Multi-branch pipe gas-liquid separator

A phase separator and separator technology, which is applied in separation methods, dispersed particle separation, liquid degassing, etc., can solve the safety impact of conventional gas-liquid separator separation effect metering equipment, high one-time investment, and large footprint. problems, to achieve the effect of reducing engineering investment and floor space, wide application and small equipment volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

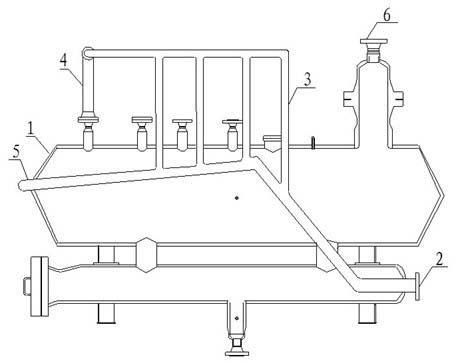

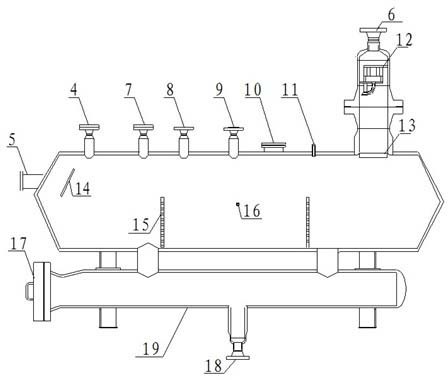

[0010] A manifold gas-liquid two-phase separator, such as figure 1 with figure 2 As shown, it includes: separator cylinder 1, gas-liquid inlet 2, air inlet branch pipe 3, gas phase inlet main pipe 4, liquid phase inlet 5, separator outlet 6, safety valve port 7, manual vent valve port 8, note Nozzle 9, manhole 10, pressure sensor interface 11, filter separation element 12, wire mesh mist catcher 13, buffer baffle 14, rectifier plate 15, liquid level gauge interface 16, ash removal port 17, sewage outlet 18, effusion Barrel 19. in:

[0011] A gas-liquid inlet 2 is arranged near the lower right side of the liquid accumulation cylinder 19, and the gas-liquid inlet 2 is connected with the gas-liquid intake manifold. The gas-liquid intake manifold is divided into an ascending pipe section and a descending pipe section. degrees to 45 degrees, the inclination range of the descending pipe section is -3 degrees to -15 degrees, and two to six vertically upward intake branch pipes ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com