A device and method for cleaning crankcase gas

A crankcase, cleaning technology, applied in the direction of crankcase ventilation, engine components, machine/engine, etc., can solve the problems of reducing the separation efficiency of centrifugal rotors and reducing centrifugal rotors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

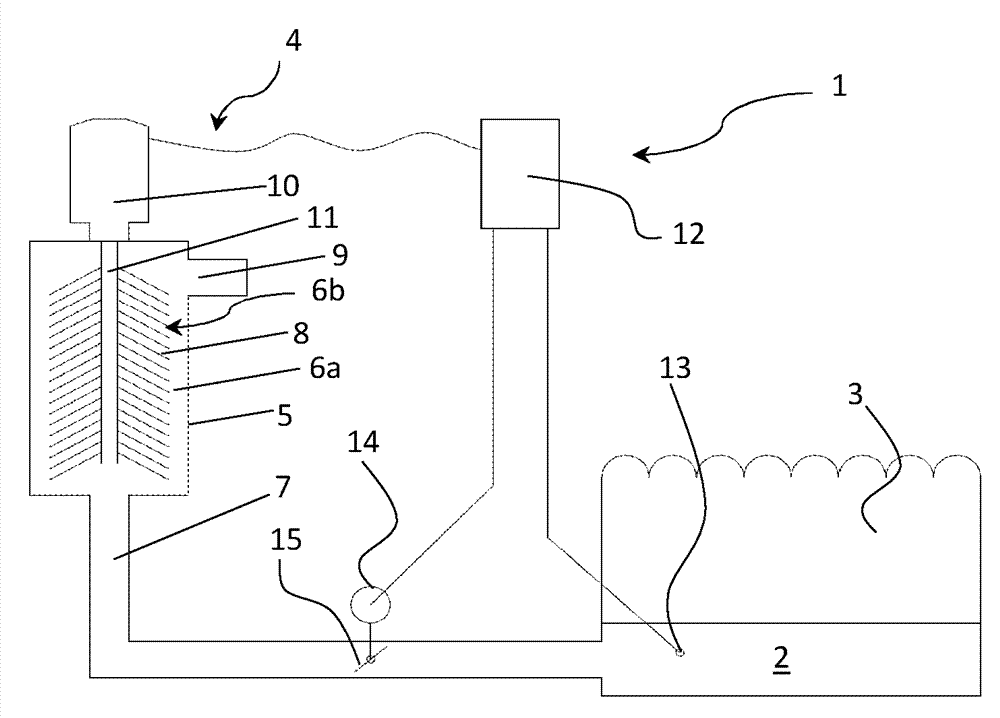

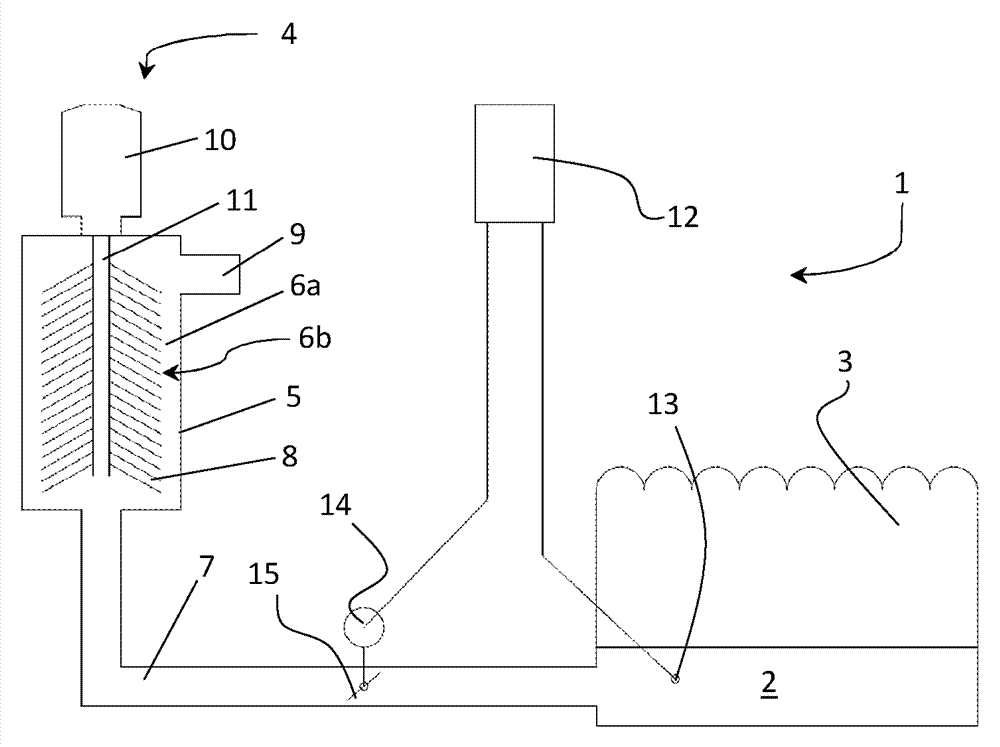

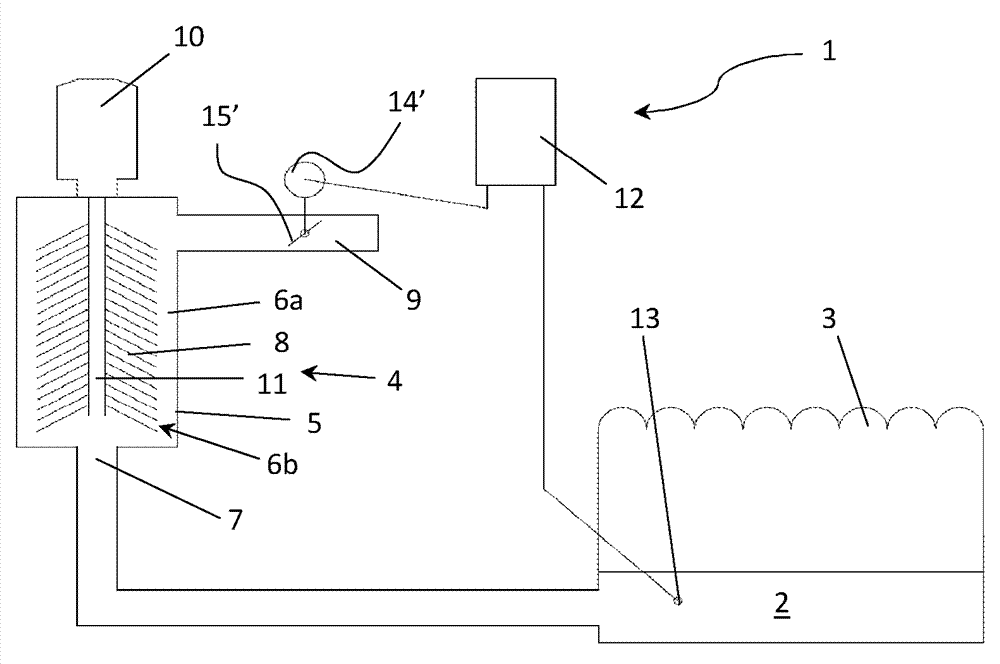

[0020] figure 1 A first embodiment of a device 1 for cleaning crankcase gases generated in a crankcase 2 during operation of an internal combustion engine 3 is disclosed. The combustion engine 3 can be, for example, a diesel engine mounted on a locomotive or a truck. The device 1 comprises a centrifugal separator 4 with a housing 5 delimiting a separation chamber 6a, wherein a centrifugal rotor 6b is arranged for cleaning said crankcase gases and is arranged, by its rotation, to remove the crankcase gases from the crankshaft Tank 2 is pumped to centrifugal separator 4 . Such centrifugal separators arranged to suck or pump crankcase gases from the crankcase are described in more detail, for example, in EP 1532353 B1 and / or WO 2010 / 008342 A1. The housing 5 of the centrifugal separator 4 is connected to the crankcase 2 via a gas inlet 7 in the form of a line arranged between the centrifugal separator 4 and the crankcase 2 . The gas inlet 7 is configured to guide crankcase gase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com