A coupled multi-stage separation beneficiation system and method

A multi-stage separation and mineral processing method technology, which is applied in the field of coupled multi-stage separation mineral processing system, can solve the problems of environmental air and water pollution, single mineral processing method, low efficiency, etc., and achieve small equipment occupation, scientific and reasonable design, and high energy efficiency. The effect of low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

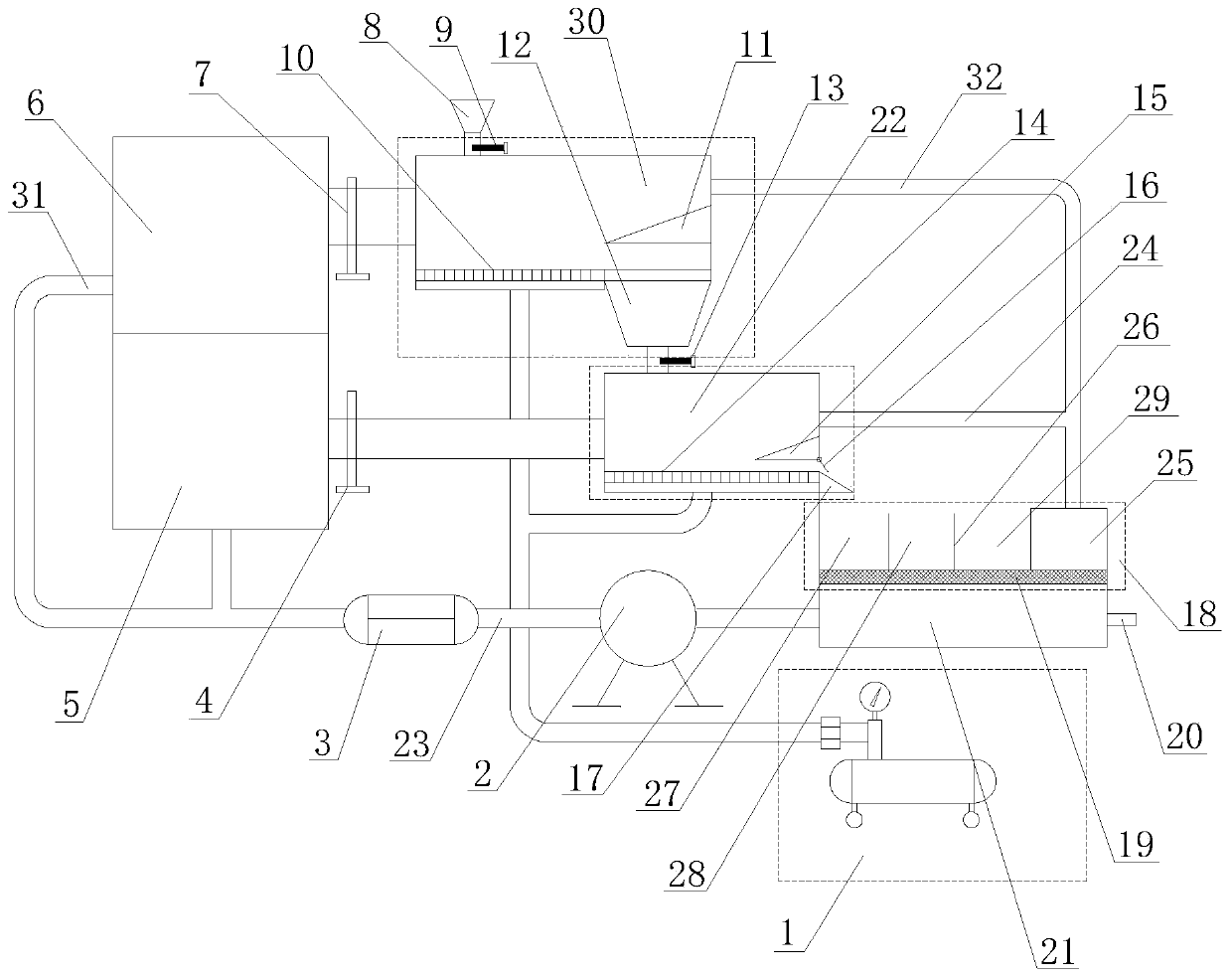

[0037] Such as figure 1 As shown, the present invention provides a coupled multi-stage separation mineral processing system with simple structure, small equipment footprint, scientific and reasonable design, easy operation, quick and efficient mineral separation, low energy consumption, and no pollution. A coupling type multi-stage separation mineral processing system of the present invention comprises a wind power device 1, a mineral processing water tank 5, a mineral processing device, a mineral receiving device 18, and a mineral processing wastewater collection box 21 storing mineral processing water inside, and said mineral processing wastewater collection box 21 The end is connected with the mineral processing water tank 5 through a water delivery pipeline 23, and is used to deliver mineral processing water for the mineral processing water tank 5. A water pump 2 and a filter 3 are sequentially arranged on the water delivery pipeline 23 along the flow direction of the miner...

Embodiment 2

[0056] This embodiment provides a coupled multi-stage separation ore dressing method, which is carried out by using the multi-stage separation ore dressing system in Embodiment 1, including the following steps:

[0057] (1) Fill the beneficiation wastewater collection box with beneficiation water through the replenishment pipe;

[0058] (2) Turn on the water pump and filter, and pump the mineral processing water in the mineral processing wastewater collection tank to the mineral processing water tank and the pre-mineral processing water tank;

[0059] (3) Simultaneously open the pre-selected mineral water flow regulating valve, the discharge flow regulating valve and the wind power device, and input the pre-selected mineral water and minerals into the main body of the pre-selected mineral water device. Layering upwards, under the action of the wind power device, the pre-selected ore distribution plate generates an upward airflow perpendicular to the horizontal plane. At this t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com