Polyarylene sulfide sulfone compound separating film and preparation method thereof

A technology of polyarylene sulfide sulfone and polyarylene sulfide, which is applied in the field of preparation of polymer separation membranes, can solve the problems of poor interception performance of polyarylene sulfide sulfone separation membranes, and achieves improved interception capacity, wide application range, porosity rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

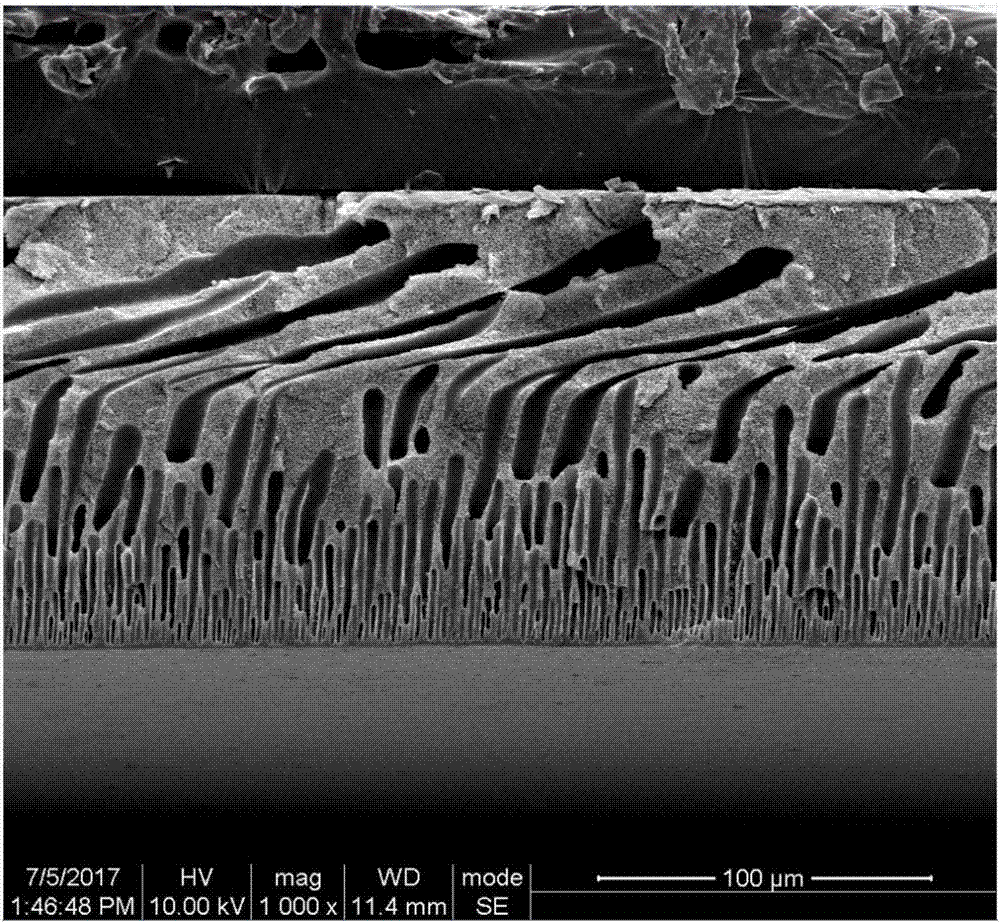

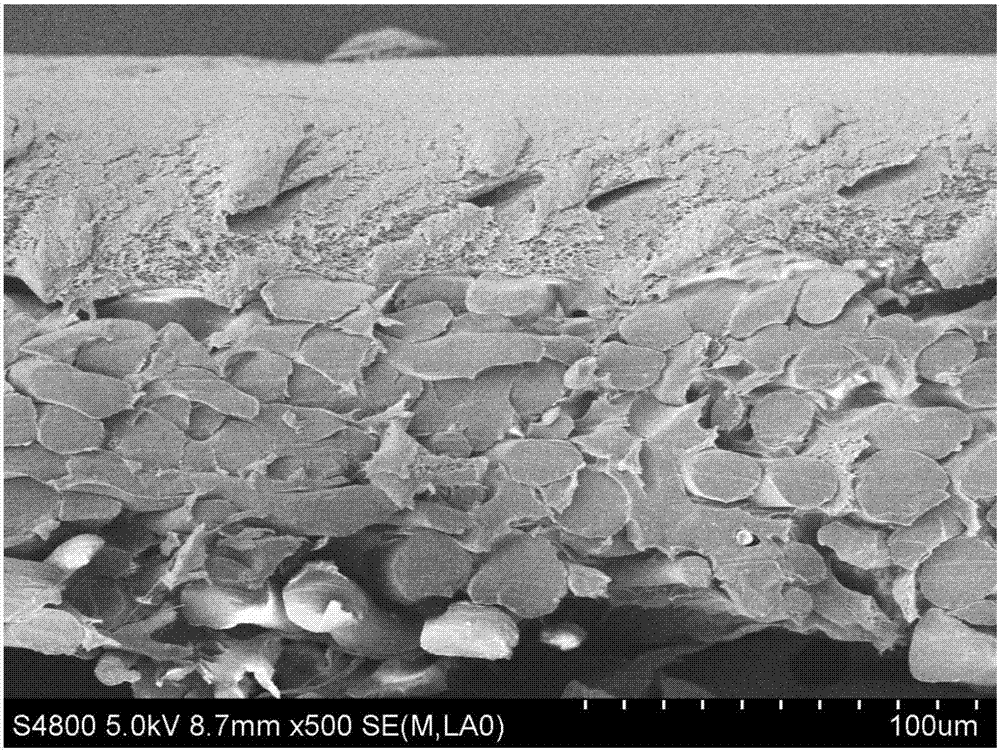

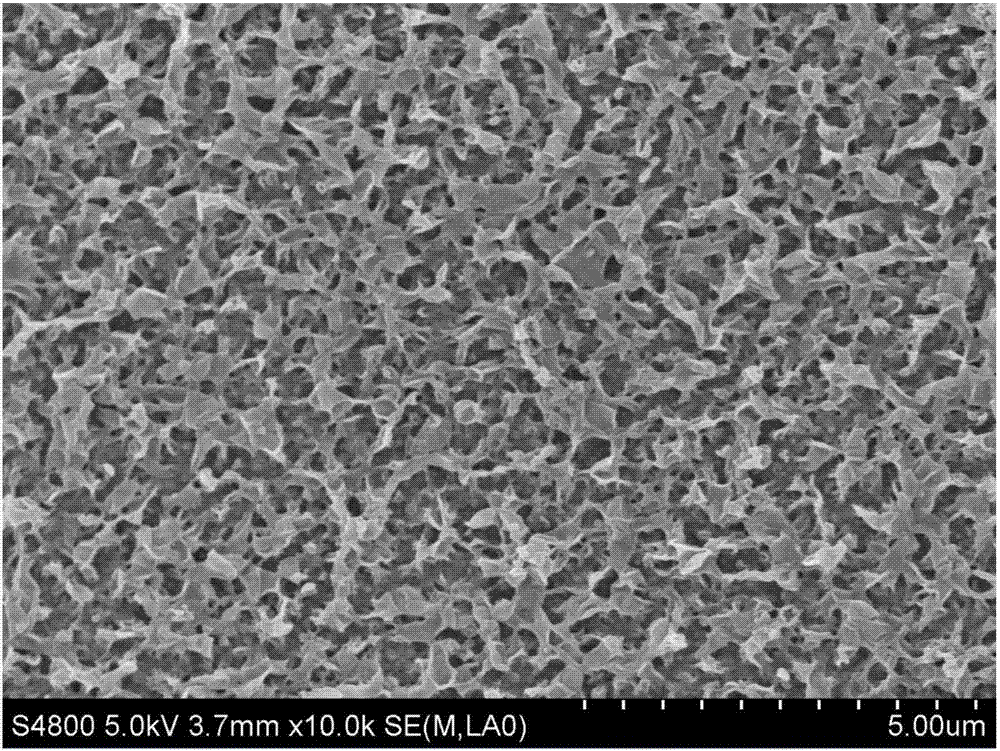

[0049] Add 44g of polyarylene sulfide sulfone resin (intrinsic viscosity 0.5dl / g), 145.5g of N-methylpyrrolidone, 3g of polyvinylpyrrolidone, 1.5g of sodium dodecylsulfonate, and 8g of silica gel into a closed mixer, and use After the nitrogen is removed from the air, stir and heat to dissolve at 150°C. After the dissolution is complete, cool down, filter to remove undissolved impurities, and stand for defoaming for 3 hours to obtain the polyarylene sulfide sulfone base membrane stock solution; scrape with a flat plate Coat a layer of 300 μm thick polyarylene sulfide sulfone-based film stock solution on a glass plate at 20°C, wait for the solvent to evaporate for 60 seconds, and the air humidity is 30% to form a primary film, then immerse in a coagulation bath to solidify The bath was distilled water at a temperature of 20 °C. After the film was completely cured, it was transferred to distilled water and soaked for 24 hours to prepare a flat base film.

Embodiment 2

[0051] The difference between this example and Example 1 lies in: polyarylene sulfide sulfone 12g, polyvinylpyrrolidone 1.2g, sodium dodecylsulfonate 1g, silica gel 3g, N-methylpyrrolidone 48g.

Embodiment 3

[0053] The difference between this example and Example 1 lies in: polyarylene sulfide sulfone 61g, polyvinylpyrrolidone 7g, sodium dodecylsulfonate 6g, silica gel 15g, N-methylpyrrolidone 205g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com