A gas-liquid separator with functions of oil return and liquid discharge

A gas-liquid separator and cyclone separator technology, applied in refrigeration and liquefaction, lighting and heating equipment, refrigeration components, etc., can solve the problems of complex structure, unsuitable separation of gas-liquid mixture, low separation efficiency, etc. Volume, large practical value, and the effect of improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

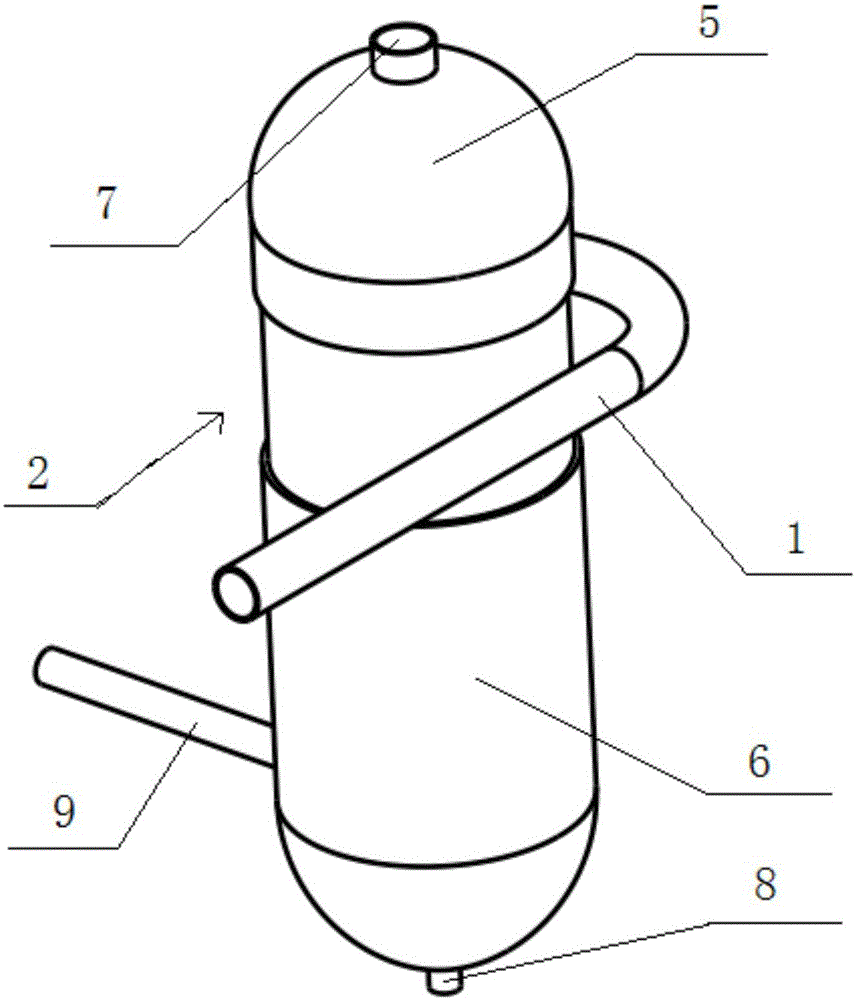

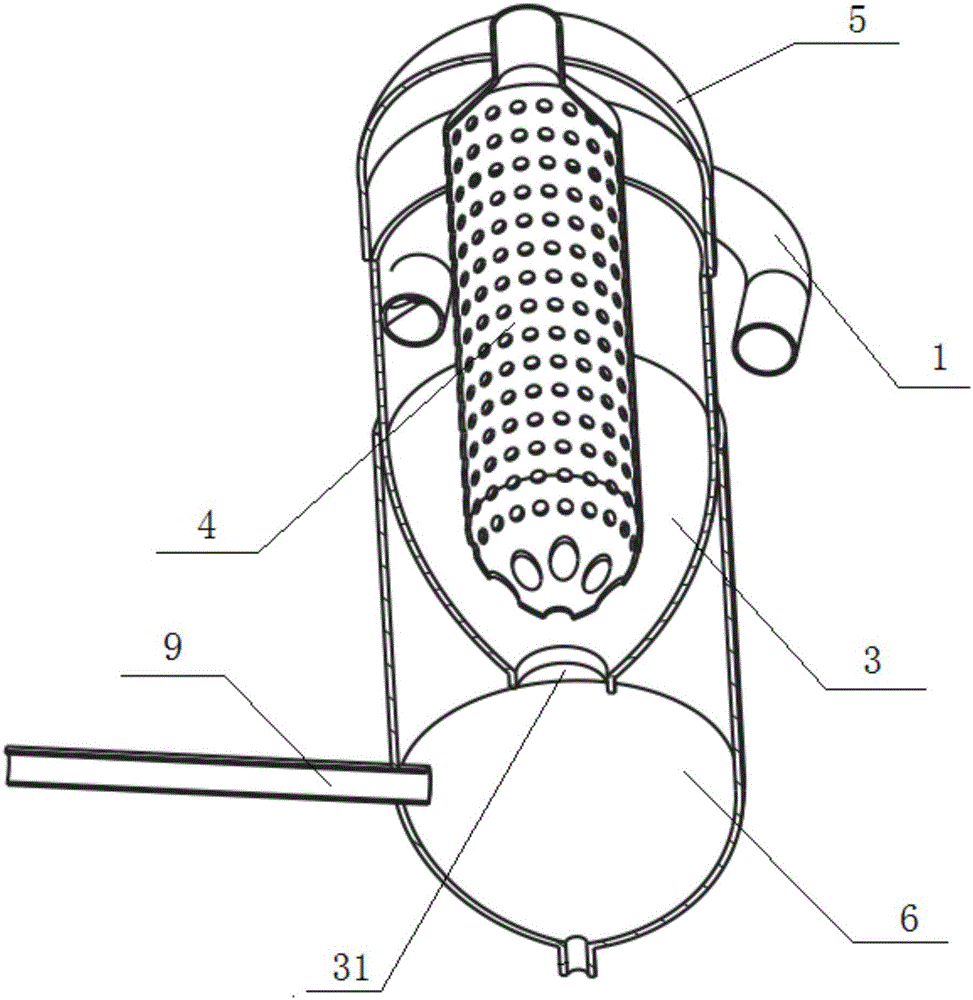

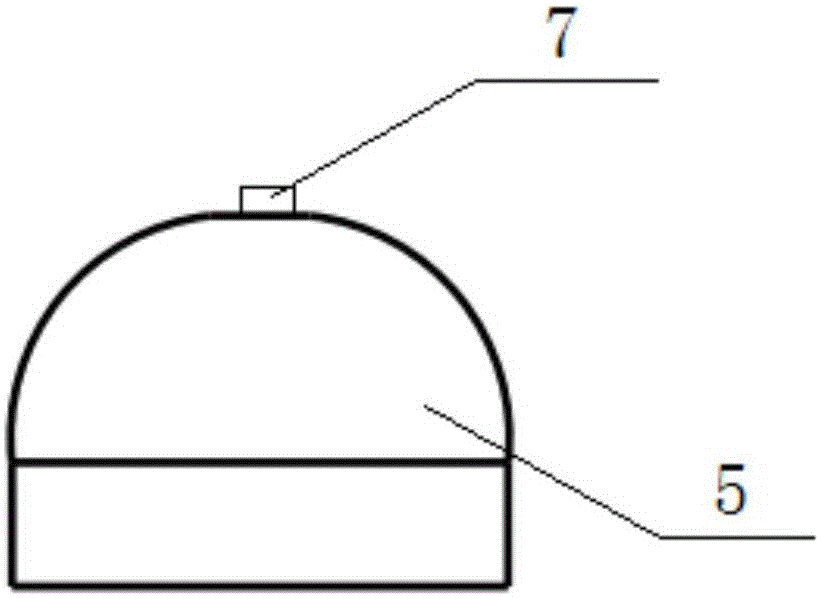

[0030] Such as figure 1 and 2 As shown, they are the overall appearance diagram and structural diagram of a gas-liquid separator with oil return and liquid discharge functions in an embodiment, and it can be seen that the embodiment is provided with a liquid separator 1 and an outer cylinder sequentially from the outside to the inside. 2. Cyclone separator 3 and annular filter screen 4. combine image 3 and Figure 4 , The outer cylinder 2 includes an upper cylinder 5 and a lower cylinder 6, and the upper cylinder 5 and the lower cylinder 6 are fixedly connected. The top of the upper cylinder body 5 is provided with an exhaust port 7 , the bottom of the lower cylinder body 6 is provided with a first liquid discharge port 8 , and the side wall of the lower cylinder body 6 is also provided with a second liquid discharge port 9 . The liquid distribution pipe 1 passes through the outer cylinder 2 and is connected with the cyclone separator 3, and is used for inputting the gas-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com