Continuous moving medium impurity or foreign matter separating device control method

A separation device and medium technology, applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of increased energy consumption, increased load and energy consumption of driving devices, and decreased flow velocity of continuous moving media, and achieve effective separation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the drawings.

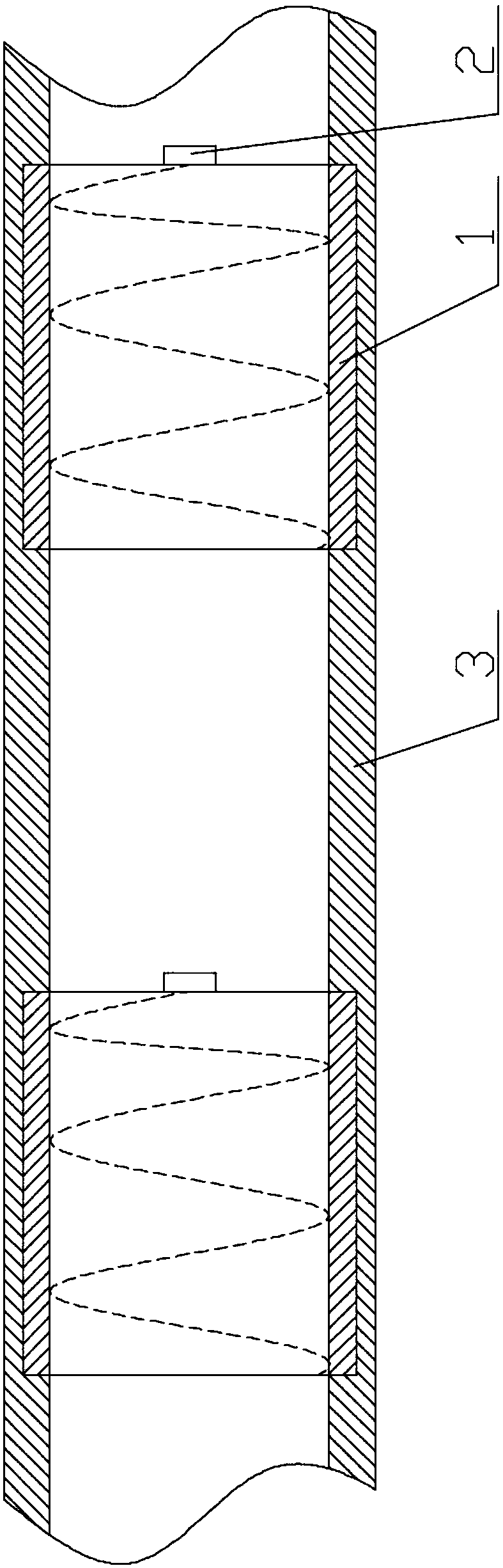

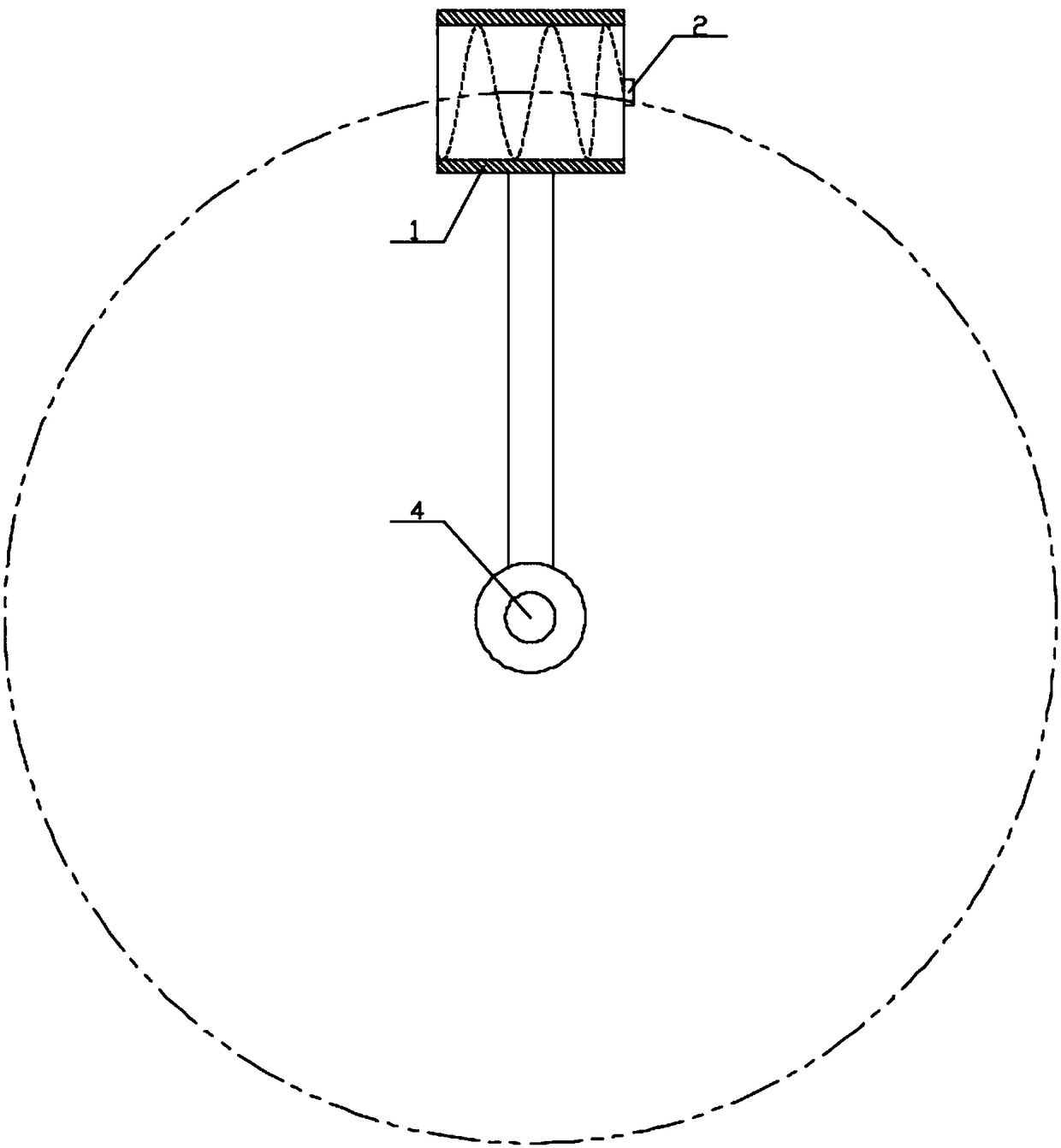

[0017] Such as figure 1 As shown, the impurity or foreign matter separation device of the continuous motion medium includes an inner cylinder 1, a spiral electromagnetic field emission mechanism 2 and an electric control mechanism; the spiral electromagnetic field emission mechanism 2 is arranged inside the inner cylinder 1, on the inner wall of the inner cylinder 1, or the inner cylinder 1. The spiral electromagnetic field emitting mechanism 2 can emit a spiral electromagnetic field along the inner wall of the inner cylinder 1 at the axial center position; the electric control mechanism includes a controller and a power supply that are electrically connected to each other, and the controller is electrically connected to the spiral electromagnetic field emitting mechanism 2.

[0018] Such as figure 1 As shown, when the impurity or foreign matter separation device of the continuous moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com