Shot blasting clearing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

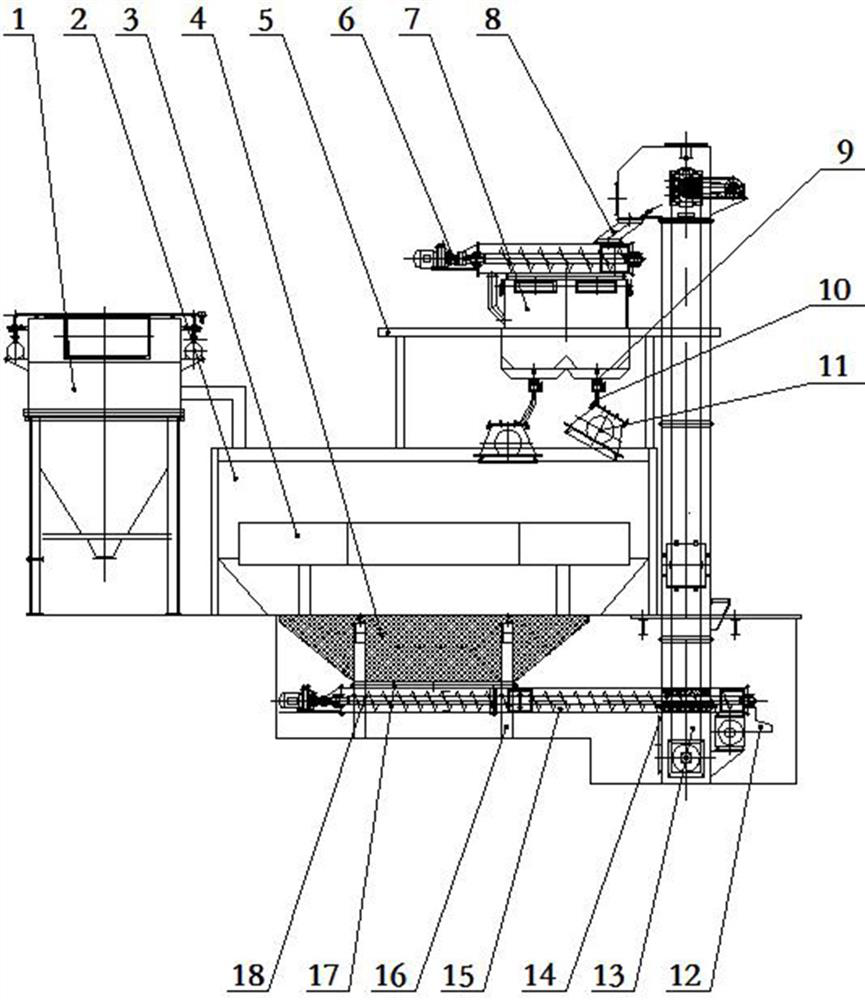

[0030] As a guideline for understanding the present invention, it should first be explained that, compared with traditional shot blasting devices, the shot blasting device according to the embodiment of the present invention has approximately the same composition, that is, both include a shot blasting chamber 2, and are installed in a shot blasting device. The shot blasting device 11 on the shot chamber 2, the collecting hopper 4 for collecting shot slag, the screw conveyor 18 for horizontally conveying the materials collected by the collecting hopper 4, and the vertical lifting of the materials conveyed by the screw conveyor 18 to a given level. The hoist 13 with the highest height, and the pellet separator 7 that separates the pellets and slag from the feed material of the hoist 13. Relatively speaking, in the embodiment of the present invention, the local structure of the above composition is improved, and an overflow hopper 12 is added. Correspondingly, the discharge port a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com