Patents

Literature

36results about How to "Achieve multi-stage separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial adjustable grading steady-flow swirler

InactiveCN105709944AImprove sorting efficiencyAdjustable sizeReversed direction vortexGas cylinderEngineering

The present invention discloses an industrial adjustable grading steady-flow swirler which comprises a stable slurry tank, an outer cylinder, an inner cylinder and an adjustment inner cylinder, the side wall of the outer cylinder is provided with a first feed pipe and a second feed pipe, the inner cylinder is provided with a second discharge pipe and a third discharge pipe, the inner tube of the outer cylinder is provided with a central tube, the central tube passes through the top of the outer cylinder and is connected with a first discharge pipe, the feed pipes and the discharge pipes are provided with regulation valves, a regulating inner cylinder is actively arranged in the inner cylinder, a gas cylinder is arranged between a sealing plate on the top of the regulating inner cylinder and the top of the outer cylinder, an outer flow-disturbing belt is arranged between the inner cylinder and the central tube, a lower conical cylinder of the outer cylinder is provided with a bottom flow opening, and the lower end of the interior of the outer cylinder is provided with symmetrical mesh-shaped baffles. The industrial adjustable grading steady-flow swirler is reasonable in structure, high in separation efficiency, and good in separation effect, separation of two or three different-density products can be achieved, working efficiency is high, device multi-stage separation can be achieved, equipment cost is reduced, and the industrial adjustable grading steady-flow swirler is energy-saving and efficient.

Owner:GUIZHOU JIQIAN NETWORK CO LTD

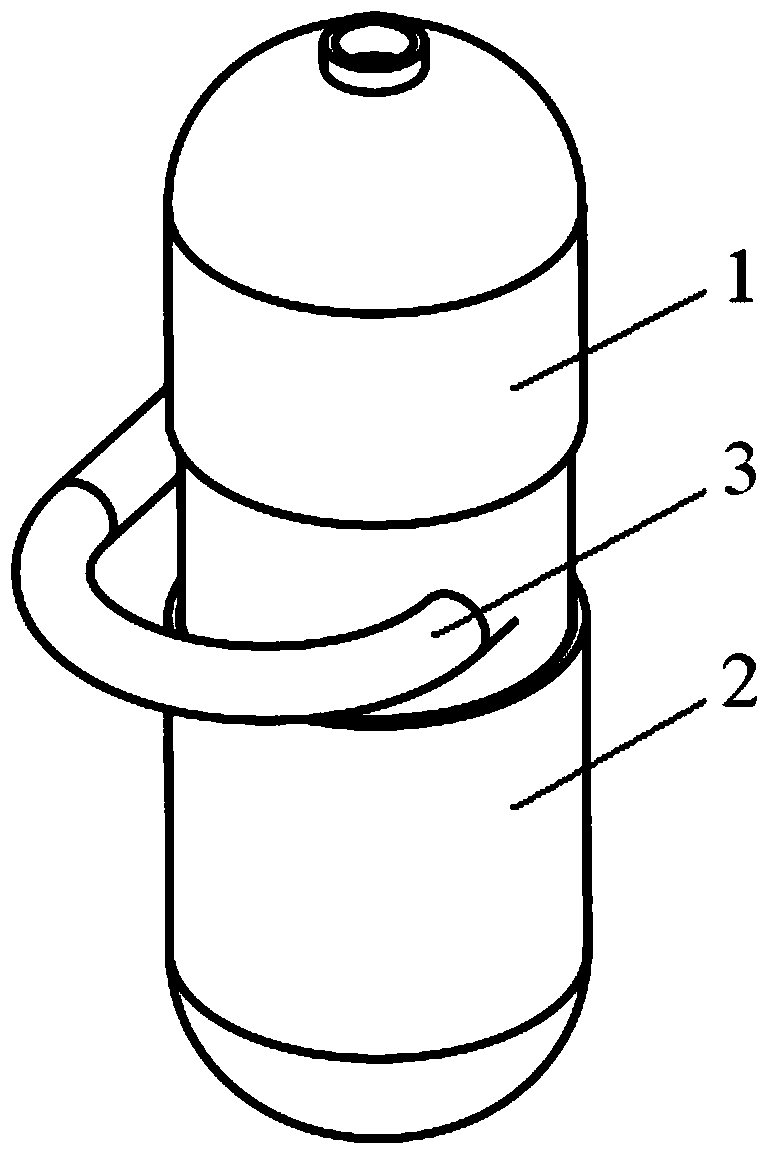

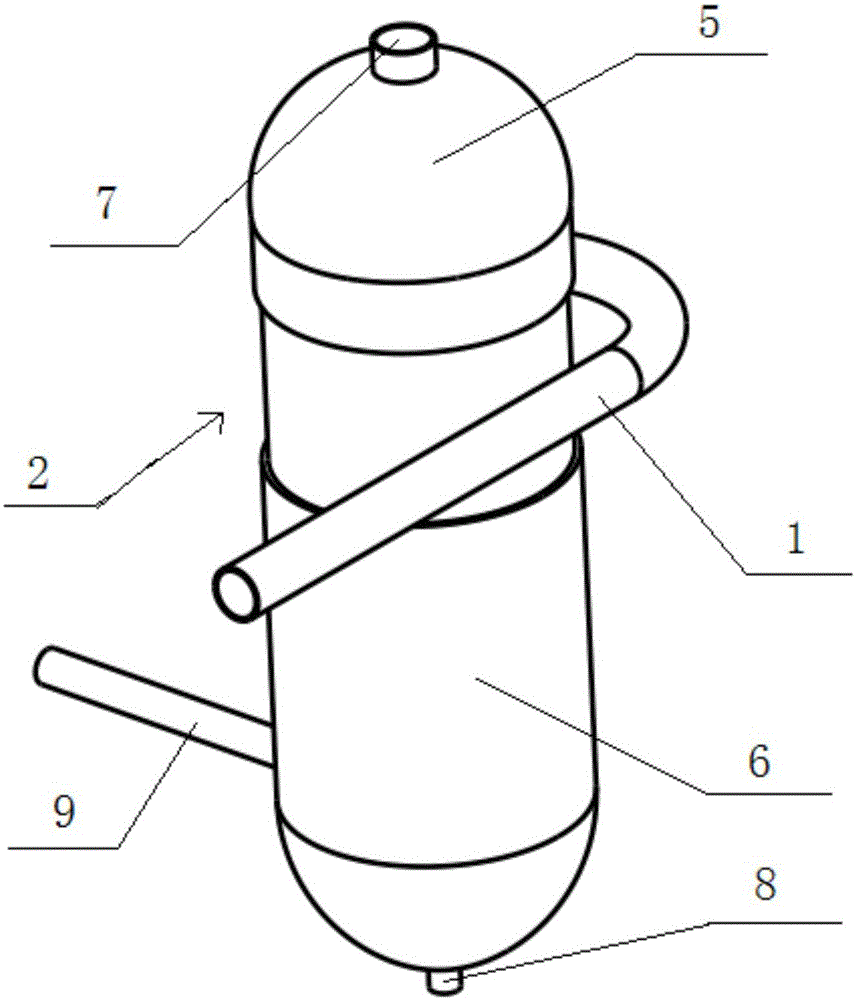

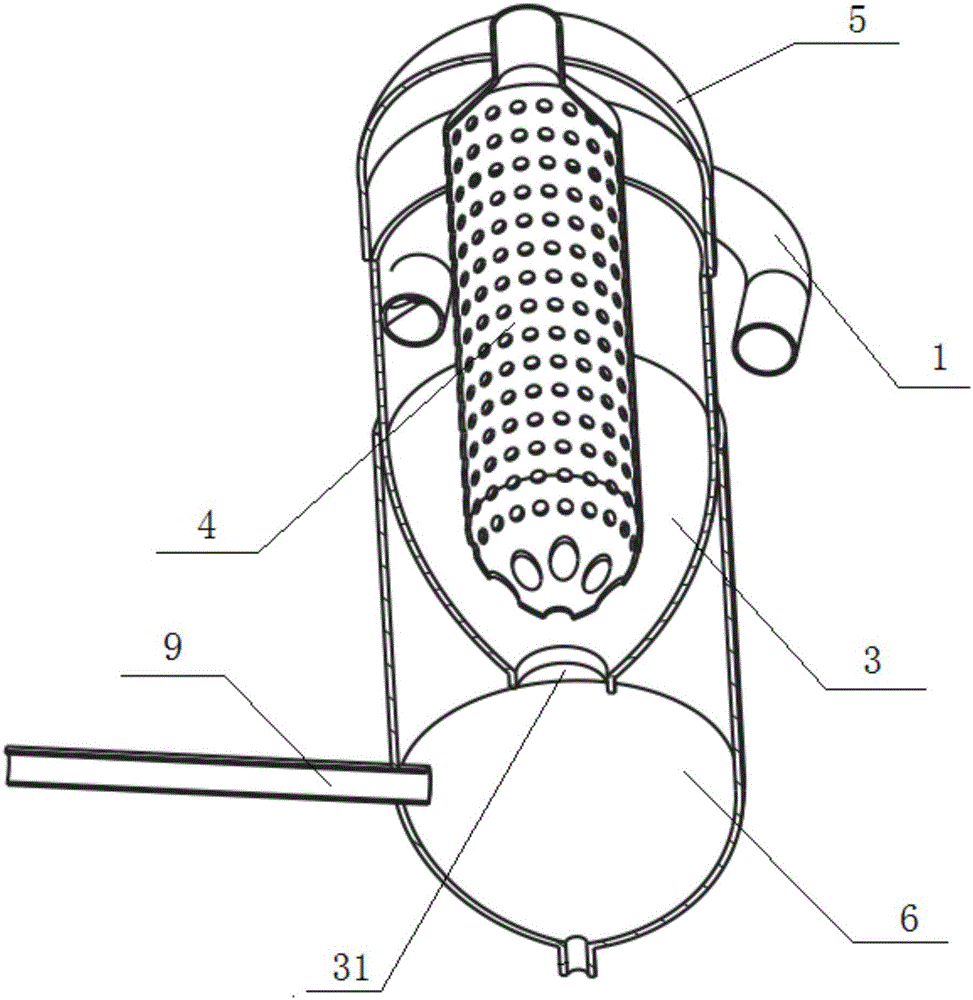

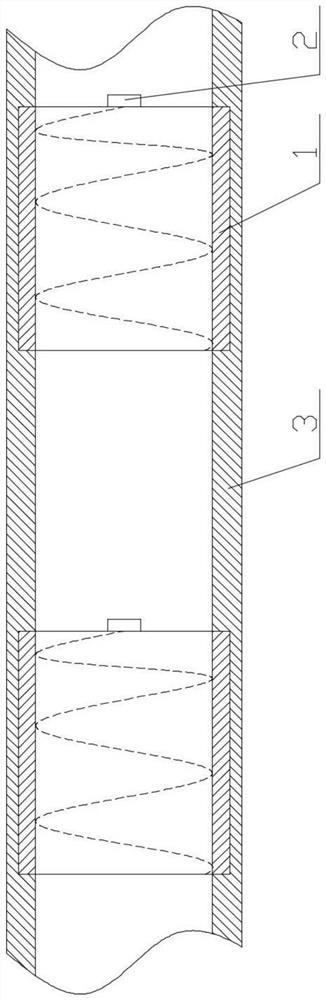

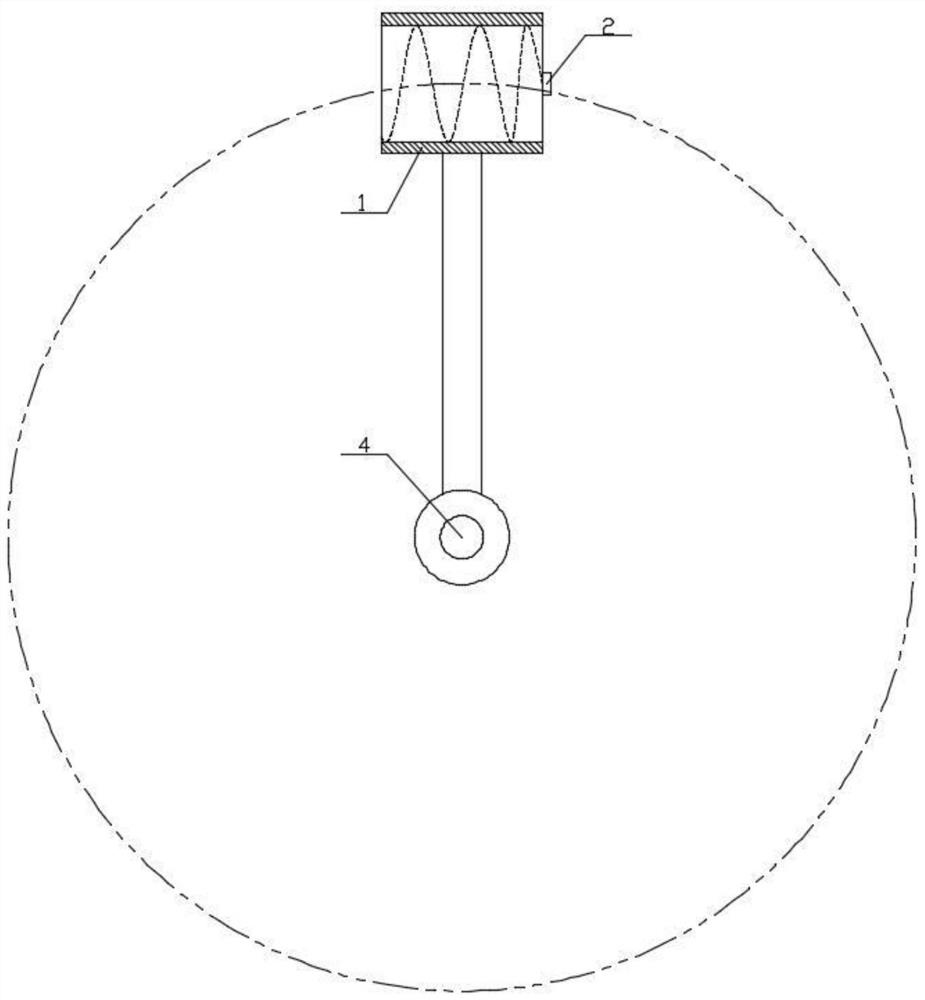

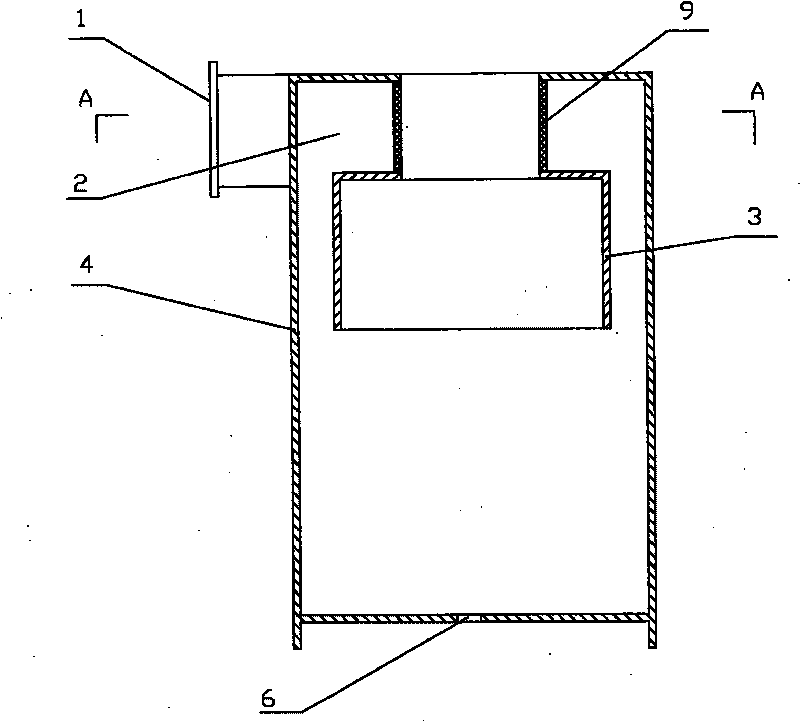

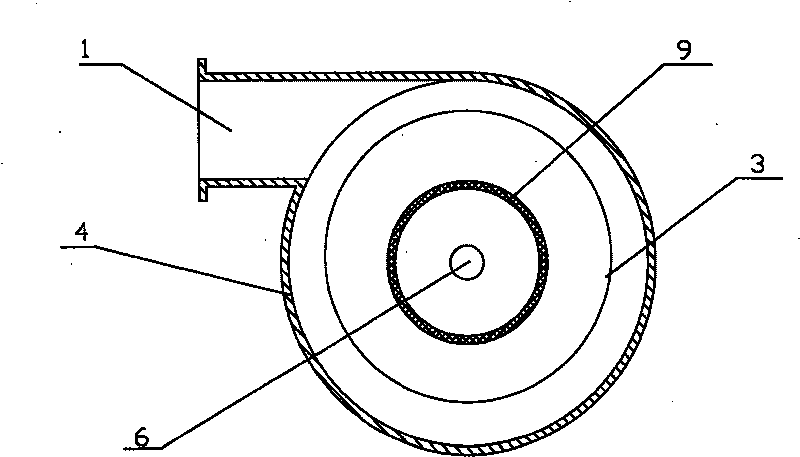

Gas-liquid separator with liquid-storing and liquid-discharging functions

ActiveCN103638749AReduce volumeAchieve multi-stage separationDispersed particle separationVapor–liquid separatorEngineering

The invention relates to a gas-liquid separator with liquid-storing and liquid-discharging functions. The gas-liquid separator comprises a barrel, an arc-shaped liquid-separating pipe outside the barrel, and a cyclone separator, a streaming core body and a baffling liquid-separating plate which are arranged in the barrel, wherein the arc-shaped liquid-separating pipe is communicated with the barrel in a tangential direction of the outer side of the barrel; the streaming core body is arranged in the cyclone separator, an annular space is formed between the cyclone separator and the streaming core body, and the baffling liquid-separating plate is arranged on the outer side of the streaming core body in a sleeved manner. Compared with the prior art, the gas-liquid separator provided by the invention has the advantages that multiple separating manners such as the centrifugal force, the gravity and the surface tension are utilized in a comprehensive way, so that the multi-level separation of gas-liquid two-phase stream is realized, the separation efficiency is remarkably improved, and the size of the gas-liquid separator is reduced.

Owner:SHANGHAI JIAO TONG UNIV

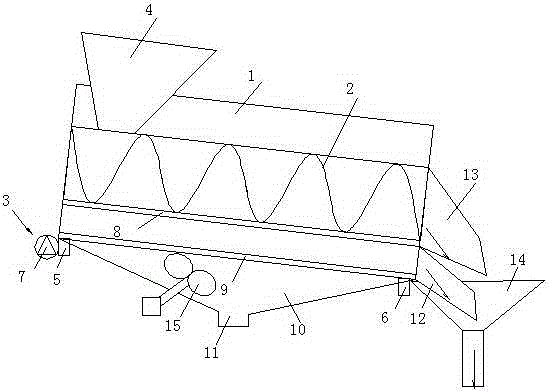

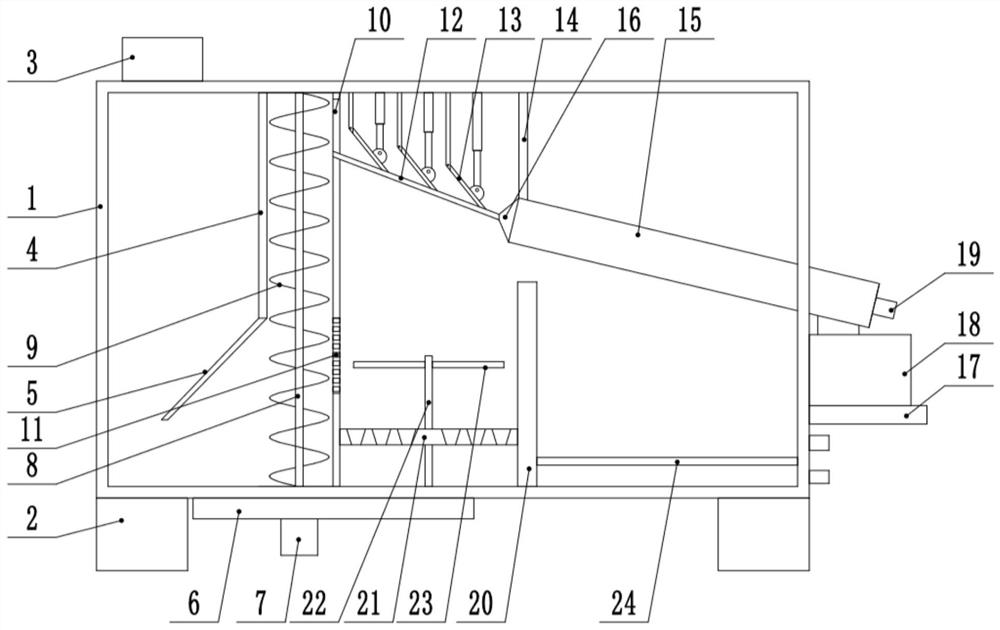

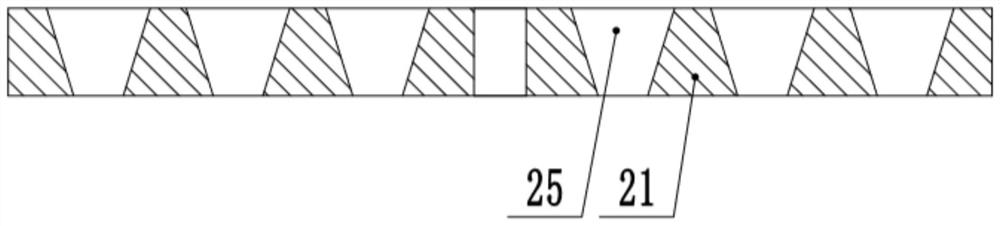

Solid-liquid fast separation device

InactiveCN105169797ASimple structureImprove separation efficiencyFiltration circuitsDrive motorEngineering

The invention relates to a solid-liquid fast separation device, which comprises a cylindrical barrel, a helical blade arranged in the barrel and a transmission device disposed outside the barrel. The upper end of the barrel is provided with a feeding hopper, the transmission device comprises a driving wheel and a driven wheel arranged at both ends of the barrel, the driving wheel is in transmission connection with a drive motor through a belt, a first stage separation plate and a second stage separation plate are disposed at an interval under the helical blade of the barrel, the first stage separation plate and the second stage separation plate are woven from a stainless steel screen, the aperture of the first stage separation plate is 30-50mm, and the aperture of the second stage separation plate is 10-25mm, a conical water collecting hopper is arranged below the second stage separation plate, the end of the water collecting hopper is provided with a water outlet, a fine sand outlet is arranged at the barrel end and between the first stage separation plate and a second stage separation plate, and the helical blade end is provided with a coarse material outlet. With a simple structure, the solid-liquid fast separation device realizes multistage separation, the separation efficiency is high, and the service life is long.

Owner:JIANGSU PENINSULA ENVIRONMENTAL ENG

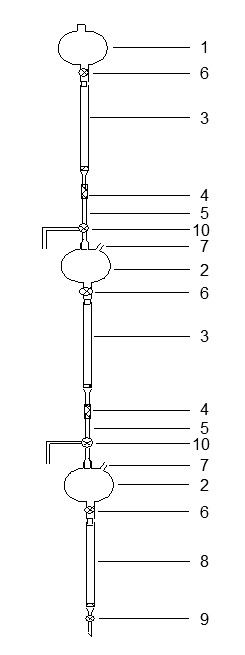

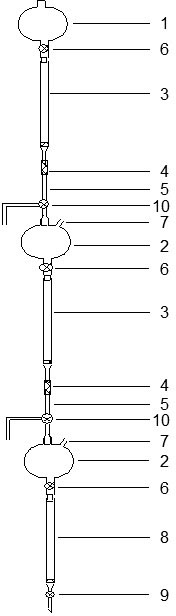

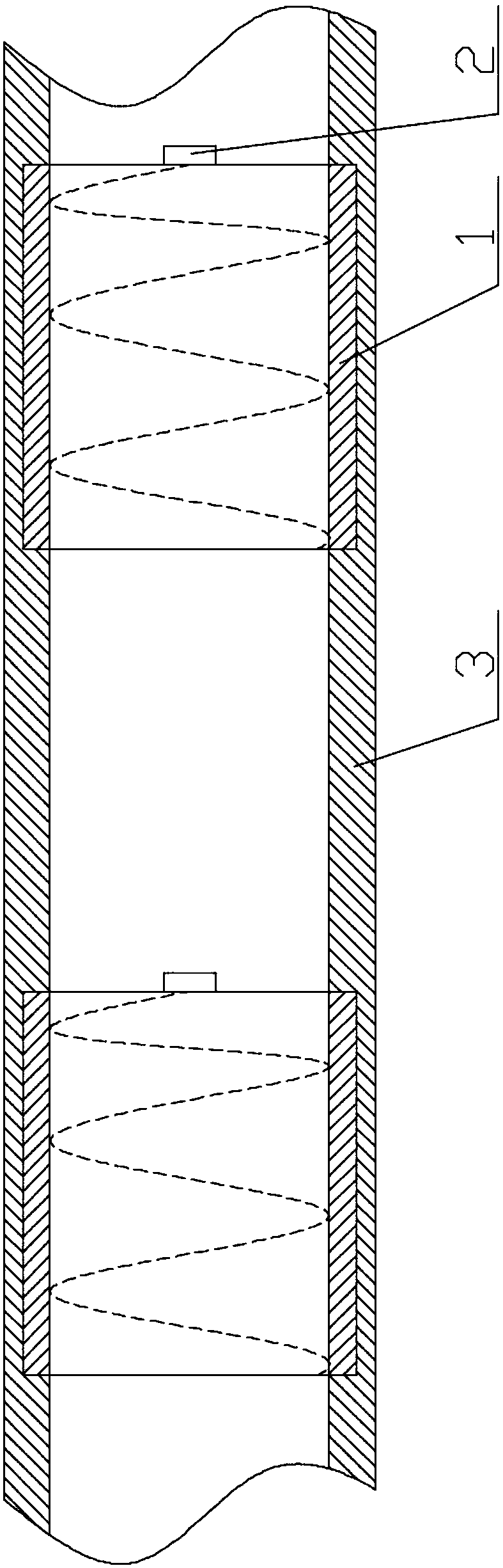

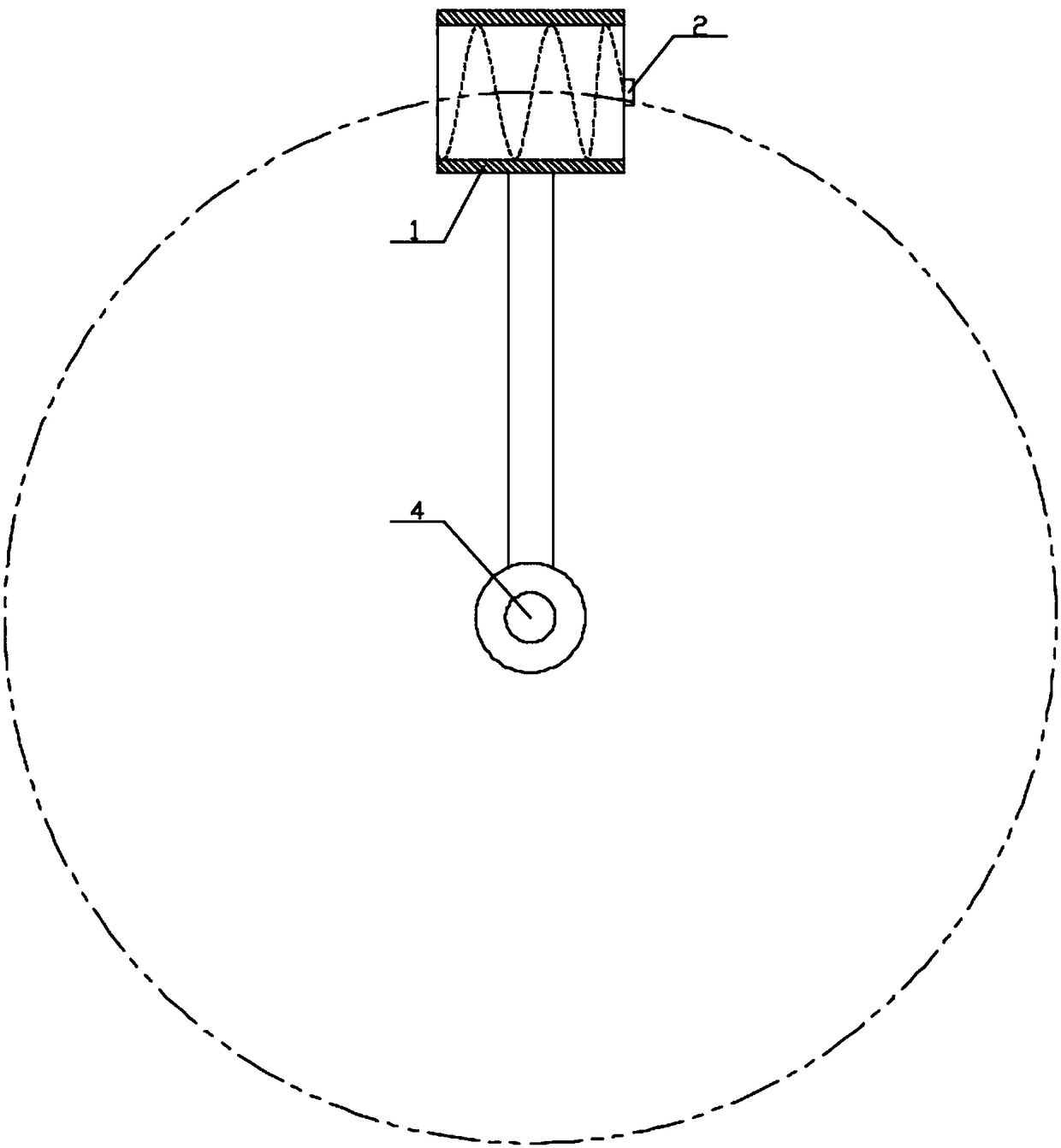

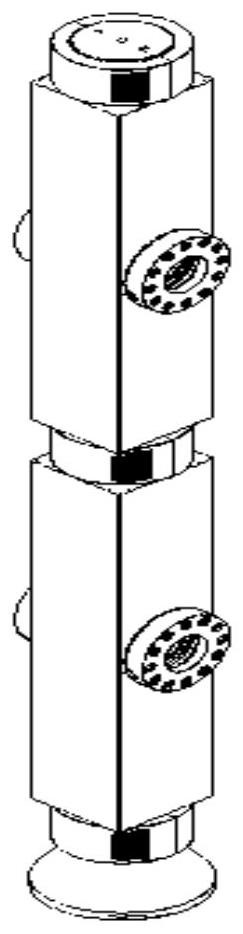

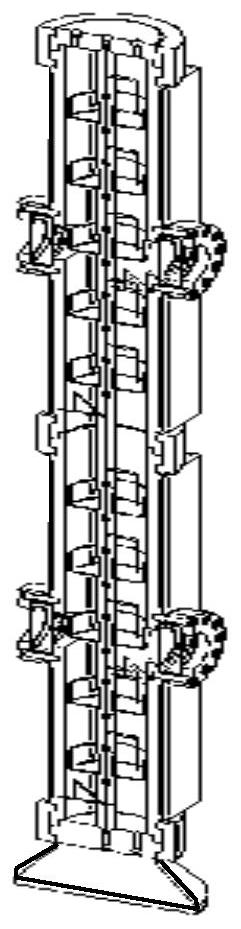

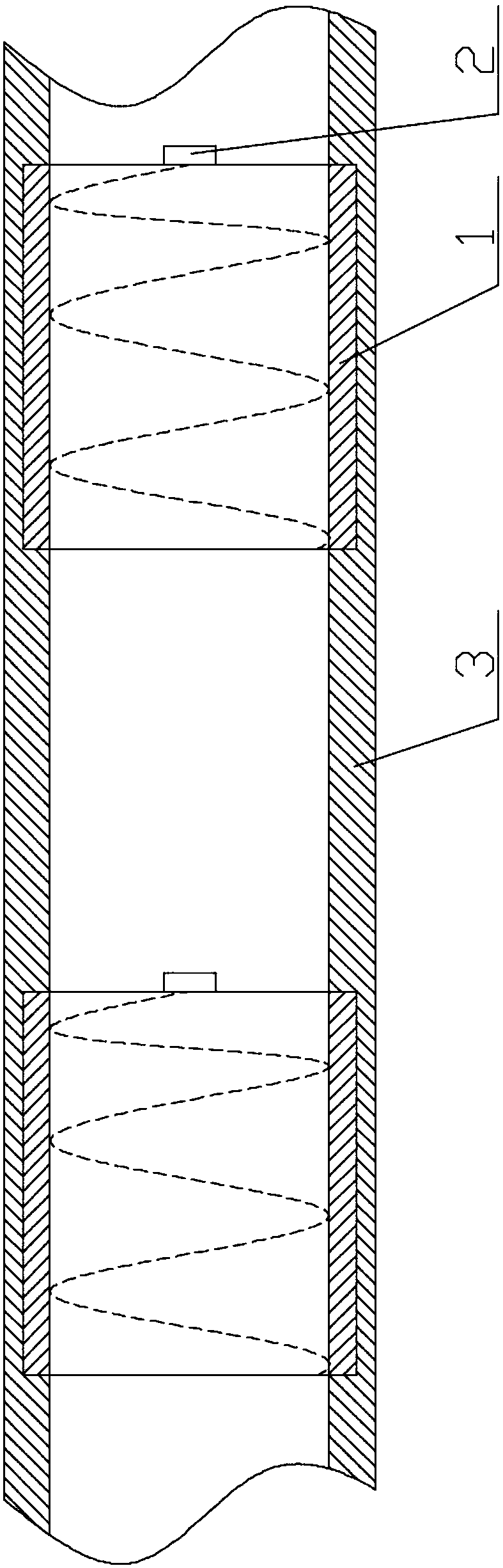

Multi-segment chromatographic column

InactiveCN102527089ALower the liquid levelReduce volumeSolid sorbent liquid separationEngineeringMulti segment

A multi-segment chromatographic column comprises a main liquid storage bottle and a plurality of auxiliary liquid storage bottles connected the main liquid storage bottle. The bottoms of the main liquid storage bottle and the plurality of auxiliary liquid storage bottles are all provided with throttling valves. Packing columns are arranged between the main liquid storage bottle and the auxiliary liquid storage bottles and among the auxiliary liquid storage bottles. T-shaped three-way tubes are arranged below the packing columns, each t-shaped three-way tube is provided with a three-way valve, each auxiliary liquid storage bottle is provided with a dissolvent filling port, a tail-segment packing column is arranged below the last auxiliary liquid storage bottle, and a valve is arranged at the lower end of the tail-segment packing column. According to actual needs, the quantity of the packing columns, packing, and packing of the ail-segment packing column can be changed flexibly, multi-stage separation of a complex mixture can be achieved, the packing columns have separation functions, the liquid storage bottles can bring convenience to addition of eluent, and the eluent does not need to be added manually and constantly. The multi-segment chromatographic column is simple in structure, convenient in use and good in effect.

Owner:CHINA UNIV OF MINING & TECH

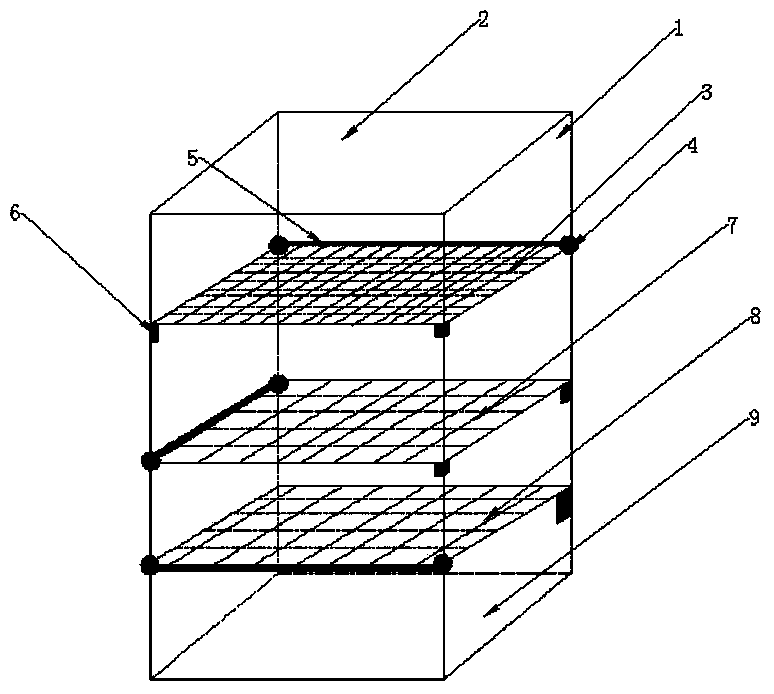

Novel combined filtering unit

InactiveCN103433195AHigh strength wear resistanceReferred to separation efficiencySievingScreeningEngineeringWear resistance

The invention relates to a novel combined filtering unit which comprises a square barrel, a feeding port, a top-layer filter screen, a middle-layer filter screen, a bottom-layer filter screen, rotating shafts, supporting pieces and a discharge port. The square barrel is made of stainless steel materials and used for providing a mineral filtering channel; the feeding port is located in the upper portion of the square barrel, and minerals can enter the barrel from the feeding port; the top-layer filter screen, the middle-layer filter screen and the bottom-layer filter screen are located at the upper end, middle end and lower end of the barrel respectively, one side of the top-layer filter screen, one side of the middle-layer filter screen and one side of the bottom-layer filter screen are linked to the rotating shafts on the wall face of the rectangular filtering unit, the other side of the top-layer filter screen, the other side of the middle-layer filter screen and the other side of the bottom-layer filter screen are supported through the supporting pieces, and all the filter screens are located on the horizontal direction; the rotating shafts are fixedly arranged on the wall face of the square barrel and serve as movable rotating shafts of the filter screens; the discharge port is located in the bottom of the square barrel, and materials are discharged from the discharge port. A plurality of filter screens with different meshes are arranged in the novel combined filtering unit, the minerals can be separated in a multi-grade mode in the different filter screens, and the novel combined filtering unit has the advantages of being high in abrasive resistance, good in adjustment performance, simple in structure, and convenient to manufacture.

Owner:天津聚贤达科技有限公司

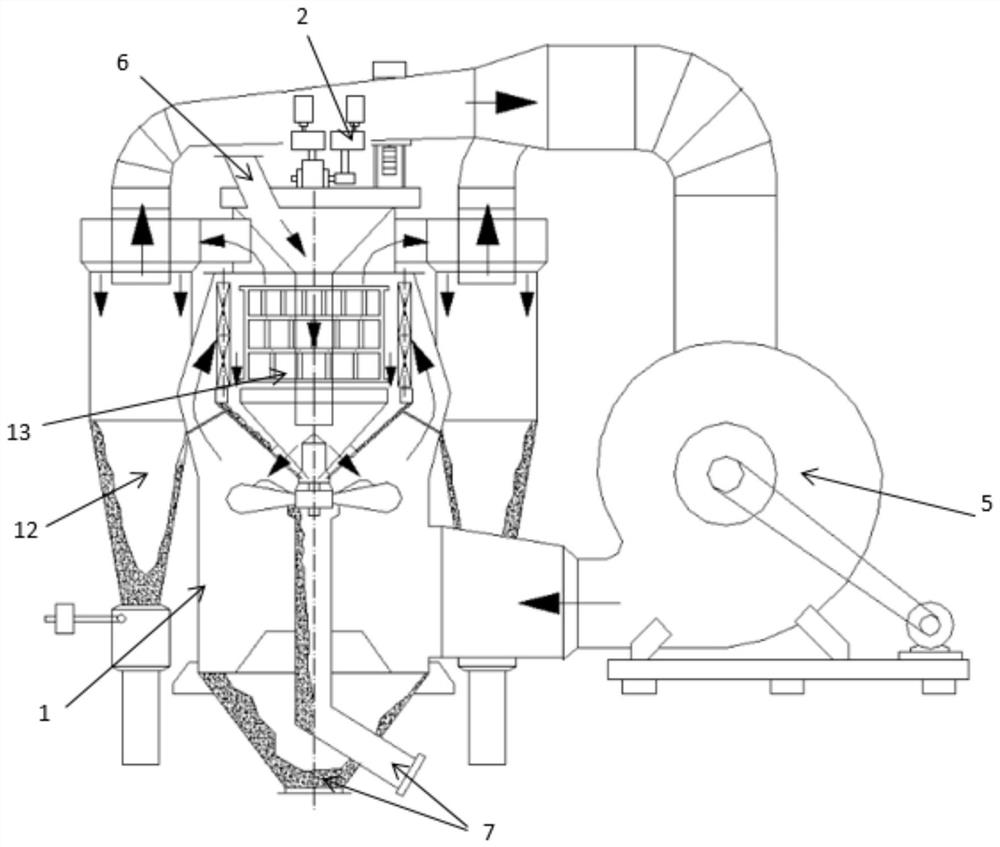

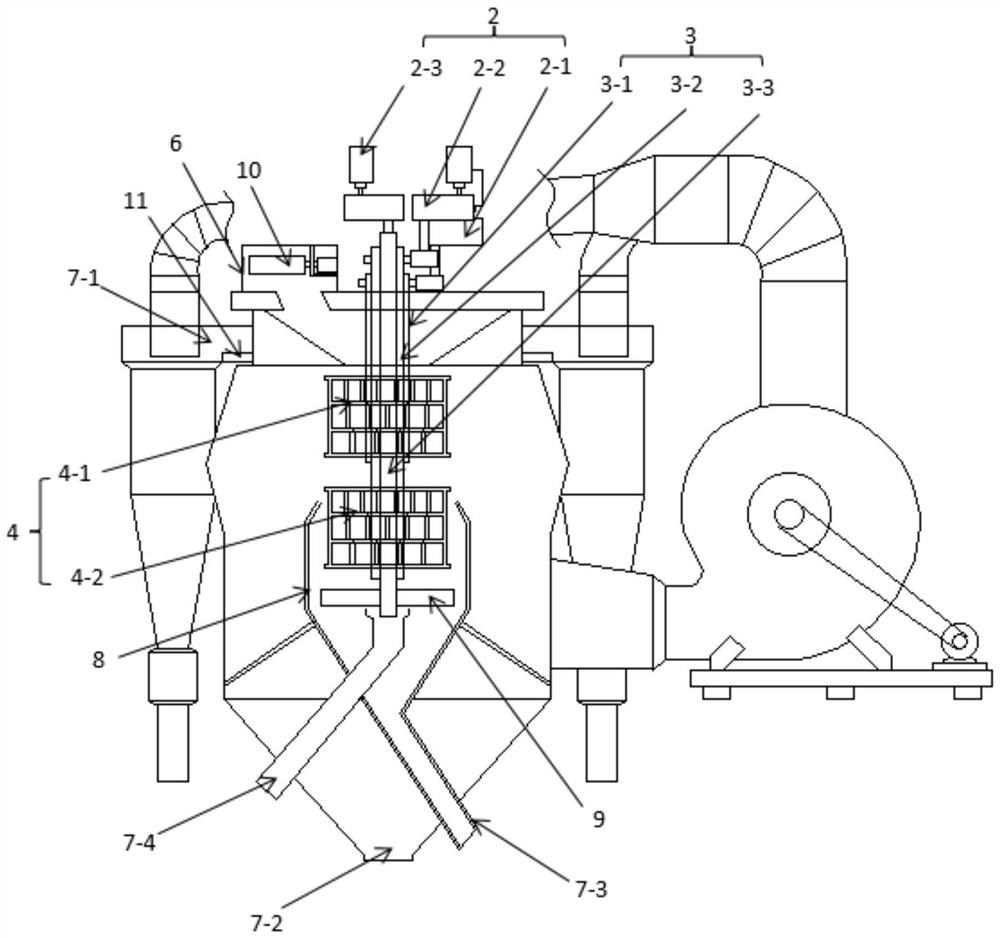

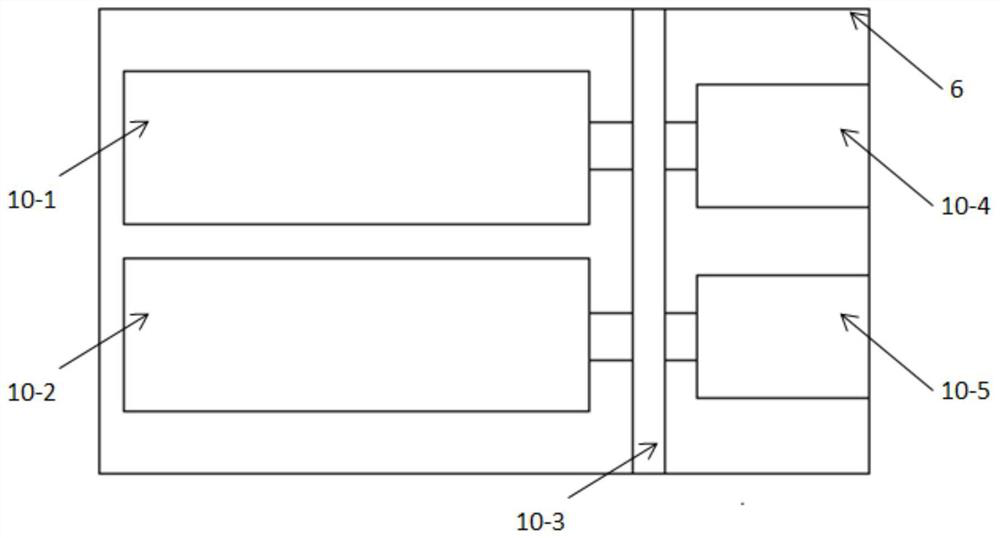

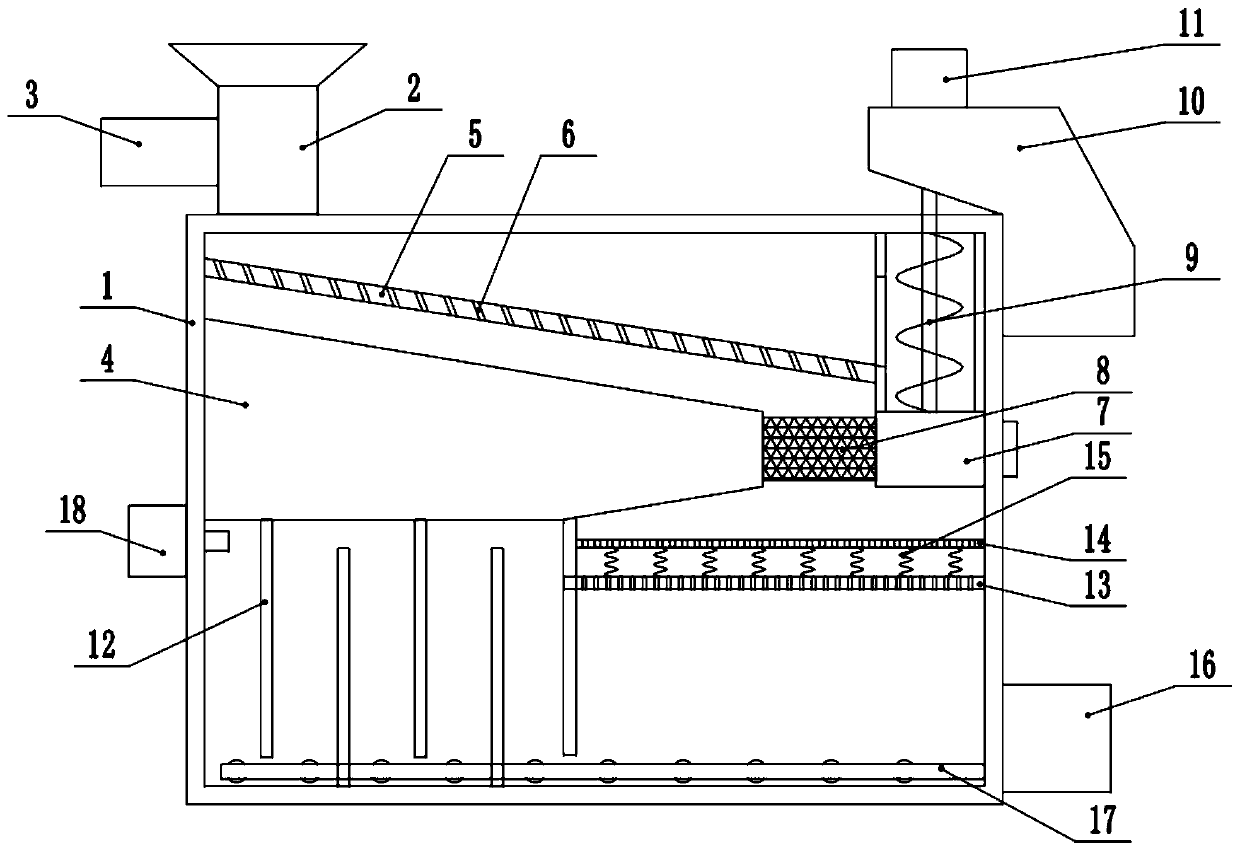

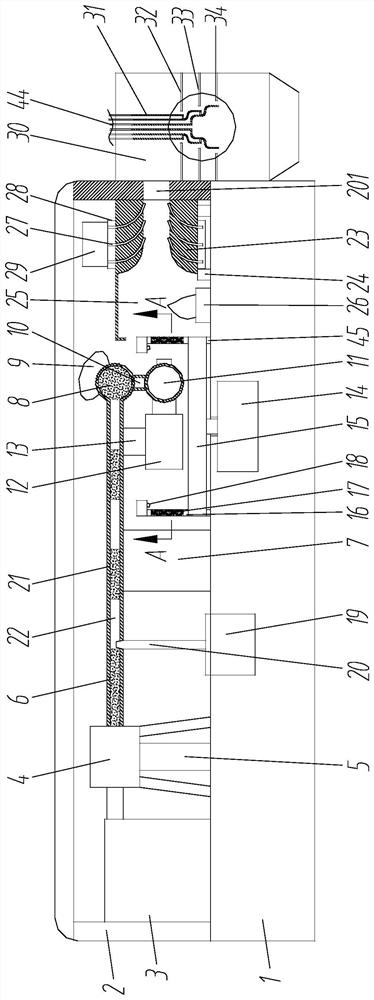

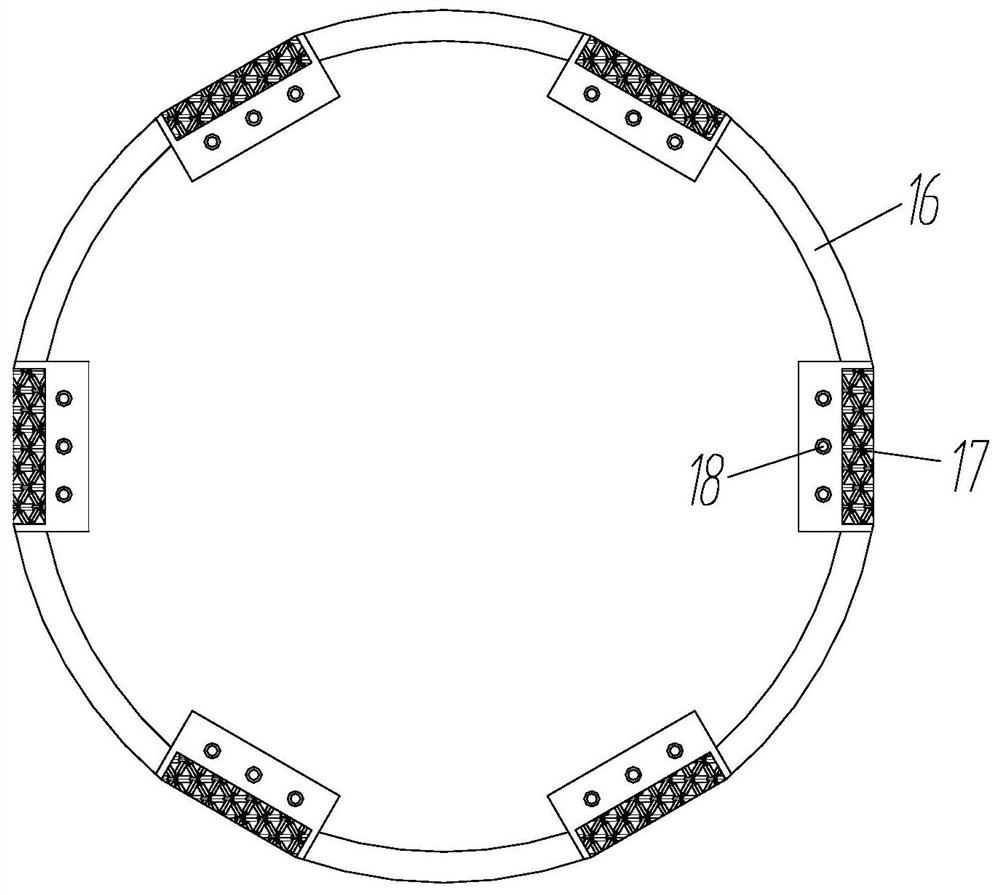

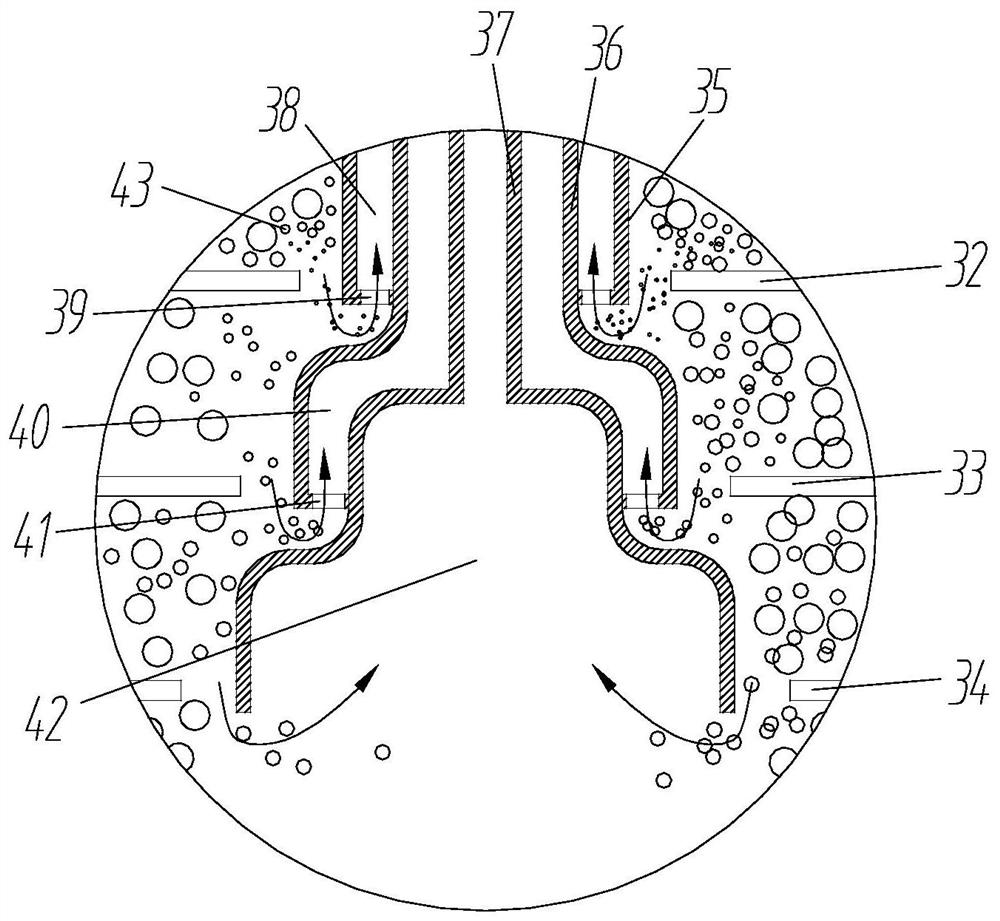

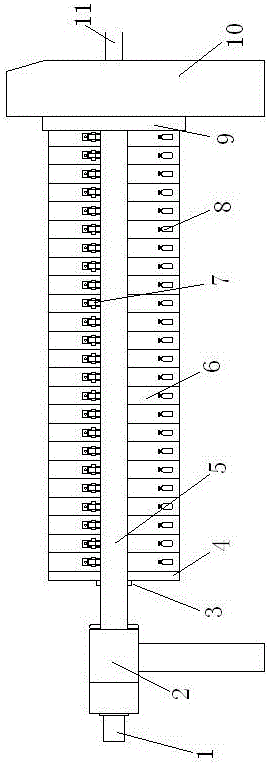

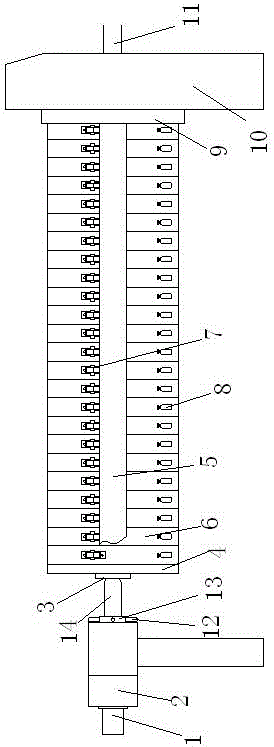

Multi-shaft, multi-rotor and multi-separation combined powder concentrator

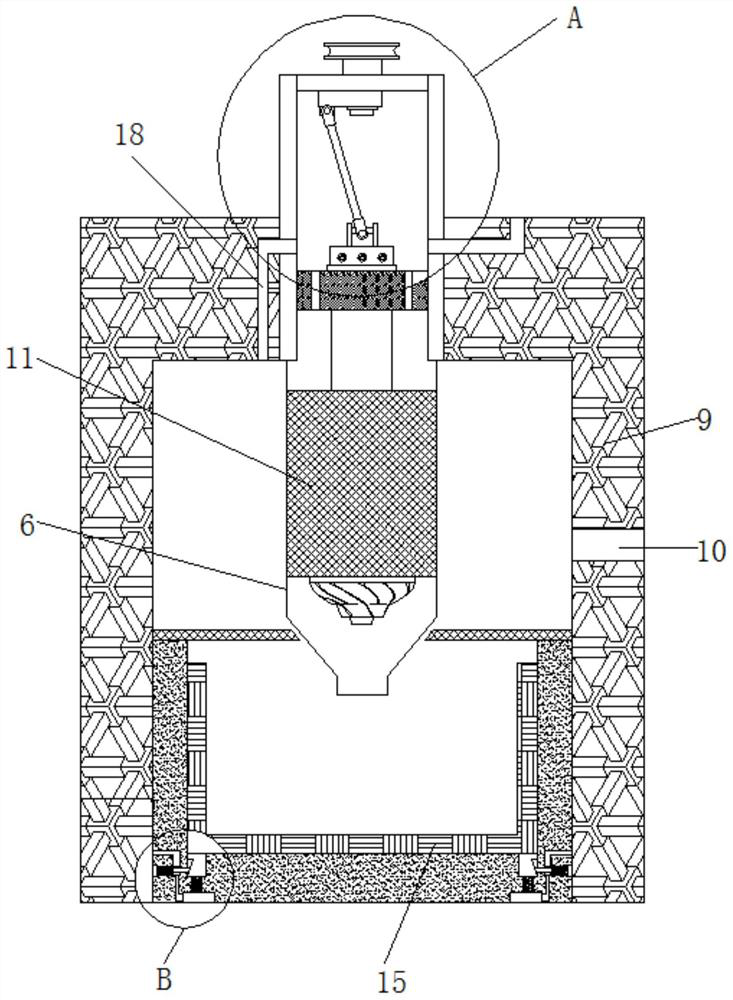

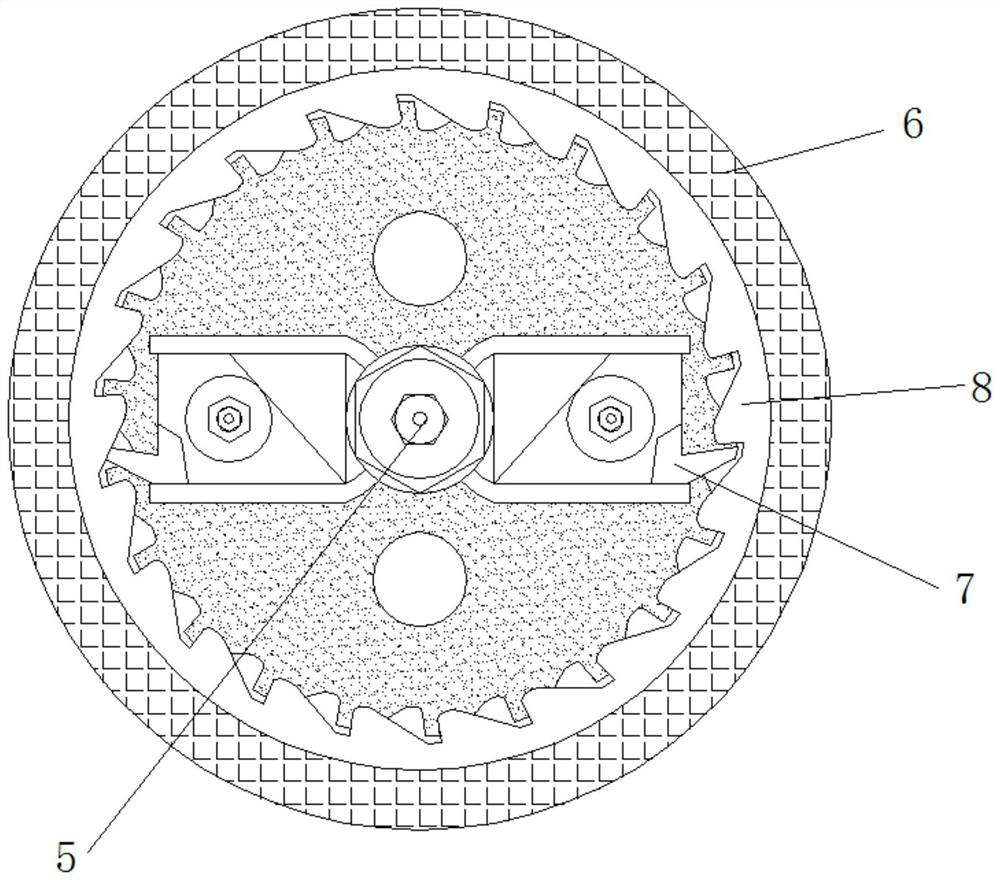

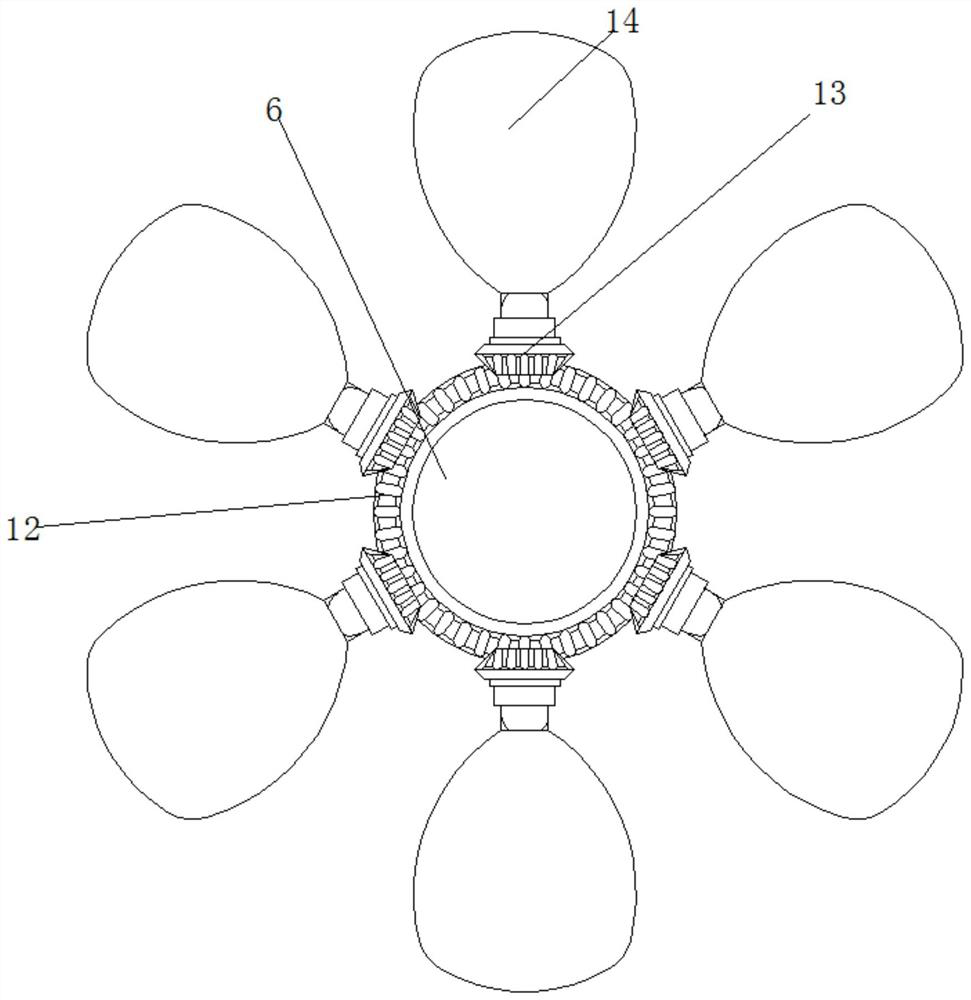

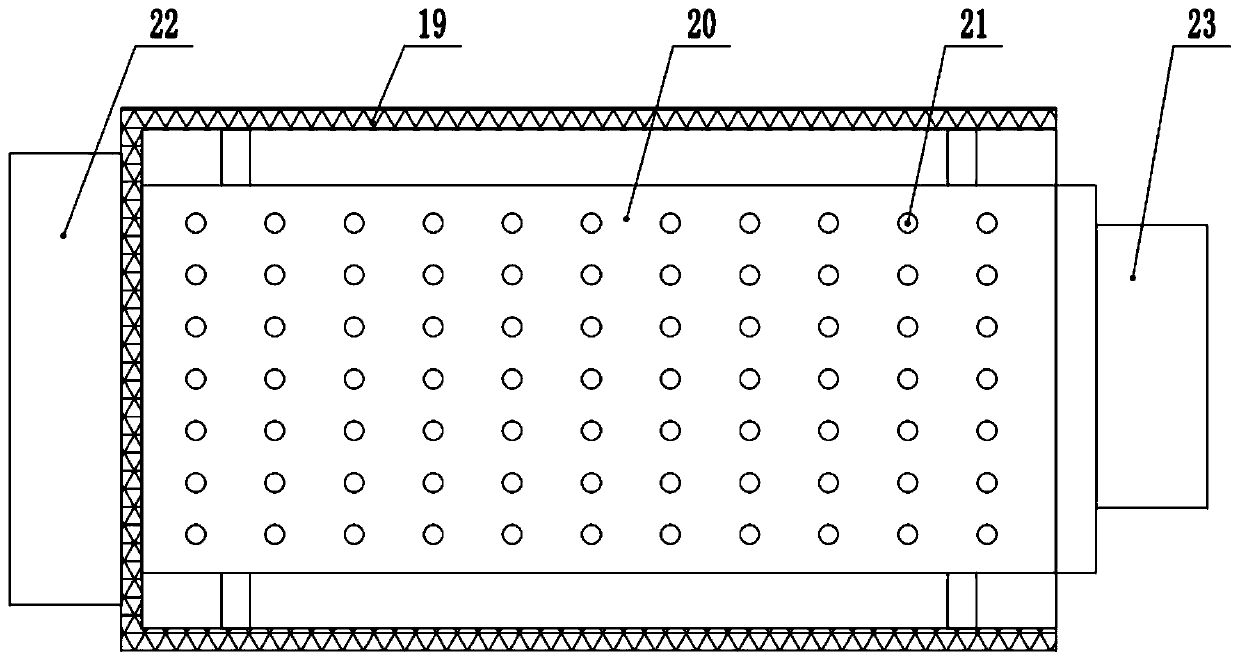

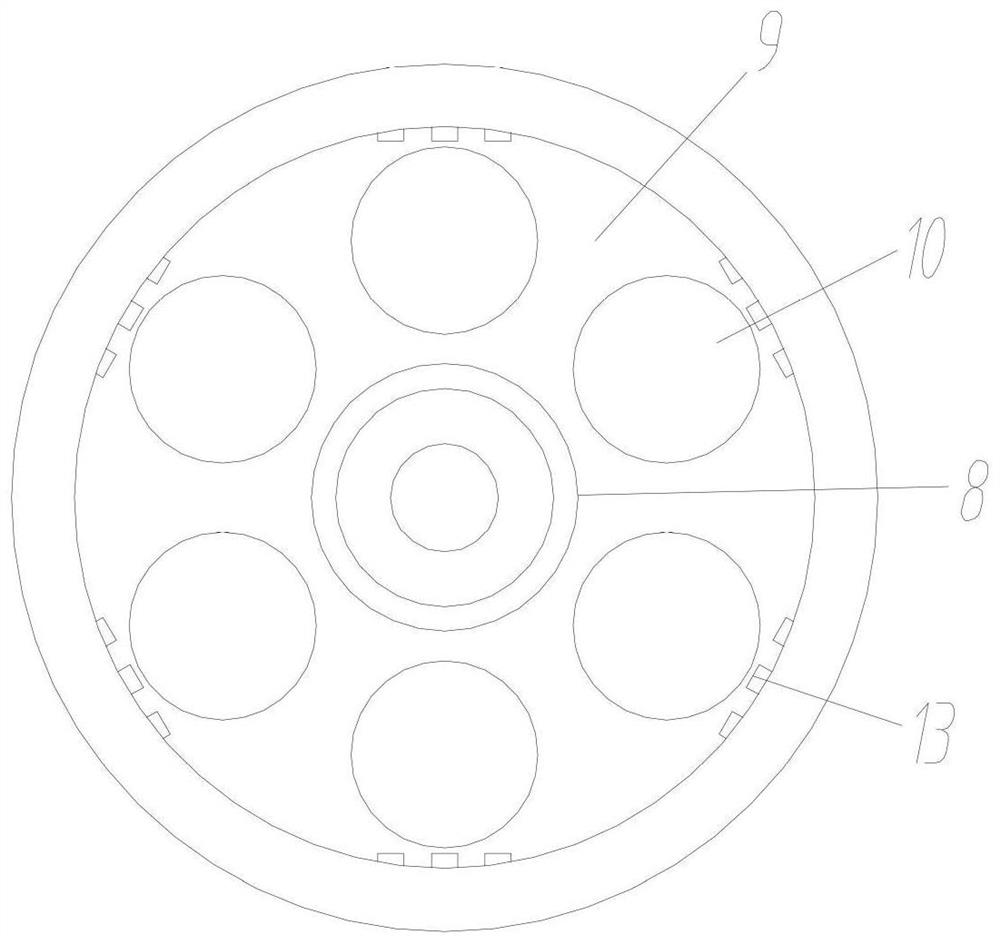

ActiveCN112090761AAchieve multi-stage separationImprove separation efficiencyGas current separationGradingEngineeringMechanical engineering

The invention discloses a multi-shaft, multi-rotor and multi-separation combined powder concentrator. The multi-shaft, multi-rotor and multi-separation combined powder concentrator comprises a shell,a plurality of driving devices, a multi-shaft and multi-rotor mechanism and an air blowing device; the multi-shaft and multi-rotor mechanism is arranged inside the shell, the driving devices are arranged on the upper side of the shell, and the driving devices drive the multi-shaft and multi-rotor mechanism to rotate; and the air blowing device is arranged on one side of the shell, and a feeding port and a plurality of discharging ports are formed in the shell. According to the multi-shaft, multi-rotor and multi-separation combined powder concentrator, a plurality of rotating shafts can be arranged according to actual requirements, each rotating shaft is provided with the driving device, multi-stage separation of materials is achieved according to different rotating speeds of different rotors, the air blowing device provides airflow for the interior of the shell, the separation efficiency of the materials is higher, the plurality of discharging openings correspond to powder of differentlevels one to one and are used for collecting the powder of different levels, and various different levels of powder can be obtained at the same time.

Owner:江苏吉达机械制造有限公司

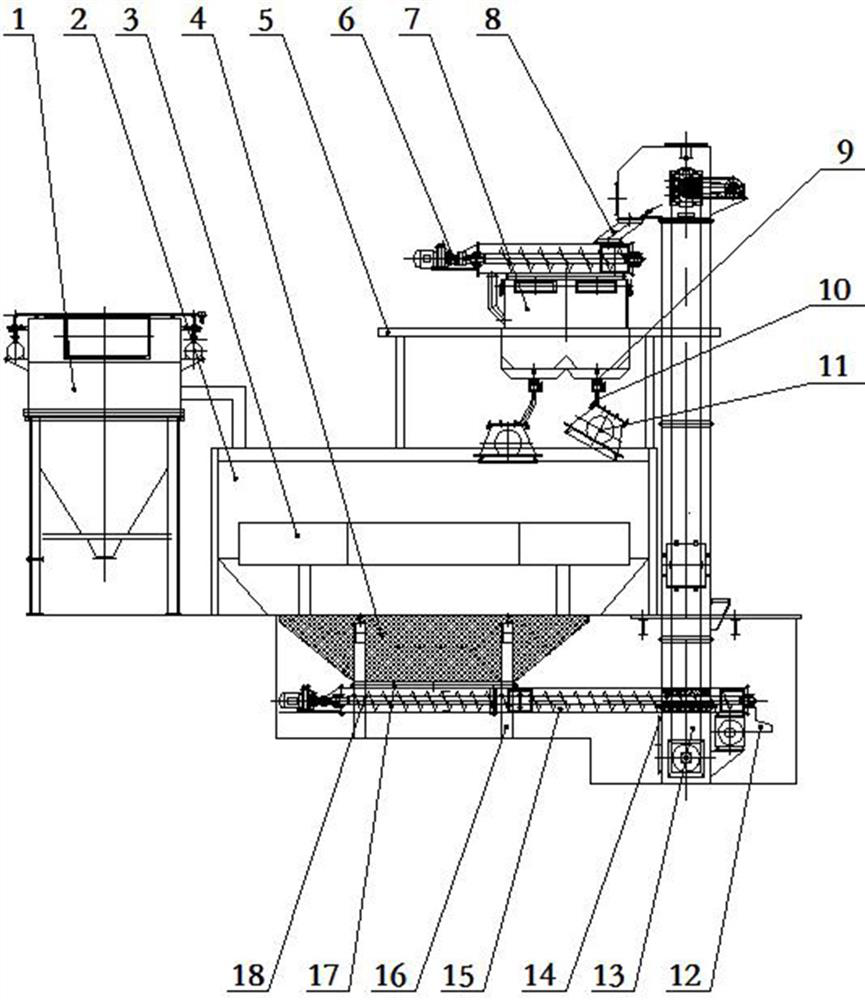

Shot blasting clearing device

ActiveCN113084712APurposefulAchieve multi-stage separationAbrasive feedersAbrasive machine appurtenancesSlagClassical mechanics

The invention discloses a shot blasting clearing device. The shot blasting clearing device comprises a shot blasting chamber, a shot blasting device, a workbench, a spiral conveyer, a material overflowing hopper, an elevator and a shot-slag separator, wherein the hopper wall of a material receiving hopper matching with the shot blasting chamber and used for collecting shot slag is a screen so as to screen the shot slag with the particle size larger than or equal to that of the shot slag, the shot blasting device is installed on the shot blasting chamber, the workbench is installed in the shot blasting chamber, the spiral conveyer is positioned below the shot blasting chamber and is used for receiving the shot slag collected by the material receiving hopper and conveying the shot slag to a given side of the shot blasting chamber; the screen drum is arranged at the tail end of a pipe shell of the spiral conveyor and is used for screening shots and slag materials meeting the shot particle size range; the material overflowing hopper is installed at the tail end of a screen drum so as to guide out residues screened by the screen drum, the elevator is located on the given side of the shot blasting chamber so as to receive the shot slag screened by the screen drum and lift the shot slag to a given height, and the shot-slag separator is used for receiving the shot slag conveyed by the elevator so as to carry out shot-slag separation and conveying the separated shot slag to the shot blasting device. According to the shot blasting clearing device, the structure is relatively compact, so that shots can be effectively recycled.

Owner:SHANDONG KAITAI SHOT BLASTING MACHINERY

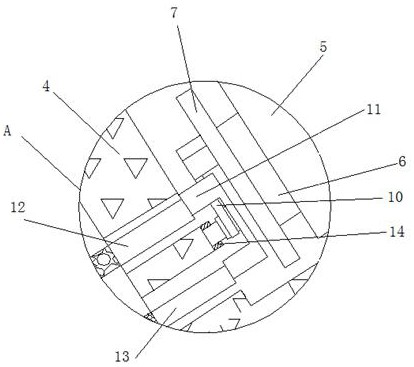

Automobile air conditioner compressor separation device based on turbine

InactiveCN112007460ALow efficiencyDoes not separate poorlyCombination devicesDispersed particle filtrationRatchetAutomobile air conditioning

The invention relates to the technical field of automobile air conditioning equipment. The invention discloses an automobile air conditioner compressor separation device based on a turbine. The devicecomprises a rotating wheel, the outer side of the rotating wheel is rotationally connected with a rotating block, one end of the rotating block is rotationally connected with a first connecting rod,the outer side of the rotating wheel is rotationally connected with a first shell, the bottom end of the first connecting rod is movably connected with a rotating shaft, the outer side of the rotatingshaft is rotationally connected with a connecting piece, the outer side of the rotating shaft is rotationally connected with a pawl, the outer side of the pawl is movably connected with ratchets, andthe outer side of the connecting piece is rotationally connected with second shell. According to the automobile air conditioner compressor separation device based on a turbine, by means of connectionof the rotating wheel and the connecting piece, multi-stage separation is achieved, the problem that an existing oil-gas separator is low in efficiency is solved, the use effect is good, when separated oil drops are attached to the inner wall of the device, the separation effect is not poor, blockage is not likely to be caused, practicability is high, the separation efficiency is high, and reliability is high.

Owner:杭州宣阳科技有限公司

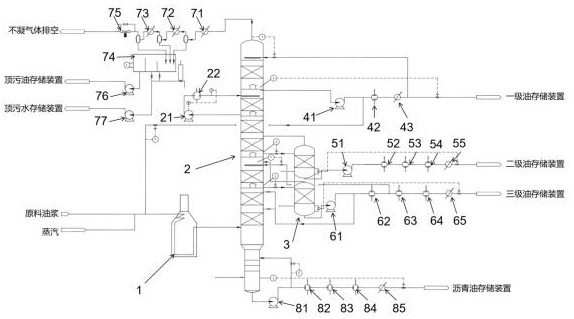

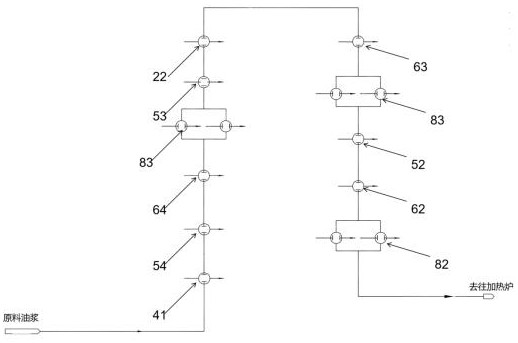

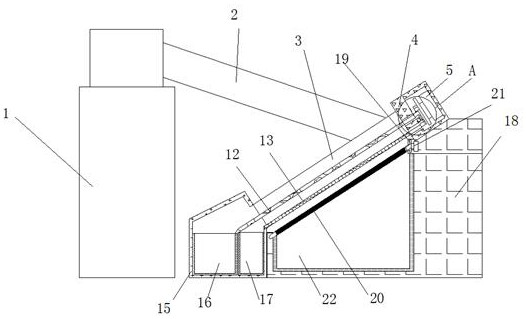

Oil-based needle coke raw material deep decompression pretreatment system

ActiveCN113817497AAchieve multi-stage separationFor maximum recoveryCoking carbonaceous materialsHydrocarbon oils treatmentCokeSlurry

The invention discloses an oil-based needle coke raw material deep decompression pretreatment system which comprises a heating furnace, a decompression tower, a decompression stripping tower, a first-line oil outlet system, a second-line oil outlet system, a third-line oil outlet system, a top dirty oil outlet system, an asphalt oil outlet system and an oil slurry heat exchange system, the decompression tower is sequentially connected with the top dirty oil outlet system, the first-line oil outlet system, the decompression stripping tower and the asphalt oil outlet system from top to bottom; the upper half part of the decompression stripping tower is connected with the second-line oil outlet system, and the lower half part of the decompression stripping tower is connected with the third-line oil outlet system; and the heat exchange system is connected with each heat exchanger. According to the oil-based needle coke raw material deep decompression pretreatment system, the raw material oil slurry is separated into first-line oil, second-line oil and third-line oil through deep decompression, so that multi-stage separation of the oil slurry is realized, the components are simpler, subsequent coking treatment is facilitated, and the needle coke product with higher quality is obtained.

Owner:辽宁宝来生物能源有限公司

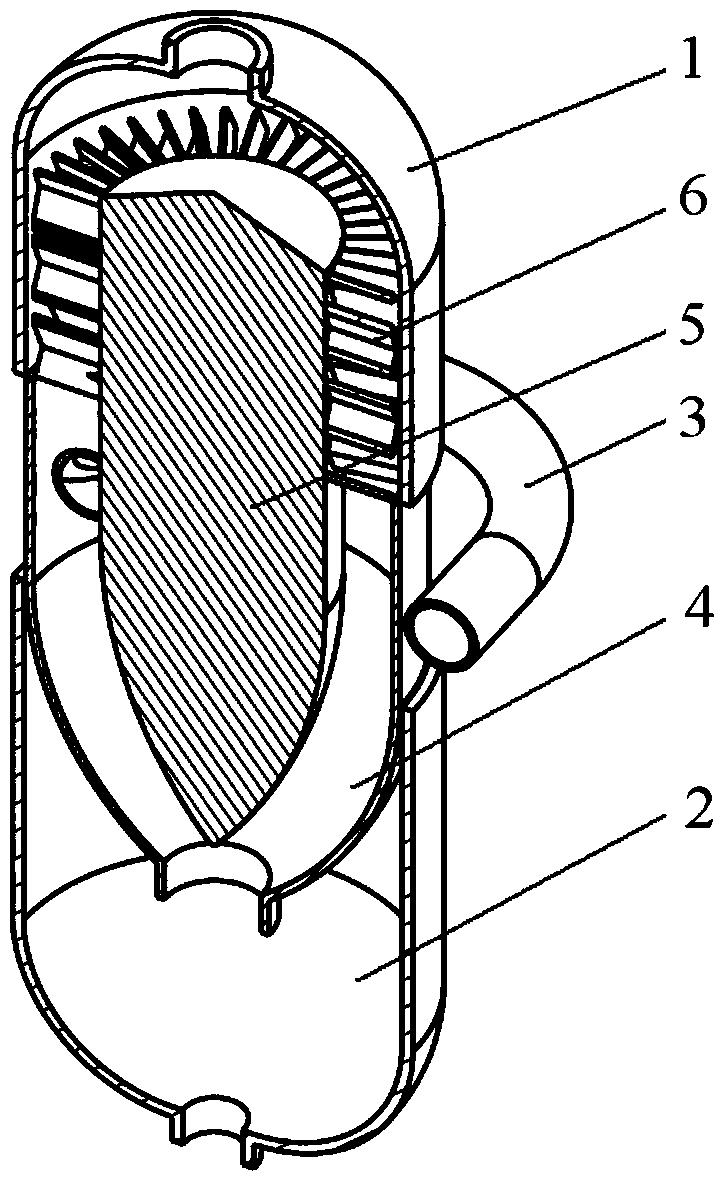

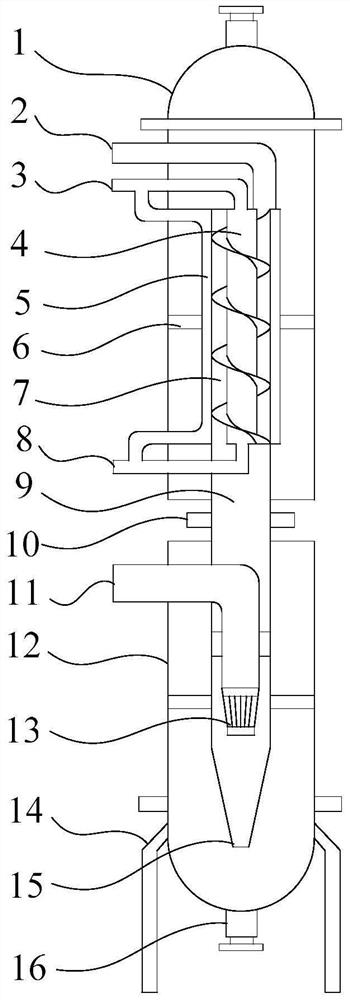

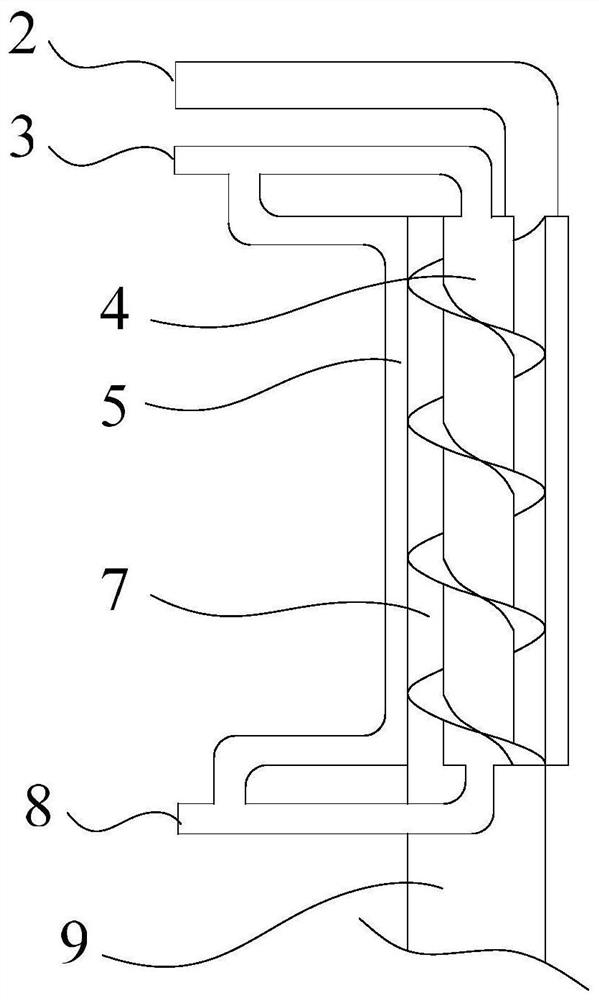

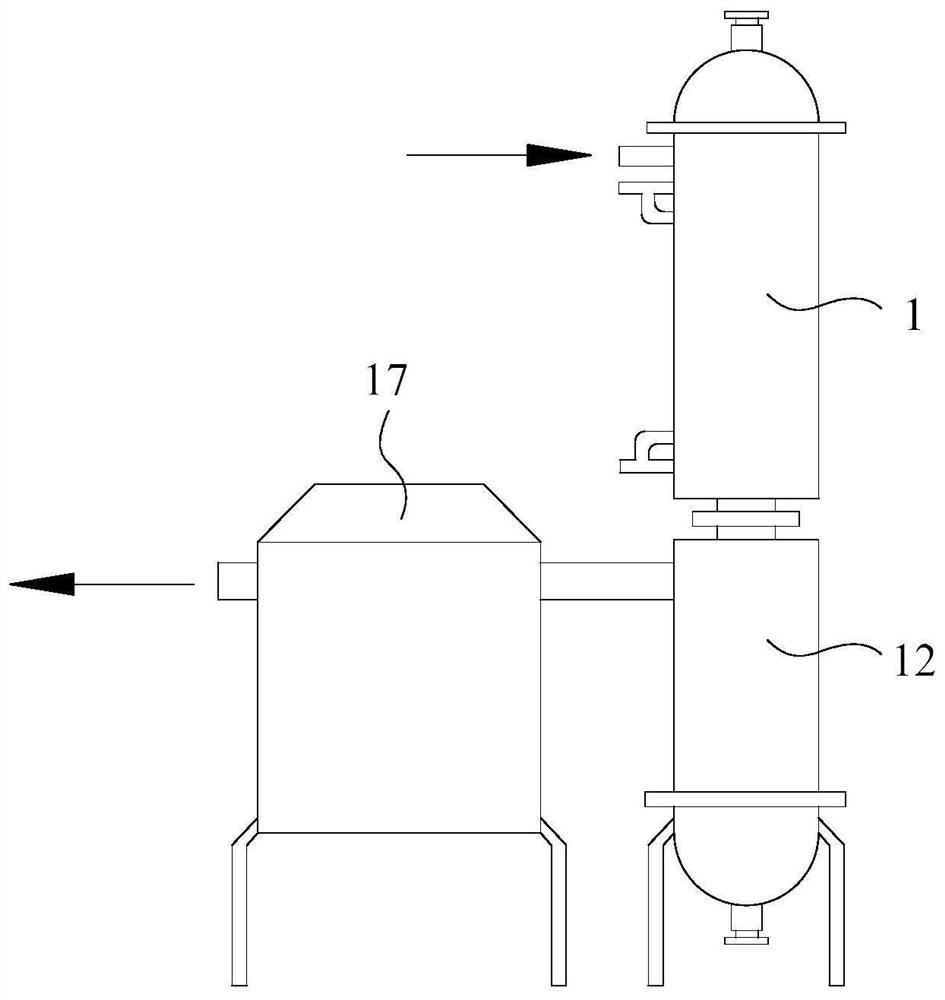

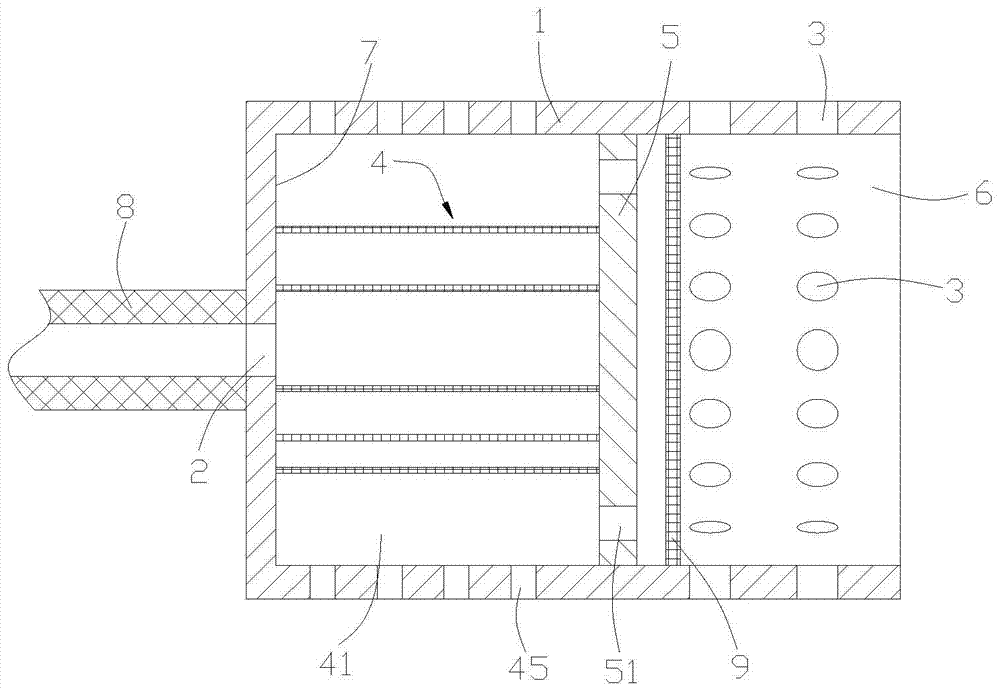

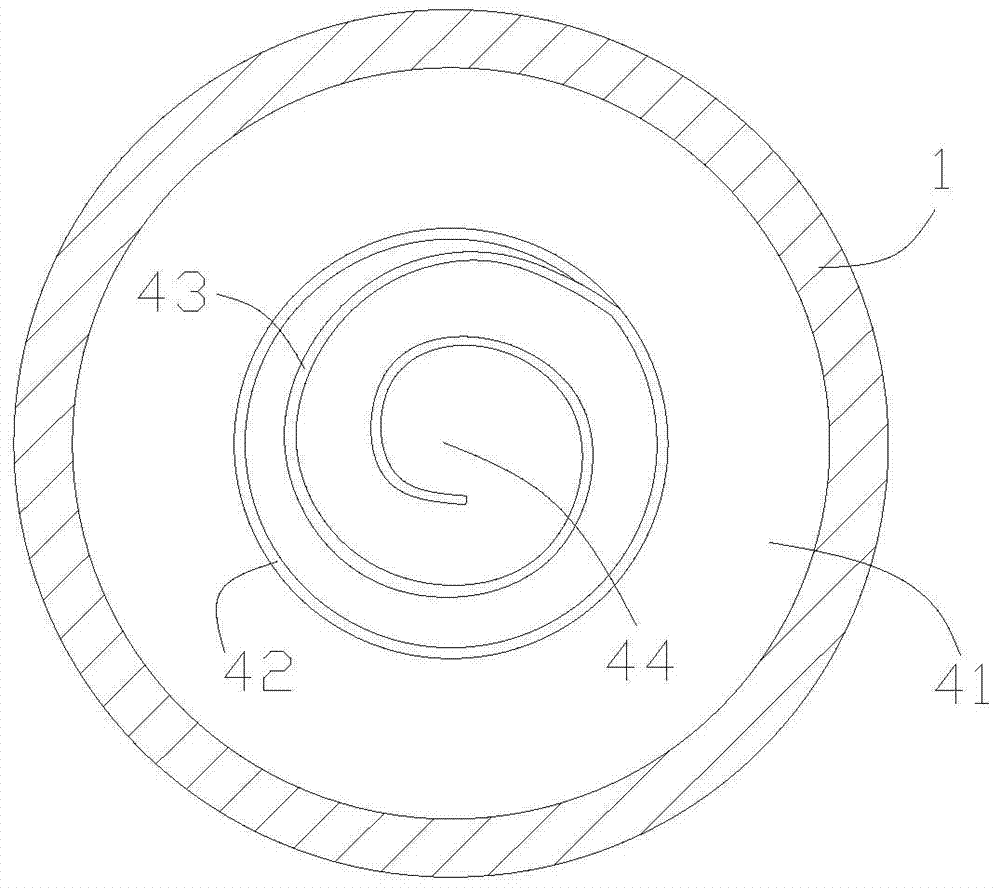

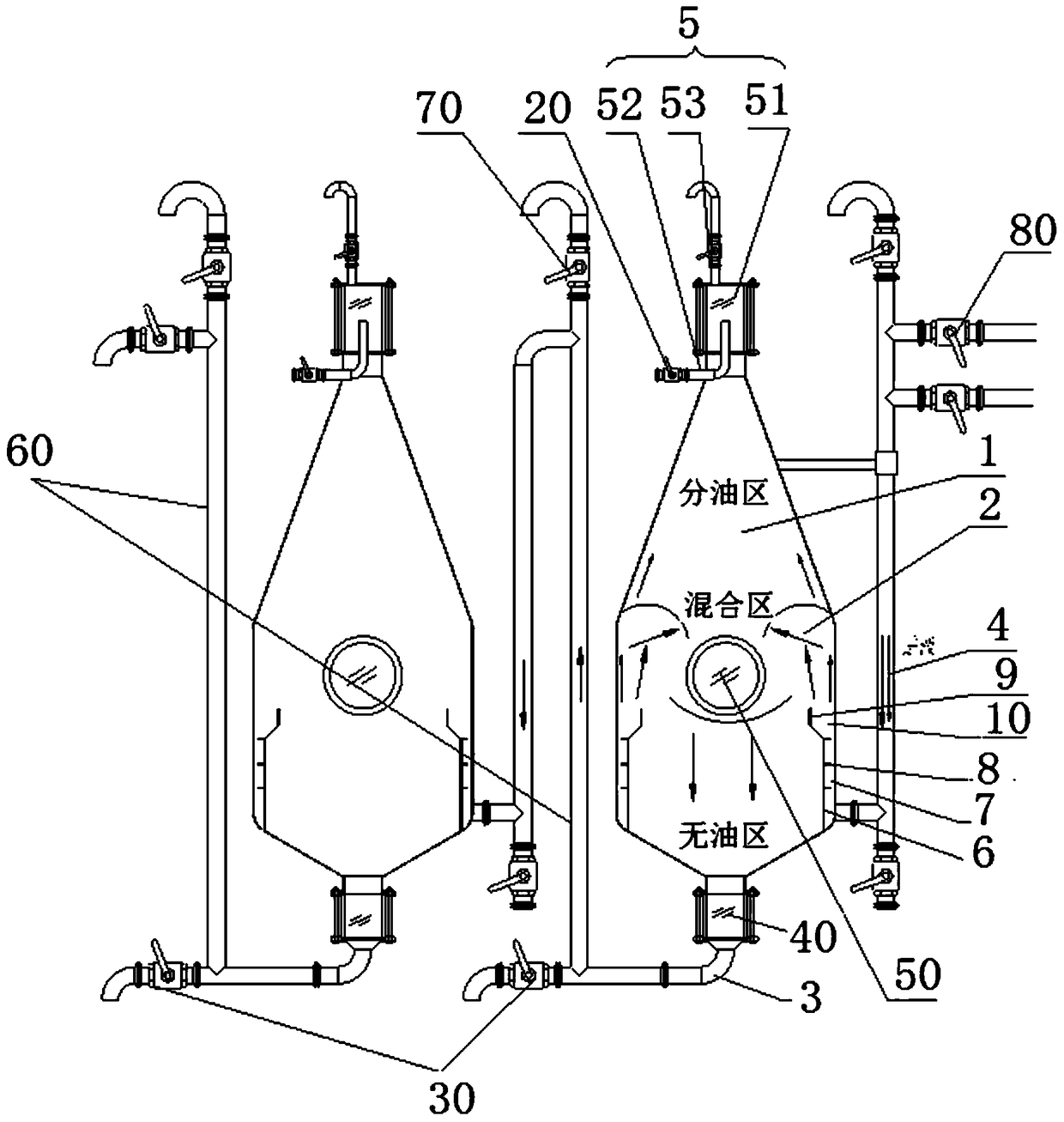

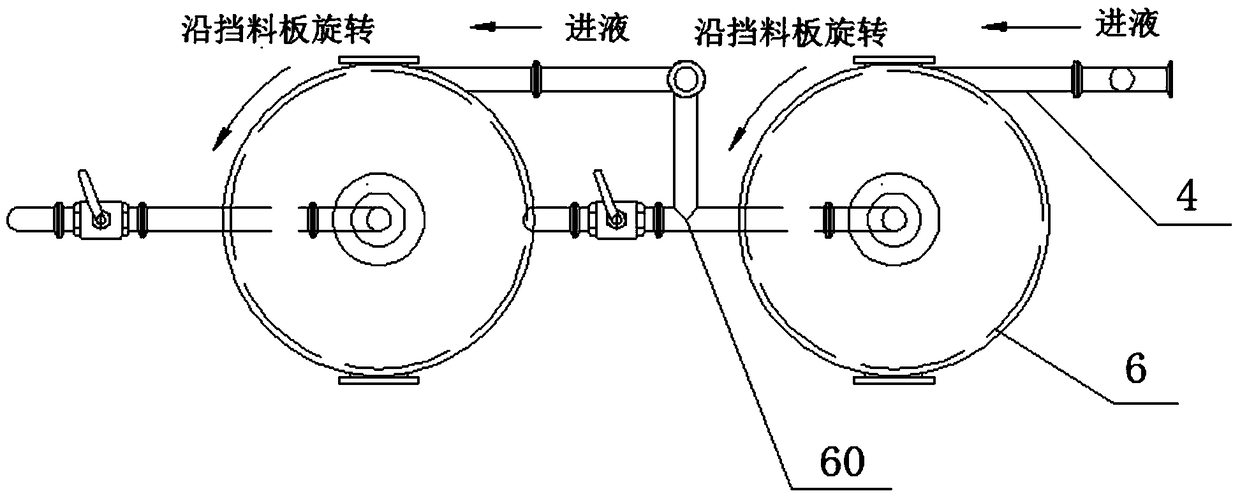

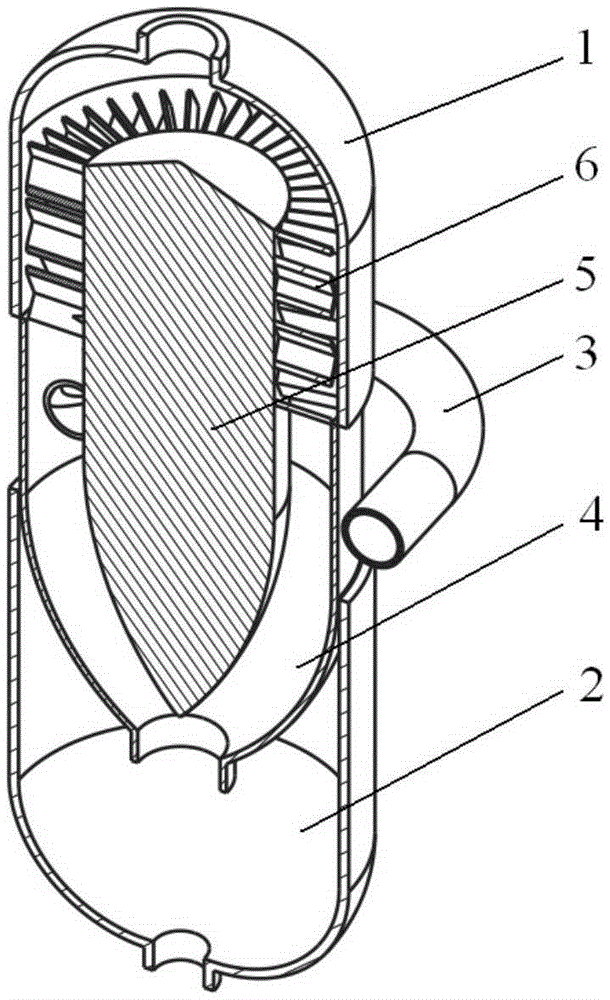

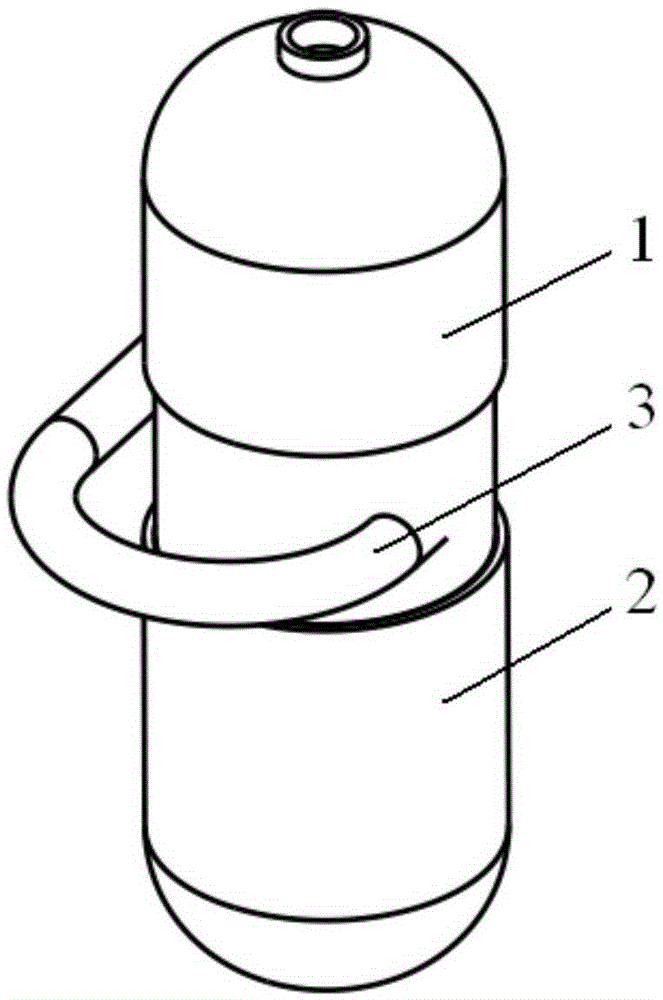

A gas-liquid separator with functions of oil return and liquid discharge

ActiveCN103673436BFunctionalIncrease in sizeRefrigeration componentsVapor–liquid separatorLiquid state

The invention discloses a gas-liquid separator with oil return and liquid discharging functions. The gas-liquid separator is sequentially provided with a liquid separating tube, an outer tube, a cyclone separator and an annular filter screen from outside to inside. The outer tube comprises an upper tube body and a lower tube body fixedly connected with the upper tube body. An exhaust port is formed in the top of the upper tube body, a first liquid discharging port is formed in the bottom of the lower tube body, and a second liquid discharging port is further formed in the side wall of the lower tube body. The liquid separating tube penetrates through the outer tube and is connected with the cyclone separator and used for inputting a gas-liquid mixture into the gas-liquid separator. The cyclone separator and the annular filter screen together define an annular space. The gas-liquid separator has a liquid storing function and the liquid discharging function, multi-stage separation performed on gas-liquid two-phase flows is achieved, the purpose that refrigeration oil, liquid state refrigerant and gas state refrigerant are respectively discharged in a separation mode, separation efficiency is obviously improved, the volume of the gas-liquid separator is shrunk, and great practical value is achieved.

Owner:SHANGHAI JIAO TONG UNIV

Heat exchange and separation integrated cyclone separation device

PendingCN113351385AImprove heat transfer effectImprove gas-liquid separation efficiencyReversed direction vortexCycloneThermodynamics

The invention provides a heat exchange and separation integrated cyclone separation device. The cyclone separation device comprises a shell, the shell is provided with an air inlet, an air outlet and an oil-gas mixture channel communicating with the air inlet and the air outlet; a heat exchange device for conducting heat exchange on an oil-gas mixture and an axial flow type cyclone separator are further arranged in the shell; the oil-gas mixture channel penetrates through the heat exchange device to lead to the cyclone separator, the oil-gas mixture channel is provided with a spiral flow channel in the heat exchange device, and the spiral flow channel is used for guiding the oil-gas mixture to spirally flow so as to be consistent with the airflow vortex direction of the cyclone separator. The heat exchange device and the separator are sequentially arranged in the cyclone separation device, high-temperature oil gas can be cooled and then separated, the spiral flow channel is formed in the inner cavity of the heat exchange device, the heat exchange area of the high-temperature oil-gas mixture is increased, and the heat exchange efficiency is improved; the spiral flow channel guides the airflow into a spiral shape to enter the axial flow type cyclone separator for multi-stage separation, and the high-temperature gas-liquid separation effect is effectively enhanced.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Environment-friendly sewage separation treatment device

InactiveCN110510764AAchieve multi-stage separationEasy to separateTreatment involving filtrationMultistage water/sewage treatmentEngineeringSewage

Relating to the field of environmental protection, the invention discloses an environment-friendly sewage separation treatment device. The device includes a treatment box, one end on the top surface of the treatment box is fixedly connected to a main feeding pipe, one side in the treatment box is fixedly connected to a flow guide seat, a fixed seat is arranged on one side of the flow guide seat, the fixed seat is fixedly connected to the treatment box, a filter unit is arranged between the fixed seat and the flow guide seat, a coarse filter plate is arranged above the flow guide seat, and is equipped with filter holes, a plurality of baffle plates are fixedly arranged below the flow guide seat, and a buffer unit is arranged below the filter unit. According to the invention, the disposed coarse filter plate can separate and remove garbage with large volume in sewage, and the garbage can be guided out by a feeding screw rod, the disposed filter unit can adsorb and filter impurities in sewage, the disposed baffle plates can precipitate granular impurities in the sewage, and arranged absorption heads can suck out the precipitated impurities, thus realizing multi-stage separation of thesewage, and the separation effect is good.

Owner:黎梦雅

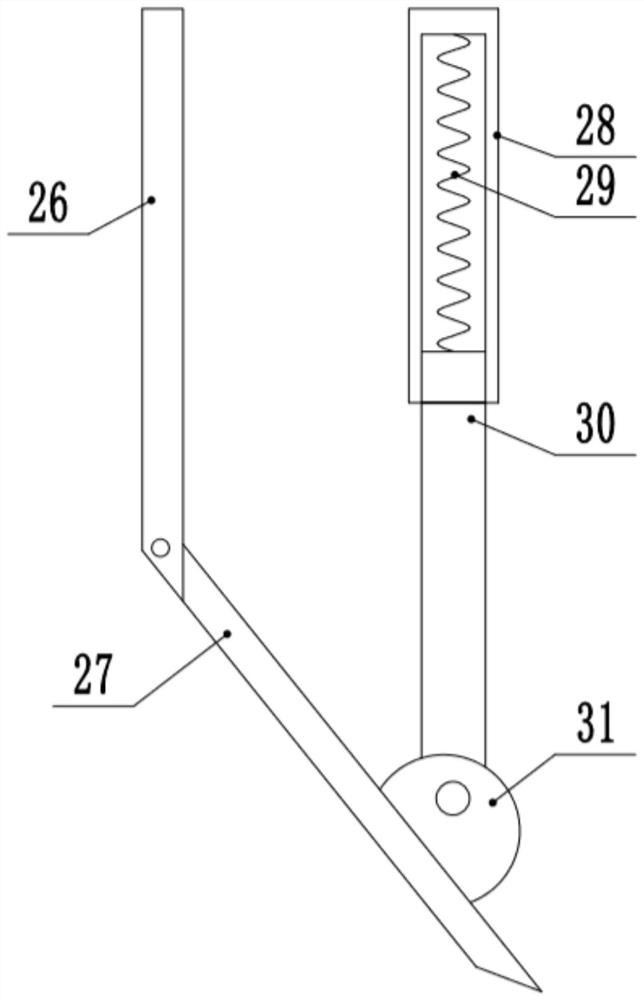

Iron ore tailing resource comprehensive utilization treatment device

InactiveCN112570134AIncrease profitAvoid dustSievingGas current separationPulverizerMining engineering

The invention discloses an iron ore tailing resource comprehensive utilization treatment device, and relates to the technical field of tailing treatment. According to the scheme, the iron ore tailingresource comprehensive utilization treatment device comprises a pulverizer, a conveying pipe is fixedly connected to the right side of the pulverizer, a dust cover is fixedly connected to the output end of the conveying pipe, a vibration machine box is fixedly connected to the right side of the dust cover, a rotating motor is fixedly mounted on the inner wall of the vibration machine box, a rotating shaft is fixedly connected to the output end of the rotating motor, a rotating disc is fixedly connected to the outer ring of the rotating shaft, an inner gear is fixedly connected to the inner ring of the rotating disc, a rocker is rotatably connected to the center of the rotating disc, and an outer gear is fixedly connected to the other end of the rocker. By means of the design of an electromagnet plate, iron is effectively recycled, the utilization rate of iron ore is increased, meanwhile, iron in tailing powder is removed, the dust cover effectively prevents dust from flying, the production environment is prevented from being polluted, and the production safety is improved.

Owner:孙欢

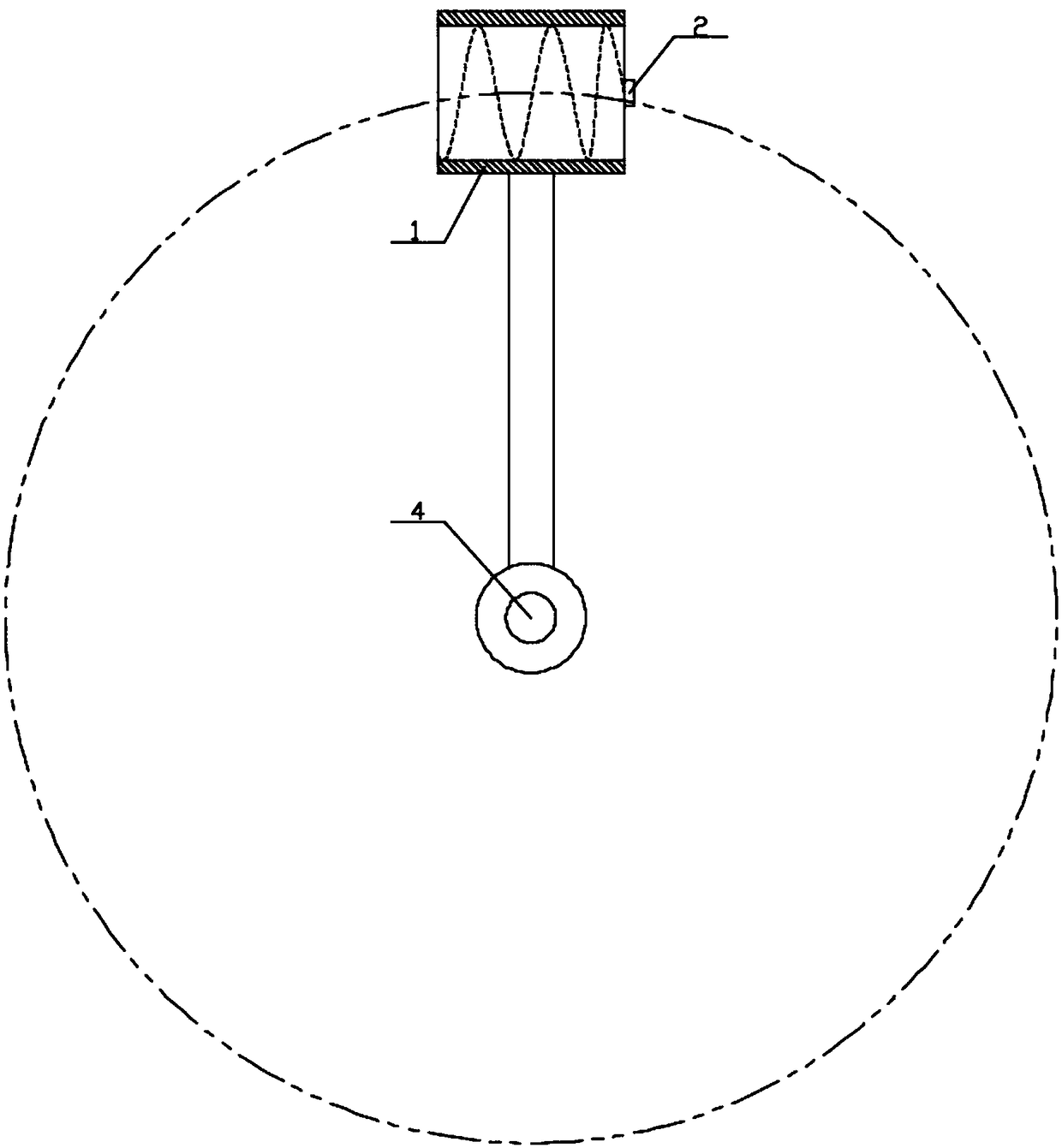

Nano-scale dynamic centrifugal separation device

The present invention relates to the field of ball mills, specifically a nanoscale dynamic centrifugal separation device, which includes a horizontally arranged separation cylinder with one end open, the other end of the separation cylinder is closed, and a discharge port is opened on the end face of the other end. The other end is fixedly connected with the rotating discharge shaft, and the discharge port communicates with the inner cavity of the discharge shaft; the inner cavity of the one end of the separation cylinder is covered with a screen, and the other end of the separation cylinder is fixed with a separator. The separation chamber communicates with the discharge port. When the material in the grinding chamber and the grinding medium enter the pre-partition of the separation cylinder, the screen can block the grinding medium and the material with larger particles in the pre-partition to realize the pre-separation of the material; the pre-separated material with smaller particles enters the spiral The separation chamber of the shaped separator can realize multi-level separation and achieve nanoscale separation effect.

Owner:HENAN NORMAL UNIV

An impurity or foreign matter separation device for continuous moving media

ActiveCN108465550BEfficient separationAchieve multi-stage separationMagnetic separationForeign matterElectrical connection

The invention discloses an impurity or foreign matter separating device for continuous moving media. The device comprises an inner cylinder, a spiral electromagnetic field trigger mechanism and an electric control mechanism; the spiral electromagnetic field trigger mechanism is arranged inside the inner cylinder and located on the inner wall of the inner cylinder or the axis of the inner cylinder,and the spiral electromagnetic field trigger mechanism can emit a spiral electromagnetic field which is in a spiral shape along the inner wall of the inner cylinder; the electric control mechanism comprises a controller and a power source which are electrically connected, and the controller is electrically connected with the spiral electromagnetic field trigger mechanism. According to the impurity or foreign matter separating device for continuous moving media, the spiral electromagnetic field trigger mechanism emits the spiral electromagnetic field which is in the spiral shape along the inner wall of the inner cylinder, suspending impurities or foreign matter in the continuous moving media flowing through the inner cylinder are subjected to polarization drifting and adsorbed to the innerwall of the inner cylinder, and impurities or foreign matters in the continuous moving media can be separated on the premise of not lowering the circulation velocity of the continuous moving media and not increasing the load and energy consumption of a driving device.

Owner:XUZHOU DKEC ELECTRICAL TECH

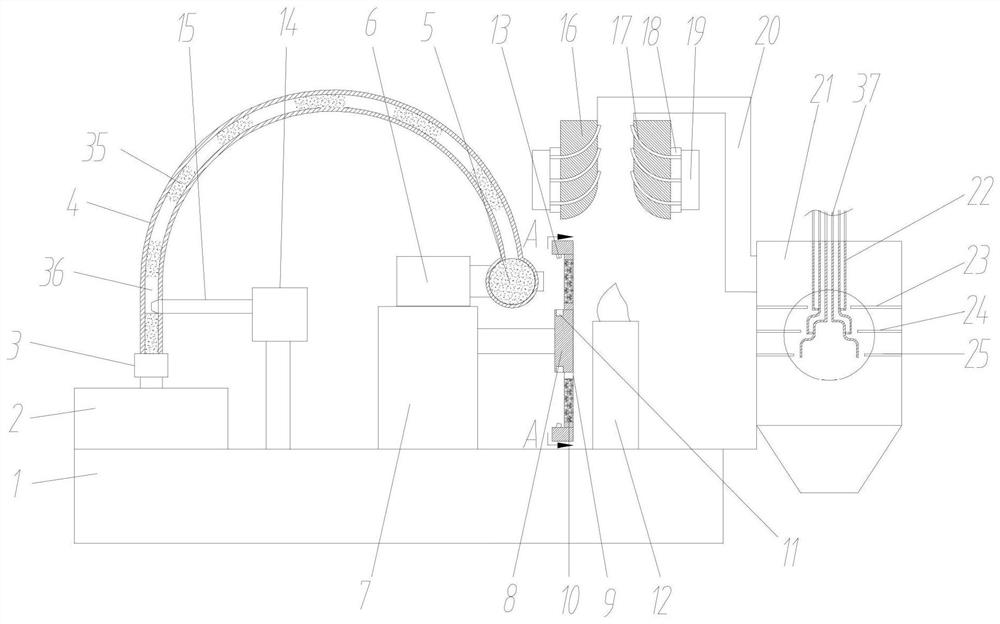

Method and device for preparing nanometer aluminum oxide by utilizing nanometer porous membrane

ActiveCN113135583ASmall sizeAchieve indirect injectionMaterial nanotechnologyAluminium oxide/hydroxide preparationAluminum IonNanoporous membrane

The invention provides a device for preparing nanometer aluminum oxide by using a nanometer porous membrane. The nanometer aluminum oxide preparation device is provided with a platform and a shell, the platform is used for supporting the whole preparation device, and an aluminum ion solution supply device, an injection device, a combustion device and a particle collection device are sequentially arranged above the platform from left to right. Compared with the prior art, the technical problem that the size of aluminum ion solution droplets jetted by the jetting device is too large is solved; the quality of the nanometer aluminum oxide particles is improved; the quality of the liquid drops obtained after the liquid drops pass through the nano-porous membrane is stabilized and refined; and nano aluminum oxide particles with different sizes can be prepared according to requirements.

Owner:SOUTH CHINA UNIV OF TECH

An oil-water separator and its light oil separation system

ActiveCN105597373BImprove separation efficiencyAchieve multi-stage separationLiquid separationOil separationEngineering

The invention discloses an oil-water separator and a light oil separation system thereof. The separator includes a vertical conical barrel and cylindrical barrel; one end of the cylindrical barrel is connected to a large end of the conical barrel, and the other end of the cylindrical barrel is provided with a drain pipe; the one end, away from the conical barrel, of the cylindrical barrel is provided with a liquid inlet pipe in tangential communication with the cylindrical barrel; a small end of the conical barrel is provided with an oil discharge device; the cylindrical barrel is internally provided with a cylindrical striker plate; an annular flow groove is formed between the striker plate and the cylindrical barrel; and the annular flow channel is respectively communicated with the conical barrel and the liquid inlet pipe. The oil-water separator of the invention employs a combination of conical barrel and cylindrical barrel; the striker plate is arranged in the cylindrical barrel, so that the annular groove is formed between the striker plate and the cylindrical barrel; the liquid entering the separator is buffered by the striker plate, and uniformly flows upwards along the edge of the separator; and most of the space is in a quiet state, thereby improving the separation efficiency.

Owner:WENZHOU YURUN MACHINERY TECH CO LTD

Environment-friendly garbage treatment device for sewage treatment

The invention discloses an environment-friendly garbage treatment device for sewage treatment, and relates to the field of environmental protection. The device comprises a treatment box; supporting seats are fixedly connected to the two ends of the bottom of the treatment box; one end of the top of the treatment box is fixedly connected with a feed hopper; the two sides of the treatment box are concave inwards; a lifting pipe is fixedly connected in the treatment box positioned at the two concave parts; an inlet is formed in one side of the lifting pipe; a slag discharging opening and a waterdischarging hole are formed in the other side of the lifting pipe from top to bottom; a filtering and lifting mechanism is arranged in the lifting pipe; a guide plate is fixedly connected to the lifting pipe below the slag discharging opening; and the end, away from the lifting pipe, of the guide plate is fixedly connected with a connecting cover. Separation of garbage in sewage can be achieved byarranging the filtering and lifting mechanism, the separated garbage can be extruded by arranging an extrusion water removal device to achieve garbage water removal, the sewage can be further subjected to impurity removal, separation and discharge by arranging a precipitation plate, multi-stage separation can be achieved, and the sewage treatment effect is good.

Owner:楼淼芳

Continuous moving medium impurity or foreign matter separating device control method

ActiveCN108480039AEfficient separationAchieve multi-stage separationMagnetic separationForeign matterElectricity

The invention discloses a continuous moving medium impurity or foreign matter separating device control method. A separating device comprises an inner cylinder, a spiral electromagnetic field emittingmechanism and an electric control mechanism; the spiral electromagnetic field emitting mechanism is arranged in the inner cylinder and is located on an inner wall of the inner cylinder or an axis position of the inner cylinder; the spiral electromagnetic field emitting mechanism can emit a spiral electromagnetic field along an inner wall of the inner cylinder; the electric control mechanism comprises a controller and a power supply connected electrically; and the controller is electrically connected with the spiral electromagnetic field. According to the continuous moving medium impurity or foreign matter separating device control method, the spiral electromagnetic field emitting mechanism emits the spiral electromagnetic field along the inner wall of the inner cylinder, so that suspendedimpurities or foreign matters flowing through a continuous moving medium in the inner cylinder are polarizably drifted and are adsorbed on an inner wall of the inner cylinder, and the impurities or the foreign matters in the continuous moving medium can be separated on the premise of not reducing the circulation speed of the continuous moving medium or increasing a load and the energy consumptionof a driving device.

Owner:XUZHOU DKEC ELECTRICAL TECH

A device for preparing nano-scale alumina particles

ActiveCN113277537BAvoid the problem of uneven dropletsAchieve indirect injectionMaterial nanotechnologyReversed direction vortexAluminum IonNanoporous membrane

The invention provides a device for preparing nano-alumina by using a nano-porous membrane, the device for preparing nano-alumina, the device has a platform, the platform is used to support the whole device, and the supply of aluminum ion solution is sequentially arranged on the platform from left to right device, injection device, combustion device and particle collection device; the present invention is compared with the prior art: the present invention is compared with the prior art: the aluminum ion solution droplet size that avoids generation is too large; The quality, uniformity and size difference of the generated droplets; nano-scale alumina particles of different sizes can be collected according to needs.

Owner:SOUTH CHINA UNIV OF TECH

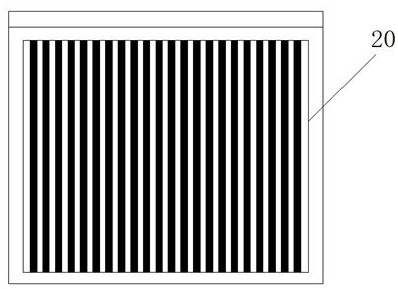

Chitin preparation method

InactiveCN104592419BImprove liquid tightnessAchieve multi-stage separationStationary filtering element filtersInorganic saltsChitin formation

A disclosed chitin preparation method comprises the following steps: crushing a chitin raw material, and sending crushed chitin into a reaction kettle; adding an acid liquid to perform acidolysis for removing inorganic salts; sending the obtained liquid to a filtering apparatus; and dewatering the obtained filtrate, so as to obtain chitin. The filtering apparatus comprises a support and multiple solid-liquid separation units, the support comprises a fixing block and a liquid-guiding block; two transverse rods for connecting the fixing block and the liquid-guiding block is arranged therebetween, and the two transverse rods are arranged at intervals in a parallel way; the main structure of each solid-liquid separation unit is a filtering frame, the filtering frame is provided with a filter screen, two opposite lateral sides of the filtering frame are both provided with a protruded handle; the filtering frames are horizontally superposed between the two transverse rods in a parallel way, and the handles are naturally put on the transverse rods; the fixing block is provided with a jacking device for performing jacking on the filtering frames; and under the effect of the jacking device, the filtering frames press the internal surface of the liquid-guiding block, one end of a liquid-guiding pipe leads to the internal surface of the liquid-guiding block, and the other end of the ilquid-guiding pipe is communicated with the reaction kettle. The preparation method is high in production efficiency.

Owner:浙江新复大海洋生物科技股份有限公司

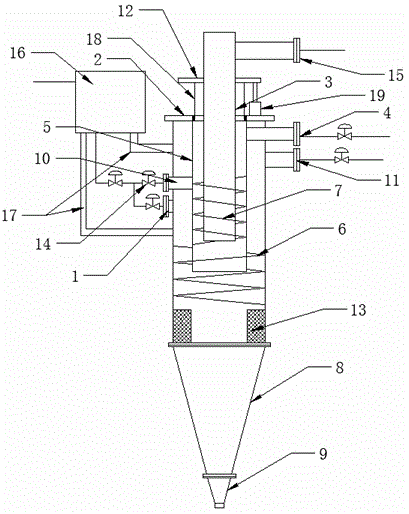

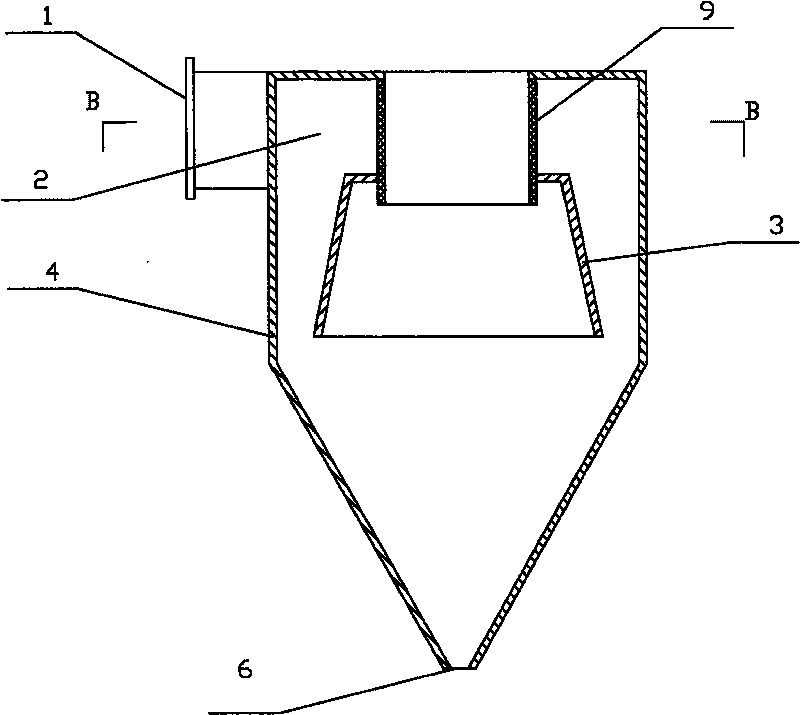

U-shaped double-hopper cyclone dust removal device

InactiveCN109107787AImprove dust removal efficiencyReduce Secondary DisturbanceReversed direction vortexCirculating fluidized bed boilerEngineering

The invention relates to the structural optimization design of a novel cyclone separator. According to the present invention, the original cyclone separator is improved and optimized so as to providethe novel dust removal technology for the circulating fluidized bed boiler, wherein the middle section is changed into the structure having two ash hoppers, and the flue gas outlet is cooperatively improved, such that the ash hoppers on both sides achieve the multi-stage dust removal and improve the dust removal efficiency, and the matching of the middle flue gas outlet and the outer side gradual-shrinkage structure achieves the small curvature radius turning of the fluid and strengthen the dust removal effect; the structure of the present invention is easy to install and fix compared to the original structure; and the main structure of the invention comprises an inlet vortex, a middle separation section with ash hoppers, a lower dust and ash collection hopper and an outlet pipe, wherein the main improvement comprises: the middle separation section with the ash hoppers and the outlet pipe.

Owner:HARBIN UNIV OF SCI & TECH

Multi-stage separation device for micro-nano particles

PendingCN113318599AControl Particle Size RangeAchieve separationMembranesPreparing sample for investigationPhysicsEngineering

The invention relates to a micro-nano particle multistage separation device which comprises a vacuum box, a plurality of separation and filtration devices and a vacuum pump, wherein the vacuum pump is communicated with the interior of the vacuum box through a vacuum pipe, the separation and filtration devices are installed on the vacuum box; one part of each separation and filtration device is located in the vacuum box, and the other part is located outside the vacuum box; a plurality of collecting devices are arranged in the vacuum box, and the collecting devices and the separating and filtering devices are arranged in a one-to-one correspondence mode and used for collecting filtrate. The multi-stage separation device for the micro-nano particles can be directly used for separating the micro-nano particles in a soil or water body sample, the particle size interval of the separated particles can be controlled by adjusting the size of the filter holes of the separation and filtration device; besides, multi-stage separation of a single sample and batch separation of a plurality of samples can be realized through the multi-separation filtering device body in the vacuum box. The device has the characteristics of high efficiency and simplicity and convenience in operation.

Owner:中国地质科学院地球物理地球化学勘查研究所

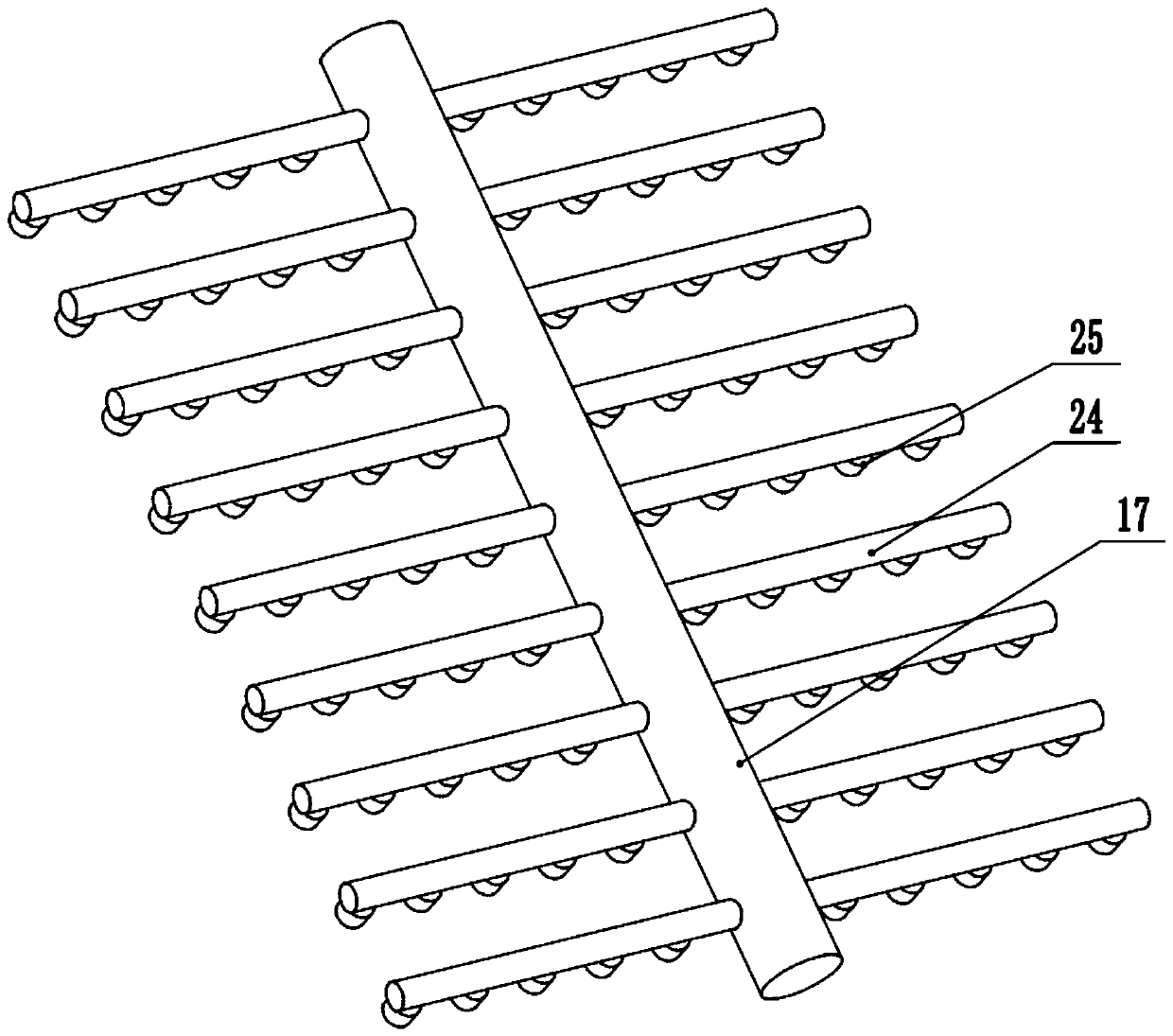

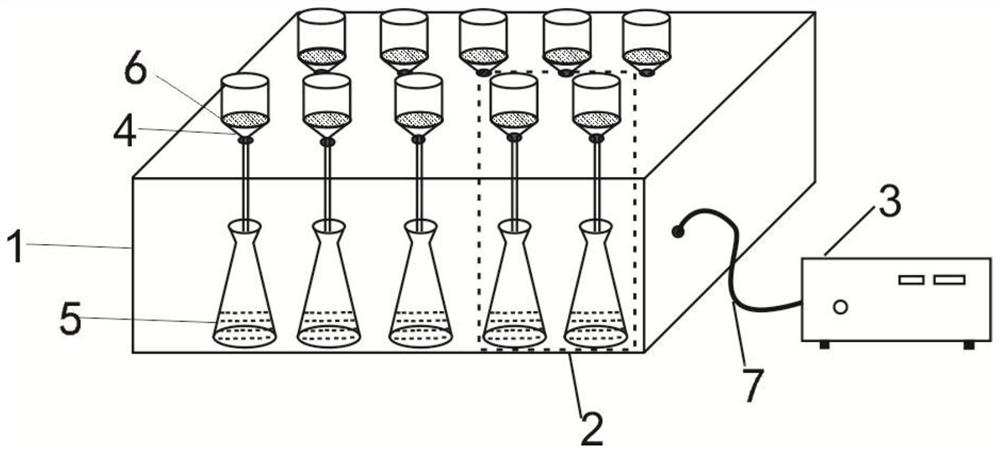

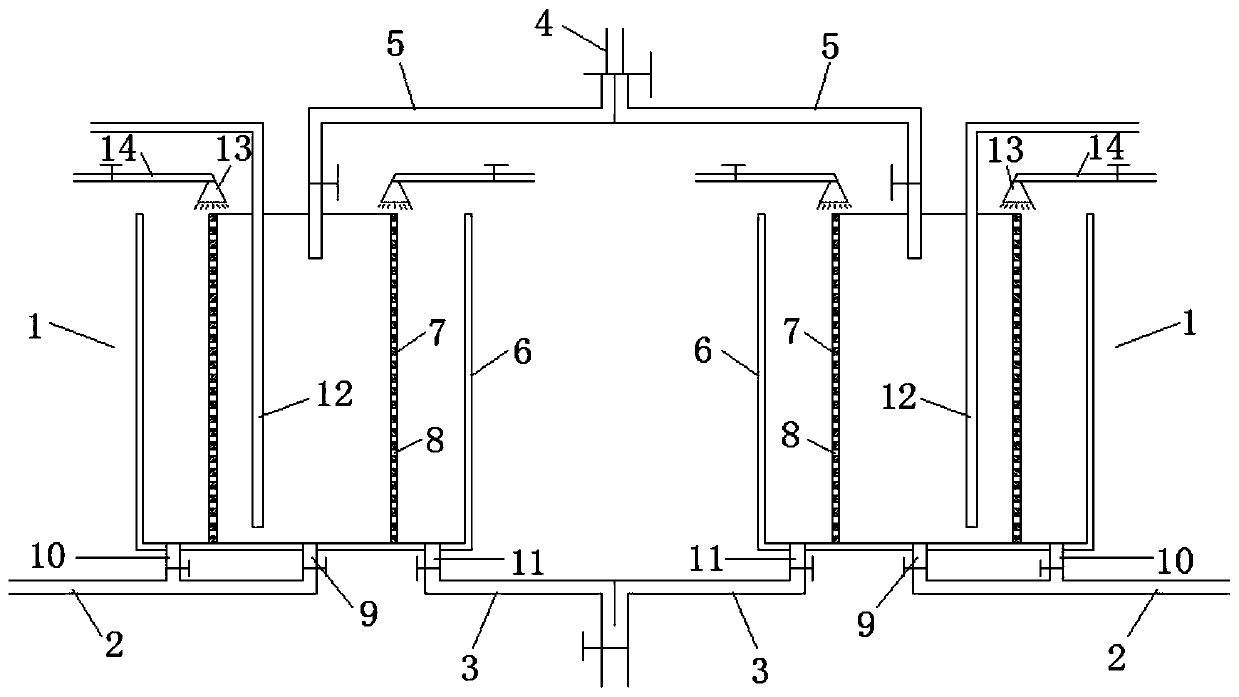

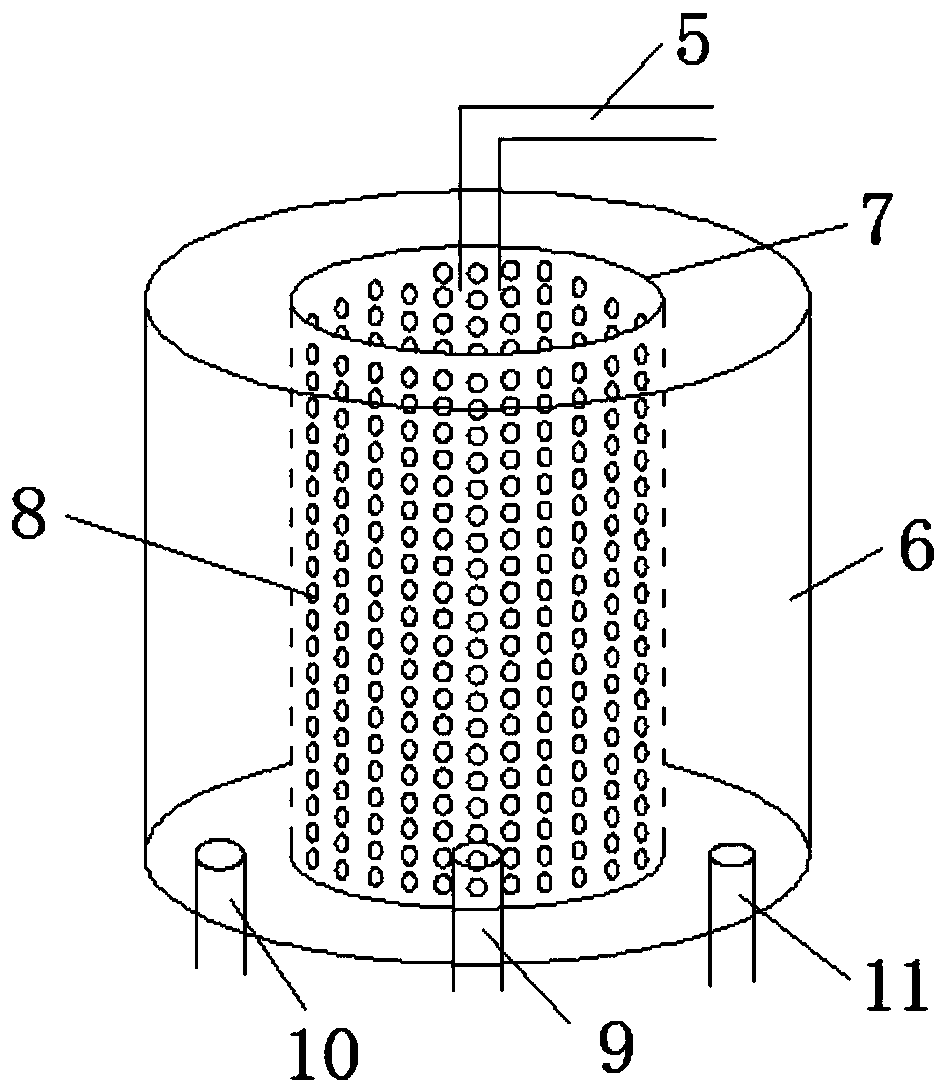

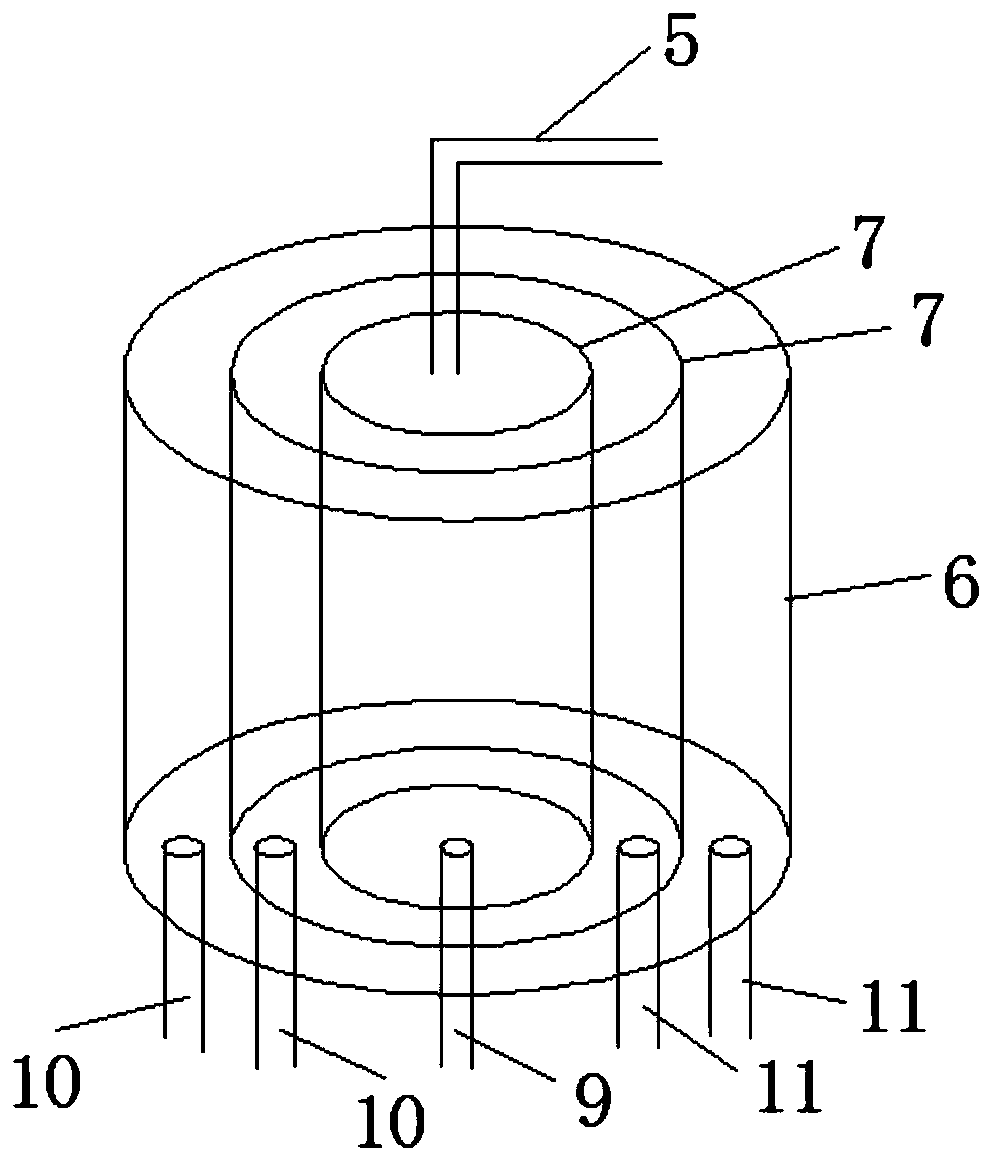

Continuous separation device for artemia nauplii

PendingCN110741990AAchieve continuous separationImprove work efficiencyClimate change adaptationPisciculture and aquariaEngineeringMechanical engineering

The invention provides a continuous separation device for artemia nauplii. The continuous separation device comprises a plurality of separation tanks, liquid discharge pipes, collecting pipes, a mainliquid inlet pipe and a plurality of liquid distribution pipes and is characterized in that each separation tank comprises a tank body, a cylindrical electromagnetic plate is arranged in the tank body, the electromagnetic plate is provided with a plurality of through holes whose diameters are larger than the width of the artemia nauplii, the bottom of the tank body is provided with a first outletlocated in an area formed by the electromagnetic plate in an enclosed manner, a second outlet and a third outlet are formed in the areas formed by the inner wall of the tank body and the electromagnetic plate in an enclosed manner, the first outlet and the second outlet are connected with the liquid discharge pipes, the third outlet is connected with one collecting pipe, and valves are arranged atthe connections of the outlets and the liquid discharge pipes and the connection of the third outlet and the corresponding collecting pipe; the liquid distribution pipes are in one-to-one correspondence to the separation tanks, one ends of the liquid distribution pipes are connected with the main liquid inlet pipe, and the other ends of liquid separation pipes are communicated with the areas formed by the electromagnetic plates in an enclosed manner; valves are arranged on the main liquid inlet pipe and the liquid distribution pipes. The continuous separation device is specially designed forthe separation of hatched magnetic artemia eggs and is capable achieving continuous and efficient separation.

Owner:ENG TECH INST CO LTD OF CNSIC

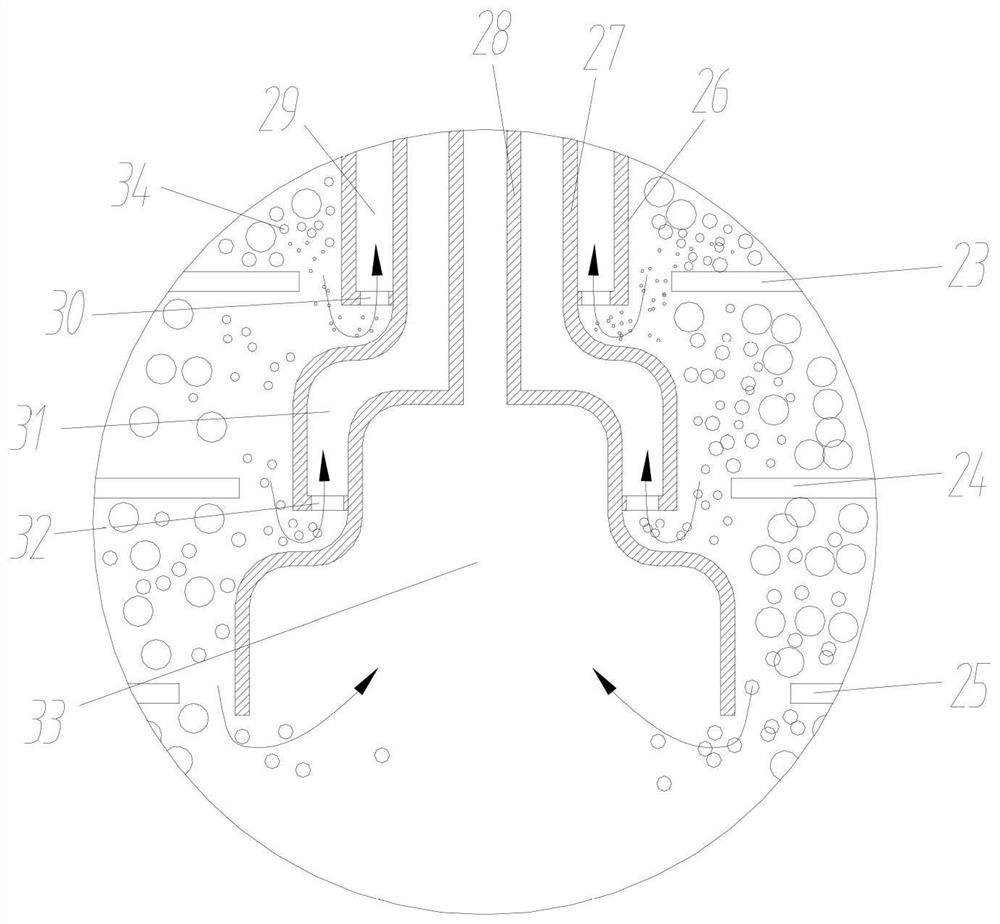

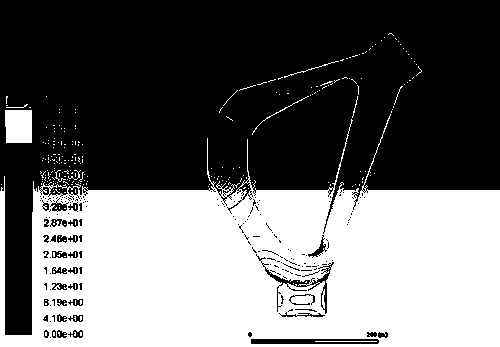

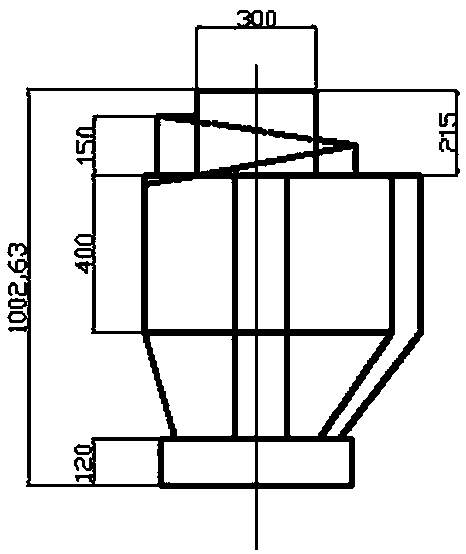

A gas-liquid separator with liquid storage and liquid discharge functions

ActiveCN103638749BReduce volumeAchieve multi-stage separationDispersed particle separationVapor–liquid separatorEngineering

The invention relates to a gas-liquid separator with liquid-storing and liquid-discharging functions. The gas-liquid separator comprises a barrel, an arc-shaped liquid-separating pipe outside the barrel, and a cyclone separator, a streaming core body and a baffling liquid-separating plate which are arranged in the barrel, wherein the arc-shaped liquid-separating pipe is communicated with the barrel in a tangential direction of the outer side of the barrel; the streaming core body is arranged in the cyclone separator, an annular space is formed between the cyclone separator and the streaming core body, and the baffling liquid-separating plate is arranged on the outer side of the streaming core body in a sleeved manner. Compared with the prior art, the gas-liquid separator provided by the invention has the advantages that multiple separating manners such as the centrifugal force, the gravity and the surface tension are utilized in a comprehensive way, so that the multi-level separation of gas-liquid two-phase stream is realized, the separation efficiency is remarkably improved, and the size of the gas-liquid separator is reduced.

Owner:SHANGHAI JIAOTONG UNIV

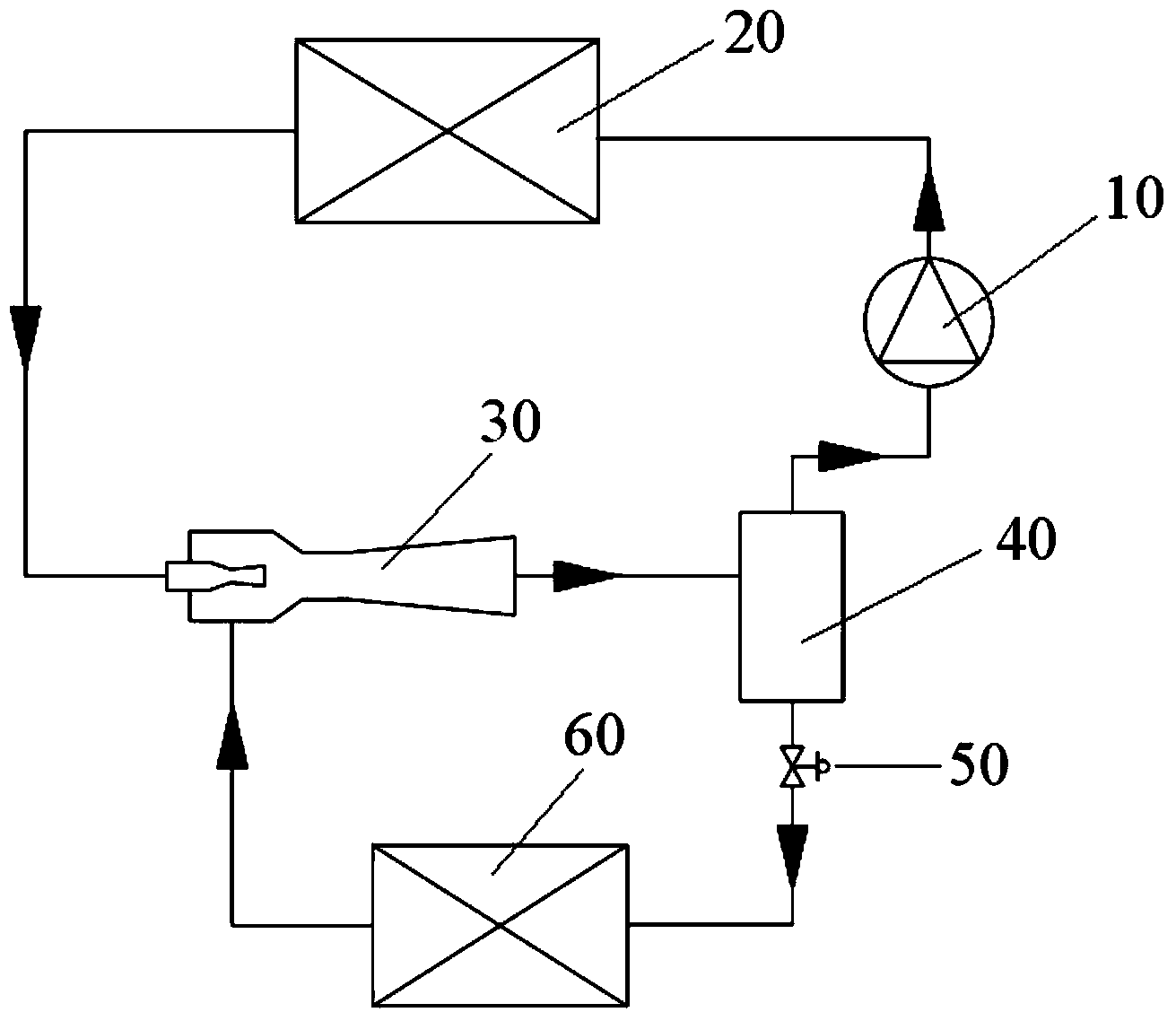

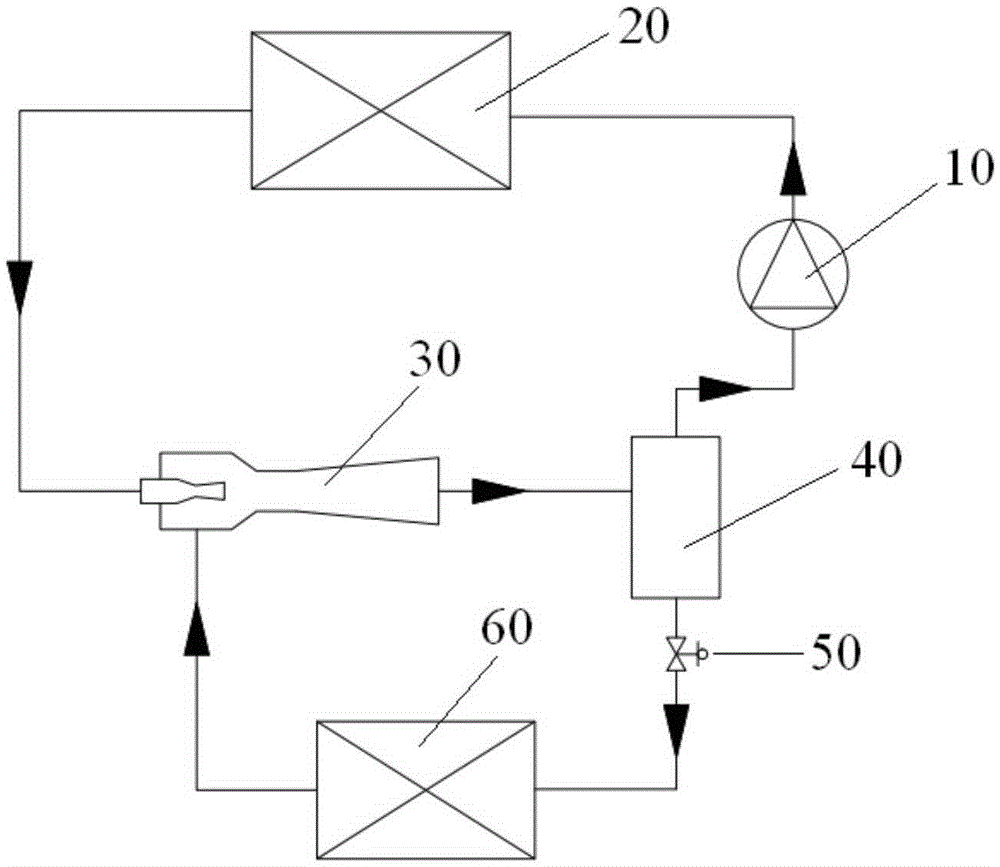

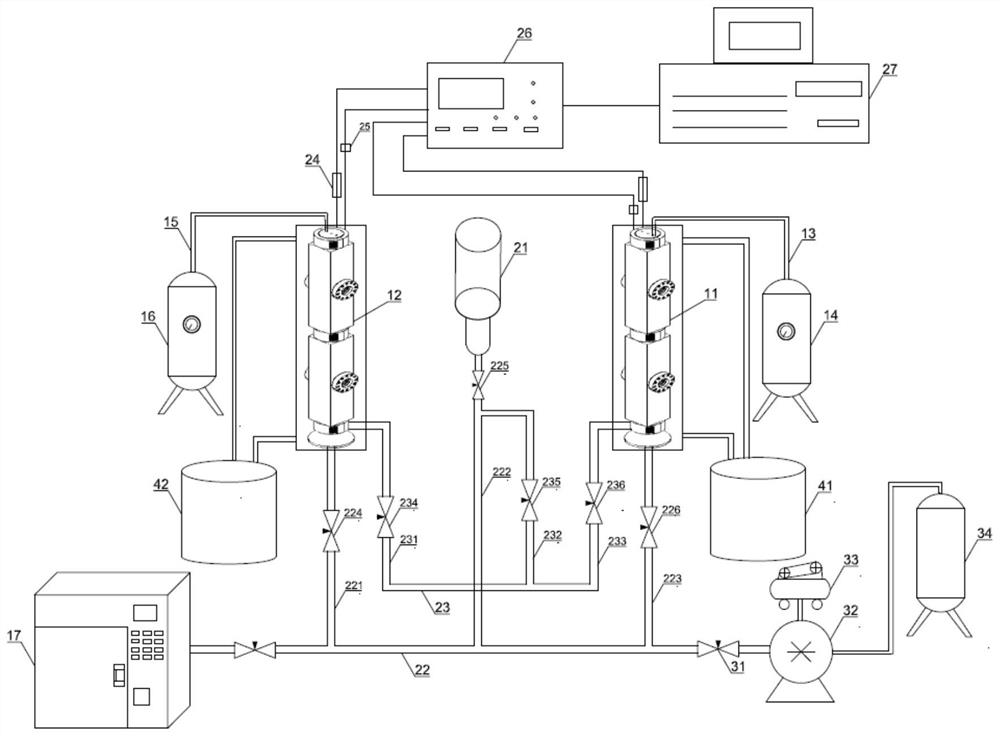

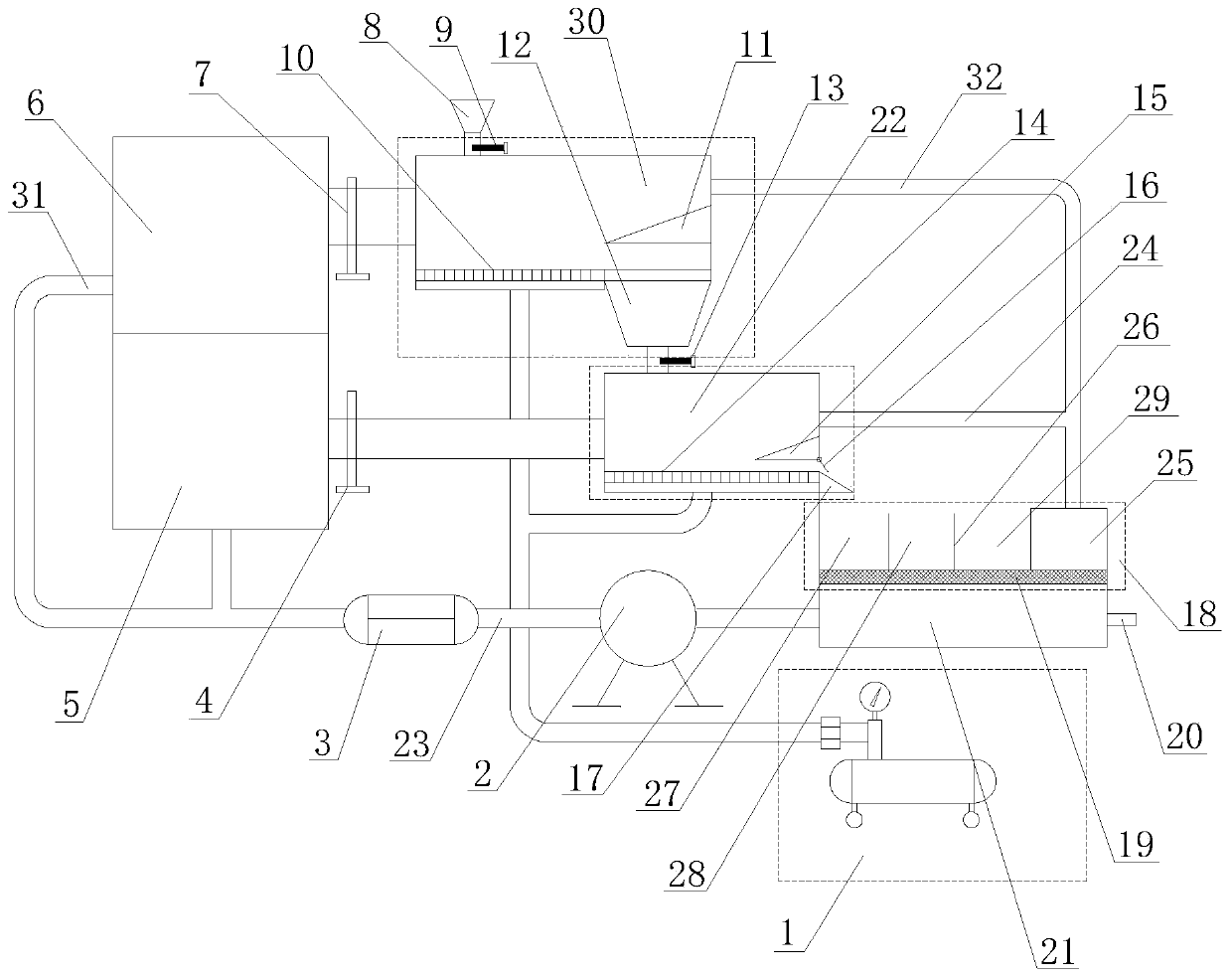

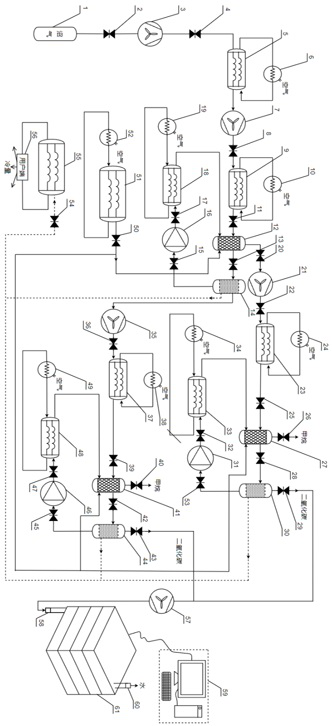

Double-kettle circulating gas hydration multi-stage separation, purification and recovery device and method

PendingCN114456863AAchieve multi-stage separationImprove the efficiency of hydration separation and purificationGaseous fuelsThermodynamicsProcess engineering

The invention relates to a double-kettle circulation gas hydration multi-stage separation, purification and recovery device and a method for carrying out hydration circulation multi-stage separation, purification and methane recovery on gas by using the device. The device comprises a gas hydration system, a gas circulation system, a gas pressurization system and a temperature adjusting system, wherein the gas pressurization system is used for pressurizing gas and filling the pressurized gas into the gas hydration system, and the temperature adjusting system is used for adjusting the temperature of the gas hydration system. According to the device, the double separation kettles are used for dynamically regulating and controlling continuous hydration separation and purification of coal mine gas, and the gas circulation system is added to control gas migration of the double kettles, so that multi-stage separation of coal mine gas with different concentrations / components can be realized, and the efficiency of hydration separation and purification of coal mine gas is improved; the recovery rate of methane in coal mine gas is improved. The device is high in universality, is suitable for separation and purification of extracted gas with different concentrations / components of different coal mines, and also has a very good separation and purification effect on low-concentration coal mine gas.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Cyclone separator

InactiveCN101011684BAchieve multi-stage separationSimple structureReversed direction vortexCycloneEngineering

A ring current cyclone separator comprises outside cyclone barrel with tangential inflow opening at the top, exhaust opening at the lower side, inner cyclone barrel inside with top cover connected with outside cyclone barrel top cover through ring current tube, cyclone cavity formed between the outside and inside cyclone barrels and ring current tube, with the inflow opening and the cyclone cavityconnected. It is simple in structure, with low cost and extensive application.

Owner:云国峰

Impurity or foreign matter separating device for continuous moving media

ActiveCN108465550AEfficient separationAchieve multi-stage separationMagnetic separationForeign matterElectricity

The invention discloses an impurity or foreign matter separating device for continuous moving media. The device comprises an inner cylinder, a spiral electromagnetic field trigger mechanism and an electric control mechanism; the spiral electromagnetic field trigger mechanism is arranged inside the inner cylinder and located on the inner wall of the inner cylinder or the axis of the inner cylinder,and the spiral electromagnetic field trigger mechanism can emit a spiral electromagnetic field which is in a spiral shape along the inner wall of the inner cylinder; the electric control mechanism comprises a controller and a power source which are electrically connected, and the controller is electrically connected with the spiral electromagnetic field trigger mechanism. According to the impurity or foreign matter separating device for continuous moving media, the spiral electromagnetic field trigger mechanism emits the spiral electromagnetic field which is in the spiral shape along the inner wall of the inner cylinder, suspending impurities or foreign matter in the continuous moving media flowing through the inner cylinder are subjected to polarization drifting and adsorbed to the innerwall of the inner cylinder, and impurities or foreign matters in the continuous moving media can be separated on the premise of not lowering the circulation velocity of the continuous moving media and not increasing the load and energy consumption of a driving device.

Owner:XUZHOU DKEC ELECTRICAL TECH

A coupled multi-stage separation beneficiation system and method

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Coupled cold storage device for separating and sealing CO2 in mixed gas by hydrate method

ActiveCN114806660AAchieve multi-stage separationIncrease concentrationDomestic cooling apparatusCarbon compoundsPorous mediumWater circulation

A coupling cold storage device for separating CO2 in sealed mixed gas by a hydrate method belongs to the technical field of natural gas hydrate technology application, and comprises a gas compression device, a refrigeration cycle device, a hydrate generation / decomposition device, a hydrate cold storage device, a water cycle device, a gas hydrate sealing device and a sensing monitoring device. Taking biogas separation and storage as an example, the refrigeration cycle device can realize cooling treatment on biogas, decomposed gas at all levels, hydrates and circulating water, and provides low-temperature conditions required by generation of the hydrates. The hydrate cold storage device can make full use of latent heat of phase change of hydrate and provide cold energy required by a user side. And the water circulation device can realize cyclic utilization of decomposed water and guarantee continuous generation of hydrates. The gas separation device can effectively separate methane and carbon dioxide gas in normal-temperature biogas, and the device can be connected in series in a multi-stage manner to obtain high-purity gas. And meanwhile, the device fully utilizes the energy to realize refrigeration by utilizing the advantage of high latent heat of phase change of hydrates, so that the energy loss of the system is reduced, and the energy utilization rate is improved. The gas hydrate sealing device can seal the captured CO2 in a porous medium in a hydrate mode, and CO2 gas emission is effectively relieved.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com