Solid-liquid fast separation device

A separation device and fast technology, applied in the fields of filtration and separation, separation methods, chemical instruments and methods, can solve the problems of turbid water quality, long time consumption, substandard discharge, etc., and achieve high separation efficiency, simple structure and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

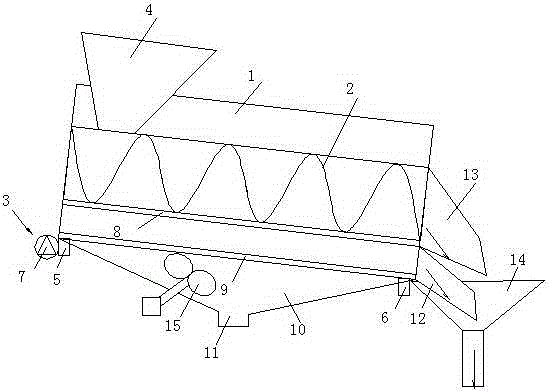

[0014] Embodiment 1: a solid-liquid rapid separation device, including a cylindrical cylinder 1, a screw blade 2 arranged in the cylinder 1, and a transmission device 3 outside the cylinder 1, a feed hopper 4 is provided at the upper end of the cylinder 1, and the transmission device 3 includes a driving wheel 5 and a driven wheel 6 arranged at both ends of the cylinder body 1, the driving wheel 5 is connected to the driving motor 7 through a belt transmission, and the cylinder surface below the cylinder body 1 spiral blade 2 is provided with one or two two-stage separation plates (8, 9 ), the primary and secondary separation plates (8, 9) are woven by stainless steel wire mesh, the aperture of the primary separation plate 8 is 30~50mm, the aperture of the secondary separation plate 9 is 10~25mm, the bottom of the secondary separation plate 9 A conical water collection bucket 10 is provided, the end of the water collection bucket 10 is provided with a water outlet 11, the end o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com