Method for improving extraction and separation efficiency of nickel and cobalt in biological leaching liquid

A technology for bioleaching and separation efficiency, applied in the direction of improving process efficiency, can solve the problems of low extraction efficiency, difficult extraction and separation of nickel and cobalt, increase neutralization cost, etc., and achieve the effect of improving extraction and separation efficiency and reducing the cost of extractant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

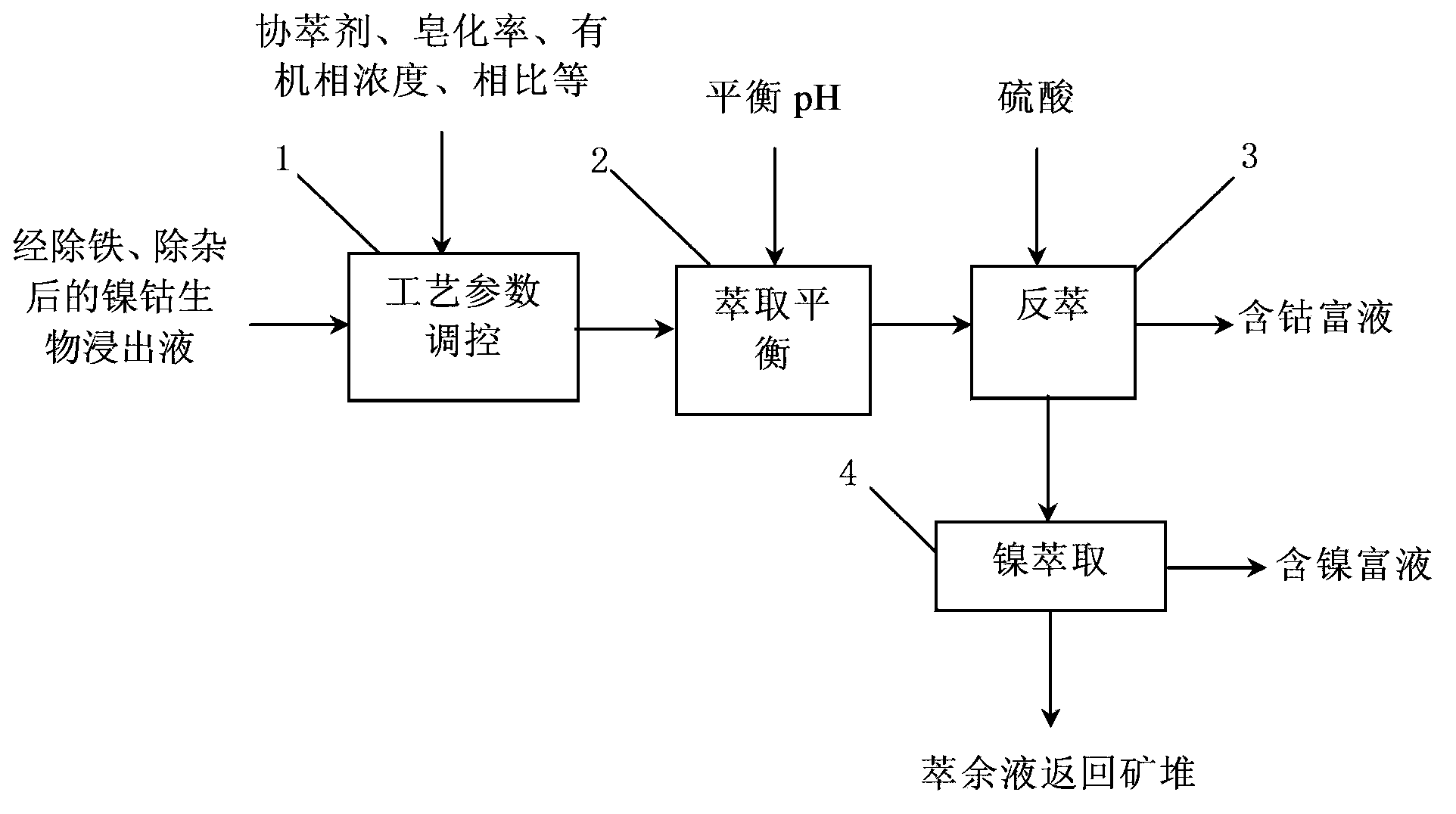

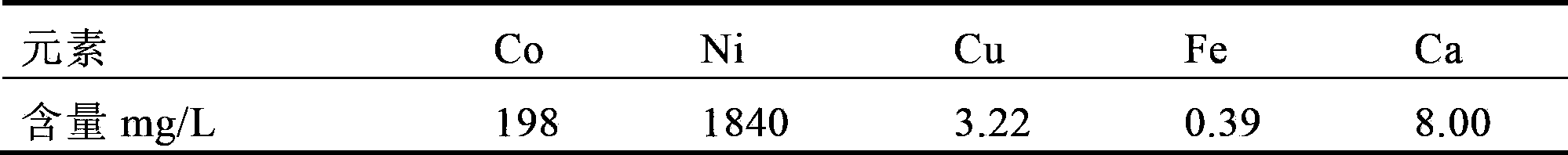

[0024] The nickel-cobalt ore of a certain mine is a low-grade complex and refractory sulfide ore. The bioleaching solution obtained by bioheap leaching contains low nickel and cobalt metals. The low concentration of nickel and cobalt in the leaching solution will seriously affect the extraction and separation efficiency of nickel and cobalt. In addition, since the pH of the bioheap leaching process is about 1.5-2.0, and the conventional nickel-cobalt extraction needs to be at a pH value of 3.5-4.0, the present invention provides a bioleach solution system for low-content nickel-cobalt, which is relatively Under the condition of low pH value, the method for effectively separating nickel and cobalt is realized through reasonable matching of each extraction process parameter. The implementation of this method can not only realize the extraction and separation of valuable metals under the condition of lower pH value, but also reduce the extraction cost, the number of extraction sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com