Method for refining and purifying polyformaldehyde dialkyl ether

A formaldehyde dialkyl ether and product technology, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry and other directions, can solve the problems of poor extraction rate of extraction unit, poor purity of extracted products, poor extraction efficiency, etc., so as to reduce production The effect of high cost, high recovery rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

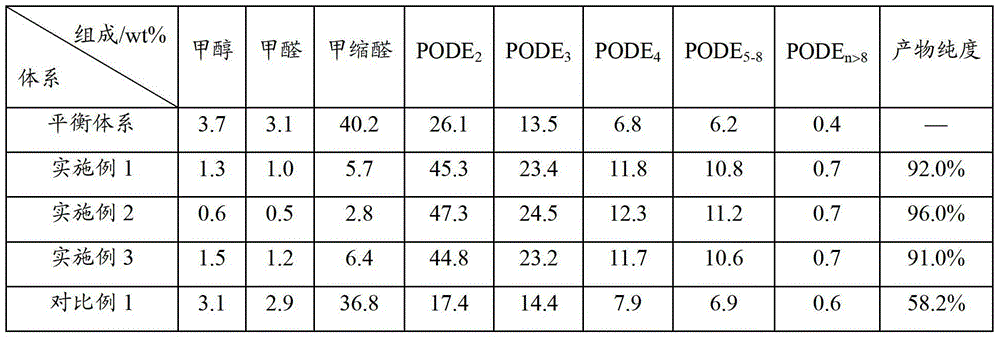

Embodiment 1

[0053] This embodiment provides a method for refining and purifying polyoxymethylene dialkyl ether, specifically:

[0054] S1. Add sodium sulfite to the equilibrium product of polyoxymethylene dialkyl ether, the input amount of sodium sulfite is 10% of the mass of the equilibrium product, heat to 40°C for reaction, and treat for 1 hour;

[0055] S2, performing solid-liquid separation on the reaction liquid obtained in step S1, and collecting liquid phase products;

[0056] S3. Carry out fractional atmospheric pressure distillation on the liquid phase product, and distill out the fraction before 60°C. The initial boiling point ~60°C is the unreacted raw material (formaldehyde, methanol and methylal), and the fraction collected at ~110°C is divided into two poly product (PODE 2 ), the fraction collected at ~160°C was the trimerization product (PODE 3 ), collecting fractions at ~200°C as tetramerization products (PODE 4 ); the fraction at ~250°C was collected as pentameric pro...

Embodiment 2

[0058] This embodiment provides a method for refining and purifying polyoxymethylene dialkyl ether, specifically:

[0059] S1. Add sodium bisulfite to the equilibrium product of polyoxymethylene dialkyl ether, the input amount of sodium bisulfite is 10% of the mass of the equilibrium product, heat to 40°C for reaction, and treat for 1 hour;

[0060] S2, performing solid-liquid separation on the reaction liquid obtained in step S1, and collecting liquid phase products;

[0061] S3. The liquid phase product is rectified at atmospheric pressure, the temperature at the bottom of the tower is 100° C., and the reflux ratio is 1. The production liquid at the top of the tower consists of methanol, methylal and a small amount of dimerization products; Then carry out fractional atmospheric pressure distillation on the polymer products with a degree of polymerization of 2 to 8, and collect the fractions at ~110°C as dimerization products (PODE 2 ), the fraction collected at ~160°C was ...

Embodiment 3

[0063] This embodiment provides a method for refining and purifying polyoxymethylene dialkyl ether, specifically:

[0064] S1. Add sodium metabisulfite to the equilibrium product of polyoxymethylene dialkyl ether, the input amount of sodium metabisulfite is 10% of the mass of the equilibrium product, heat to 40°C for reaction, and treat for 1 hour;

[0065] S2, performing solid-liquid separation on the reaction liquid obtained in step S1, and collecting liquid phase products;

[0066] S3. Carry out fractional atmospheric pressure distillation on the liquid phase product, distill out the fraction before 60°C, the initial boiling point ~60°C is the unreacted raw material (formaldehyde, methanol and methylal), and the fraction collected at ~110°C is dimerization Product (PODE 2 ), the fraction collected at ~160°C was the trimerization product (PODE 3 ), collecting fractions at ~200°C as tetramerization products (PODE 4 ); the fraction at ~250°C was collected as pentameric prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com