[0003] At present, the manure

cleaning methods commonly used in large-scale

pig farms at home and abroad mainly include water soaking manure, water flushing manure and dry manure cleaning process. The remaining water is discharged into the manure ditch under the gap floor. After the manure ditch is full, the gate is opened, and the manure is discharged through the

sewage main ditch.

Solid-liquid separation,

solid composting and

fermentation to produce organic fertilizers, and liquids are treated in accordance with the urban domestic

sewage treatment process and the pollutant

discharge standards for

livestock and poultry breeding (GB18596-2001), trying to "

discharge up to standard". The disadvantages are: (1) Toxic and harmful gases endanger the health of pigs. The

feces stay in the pig house for a long time, and part of the anaerobic

fermentation in the manure ditch produces a large amount of harmful gases such as

ammonia,

hydrogen sulfide, and

methane, which makes the pigs Decreased

appetite, endangering the health of pigs; (2)

High energy consumption, in order to reduce the harm of toxic and harmful gases to pigs’ health, people are forced to solve the problem of poisonous gas

pollution by forced ventilation with

high energy consumption, but in winter, forced Ventilation makes the pig house unable to keep warm, and the pigs are susceptible to infectious diseases such as influenza. At the same time, a large amount of toxic and harmful gases pollute the environment and endanger the health of the breeders; (3) The excrement is mixed with the flushing water and drinking water, increasing the excrement resources Difficulty in chemical utilization and manure treatment, because the nutrients in the

biogas residue are dissolved in the

biogas slurry, it is difficult to meet the standards for

organic fertilizer nutrients made from

biogas residues, and it is difficult to meet the

discharge standards due to the

high concentration of COD and

ammonia nitrogen in the biogas

slurry[0004] The way of cleaning manure by water is to wash the pens with water every day, and the flushing water mixed with

feces and

urine flows into the manure ditch in the house. A flusher is installed at one end of the manure ditch, and the flusher is used to flush the manure ditch several times a day. The manure in the manure ditch is flushed into the main sewage ditch, and then discharged through the main sewage ditch for manure treatment. The discharged manure is generally treated by the following methods: first perform biogas anaerobic

fermentation, then separate

solid-liquid, and solid

compost fermentation The

organic fertilizer is produced, and the liquid is treated in accordance with the urban domestic

sewage treatment process and the pollutant discharge standard for

livestock and poultry breeding (GB18596-2001), trying to "discharge up to the standard". The disadvantages of this cleaning and treatment method are: (1 ) Large

water consumption, serious waste of

water resources; (2) After solid-liquid separation, the

nutrient content in the

dry matter is low, and the value of the

organic fertilizer produced is reduced; (3) The amount of sewage is large, and the excrement is mixed with flushing water and drinking water Mixing will increase the difficulty of

resource utilization of

feces and

urine and the treatment of manure, and it is difficult to achieve discharge standards

[0005] The dry manure method, that is, the manure is diverted once it is produced, the dry manure is collected and transported away by machinery or manually, and the

urine and flushing

water flow out from the sewer. Generally, the following methods are used for follow-up treatment: dry manure is composted and fermented to obtain organic fertilizers , the liquid is treated in an

environmentally friendly manner according to the urban domestic

sewage treatment process and the pollutant discharge standard for livestock and poultry breeding (GB18596-2001), trying to "discharge up to the standard". The disadvantages of this cleaning and treatment method are: (1) Manual cleaning of manure The labor load is heavy, the

working environment is poor, the productivity is low, and the cost of manure cleaning is high. The manure cleaners and pigs are prone to cross-infection and epidemic diseases; A large amount of urine and some feces lead to high concentrations of COD and

ammonia nitrogen in the flushing water, making it difficult to achieve discharge standards

[0006] In short, the disadvantages of these methods of manure cleaning and manure treatment are that the flushing water, drinking water and manure are mixed, which brings about the problem of increasing the amount and difficulty of sewage treatment; and the liquid is rich in

organic matter and

nitrogen. The concentrations of

phosphorus and

potassium, COD and

ammonia nitrogen are high, and it is difficult for common sewage treatment technologies to make them meet the discharge standards. mg / L and

total phosphorus 8 mg / L, which are respectively 8 times, 16 times and 16 times the

limit value in the urban sewage treatment

plant pollutant discharge standard (GB18918-2002, first-class A standard), the so-called "standard discharge "In fact, it is the

root cause of

eutrophication in water bodies, and the "standard discharge" sewage continues to pollute the environment

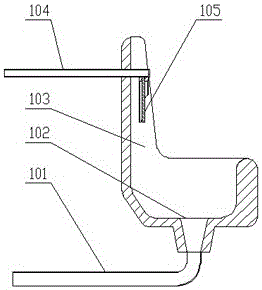

[0007]

Chinese patent CN 105993973 A discloses a large-scale pig farm pollutant

source separation system and method. The method is to set an inverted splayed slope and an inclined dung cleaning ditch under the slatted floor, and set a scraper in the dung cleaning ditch. The feces system, by regularly cleaning the excrement and urine in the ditch, realizes the separation of feces and urine from the flushing water. The

disadvantage is that the depth of the excrement cleaning structure composed of the inverted splayed slope and the inclined ditch is large, and the strength of the slatted floor bearing beam The requirements are high, resulting in high cost of infrastructure; there may be feces accumulation on the inverted splayed slope, which affects the effect of manure cleaning; feces and urine are mixed together, and solid-liquid separation treatment is required, which greatly reduces the amount of solids separated from solid-liquid, and The

nutrient content is low, the

fertilizer value is reduced, and the patent does not cover the treatment method of manure

Login to View More

Login to View More  Login to View More

Login to View More