Porous color matching agent and preparation method thereof

A technology of toner and porous structure, which is applied in the field of electrophotographic toner for printing and copying and its preparation, and can solve the problem that it is difficult to prepare toner particles with porous structure, and the toner with porous structure is sensitive and fragile, and does not have Solve problems such as mechanical processing strength to achieve the effect of increasing page output, reducing fixing temperature and printing consumption, and meeting strength requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

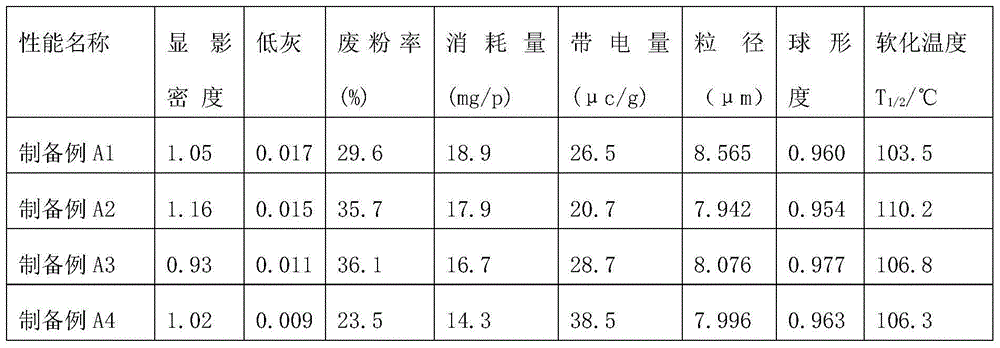

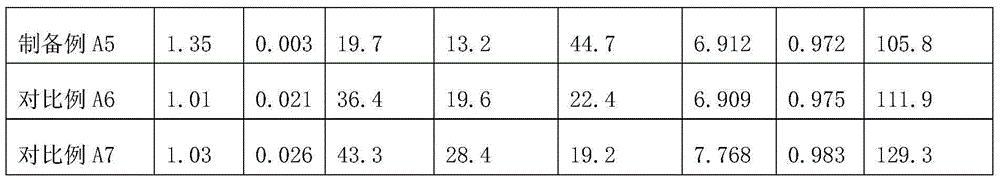

preparation example A1

[0039] In a 250ml beaker, add 1 gram of carboxymethylcellulose, 2 grams of silica sol (50% solid content), 97 grams of deionized water, stir to form a hydroxymethylcellulose-silica sol aqueous solution, which is the first hydrophilic colloid solution. Take another 500ml beaker and add 5 grams of palm wax, 3 grams of carbon black pigment and 92 grams of polymer resin, then add 200 grams of ethyl acetate, heat to 45 ° C in a water bath, stir and dissolve at a speed of 200 rpm, and form an organic phase solution. Use IKA T50 to homogenize the organic phase solution at 4000 rpm, and slowly add the first hydrophilic colloid solution to the organic phase solution, and homogeneously emulsify for 15 minutes to prepare the first water-in-oil suspension. Add 1000 grams of deionized water and 2 grams of silica sol into a 2L beaker, and stir to form a second hydrophilic colloid solution. Use IKA T50 to homogenize the second hydrophilic colloid solution at 2800 rpm, slowly add the first s...

preparation example A2

[0041] In a 250ml beaker, add 10 grams of carboxymethyl cellulose, 10 grams of silica sol (50% solid content), 80 grams of deionized water, and stir to form an aqueous solution of hydroxymethyl cellulose-silica sol, which is the first hydrophilic colloid solution. Take another 500ml beaker and add 13.4 grams of palm wax, 16.7 grams of carbon black pigment and 137 grams of polymer resin, then add 333 grams of ethyl acetate, heat to 45 ° C in a water bath, stir and dissolve at a speed of 200 rpm, and form an organic phase solution. Use IKA T50 to homogenize the organic phase solution at 4000 rpm, and slowly add the first hydrophilic colloid solution to the organic phase solution, and homogeneously emulsify for 15 minutes to prepare the first water-in-oil suspension. Add 1667 grams of deionized water and 33.32 grams of silica sol in a 2L beaker, and stir to form a second hydrophilic colloid solution. Use IKA T50 to homogenize the second hydrophilic colloid solution at 2800 rpm, ...

preparation example A3

[0043] In a 250ml beaker, add 1 gram of carboxymethylcellulose, 10 grams of silica sol (50% solid content), 89 grams of deionized water, stir to form hydroxymethylcellulose-silica sol aqueous solution, which is the first hydrophilic colloid solution. Take another 500ml beaker and add 10.66g of palm wax, 10.66g of carbon black pigment and 111.79g of polymer resin, then add 267g of ethyl acetate, heat it in a water bath to 45°C, stir and dissolve at a speed of 200rpm, and form an organic phase solution. Use IKA T50 to homogenize the organic phase solution at 4000 rpm, and slowly add the first hydrophilic colloid solution to the organic phase solution, and homogeneously emulsify for 15 minutes to prepare the first water-in-oil suspension. Add 1333 grams of deionized water and 6.67 grams of silica sol in a 2L beaker, and stir to form a second hydrophilic colloid solution. Use IKA T50 to homogenize the second hydrophilic colloid solution at 2800 rpm, slowly add the first suspensio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com