Two-stage PSA method for recovering C2+ from refinery dry gas according to concentration

A refinery dry gas, refinery technology, applied in the field of separation and recovery of valuables in petrochemical tail gas, can solve the problems of methane exceeding the standard, cross-contamination of composite beds, low yield and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

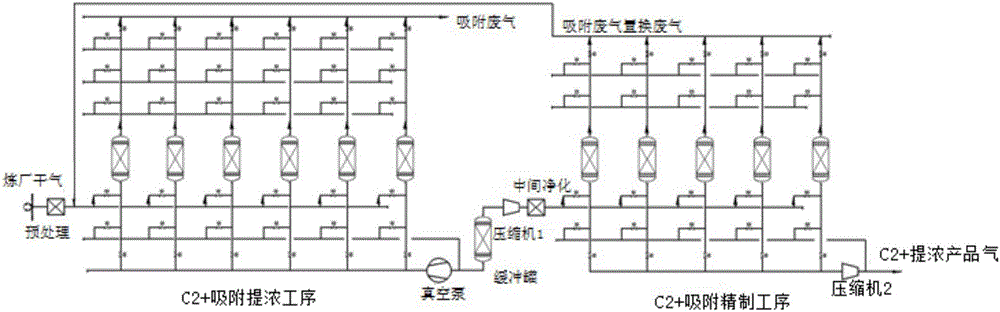

[0045] Such as figure 1 As shown, the two-stage concentration pressure swing adsorption (PSA) method of recovering C2+ from refinery dry gas includes the following procedures:

[0046] (1) C2+ adsorption concentration process, the components are ethane (C2) 22.7% (volume ratio, the following is similar), ethylene (C2) 0.37%, propane (C3) 6.3%, propylene (C3) 0%, carbon four And the above components (C4+) 1.24%, methane (CH4) 25.1%, hydrogen (H2) 39.0%, nitrogen (N2) 5.2%, oxygen (O2) 0.02%, carbon monoxide (CO) 0.01%, carbon dioxide (CO2) 0.03 %, and 0.03% of other impurities such as water, heavy metals, arsenic, sulfide, etc., the refinery dry gas (mainly saturated dry gas) with a temperature of 30-50°C and a pressure of 1.0-2.0 MPa is used as raw material gas after pretreatment. Enter a first-stage pressure swing adsorption system consisting of 6 adsorption towers, that is, adopt the PSA mode of 6-2-2V, among which, 2 towers are in the adsorption state, and the other 4 are ...

Embodiment 2

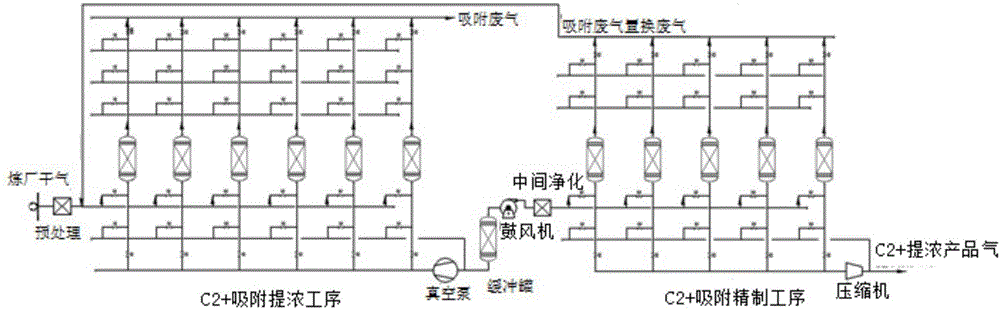

[0050] Such as figure 2 As shown, on the basis of the two-stage concentration pressure swing adsorption (PSA) method of reclaiming C from refinery dry gas described in Example 1, the pressure of described refinery dry gas (mainly saturated dry gas) is 0.2 ~0.3MPa, other feed conditions are the same as embodiment 1, adopt air blower to replace compressor in pretreatment unit and intermediate purification process, at last, from the C2+ concentration product gas that flows out in the adsorption refining (2#PSA) process, according to The pressure is required to pressurize and transport to the outside of the boundary area. At this time, the C2+ concentration of the product gas (C2+ concentrated gas) can reach more than 92%, the content of methane (CH4) is less than 4%, and the yield of C2+ components can reach more than 90%. .

Embodiment 3

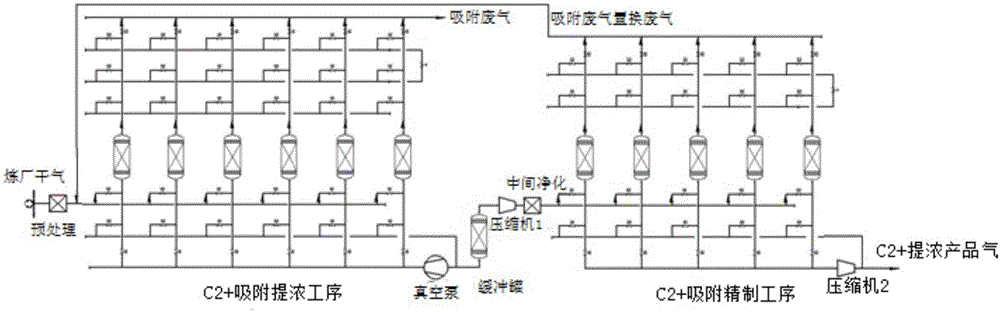

[0052] Such as image 3 As shown, on the basis of the two-stage concentration pressure swing adsorption (PSA) method of reclaiming C from refinery dry gas described in Example 1, the pressure of the described refinery dry gas (saturated dry gas as the main) is 3.0 ~4.0MPa, other feed conditions are the same as in Example 1, the pressure equalization (decrease and rise) in the described C2+ adsorption concentration process, C2+ adsorption refining process, and the steps of parallel discharge adopt the relaxation and equalization combined by the program control valve and the regulating valve. Pressure (slow equalization) mode. Among them, in the process of C2+ adsorption concentration (1#PSA) and C2+ adsorption refining process, corresponding program control valves are installed on the inlet and outlet pipes of the inlet and outlet of each tower, and regulating valves are installed between the inlet and outlet pipes. Evenly, to prevent the flow rate of the gas from changing too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com