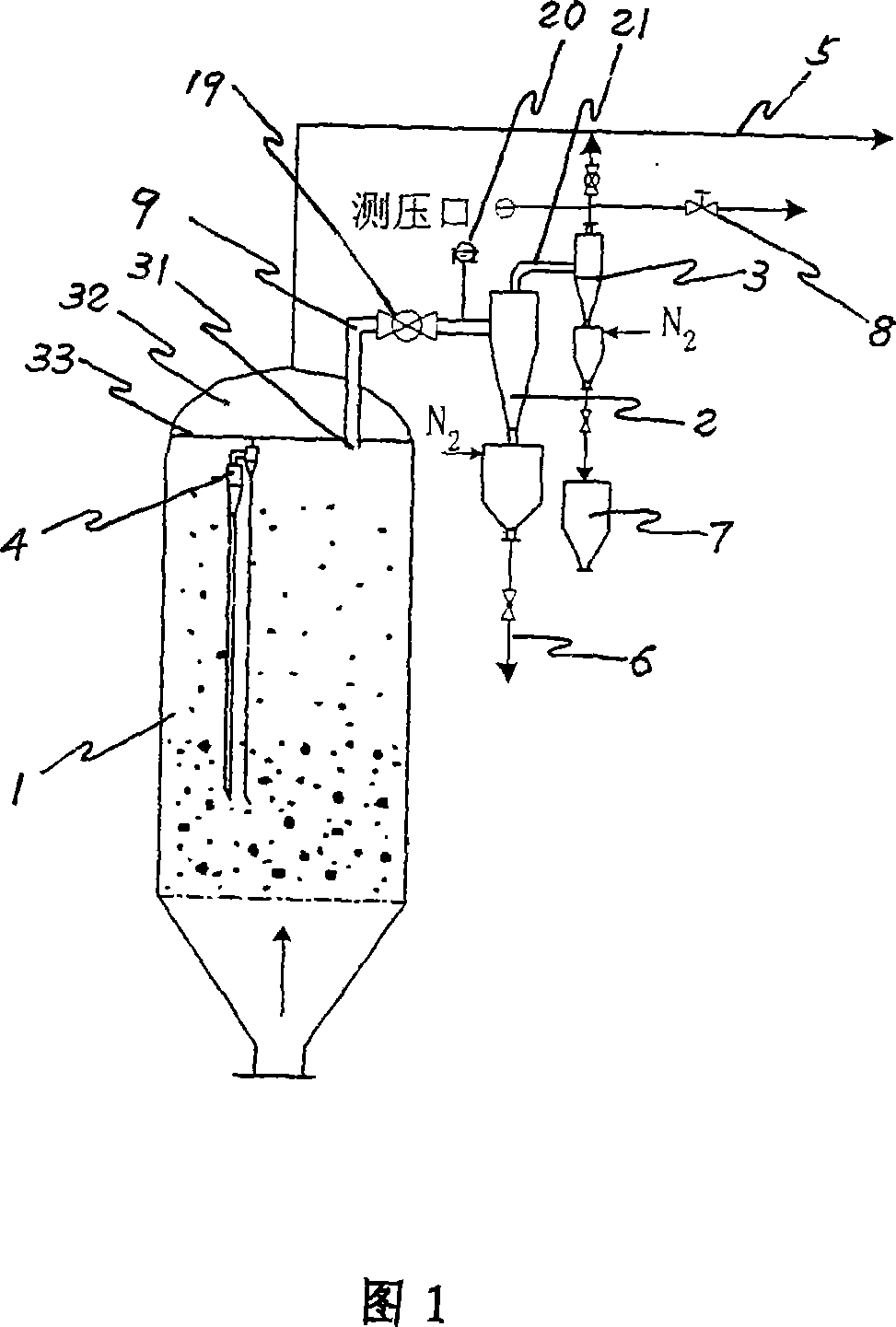

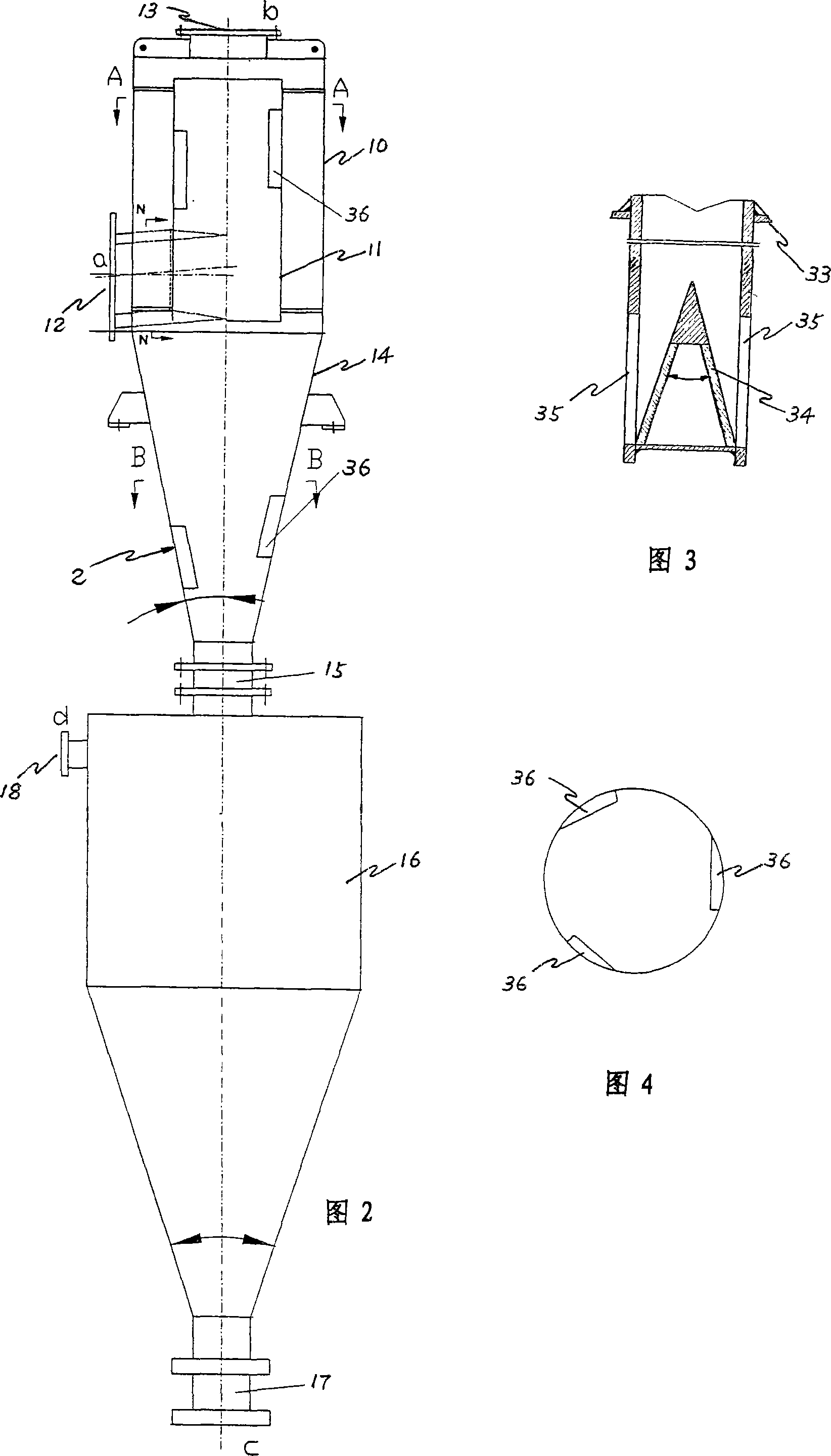

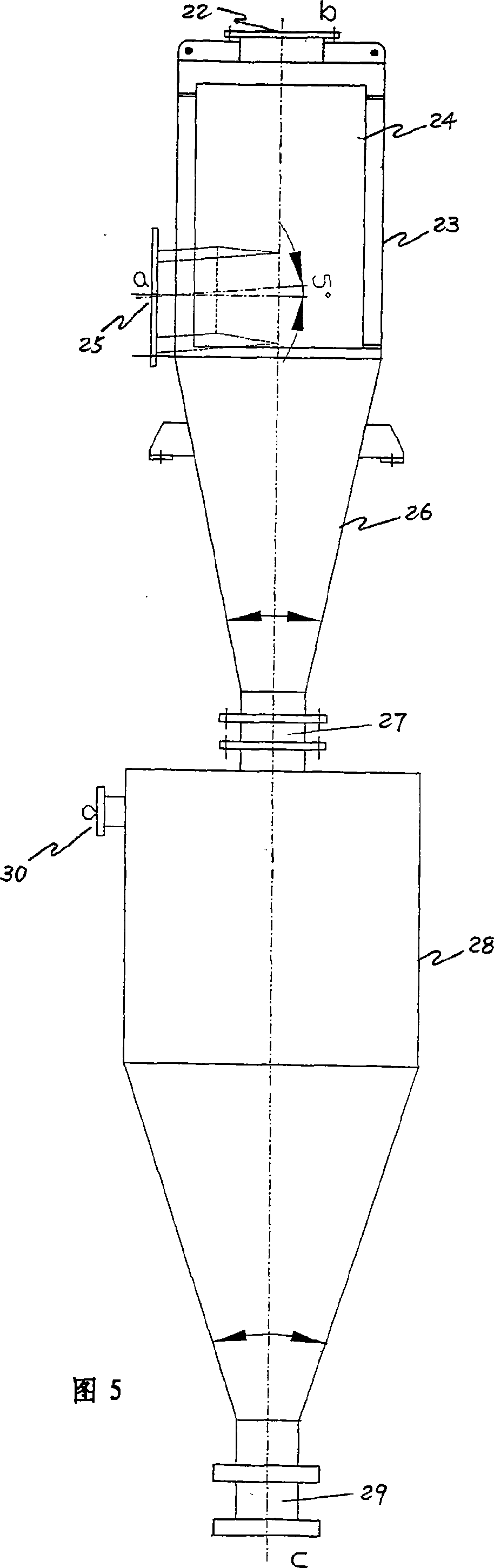

Powder granule circulation whirlwind multi-level grading device and its grading method and use

ActiveCN101143350AImprove separation efficiencyReduce separation efficiencyOrganic chemistryReversed direction vortexCycloneFluidized bed

A circumfluent cyclone multi-grade classification device and a classification method and use of powder particles are provided. The device includes a particle classifier and a cyclone dust remover, which respectively comprises a direct cylinder, an inner part, a gas import, a cone, two ball valves, an ash storehouse, a nitrogen import, etc. the inner lateral of the inner part of the classifier and the inner lateral of the cone are respectively equipped with two to four flat slab-shaped or arc slab-shaped guide slide ways. The method includes that air containing dusts is extracted and is introduced into the particle classifier. The particles lager than 15-20 Mu m are separated and are returned. The extracted air is introduced into the cyclone dust remover. The dust remover is used to remove the fine particles smaller than 15 Mu m. And the air of which the fine particles are returned to a reactor. The catalyst particles which are larger than 20 Mu m are recovered through the classification of the catalyst particles which can be used in an acrylonitrile fluidized bed reactor. Fine catalyst powders can be ensured to be not carried out by airflow, classified and discharged. The equipment can be prevented from being blocked. The efficiency is improved and the cost is lowered. The device can be widely applied to the multi-grade classifications of various powder particles.

Owner:QINGDAO UNIV OF SCI & TECH

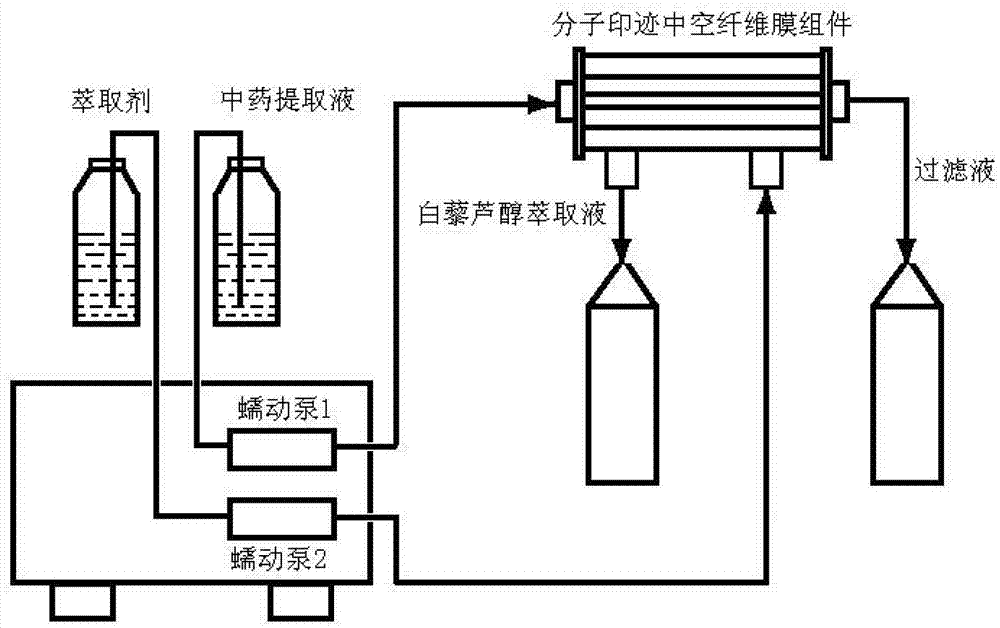

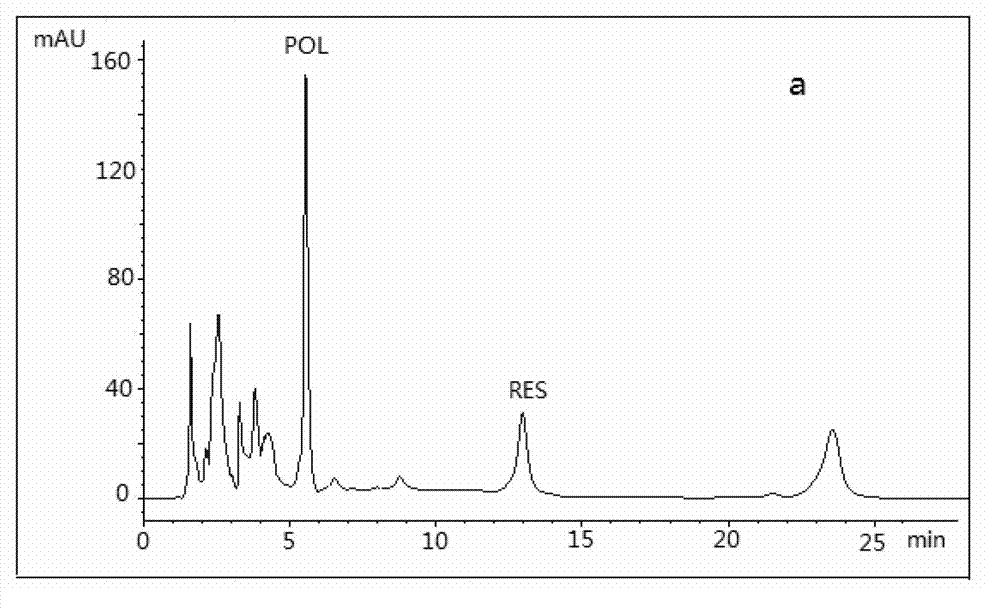

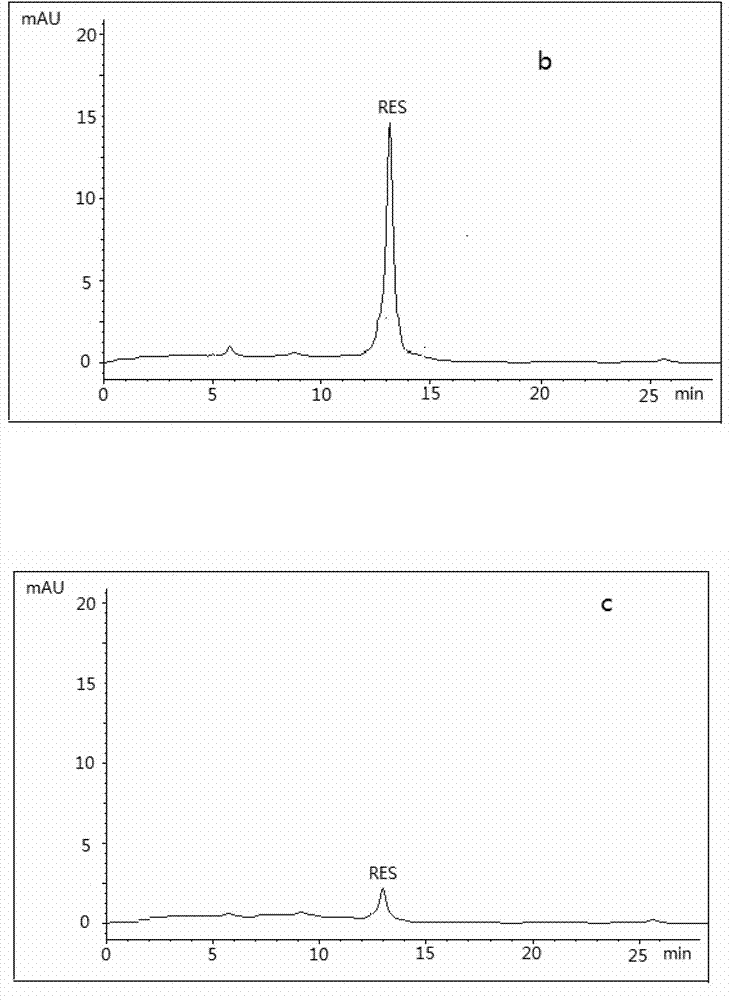

Method for separating trans-resveratrol from giant knotweed

InactiveCN102924239AAchieving Selectively Permeable SeparationLess quantitySemi-permeable membranesOrganic chemistryAlcoholAcetonitrile

The invention relates to a method for separating trans-resveratrol from giant knotweed. The method comprises the following steps of: (1) crushing the giant knotweed, adding methanol or 80 to 95 volume percent ethanol in an amount which is 20 to 50 times the massic volume of the giant knotweed, extracting, purifying by using macroporous resin, concentrating under reduced pressure, and drying to obtain an alcohol extract of the giant knotweed; (2) dissolving the alcohol extract of the giant knotweed into water, methanol or acetonitrile to ensure that the concentration of the alcohol extract of the giant knotweed in the obtained solution is 10 to 1,000mu g / ml to obtain a sample solution; and (3) pumping the sample solution and an extracting agent into a membrane separator, ensuring that the sample solution flows at the rate of 0.3 to 1.0ml / min in a membrane tube and the extracting agent contraflows at the rate of 0.3 to 1.0ml / min outside the membrane tube, adding a pH regulator into the extracting agent outside the membrane tube (the volume ratio of the pH regulator to the extracting agent is 0.1:99.9-1:99) after two phases inside and outside the membrane tube are balanced, collecting an extracting solution which flows outside the membrane tube, and concentrating under reduced pressure to obtain the trans-resveratrol. The method is high in selectivity and separation efficiency.

Owner:SOUTHERN MEDICAL UNIVERSITY

Gas-liquid separator with liquid-storing and liquid-discharging functions

ActiveCN103638749AReduce volumeAchieve multi-stage separationDispersed particle separationVapor–liquid separatorEngineering

The invention relates to a gas-liquid separator with liquid-storing and liquid-discharging functions. The gas-liquid separator comprises a barrel, an arc-shaped liquid-separating pipe outside the barrel, and a cyclone separator, a streaming core body and a baffling liquid-separating plate which are arranged in the barrel, wherein the arc-shaped liquid-separating pipe is communicated with the barrel in a tangential direction of the outer side of the barrel; the streaming core body is arranged in the cyclone separator, an annular space is formed between the cyclone separator and the streaming core body, and the baffling liquid-separating plate is arranged on the outer side of the streaming core body in a sleeved manner. Compared with the prior art, the gas-liquid separator provided by the invention has the advantages that multiple separating manners such as the centrifugal force, the gravity and the surface tension are utilized in a comprehensive way, so that the multi-level separation of gas-liquid two-phase stream is realized, the separation efficiency is remarkably improved, and the size of the gas-liquid separator is reduced.

Owner:SHANGHAI JIAO TONG UNIV

Method and device for recovering waste air circuit breaker

InactiveCN103480630AImprove work efficiencyFully automatedSolid waste disposalRecovery methodCyclonic separation

The invention provides a method and device for recovering a waste air circuit breaker. The method includes the steps that firstly, the waste air circuit breaker is crushed by a hammer crusher into fragments with 5-15-mm granularity, then, fine plastic particles and dust generated in the process of processing the waste air circuit breaker are separated and removed by a cyclone separation system and a bag-type dust remover, ferromagnetic matter in the waste air circuit breaker is separated and crushed by a magnetic separator, and eventually copper, aluminum, silver alloy and other metal concentrated bodies and plastic in the waste air circuit breaker are separated and crushed through a vortex selection method. According to the method and device for recovering the waste air circuit breaker, recovery working efficiency of the waste air circuit breaker is improved.

Owner:SHANGHAI JIAO TONG UNIV

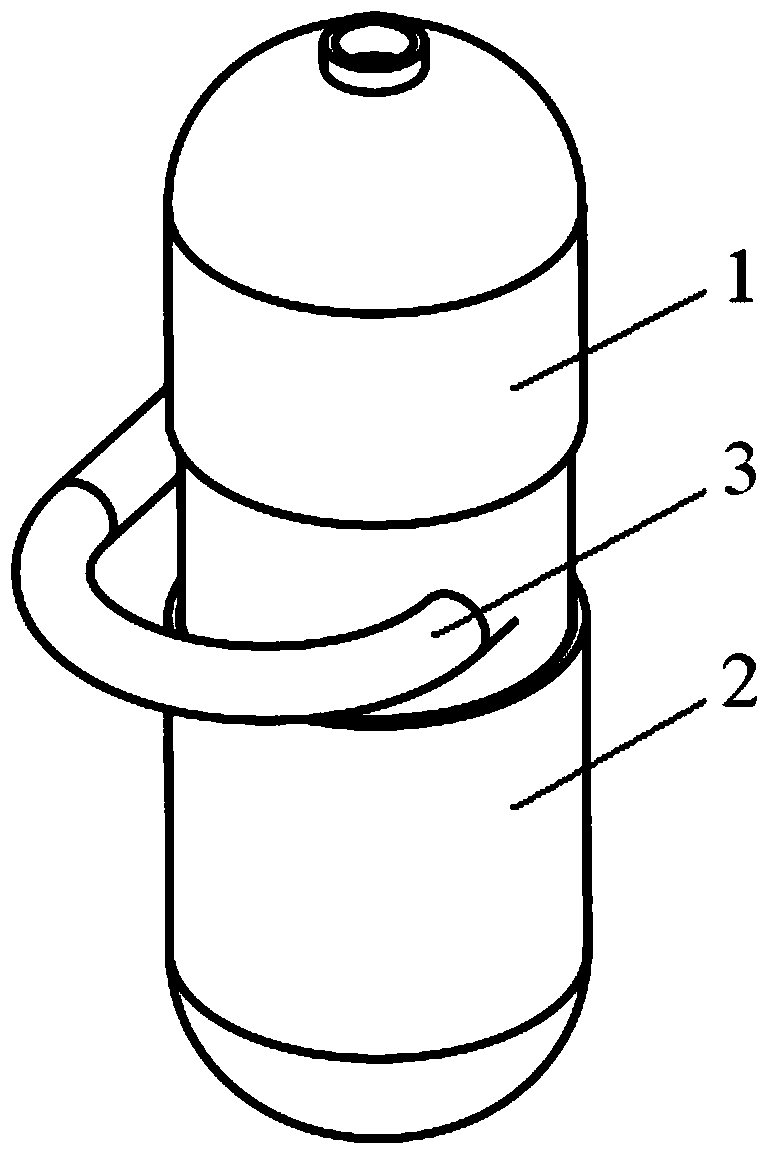

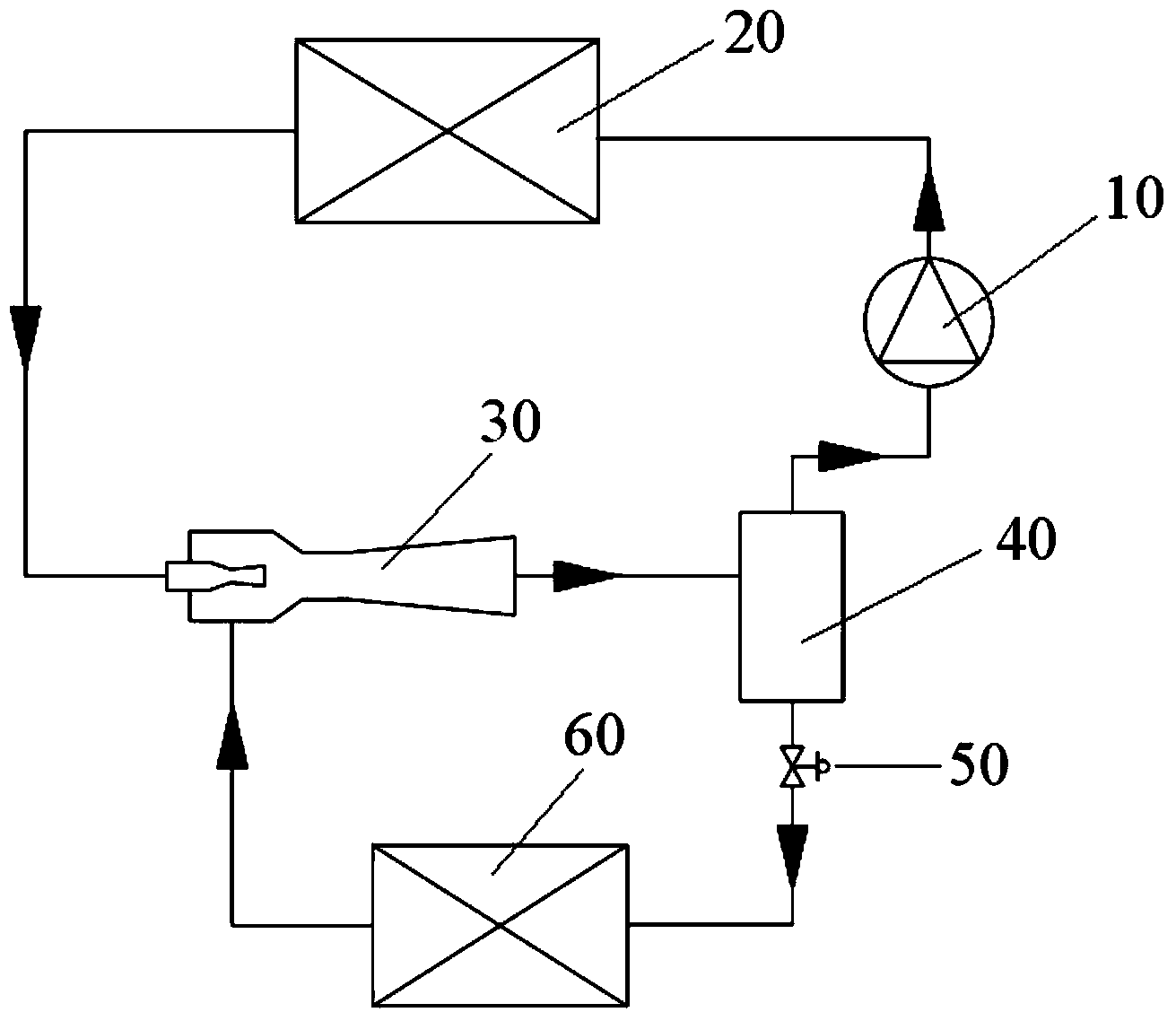

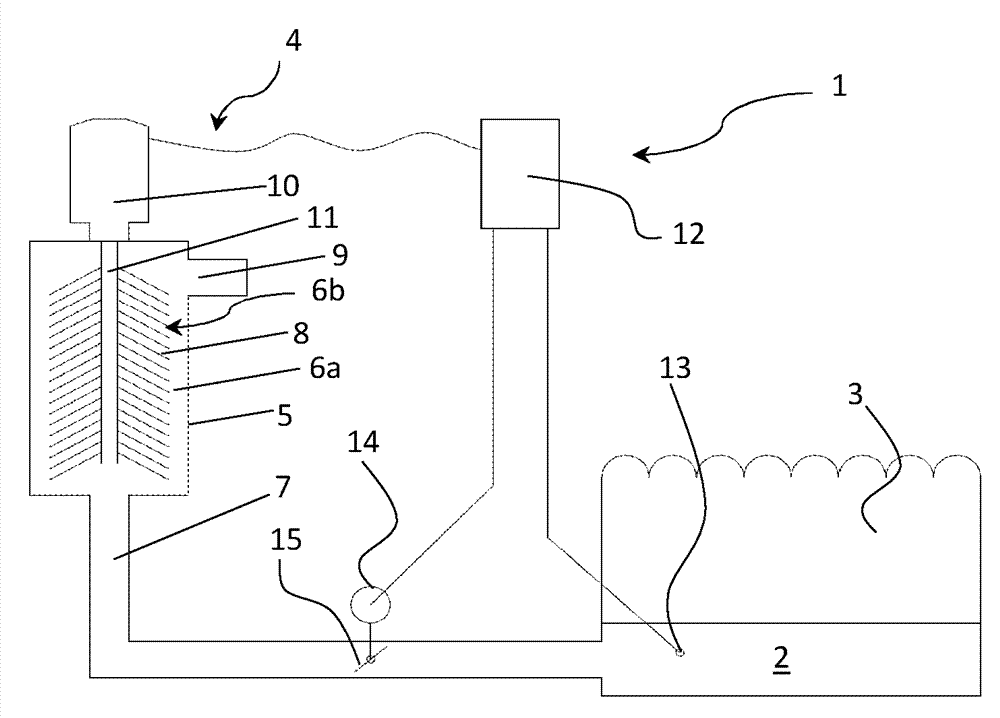

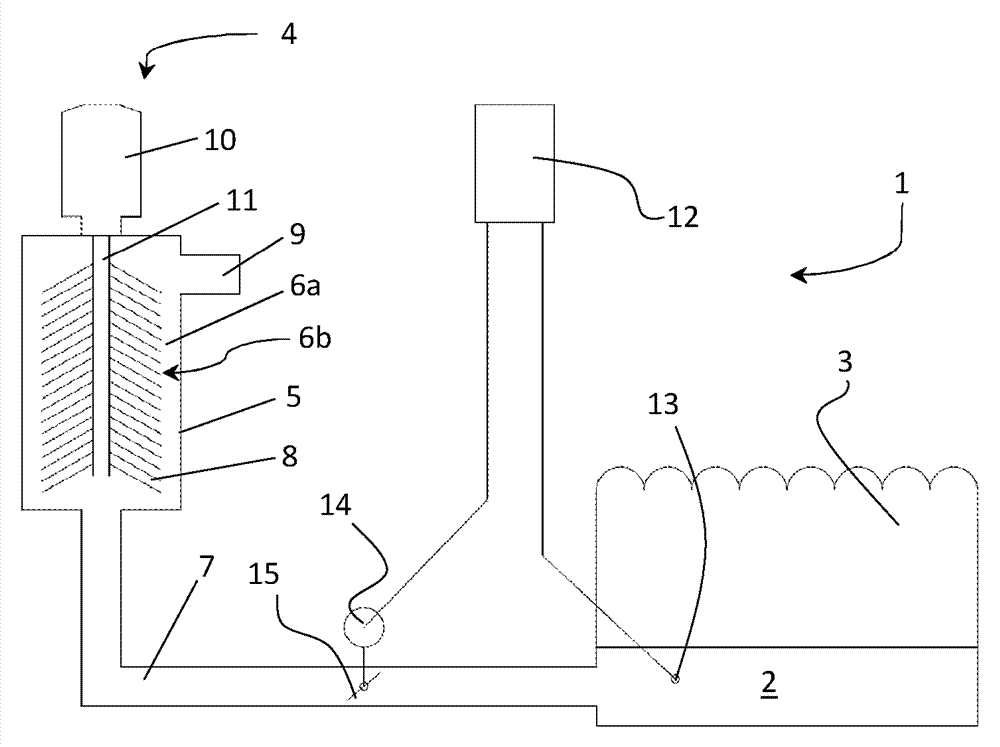

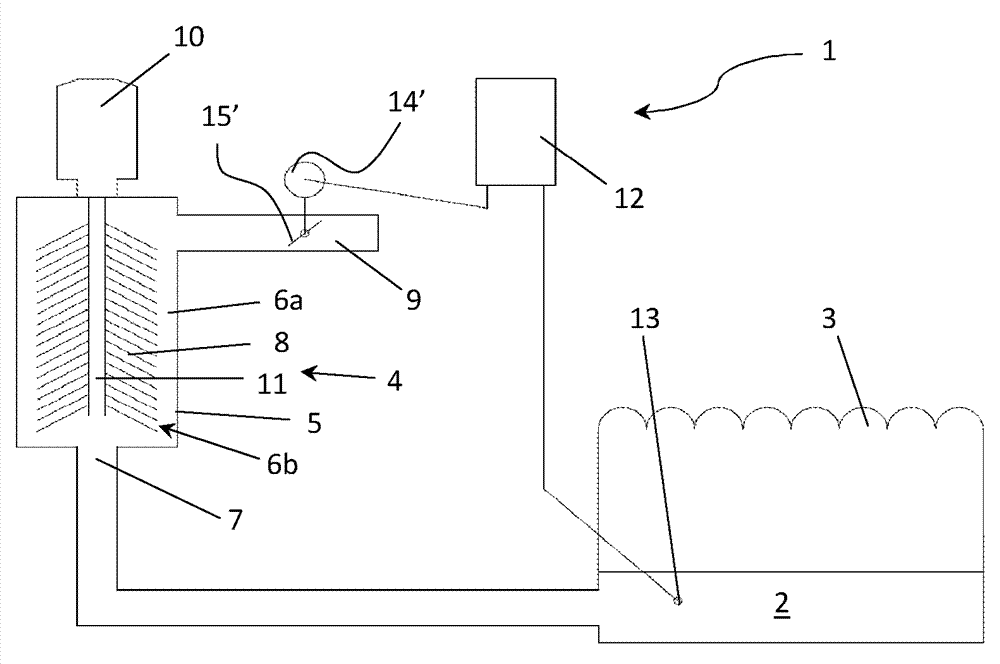

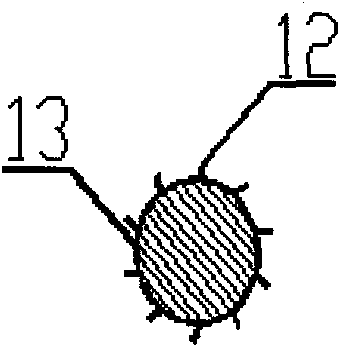

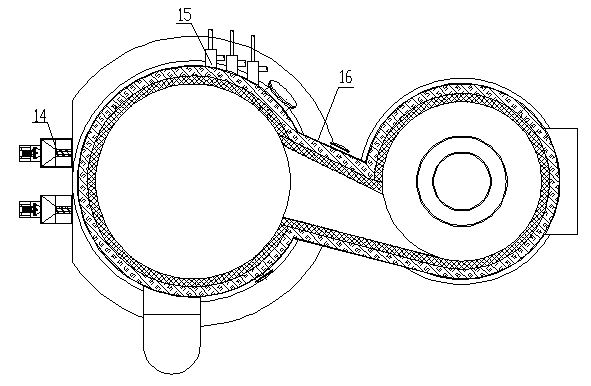

A device and method for cleaning crankcase gas

ActiveCN103097674AHigh speed rotationImprove separation efficiencyMachines/enginesCrankcase ventillationCombustionCrankcase

The present invention relates to a device (1) and method for cleaning of crankcase gas being produced in a crankcase (2) during operation of an internal combustion engine (3). The device (1) comprises a centrifugal separator (4) having a housing (5) and a separation chamber (6a) in which a centrifugal rotor (6b) is arranged for cleaning of said crankcase gas. The separator (4) is connected to a gas inlet (7) for conducting crankcase gas from the crankcase (2) to the centrifugal separator (4) and a gas outlet (9) for conducting the cleaned gas from the separator (4). A motor (10) is arranged to rotate the centrifugal rotor (6b) with control equipment (12) for changing the rotational speed of the centrifugal rotor (6b). A sensor (13) is provided for detection of a parameter, the magnitude of which is related to a gas pressure in the crankcase (2). The sensor (13) is arranged to communicate with the control equipment (12) of the motor, the control equipment (12) being operatively connected to a valve (15, 15') which is arranged for adjusting the flow of gas through the centrifugal separator (4). The control equipment (12) is arranged to change the position of the valve (15, 15') in response to a detected change of said parameter in a way such that the gas pressure in the crankcase (2) is maintained at a predetermined value, or at a predetermined pressure interval, during operation of the combustion engine.

Owner:ALFA LAVAL CORP AB

Multi-branch pipe gas-liquid separator

ActiveCN102008867AEasy to separateSolve the defects of gas-liquid separationCombination devicesLiquid degasificationGas phaseEngineering

The invention discloses a multi-branch pipe gas-liquid separator. The separator comprises a separator cylinder body and a liquid-accumulating cylinder, wherein a gas-liquid inlet is formed at the position close to the right side of the liquid-accumulating cylinder and is connected with a gas-liquid inlet header pipe; the gas-liquid inlet header pipe is divided into an ascending pipe section tail and a descending pipe section; gas inlet branch pipes are arranged at the tail end of the ascending pipe section and the head of the descending pipe section of the gas-liquid inlet header pipe respectively; the gas inlet branch pipes are arranged above the separator cylinder body and are connected first to positions parallel to separator cylinder body and then to a gas phase inlet header pipe; and the tail end of the descending pipe section of the gas-liquid inlet header pipe is connected with a liquid phase inlet arranged at the upper left of the separator cylinder body. The separator has the advantages of effectively capturing the slug flow formed in a pipe conveying and cleaning process and achieving the effect of quick, safe and effective separation.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

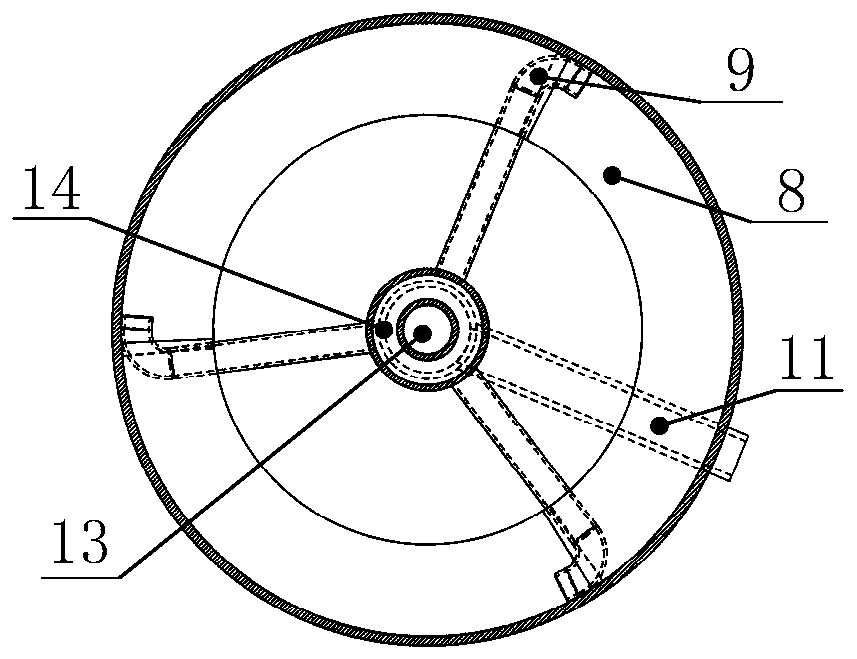

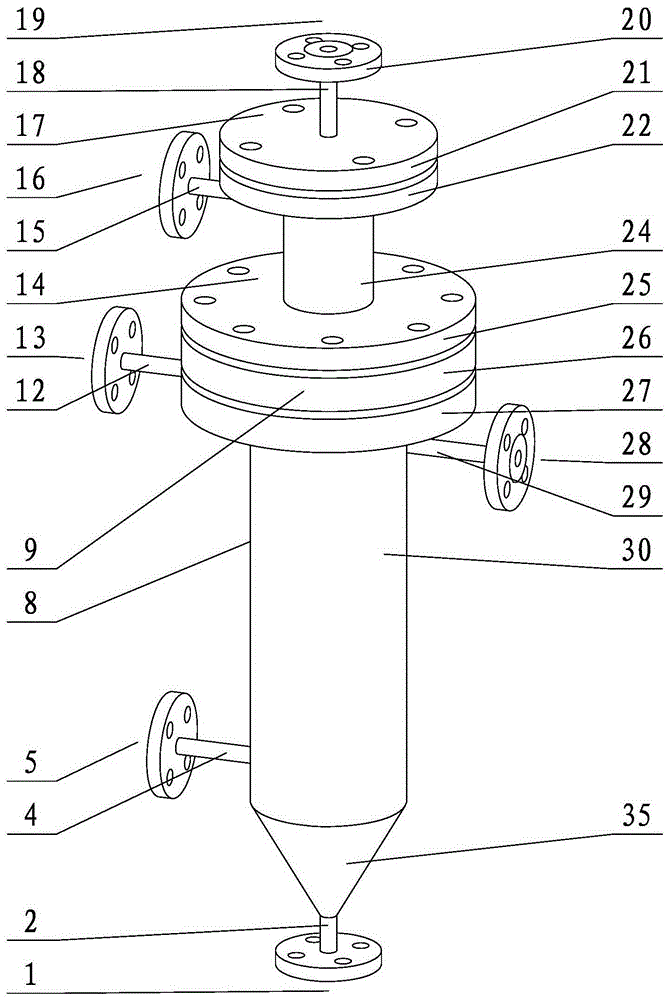

Single-stage, multi-stage and variable-stage rotational flow air floatation oil-containing sewage treatment device

ActiveCN110902758AFacilitates collision adhesionEasy to separateWaste water treatment from quariesFatty/oily/floating substances removal devicesSewage treatmentTreated water

The invention discloses a single-stage, multi-stage and variable-stage rotational flow air floatation oil-containing sewage treatment device, which comprises an outer shell comprising all stages of cylinder bodies, an upper seal head and a lower seal head, an inlet and outlet pipeline part comprising all stages of overflow pipes, all stages of reflux pipes, an underflow pipe and a central verticalpipe, and an internal structure comprising all stages of water distribution pipes, all stages of flow guide plates, annular channels and treated water collecting plates, wherein the first-stage overflow pipe is positioned at the top of the upper seal head, other overflow pipes are positioned on the upper side surfaces of various stages of the cylinder bodies, the underflow pipe is positioned at the lower seal head, various stages of the reflux pipes penetrate through various stages of the cylinder bodies and are communicated with various stages of the annular channels, the central vertical pipe is located on the axis of the cylinder bodies and penetrates through the lower seal head, the annular channels and various stages of the cylinder bodies, the first-stage water distribution pipe ispositioned at the top of the central vertical pipe, other water distribution pipes are positioned at the bottoms of the annular channels, various stages of the flow guide plates spirally incline upwards and are fixed on the inner walls of various stages of the cylinder bodies, and the treated water collecting plate is positioned between the two cylinder bodies. The device of the invention is compact in structure, easy and convenient to operate, wide in applicability and good in oil removal effect, wherein the single-body multi-stage design meets the requirements of different effluent qualitiesand treatment capacities.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

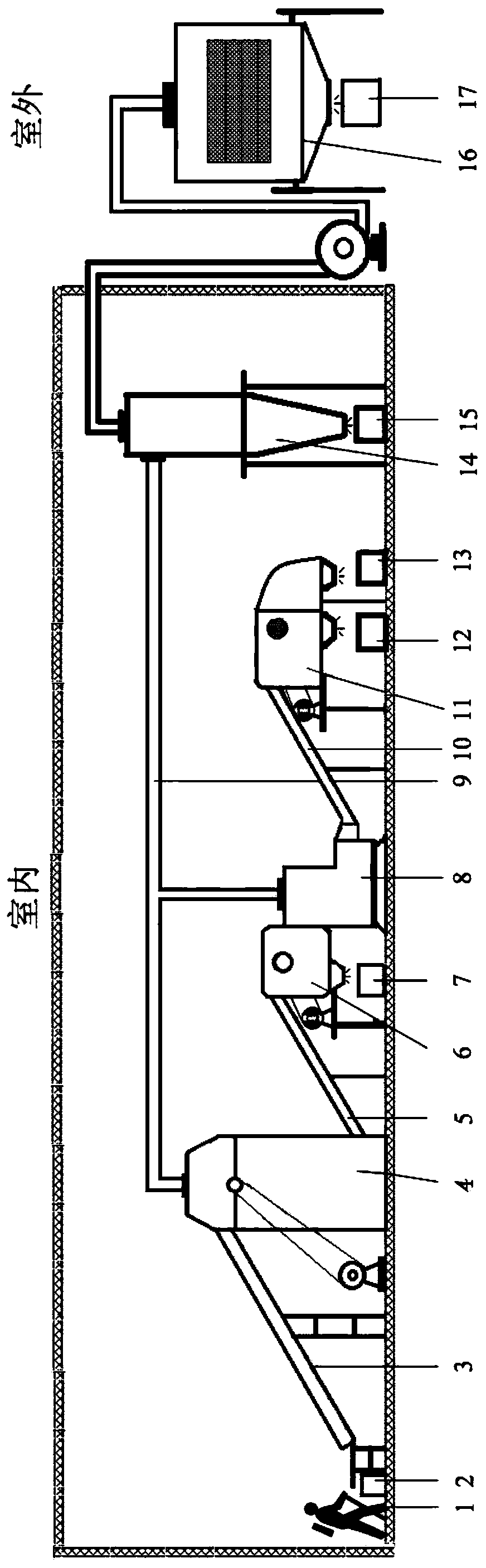

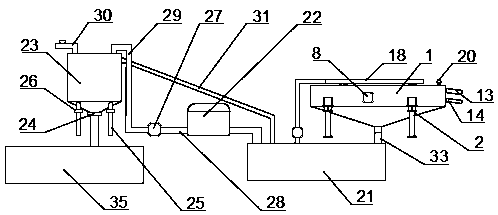

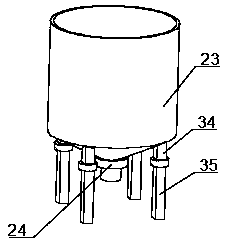

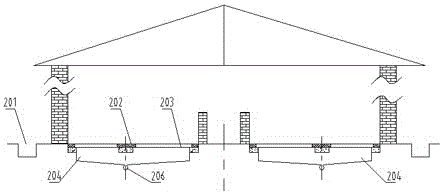

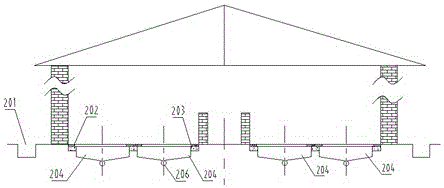

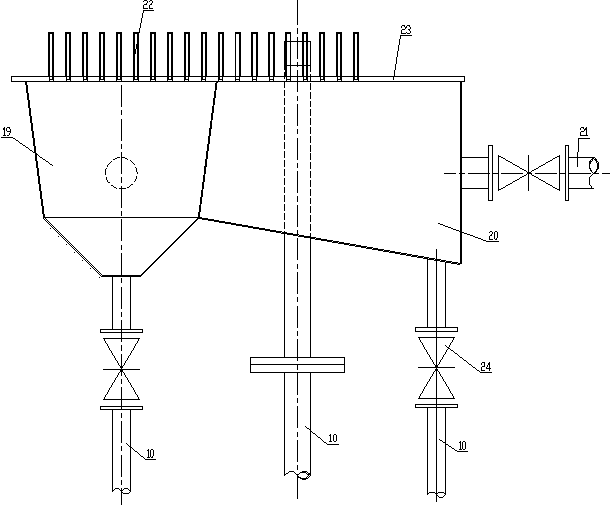

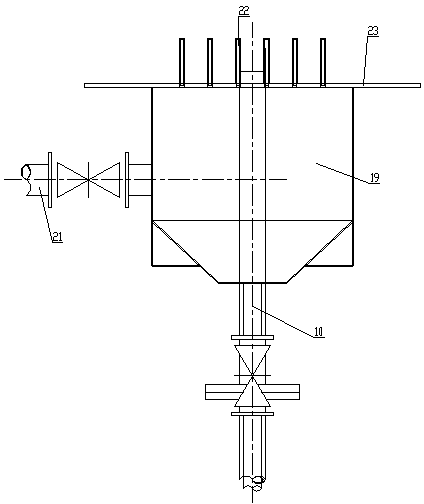

Method and system for recycling utilization of mass fresh mixed waste concrete

The invention belongs to the technical field of recycling utilization of waste concrete, and specifically provides a method and a system for recycling utilization of mass fresh mixed waste concrete. The method comprises the following steps: step 1, separating and recovering sand gravels from the waste concrete; step 2, recovering a waste slurry; and step 3, blending the recovered slurry into a fresh slurry for production of fresh mixed concrete. The system comprises a sand gravel separator, a waste slurry pool, a cyclone, a solid-content adjusting tank and a slurry recovery pump, wherein a plurality of supporting columns are arranged on the outer wall of the solid-content adjusting tank; each supporting column is provided with a weighing device; the slurry inlet of the cyclone extends intothe waste slurry pool; the slurry outlet of the cyclone is connected with the feed inlet of the slurry recovery pump; the discharge outlet of the slurry recovery pump is connected with the slurry inlet end of a slurry recovery pipe; and the slurry outlet end of the slurry recovery pipe extends into the solid-content adjusting tank. The method and the system provided by the invention can treat mass waste concrete, realize recycling utilization of a generated waste slurry for production of the fresh mixed concrete, and save resources.

Owner:CHONGQING CONSTR ENG NEW BUILDING MATERIALS +1

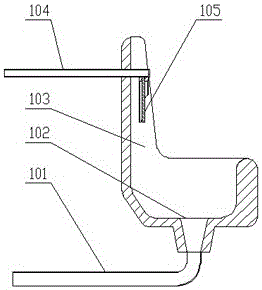

System and method for separating and treating pollutant sources of large-scale pig farm

InactiveCN106804439AReduce pollutionReduce the amount of waterClimate change adaptationExcrement fertilisersPig farmsFeces

The invention discloses a system and a method for separating and treating the pollutant sources of a large-scale pig farm. The system comprises a pollutant source separation hog house, an excrement conveying device, an excrement fermenting device, a liquid conveying device, a fecaluria liquid fermenting device, a fence washing water SBR reactor and an ecological wetland, wherein the pollutant source separation hog house adopts the structure that short beams running through the whole hog house in the length direction are established in a hogcote, transverse beams and longitudinal beams are established between the short beams, a slatted floor is paved on the transverse beams and the longitudinal beams, every two short beams and a V-shaped bottom surface form a U-shaped excrement groove, the higher ends of the U-shaped excrement grooves are connected to an excrement collection pool, the lower ends of the U-shaped excrement grooves are connected to a liquid collection pool, and an excrement scrapping system is arranged in each U-shaped excrement groove. The separation of fecaluria from rainwater, drinking residual water and fence washing water and the separation of excrement from fecaluria liquid in advance are realized, so that the problem of difficult solid-liquid separation in subsequent procedures is solved, and the resource utilization and pollution treatment effect is good.

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD

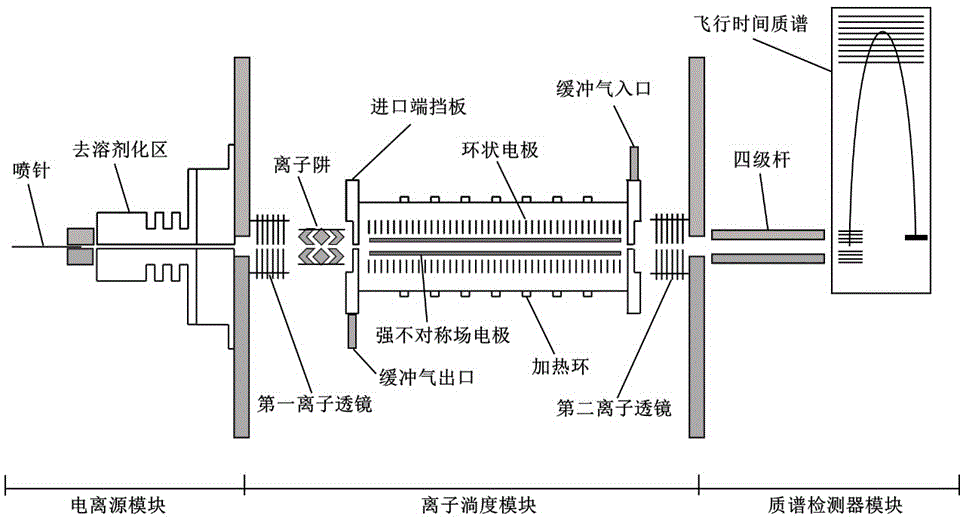

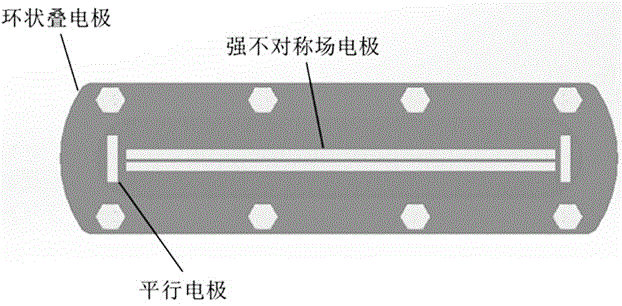

Three-dimensional ion mobility combinational mass spectrometer

InactiveCN106057626AReduce the chance of collisionIncreased chance of collisionElectron/ion optical arrangementsSpecific reaction combinationsMass spectrometry detectorDesolvation

The invention belongs to the technical field of sample separation and analysis of isomeride, and specifically to a three-dimensional ion mobility combinational mass spectrometer. The three-dimensional ion mobility mass spectrometer comprises an ionization source module, an ion mobility module and a mass spectrometry detector module, wherein the ionization source module comprises an ion source spraying needle and a desolvation region; the ion mobility module comprises a first ion focusing lens, an ion trap, an inlet end baffle, a buffering gas outlet, annular electrodes, heating rings, strong asymmetric electrodes, a buffering gas inlet and a second ion focusing lens; the mass spectrometry detector module comprises an ion transmission four-stage rod and a flight time mass spectrum; the centers of the ionization source module, the ion mobility module and the mass spectrometry detector module are on the same axle wire; the ionization source module is connected to the first ion focusing lens of the ion mobility module; and the ion mobility module is connected with an ion transmission focusing apparatus of the mass spectrometry detector module through the second ion focusing lens. According to the three-dimensional ion mobility combinational mass spectrometer, the annular overlapped electrodes are adopted to drive ions to fly, and the buffering gas enters from the negative direction; and meanwhile, a one-dimensional electric field is further added to the third dimension, so that the collision probability between the buffering gas and ions is increased, and the separation efficiency is greatly increased.

Owner:FUDAN UNIV

Tail gas recovery method of tetrafluoroethylene production and its membrane module

InactiveCN102284232ALow recovery rateReduce consumptionSemi-permeable membranesDispersed particle separationExhaust gasPolyolefin

The present invention provides a membrane module for recovery of tail gas from tetrafluoroethylene production, which includes a filter, a plurality of parallel and / or serial membranes, wherein the membrane is a polyolefin non-porous hollow fiber membrane; the present invention also provides a Tail gas recovery method for tetrafluoroethylene production, which uses the aforementioned membrane module; using the membrane module based on the present invention and the corresponding tetrafluoroethylene tail gas recovery method, under the same working conditions and operations, the total recovery rate of tetrafluoroethylene is increased by 10% at most around, and significantly reduce membrane consumption.

Owner:阳光乐程(北京)网络科技有限公司

Membrane-separation-type Culture Device, Membrane-separation-type Culture Kit, Stem Cell Separation Method Using Same, And Separation Membrane

InactiveCN104673670ASorting is efficient and cheapShorten the timeSemi-permeable membranesMembranesHydrophilic polymersHydrophobic polymer

Owner:NAT CENT FOR GERIATRICS & GERONTOLOGY +1

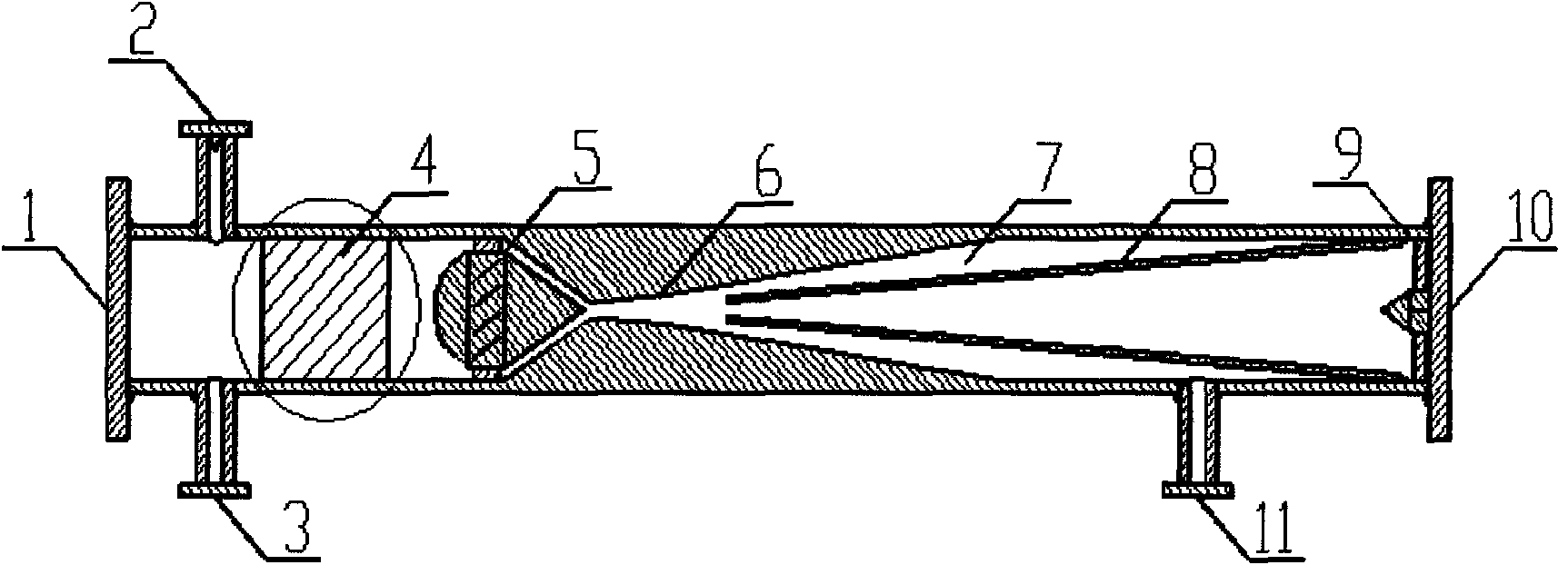

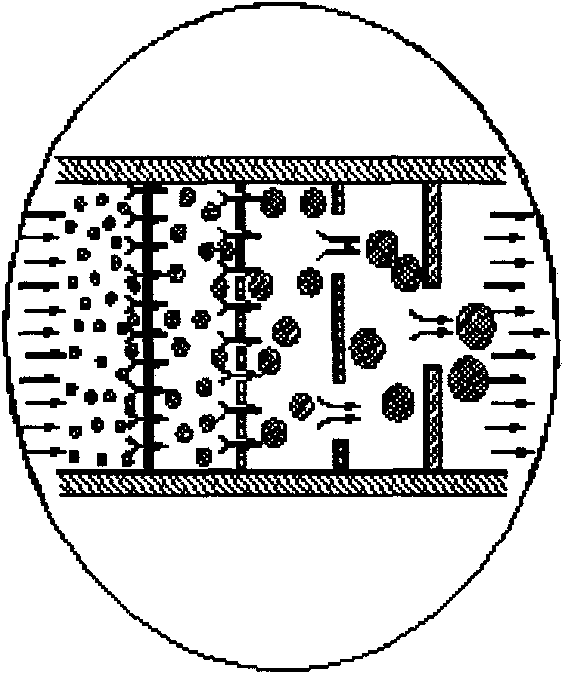

Natural gas dehydration method using pre-nucleating supersonic vortex tube

ActiveCN102166464ASmall particle sizeControl the number of nucleiDispersed particle separationGaseous fuelsSolid particleLarge particle

The invention relates to a natural gas dehydration method using a pre-nucleating supersonic vortex tube, which comprises the following steps of: introducing a raw material gas into a raw material gas separator and a raw material gas filter separator to remove large particles, cooling the raw material gas, removing fine solid particles through a fine filter, and introducing the raw material gas into the pre-nucleating supersonic vortex tube; adding a nucleating agent from a nucleating agent inlet or discharging the nucleating agent from a nucleating agent outlet, forming proper particle size through a coalescent nucleating device, generating vortex rotation in a vortex generator, and accelerating and cooling the raw material gas through a Laval nozzle; introducing the raw material gas intoa liquid separating cavity under the action of centrifugal force, and introducing the raw material gas into a gas-liquid separator through a condensate outlet; eliminating the vortex of a gas flow inthe center of the tube through a rectifier, introducing a gas mixture separated from a dry gas outlet and the gas-liquid separator into a gas-gas heat exchanger, exchanging heat with the raw materialgas to heat the raw material gas, exporting the gas mixture, introducing water separated from the raw material gas separator, the raw material gas filter separator and the gas-liquid separator into awater storage tank, and discharging the water. After water-containing natural gas is treated by the natural gas dehydration process using the pre-nucleating supersonic vortex tube, the dew point of water reaches subzero 5 DEG C, and the exporting requirement is satisfied.

Owner:PETROCHINA CO LTD

Parallel-adjustable hydrocyclone

ActiveCN106238234AReduce concentrationReduce separation efficiencyReversed direction vortexEngineeringHydrocyclone

The invention provides a parallel-adjustable hydrocyclone and relates to hydrocyclones. The parallel-adjustable hydrocyclone comprises a lower tank body, a middle tank body, an upper tank body and an overflow pipe component. When the parallel-adjustable hydrocyclone is in work, part of coarse granules, which settle at two radial inner sides of a tubular body of the upper tank body, of a suspension can be discharged from a separated liquid outlet in time, the concentration of the suspension treated in the parallel-adjustable hydrocyclone can be lowered, the decrease of the separation efficiency of the parallel-adjustable hydrocyclone is avoided, and the coarse granules of the suspension cannot be accumulated at an underflow opening, so that the separation size of the parallel-adjustable hydrocyclone is stabilized. The parallel-adjustable hydrocyclone has the advantage of overcoming the fluctuation of the concentration of the suspension.

Owner:高唐融知融智科技服务有限公司

Pulsation swirler with internally arranged screw rod

ActiveCN107824346AEasy to separateReduce radial rangeReversed direction vortexEngineeringVolumetric Mass Density

Provided is a pulsation swirler with an internally arranged screw rod. The main purpose is to provide swirling separation equipment which is high in separation efficiency, small in equipment size andconvenient to operate and maintain. The pulsation swirler is characterized in that the interrupted screw rod is arranged in the center of a cyclone separator, the interrupted screw rod is of a hollowstructure and is composed of spiral sections and open hole sections in an interval distribution manner, and the spiral rotation direction of the spiral sections is opposite to the rotational flow direction after liquid enters the swirler; a backwash round tube is nested in the interrupted screw rod, open hole sections on the backwash round tube correspond to those of the interrupted screw rod, a top end opening of a hollow part of the interrupted screw rod and the backwash round tube is connected with an overflow port of the swirler, the liquid can enter the internal hollow part through the open hole sections of the screw rod and the backwash round tube, moves upwards and is discharged from the swirler through the overflow port. The swirler can effectively solve the technical problems of small density differences of two-phase media, high viscosity of separation media, low separation accuracy and the like.

Owner:NORTHEAST GASOLINEEUM UNIV

Measurement method for residual solvents in edible vegetable oil

InactiveCN108303479AAccurate measurement rangeHigh precisionComponent separationVegetable oilStandard solution

The invention discloses a measurement method for residual solvents in edible vegetable oil. The measurement method comprises following steps: (1), preparation of a standard solution; (2), preparationof a vegetable oil sample; (3), making of a standard curve; (4), sample measurement. By means of improvement, the residual solvents are increased to 1 mg / kg from original quantitative detection limitbeing 10 mg / kg, and accuracy is higher; by means of change of a packed column and volume of an added solution, so that an obtained result is more accurate, and the method can be taken as supplementarymeans for identifying a pressing method and a leaching method.

Owner:吉林省百利生物科技有限公司

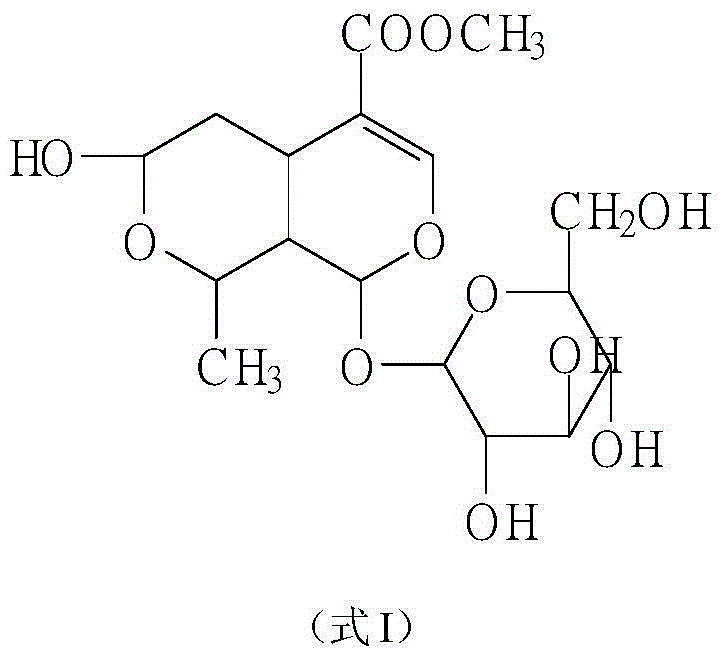

Method for preparing morroniside

ActiveCN104987354AReduce manufacturing costReduce dosageSugar derivativesSugar derivatives preparationCornus officinalisSilica gel

The invention discloses a method for preparing morroniside. The method comprises the following steps: 1) carrying out permeating extraction on cornus officinalis to obtain a cornus officinalis extraction solution; 2) concentrating the cornus officinalis extraction solution obtained in the step 1) to obtain cornus officinalis extract; 3) uniformly mixing the cornus officinalis extract with a silica gel, drying and grinding the mixture, and filling the mixture in a chromatographic column, wherein the chromatographic column is filled with a hollow silica gel for chromatography; and 4) eluting the chromatographic column by using an eluant and collecting a flowing component, then removing the eluant in the flowing component, dissolving residues by methanol, and carrying out recrystallization to obtain morroniside. The purity of the product obtained by the method is greater than 70%, so that the product can be used for further purification and production of high purity morroniside and can be directly used for producing various target products. The method not only is suitable for small-scaled preparation in a lab, but also is suitable for large-scaled industrial production.

Owner:BEIJING INST FOR DRUG CONTROL

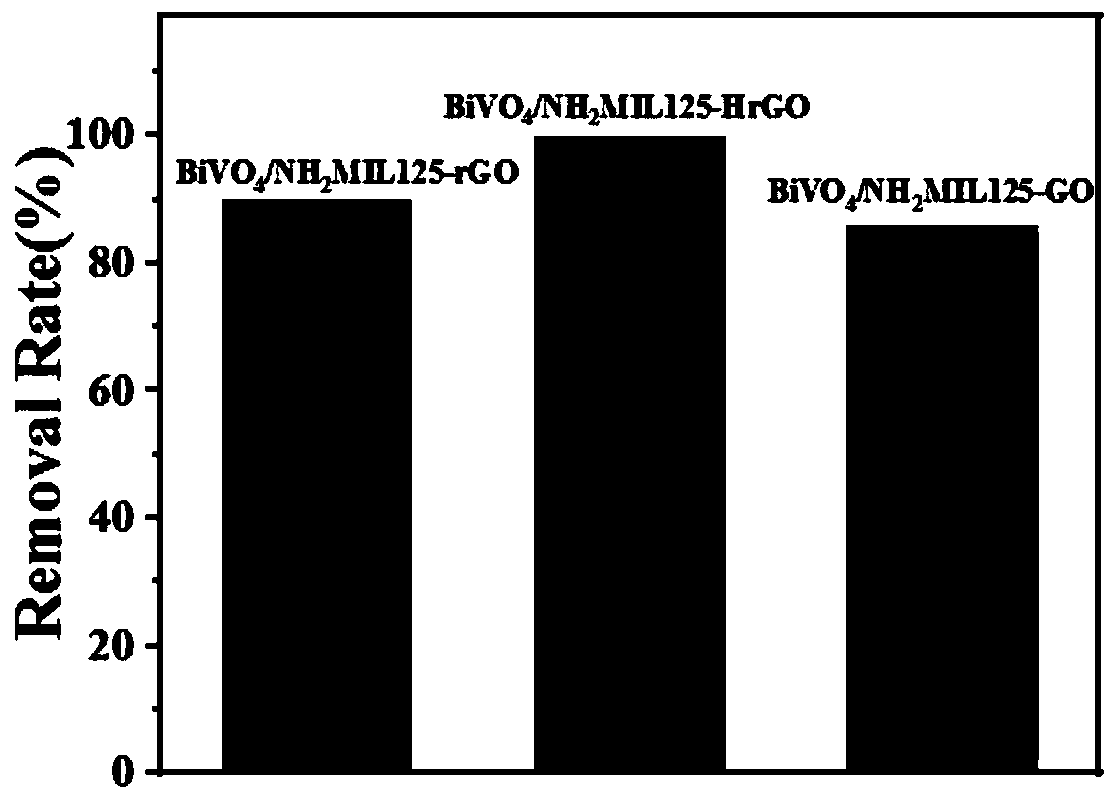

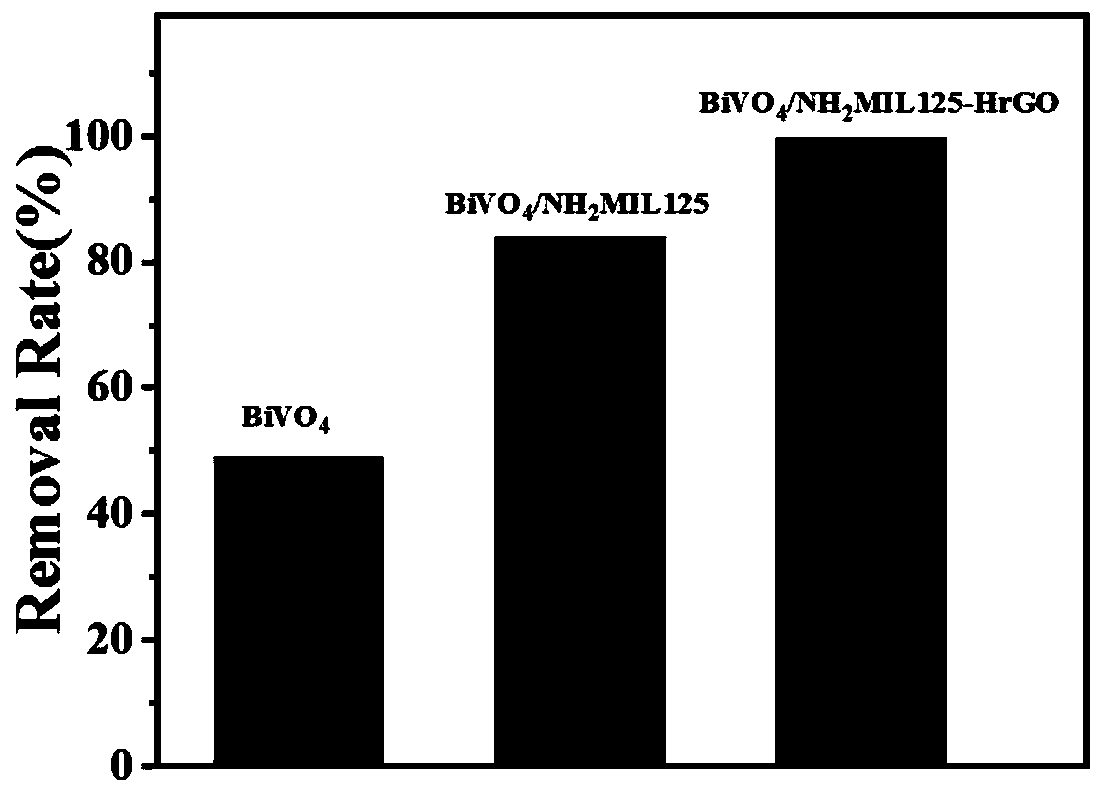

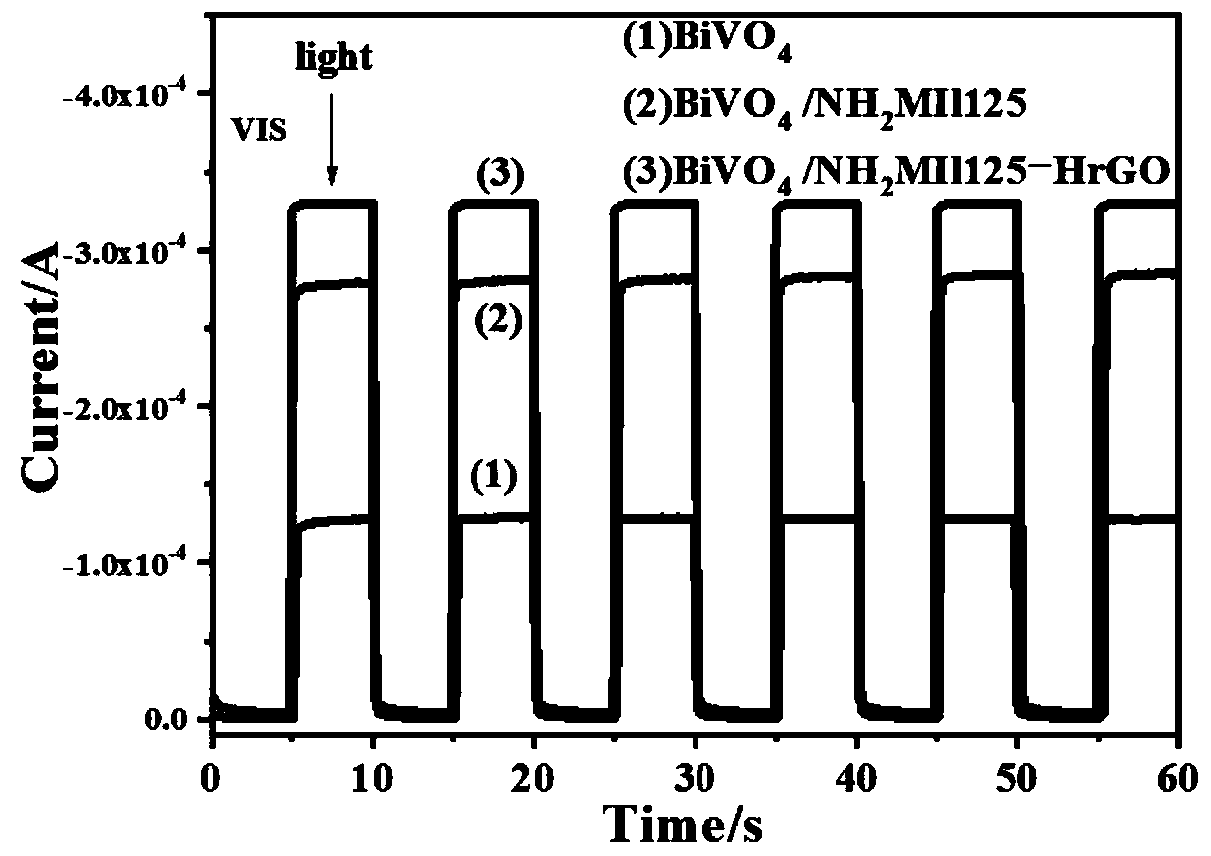

MOF and HrGO co-modified bismuth vanadate electrode as well as preparation method and application thereof

ActiveCN111348728AImprove efficiencyImprove photoelectric conversion efficiencyWater/sewage treatment by irradiationWater contaminantsSolventPlasma treatment

The invention discloses an MOF and HrGO co-modified bismuth vanadate electrode as well as a preparation method and application thereof in the field of photoelectrocatalysis, the preparation method comprises the following steps: (1) dissolving bismuth nitrate in nitric acid, then adding ammonium metavanadate and polyvinyl alcohol, and carrying out ultrasonic treatment to obtain a seed solution; smearing the seed solution on a clean conductive glass, drying, calcining, and taking out a product as a substrate electrode for later use; (2) dissolving bismuth nitrate and ammonium metavanadate in nitric acid, putting the substrate electrode prepared in the step (1) into an obtained solution, carrying out hydrothermal reaction,and after the reaction is finished, calcining to obtain a BiVO4 electrode; (3) dissolving 2-aminoterephthalic acid into DMF, dissolving butyl titanate in methanol, mixing obtained two solutions to be uniform through stirring, adding reduced graphene oxide obtained by hydrogen plasma treatment, uniformly mixing, finally adding the BiVO4 electrode, and carrying out solvothermal reaction to obtain the BiVO4 / NH2MIL125-HrGO composite membrane electrode.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

High-temperature cyclone separation type three-waste co-combustion furnace

InactiveCN104197338APrevent reverse stringingImprove combustion efficiencyIncinerator apparatusCycloneCombustor

The invention discloses a high-temperature cyclone separation type three-waste co-combustion furnace which comprises a combustion furnace and a separator communicated with an ash outlet of the combustion furnace. The combustion furnace is provided with a secondary air device, a combustor and a spiral coal feeder, a smoke outlet is formed in the upper portion of the separator, and a waste gas premixing device is installed on the side portion of the combustion furnace. An air distributing device is installed on the bottom of the combustion furnace, and an igniter and an air inlet are installed in the lower portion of the air distributing device. A central cylinder stretching downwards is arranged at the smoke outlet in the top of the separator, the lower end face of the central cylinder and the central line of the ash outlet are on the same horizontal plane, and a gas outlet pipe is connected to the smoke outlet in the top of the separator. A discharge port is formed in the bottom of the separator, the discharge port is communicated with a material return port in the lower portion of the combustion furnace through a material return pipe formed by sequentially connecting a first vertical section, a horizontal section, a second vertical section and an inclined section, the first vertical section is connected with the discharge port, the bottom end of the inclined section is connected with the material return port formed in the lower portion of the combustion furnace, and a material return device is arranged at the connecting position of the first vertical section and the horizontal section.

Owner:山东福源节能服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com