Gas-liquid separator with liquid-storing and liquid-discharging functions

A technology of gas-liquid separator and cyclone separator, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low separation efficiency, large volume, and no drainage function, etc., to improve separation efficiency. , the effect of reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

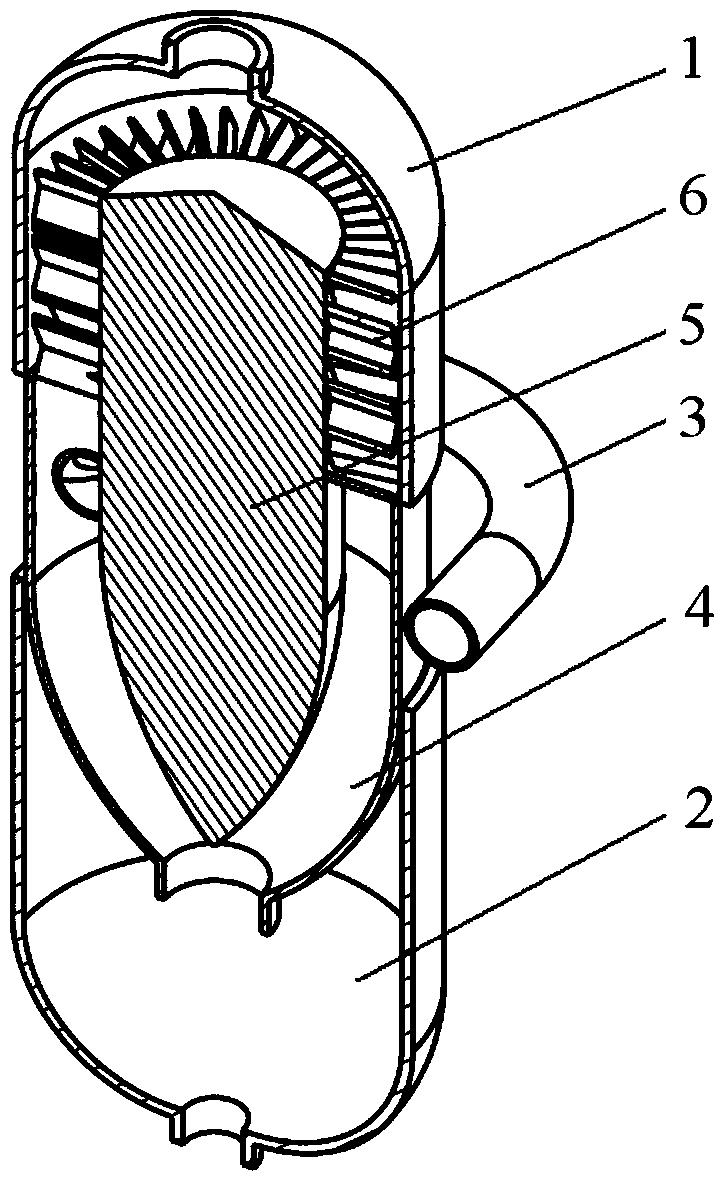

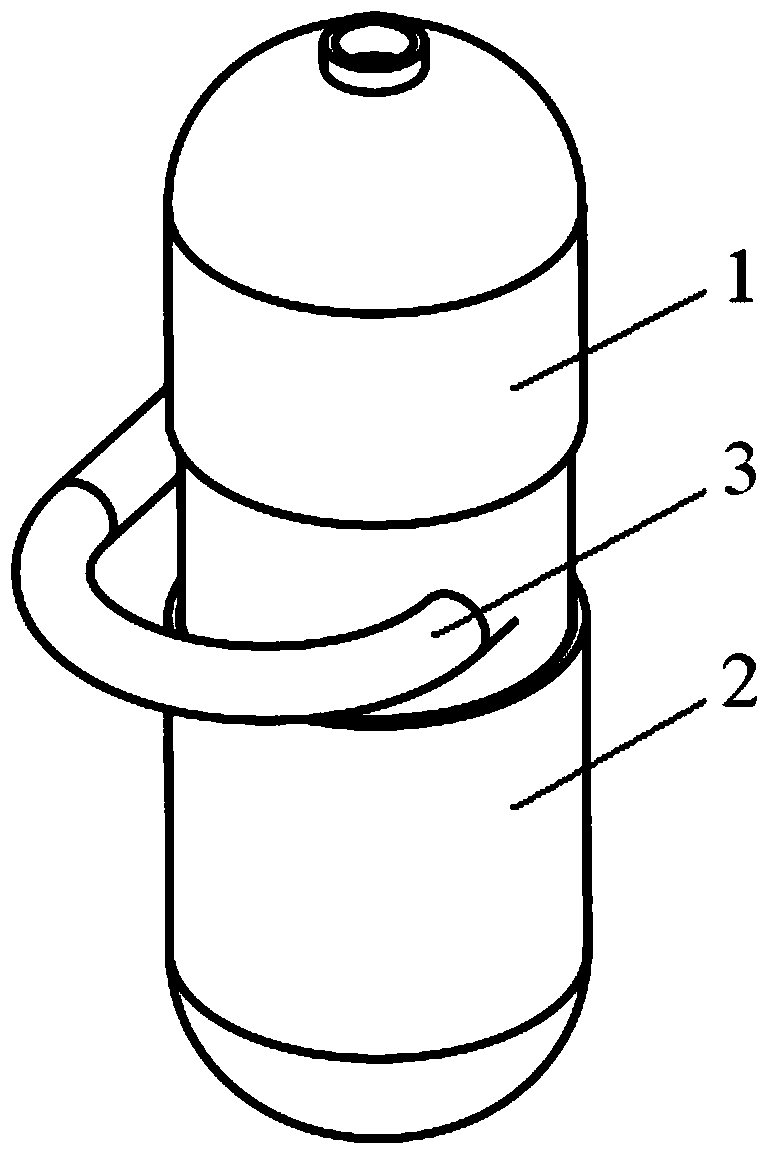

[0025] A gas-liquid separator with liquid storage and liquid discharge functions, its structure is as follows Figure 1-2 As shown, it includes the upper cylinder 1 and the lower cylinder 2 nested, the arc-shaped liquid pipe 3 arranged outside the cylinder, the cyclone separator 4 arranged in the cylinder, the flow-around core 5 and the deflection points. Liquid plate6. The flow-around core 5 is arranged inside the cyclone separator 4 , an annular space is formed between the cyclone separator 4 and the flow-around core 5 , and the baffle and separator plate 6 is sleeved on the outside of the flow-around core 5 .

[0026] A gas outlet is provided at the top of the upper cylinder 1, and a liquid outlet is provided at the bottom of the lower cylinder 2. The upper part of the cyclone separator 4 is a cylindrical cylinder, the lower part is an arc-shaped cylinder with a reduced cross-section, and the bottom has an opening. The arc-shaped liquid distribution pipe 3 is connected to ...

Embodiment 2

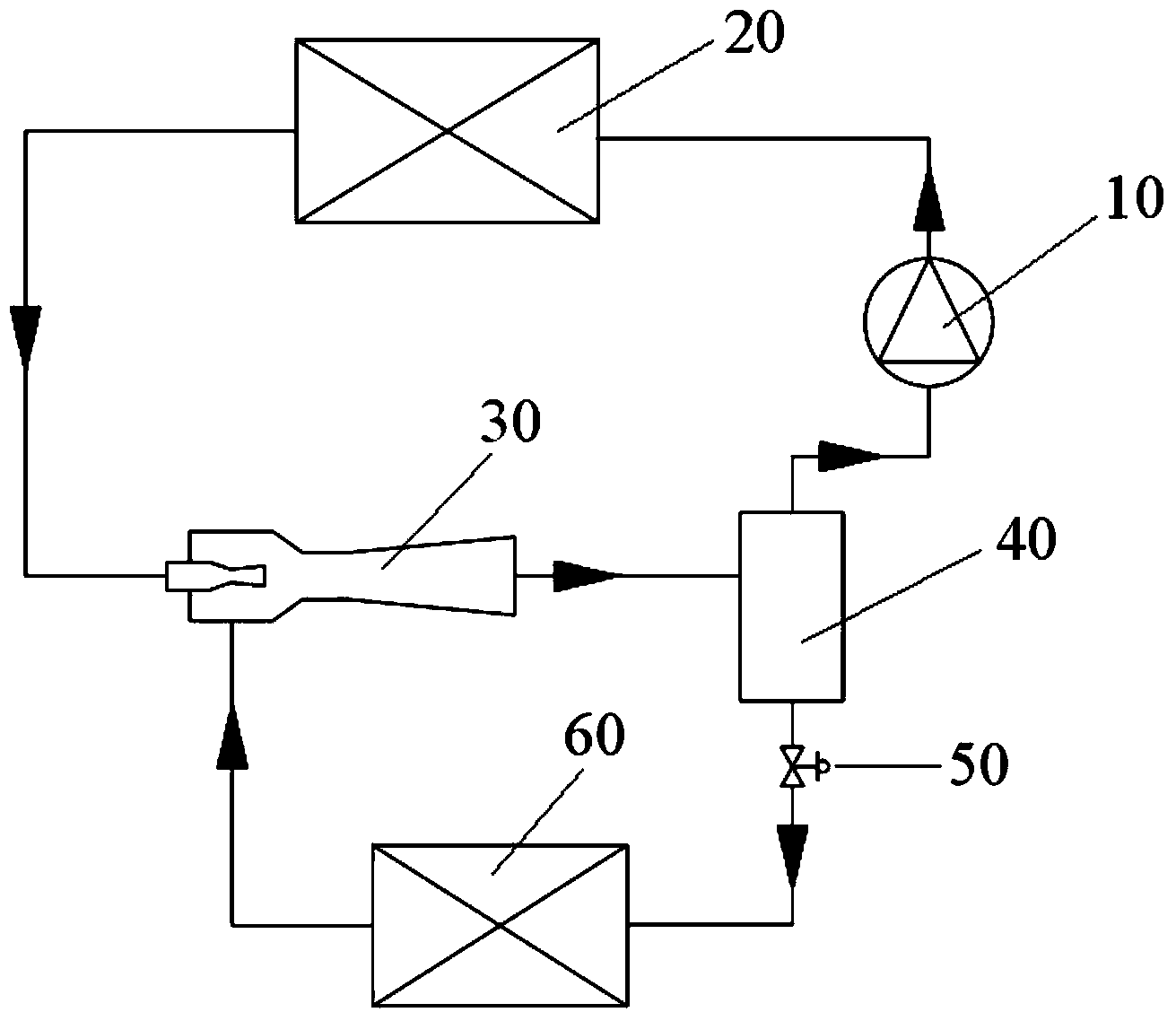

[0029] Ejector system with gas-liquid separator

[0030] The structure of the present invention applied in the injector system is as image 3 As shown, this embodiment is a refrigeration system with an ejector, which is composed of a compressor 10 , a condenser 20 , a gas-liquid separator 40 , an ejector 30 , a throttle valve 50 and an evaporator 60 . The connection relationship between the components: the outlet of the compressor 10 is connected to the inlet of the condenser 20, and then the outlet of the condenser 20 is connected to the inlet of the ejector 30, the outlet of the ejector 30 is connected to the inlet of the gas-liquid separator 40, and the evaporator 60 The inlet is connected to the liquid phase outlet of the gas-liquid separator 40, the outlet of the evaporator 60 is connected to the injection port of the ejector 30, and the gas phase outlet of the gas-liquid separator 40 is connected to the suction port of the compressor 10 to form a complete cycle.

[0031...

Embodiment 3

[0033] Refrigeration system with evaporator inlet gas bypass

[0034] The structure in the application gas bypass refrigeration system of the present invention is as Figure 4 As shown, the refrigeration system with the gas bypass function before the evaporator in this embodiment is composed of a compressor 10 , a condenser 20 , an expansion valve 70 , a gas-liquid separator 40 , an evaporator 60 and a regulating valve 80 . The connection relationship between the components: the outlet of the compressor 10 is connected to the inlet of the condenser 20, and then the outlet of the condenser 20 is connected to the inlet of the expansion valve 70, and the outlet of the expansion valve 70 is connected to the inlet of the gas-liquid separator 40, and the gas-liquid separator The liquid phase outlet of 40 is connected with the inlet of the evaporator 60, and the outlet of the evaporator 60 is mixed with the gas at the gas phase outlet of the gas-liquid separator 40, and then connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com