Elevation type three-phase separator

A technology of three-phase separator and elevation angle, which is applied in the direction of liquid separation, separation method, and dispersed particle separation, etc., can solve the problems of low separation efficiency, unsatisfactory separation effect, and large equipment volume, and achieve high separation efficiency, compact structure, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

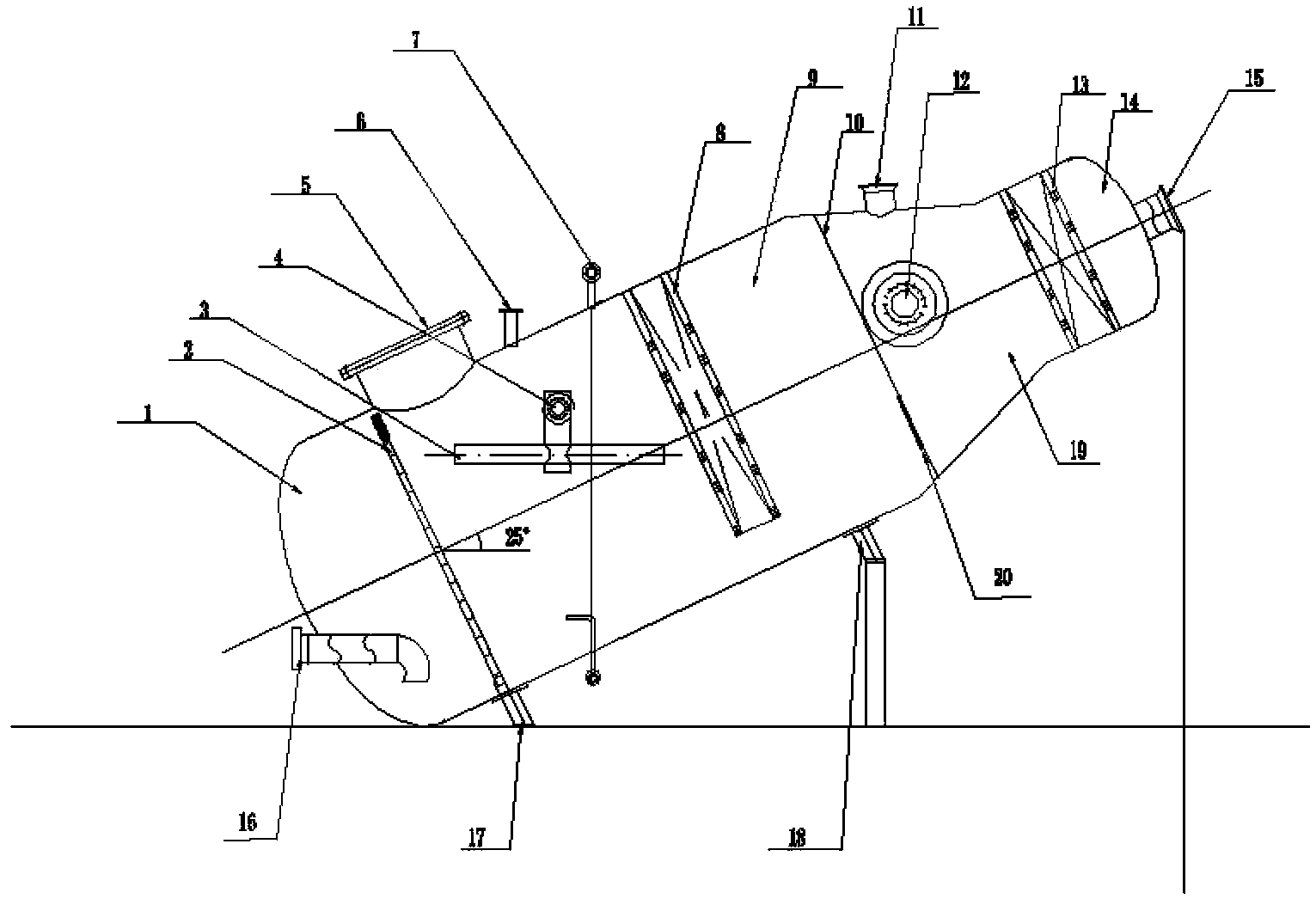

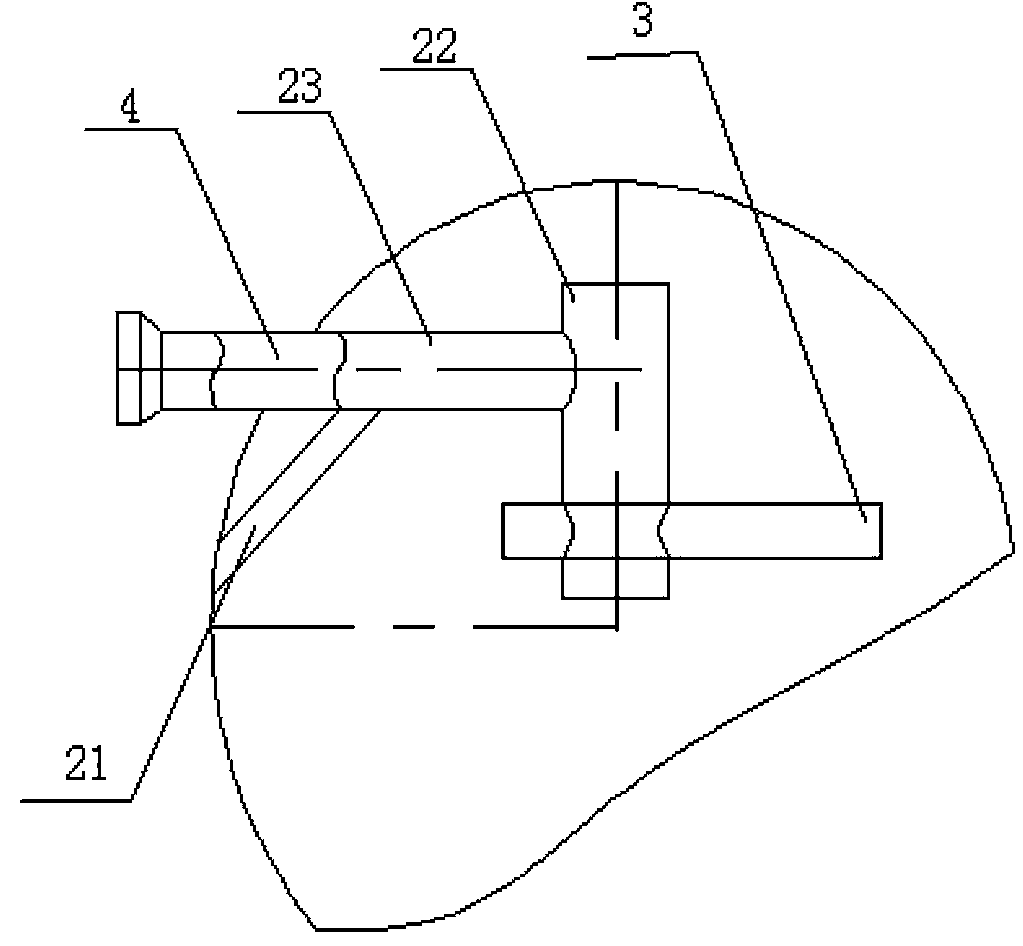

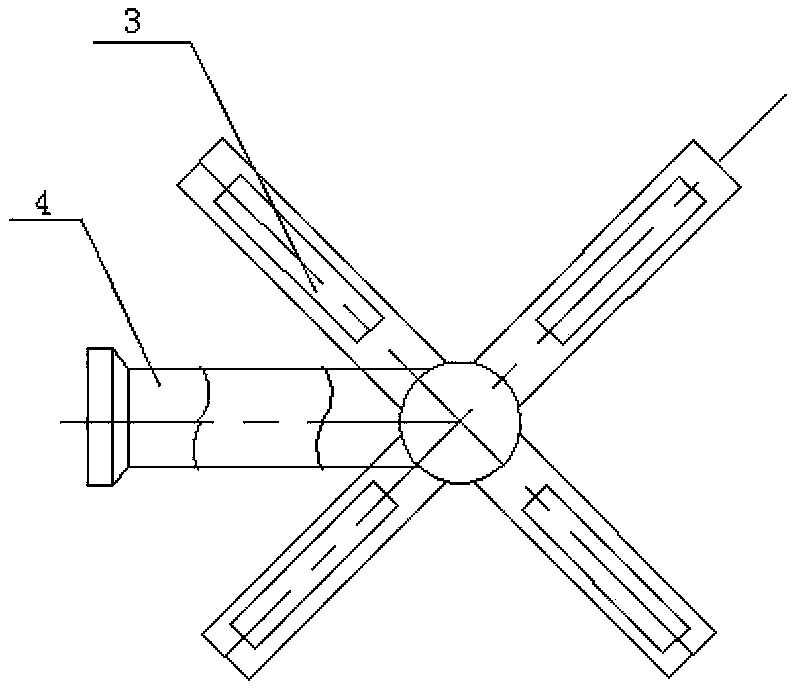

[0021] like figure 1 As shown, the main body of the present invention is a steel tank body 1 whose axis and the horizontal plane form a certain angle. Angle placement can overcome the shortcomings of the small oil-water interface area of the vertical separation container and the small distance between the oil-water interface of the horizontal separation container and the drain outlet, and can reduce the oil content of the separated sewage, thereby improving the quality of oil-water separation. The lower side of the tank body 1 is welded with a first support 17 and a second support 18 , and the length of the second support 18 is greater than that of the first support 17 .

[0022] The tank body 1 is in the shape of a hollow cylinder with non-equal diameters. From the bottom to the top, it can be divided into a large-diameter cylindrical section, a variable-diameter conical section and a small-diameter cylindrical section. Both ends of the tank body 1 are elliptical heads.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com