Natural gas dehydration method using pre-nucleating supersonic vortex tube

A supersonic, vortex tube technology, applied in separation methods, chemical instruments and methods, gas fuels, etc., can solve the problems of difficult to grasp nucleation particle size and nucleation number, blocked pipelines, difficult nucleation, etc., and achieves optimization. Gas-liquid separation performance, improving condensation efficiency, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

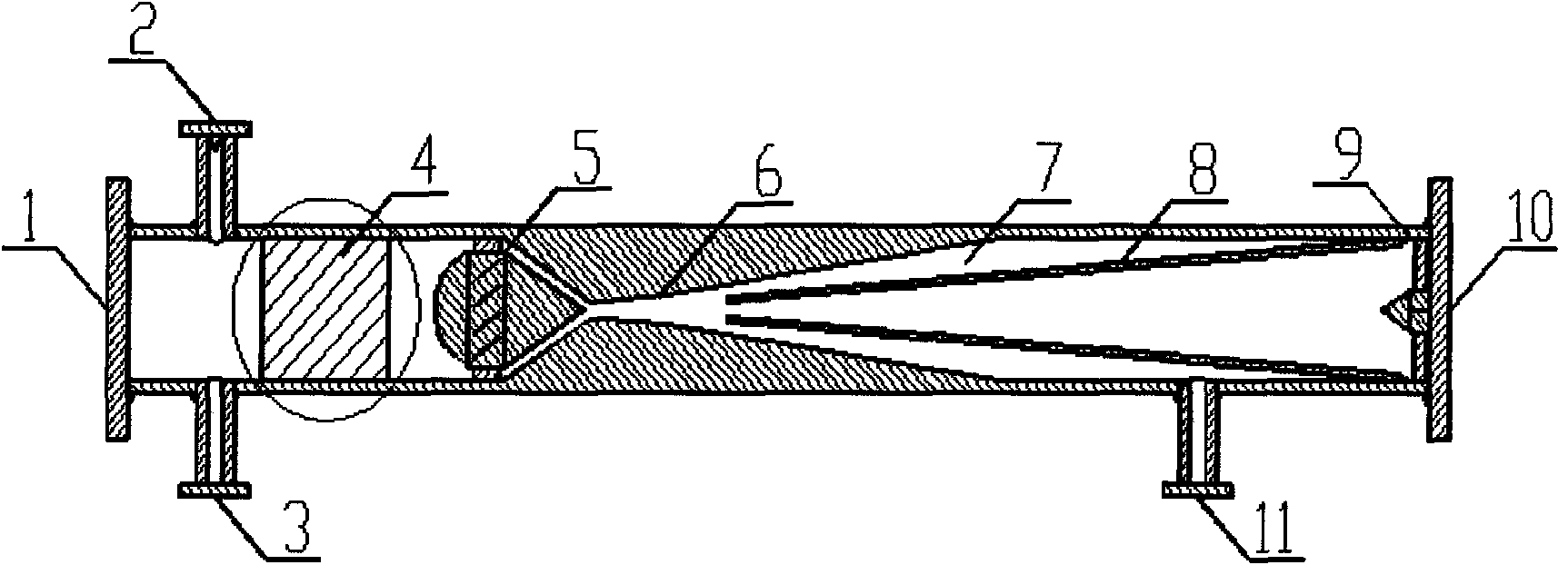

[0037] The implementation of the pre-nucleation supersonic vortex tube is illustrated by taking the dehydration of high-pressure natural gas as an example. The process flow is as follows Figure 5 shown. Composed of raw gas storage tank 16, raw gas separator 17, raw gas filter separator 18, gas-gas heat exchanger 19, fine filter 20, pre-nucleation supersonic vortex tube 21, gas-water separator 22, dehydrated dry gas Tank 23, water storage tank 24 and drainage tank 25 constitute;

[0038] The raw material gas storage tank 16 is connected with the raw material gas filter separator 18 through the raw material gas separator 17; the raw material gas filter separator is connected with the gas-gas heat exchanger 19; the gas-gas heat exchanger 19 is connected with the fine filter 20; the fine filter 20 is connected to the feed gas inlet 1 of the pre-nucleation supersonic vortex tube 21; the condensate outlet 11 of the pre-nucleation supersonic vortex tube 21 is connected to the gas-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com