Novel combined filtering unit

A filter device and a new type of technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of separating minerals of different particle sizes, inconvenient to replace and maintain, reduce separation efficiency, etc., to achieve simple structure and improve separation efficiency. , the effect of good adjustment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

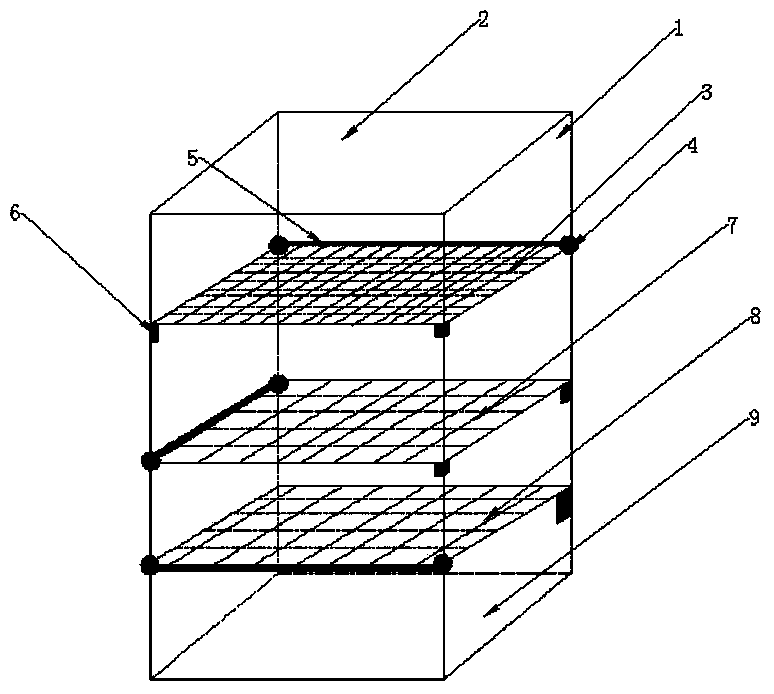

[0017] The present invention will be further described below in conjunction with the accompanying drawings. The square cylinder 1 is made of stainless steel and is used to provide mineral filtering passages. The feeding port 2 is located on the upper part of the square cylinder 1, through which minerals enter the cylinder. The top filter 3, the middle filter 7, and the bottom filter 8 are respectively located at the upper end, middle end, and lower end of the cylinder body 1. One side link 4 is on the rotating shaft 5 on the wall of the rectangular filter device, and the other side passes through the support piece. 6 supports, the entire filter screen is in the horizontal direction, the filter screen can be rotated 5 times through the rotating shaft, and it is convenient to put it down and put it away, and the filter diameter of the three-layer filter screen decreases in turn. The discharge port 9 is located at the bottom of the square cylinder 1, and the separated material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com