Nano-scale dynamic centrifugal separation device

A technology of centrifugal separation and separation device, which can be used in centrifuges and other directions to solve the problems of low separation efficiency and poor separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

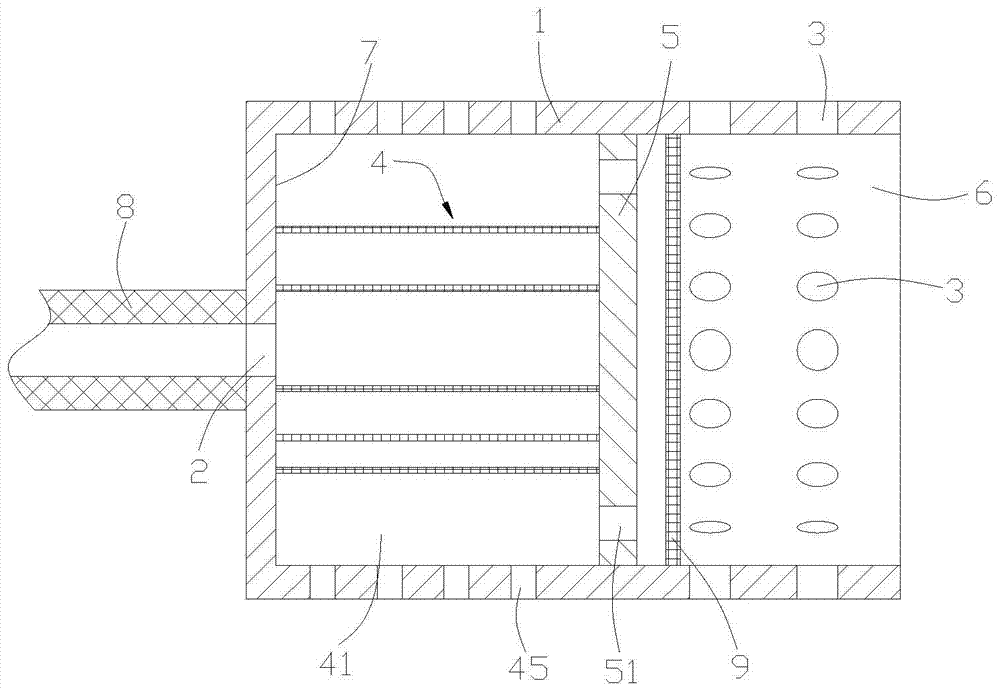

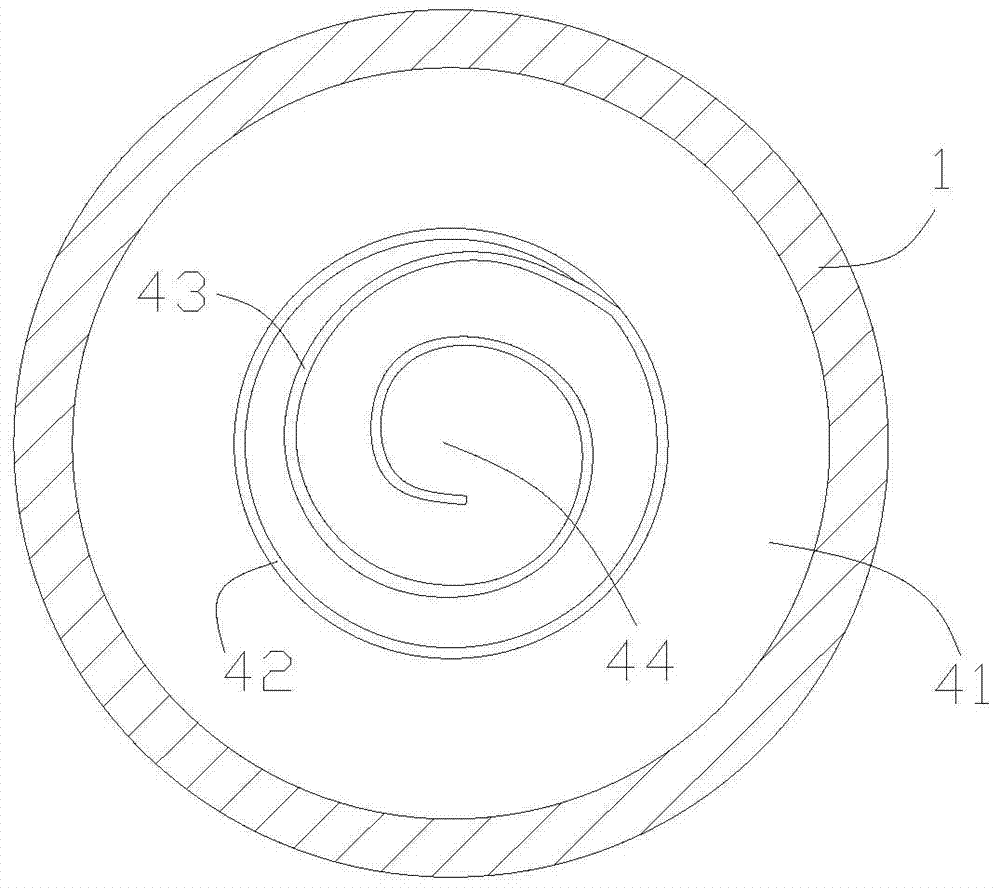

[0013] Combine below figure 1 , figure 2 Introduce in detail the nanoscale dynamic centrifugal separation device of the present invention, comprising a horizontally arranged separation cylinder 1 with one end open, the other end of the separation cylinder is closed, and a discharge port 2 is provided on the end face of the other end, and the other end of the separation cylinder is It is fixedly connected with the rotating discharge shaft 8, and the rotation of the discharge shaft drives the rotation of the separation cylinder to realize dynamic separation and improve the separation efficiency; the discharge port is connected with the inner cavity of the discharge shaft; the inner cavity at one end of the separation cylinder is covered with a screen 9. A separator 4 is fixed in the cavity at the other end of the separation cylinder, and the separation cavity of the separator communicates with the discharge port; the materials and grinding media flowing in from the one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com