Roadway barrier components formed using a system for recycling wet concrete and means for assembling multiple components into a continuous safety barrier wall

a technology for road barriers and components, applied in groynes, piers, ways, etc., can solve the problems of large added cost of transportation and disposal city problems, and waste of refuse solid materials, and achieve the effect of low cost of individual components and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention is pre-cast roadway barrier components fabricated of the recycled excess or residual wet concrete remaining in ready-mix concrete trucks after completion of a job, and the means for assembling the individual components into a continuous safety barrier wall.

[0039] The recycling of the excess or residual wet concrete begins with the mixing trucks returning to the plant during and at the end of the workday. “Residual-collection” molds are kept on-hand at the plant, and as the ready-mix cement return they evacuate their excess wet concrete into the residual-collection molds. The molds are configured to form pre-cast structural components such as roadway barrier sections, and the like.

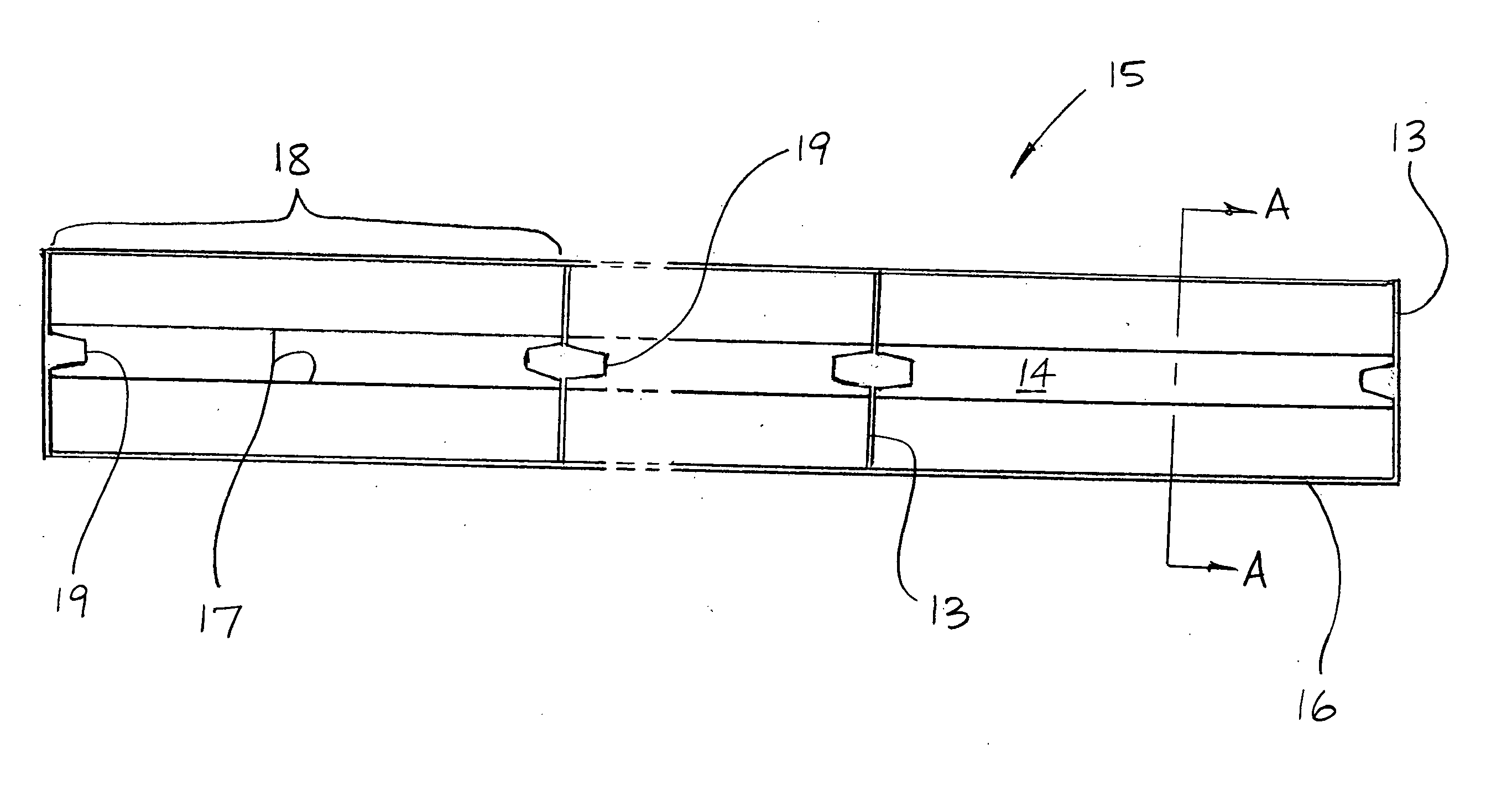

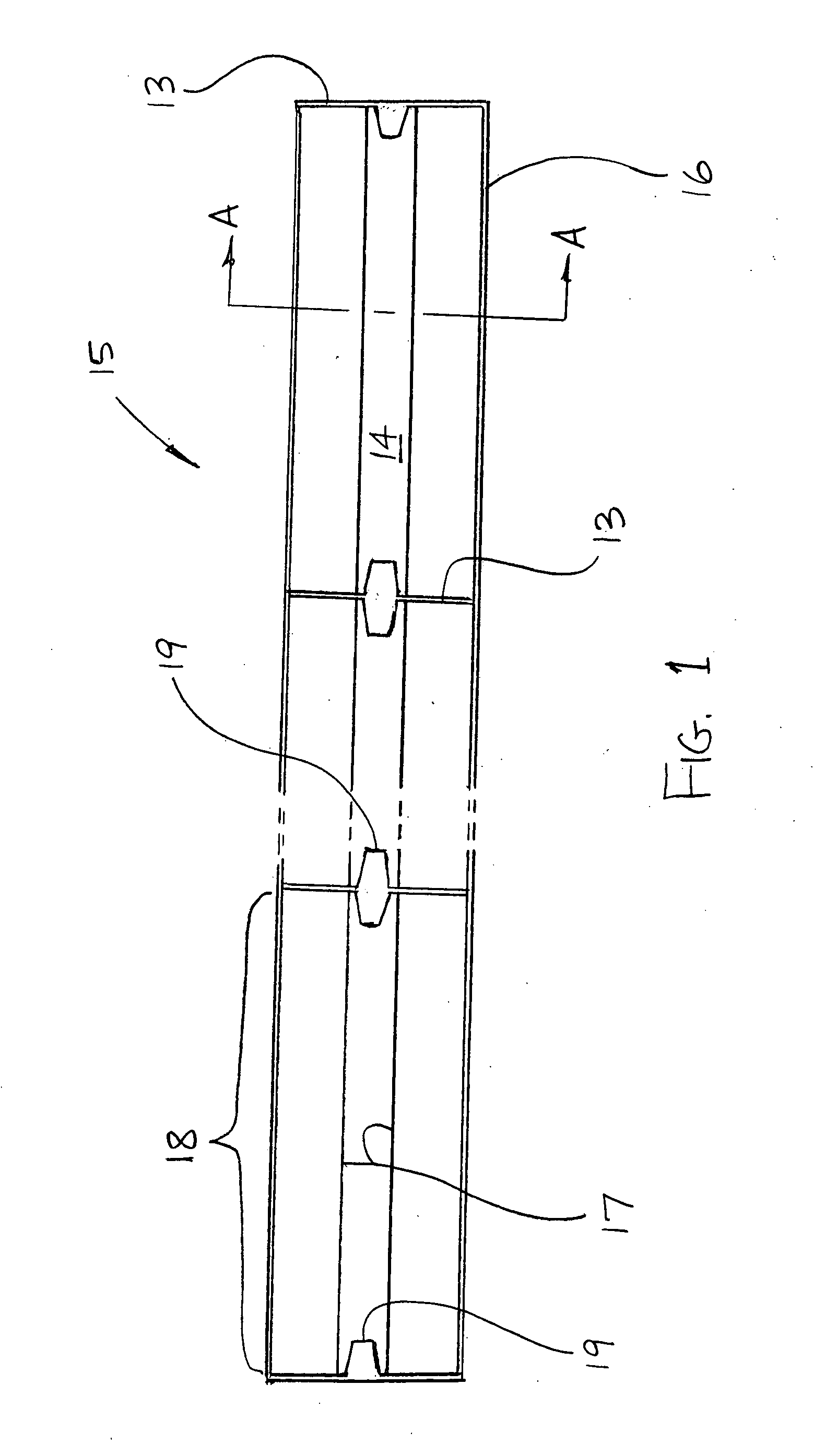

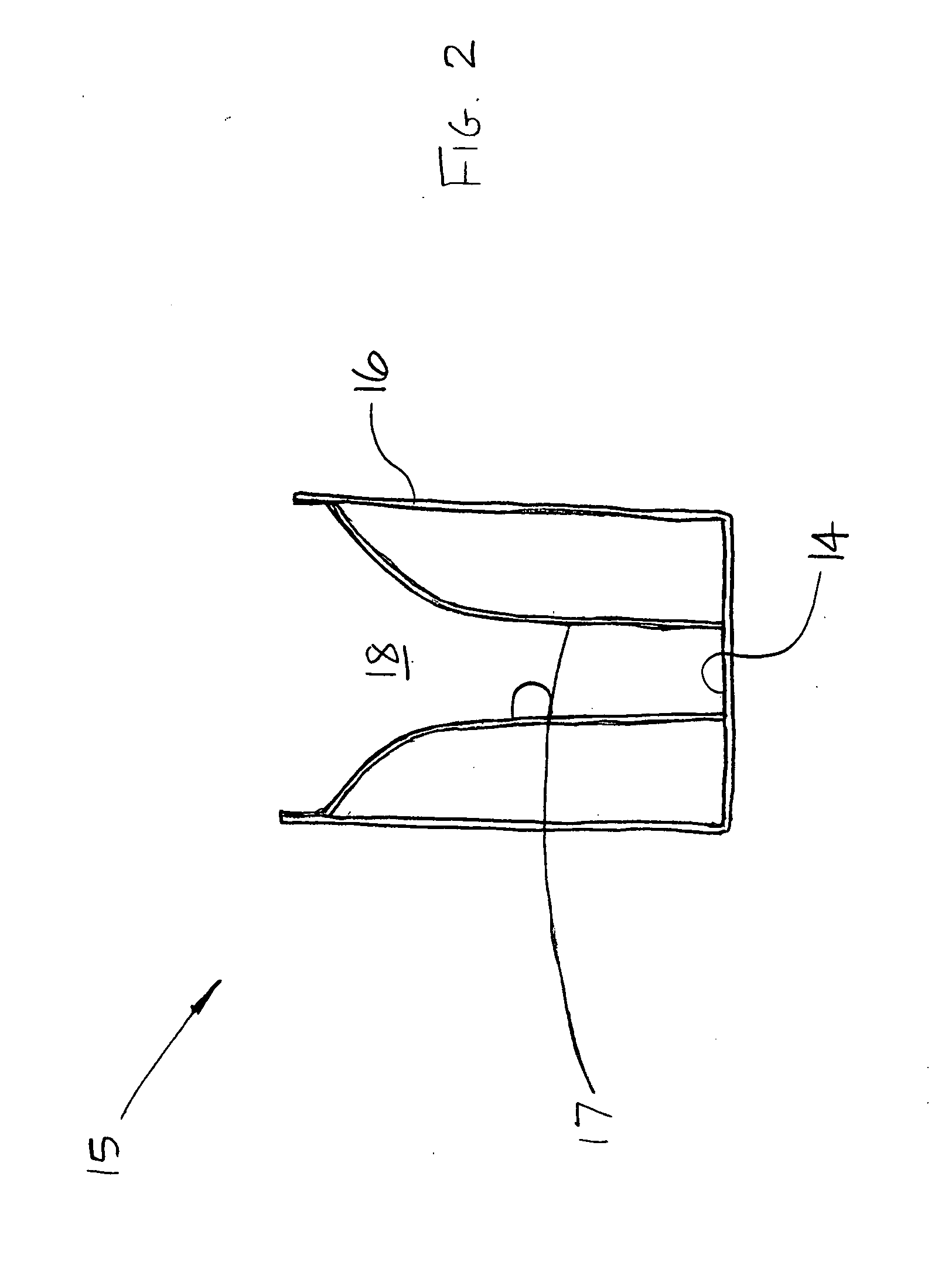

[0040]FIGS. 1 and 2 are, respectively, plan and cross-sectional views of a casting bed 15 including a plurality of molds 18 used to create roadway barrier sections according to a preferred embodiment of the present invention.

[0041] As stated above, at the end of a workday it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com