Ferrochrome preparation method

A technology of ferrochromium alloy and chromite powder, applied in the field of metallurgy, can solve the problems of increasing the pre-oxidation link, increasing the investment cost, and lengthening the process, and achieves the effects of shortening the production process, reducing the preparation cost and lowering the price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

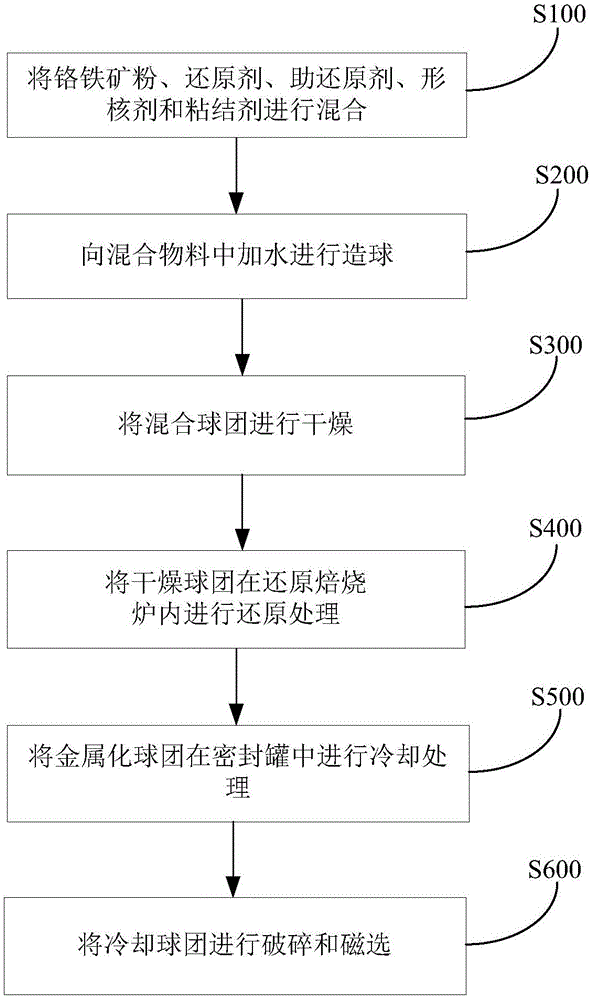

Method used

Image

Examples

Embodiment 1

[0057] Composition of materials: TFe content in chromite powder is 15.81wt%, Cr / Fe mass ratio is 1.8, particle size below 75 microns accounts for 88wt%; reducing agent adopts blue carbon, fixed carbon is 82.26wt%, particle size Those below 75 microns can account for more than 96wt%; the auxiliary reducing agent is sodium carbonate, and those with a particle size below 75 microns account for 90wt%; the nucleating agent is ferrochrome powder, and the average particle size is 0.5 mm; the binder is bentonite;

[0058] Preparation method: mix chromite powder with reducing agent, co-reducing agent, nucleating agent and bentonite according to the mass ratio of 100:30:3:5:3 to obtain a mixed material, and then add 8wt of the mixed material to the mixed material After adding 100% water, pelletizing is carried out to obtain material pellets (particle diameter is 10 mm), and the obtained material pellets are dried to obtain dry pellets, and then the dry pellets are distributed into the re...

Embodiment 2

[0060] Material composition: TFe content in chromite powder is 13.28wt%, Cr / Fe mass ratio is 1.42, particle size below 75 microns accounts for 98wt%; reducing agent is anthracite, fixed carbon is 80.44wt%, particle size is low 92wt% of the particle size is 75 microns; limestone is used as the auxiliary reducing agent, and 85wt% is used for the particle size below 75 microns; the nucleating agent is ferrochrome powder, and the average particle size is 0.2 mm; the binder is bentonite;

[0061] Preparation method: mix chromite powder with reducing agent, co-reducing agent, nucleating agent and binder according to the mass ratio of 100:35:3:5:3 to obtain a mixed material, and then add the mixture to the mixed material After feeding 8wt% of water, pelletizing is carried out to obtain material pellets (particle diameter is 10 mm), and the obtained material pellets are dried to obtain dry pellets, and then the dry pellets are distributed into the regenerative rotary hearth furnace , th...

Embodiment 3

[0063] Composition of materials: TFe content in chromite powder is 13.28wt%, Cr / Fe mass ratio is 2.17, particle size below 75 microns accounts for 86wt%; reducing agent adopts blue carbon, fixed carbon is 82.26wt%, particle size Those below 75 microns account for 96 wt%; the co-reducing agent is borax, and those with a particle size below 75 microns account for 86 wt%; the nucleating agent is iron powder, and the average particle size is 0.5 mm; the binder is molasses;

[0064] Preparation method: mix chromite powder with reducing agent, co-reducing agent, nucleating agent and binder according to the mass ratio of 100:26:3:5:3 to obtain a mixed material, and then add the mixture to the mixed material After feeding 8wt% of water, pelletizing is carried out to obtain material pellets (particle diameter is 10 mm), and the obtained material pellets are dried to obtain dry pellets, and then the dry pellets are distributed into the regenerative rotary hearth furnace , the thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com