Cobalt-based plasma powder surfacing material, preparation method and application thereof

A surfacing material and plasma technology, applied in the field of surfacing, can solve the problem that cobalt-based alloys and wear-resistant phases cannot be used together, and achieve good wettability and compatibility, good wear resistance, and extreme pressure resistance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The raw materials used in the preparation of the cobalt-based plasma powder surfacing material in this embodiment are:

[0034] Cobalt-based alloy powder: The particle size of cobalt alloy powder is 100-325 mesh, the weight percentage of carbon is 2.0%, the weight percentage of chromium is 23.1%, the weight percentage of tungsten is 10.8%, and other elements are nickel, molybdenum, iron, silicon, etc. The sum of the weight percentages is 3.1%, and the balance is cobalt.

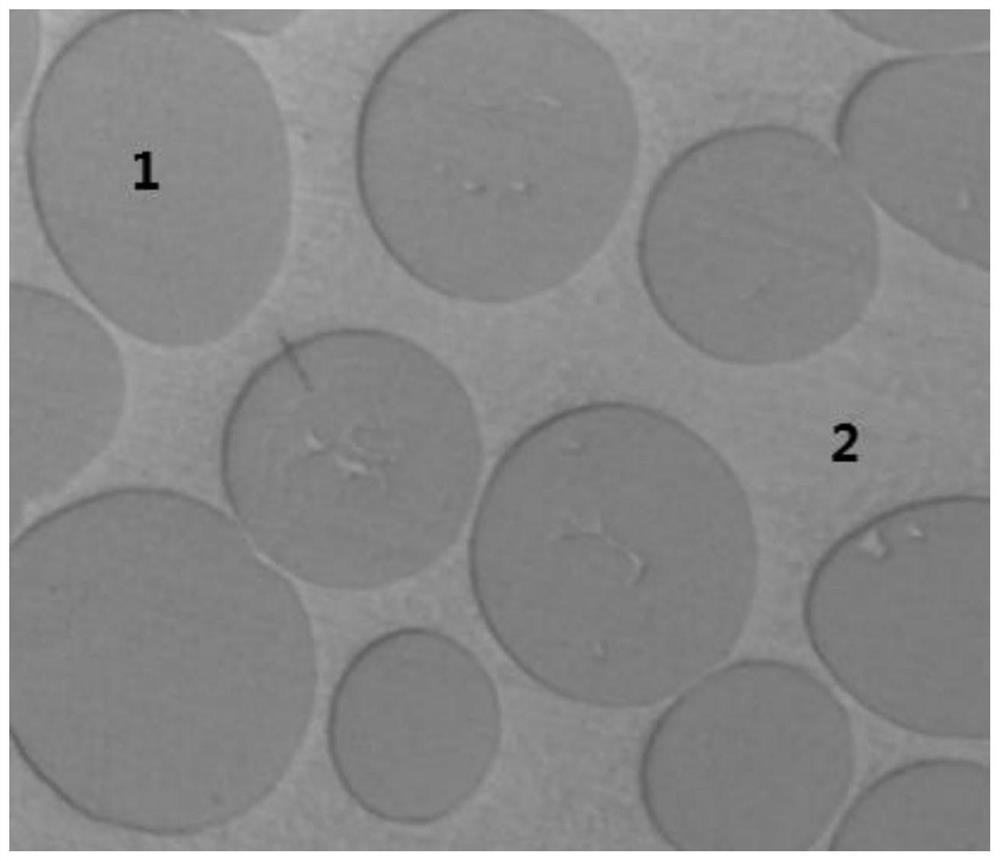

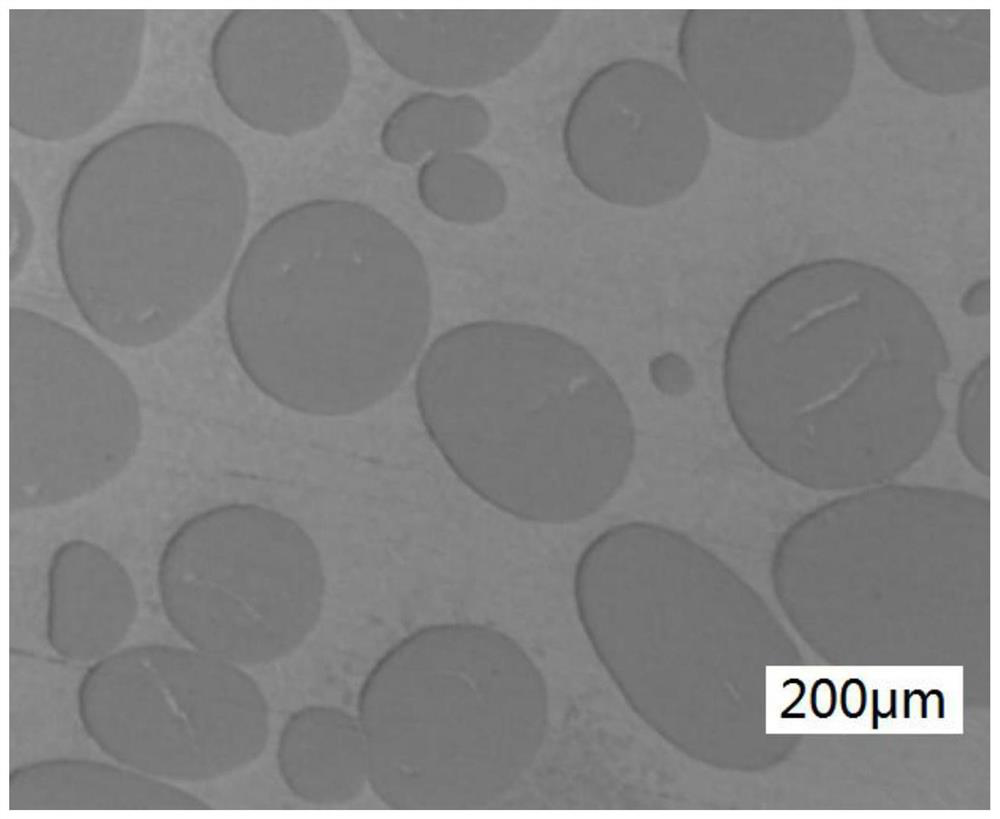

[0035] Sintered WC-Co cemented carbide spherical particles: WC powder and cobalt powder are mixed by weight in a proportion of 92% WC + 8% Co, and then mixed and ball-milled. -80 mesh sieve, sintered, and passed through 60-100 mesh sieve to obtain sintered WC-Co cemented carbide spherical particles, the particle size of which is 60-100 mesh, and the weight percentage of cobalt is 8%.

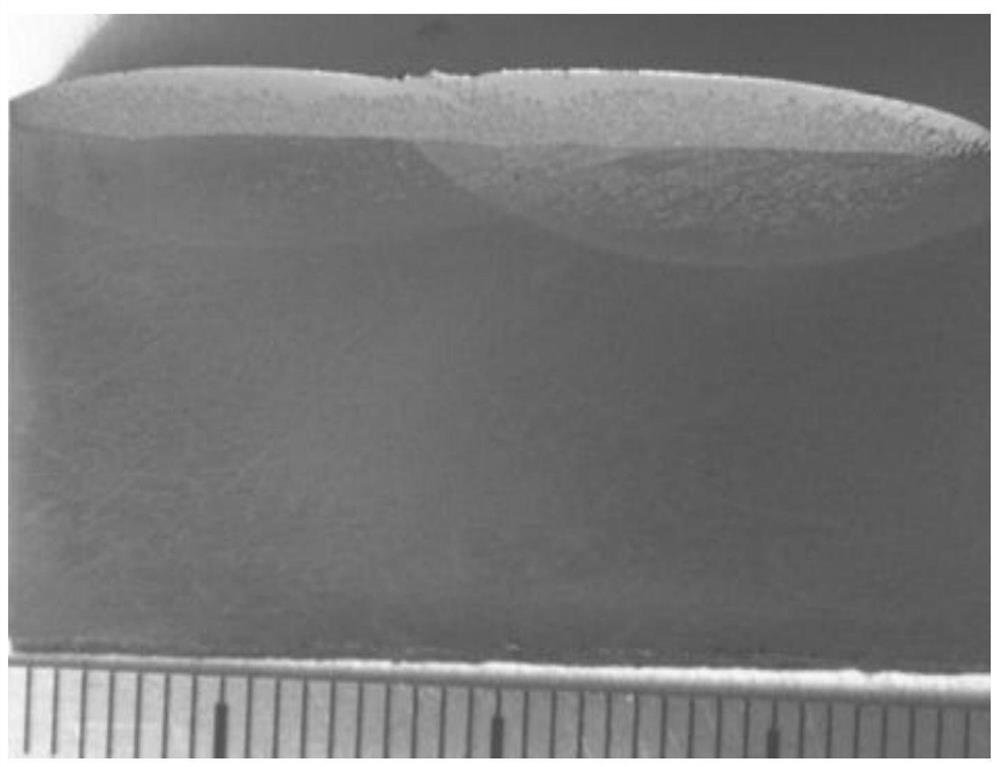

[0036] The specific preparation method of the cobalt-based plasma powder surfacing material of the present embodiment i...

Embodiment 2

[0044] The raw materials used in the preparation of the cobalt-based plasma powder surfacing material in this embodiment are:

[0045] Cobalt-based alloy powder: The particle size of the alloy powder is 100-325 mesh, the weight percentage of carbon is 1.5%, the weight percentage of chromium is 15.3%, the weight percentage of tungsten is 5.9%, and the weight of other nickel, molybdenum, iron, silicon, etc. The sum of the percentages shall not exceed 3.8%, and the balance shall be cobalt.

[0046] Sintered WC-Co cemented carbide spherical particles: WC powder and cobalt powder are mixed by weight in a ratio of 88% WC + 12% Co, and then mixed and ball-milled. 80-mesh sieve, sintered, and passed through a 60-100-mesh sieve to obtain sintered WC-Co cemented carbide spherical particles, the particle size of which is 60-100 mesh, and the weight percentage of cobalt is 12%.

[0047] The specific preparation method of the cobalt-based plasma powder surfacing material of the present em...

Embodiment 3

[0052] The raw materials used in the preparation of the cobalt-based plasma powder surfacing material in this embodiment are:

[0053] Cobalt-based alloy powder: The particle size of the alloy powder is 100-325 mesh, the weight percentage of carbon is 2.6%, the weight percentage of chromium is 30.4%, the weight percentage of tungsten is 15.1%, and the weight of other nickel, molybdenum, iron, silicon, etc. The sum of the percentages shall not exceed 2.6%, and the balance shall be cobalt.

[0054] Sintered WC-Co cemented carbide spherical particles: WC powder and cobalt powder are mixed by weight in a ratio of 96% WC + 4% Co, and then mixed and ball-milled. -80 mesh sieve, sintered, and passed through 60-100 mesh sieve to obtain sintered WC-Co cemented carbide spherical particles, the particle size of which is 60-100 mesh, and the weight percentage of cobalt is 4%.

[0055] The specific preparation method of the cobalt-based plasma powder surfacing material of the present embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com