U-shaped double-hopper cyclone dust removal device

A technology of cyclone dust collector and cyclone separator, which is applied in the direction of swirling devices and devices whose axial direction can be reversed, can solve the problems of many consumables, affect boiler efficiency, and occupy a large area, and achieve reduction The effect of secondary disturbance, high fixed safety, and improved dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

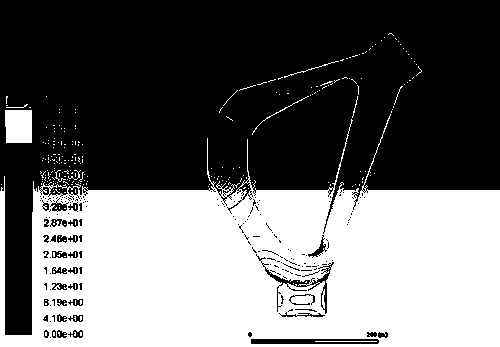

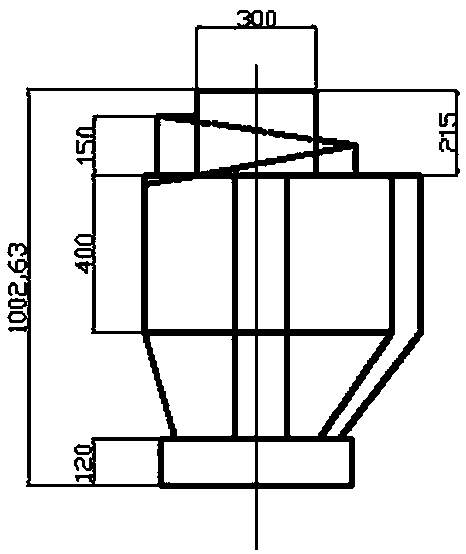

[0008] According to the formula The centrifugation of the particles is related to the mass, velocity and centrifugal radius of the particles. For centrifugal separators, the greater the centrifugal force on solid particles, the better the separation effect. Therefore, the cyclone separator requires the fluid to have a larger inlet velocity and a smaller centrifugal radius. However, the increase of the inlet velocity will increase the energy loss of the separator, and the smaller centrifugal radius will affect the structural size and dust handling capacity. Taking into account the simulation ( Figure 5 ), the separation effect has been greatly improved compared with the ordinary cyclone separator and inertial separation, and it is almost unlimited in terms of structure matching and flue gas treatment capacity, because this structure makes the turning radius of the fluid locally smaller, not comprehensive smaller.

[0009] The working principle of the double-bucket cyclone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com